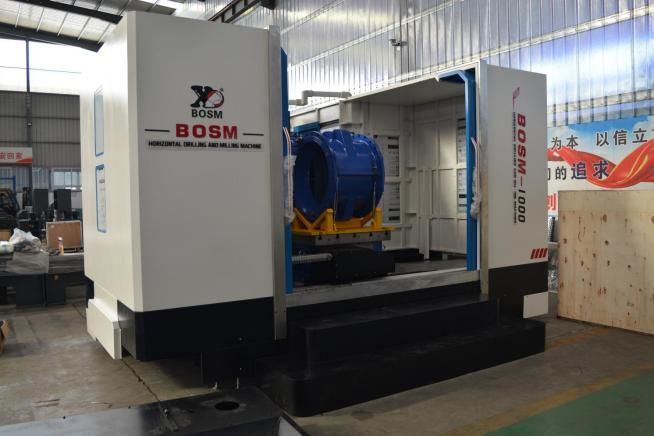

I-BOSM -4Z2000 Isivinini esiphezulu se-CNC sokubhola nomshini wokugaya

1. Ukusetshenziswa kwezisetshenziswa:

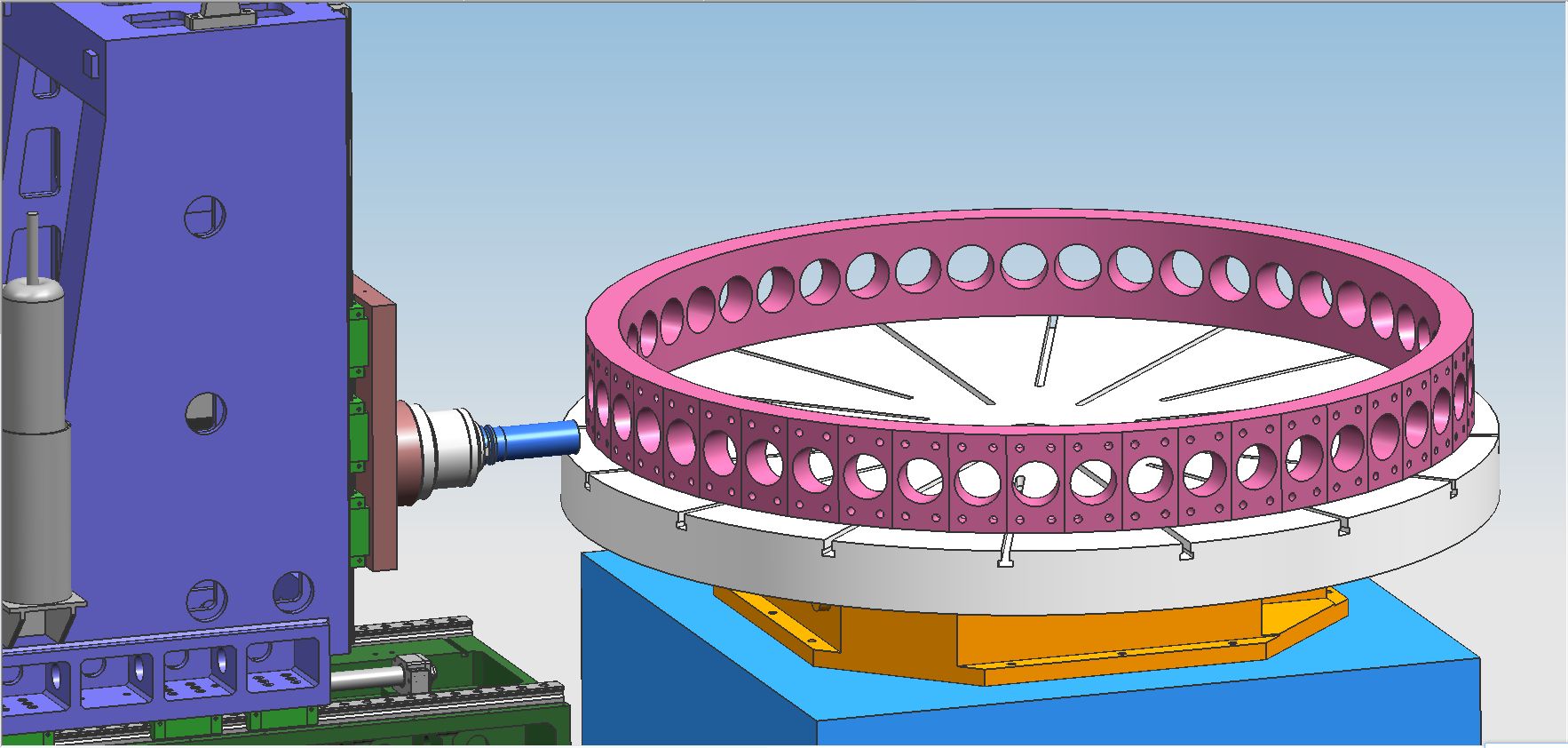

Umshini wokugaya we-BOSM-1000 ovundlile we-CNC usetshenziselwa kakhulu ukubhola okunezici eziningi, ukugaya, ukucofa kanye nokucutshungulwa okuyisicefe kwamavalvu, amabhulokhi ama-valve, ama-reducers, ama-flange, ama-discs, izindandatho, izisekelo zokuhlaba kanye nezinye izinto zokusebenza ngaphakathi kobubanzi obusebenzayo bokujiya. . Ukubhoboza, ukugaya, ukucofa kanye nesicefe kungabonakala ezingxenyeni zempahla eyodwa kanye nezinto eziyinhlanganisela. Inqubo yokwenza imishini yoMshini ilawulwa ngedijithali, futhi ukusebenza kulula kakhulu. Ingabona i-automation, ukunemba okuphezulu, izinhlobonhlobo eziningi kanye nokukhiqizwa okukhulu.

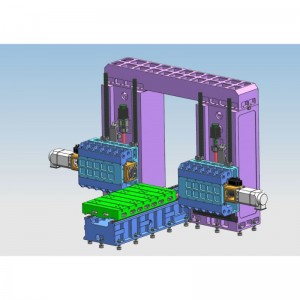

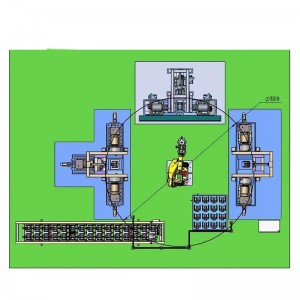

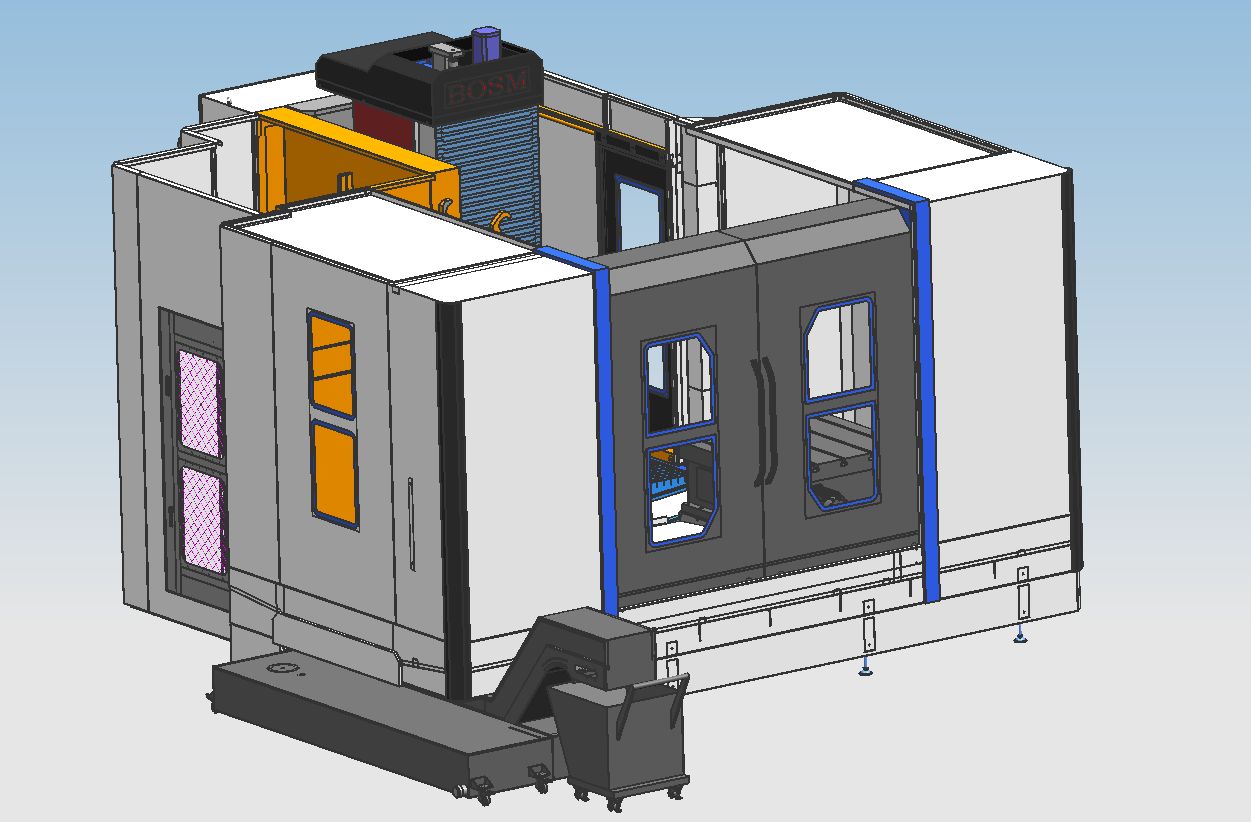

2. Isakhiwo sezisetshenziswa:

Lo mshini ikakhulukazi wakhiwe ngombhede, itafula le-CNC indexing rotary, ikholomu ephathekayo, isihlalo sesihlalo esinyakazayo, ukubhola kanye nekhanda lamandla okugaya, idivayisi yokugcoba okuzenzakalelayo kanye nedivayisi yokuvikela, idivayisi yokupholisa ejikelezayo, isistimu yokulawula idijithali, isistimu ye-hydraulic, isistimu kagesi nokunye. Umzila wesitimela ohambayo uyasekelwa futhi uyaqondiswa, futhi isikulufu sokunemba siyashayelwa. Umshini unokunemba kokuma okuphezulu nokuphinda ukunemba kokuma.

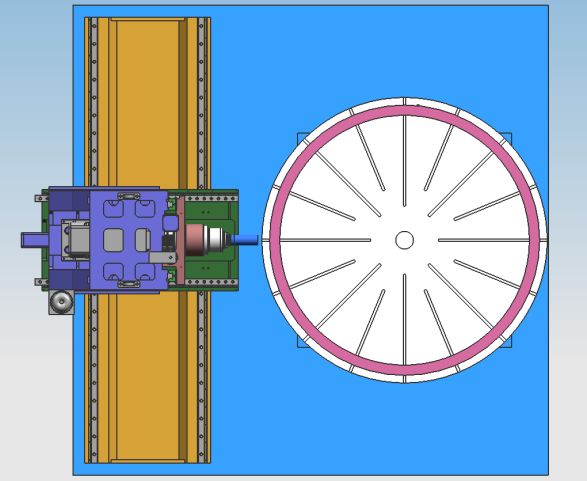

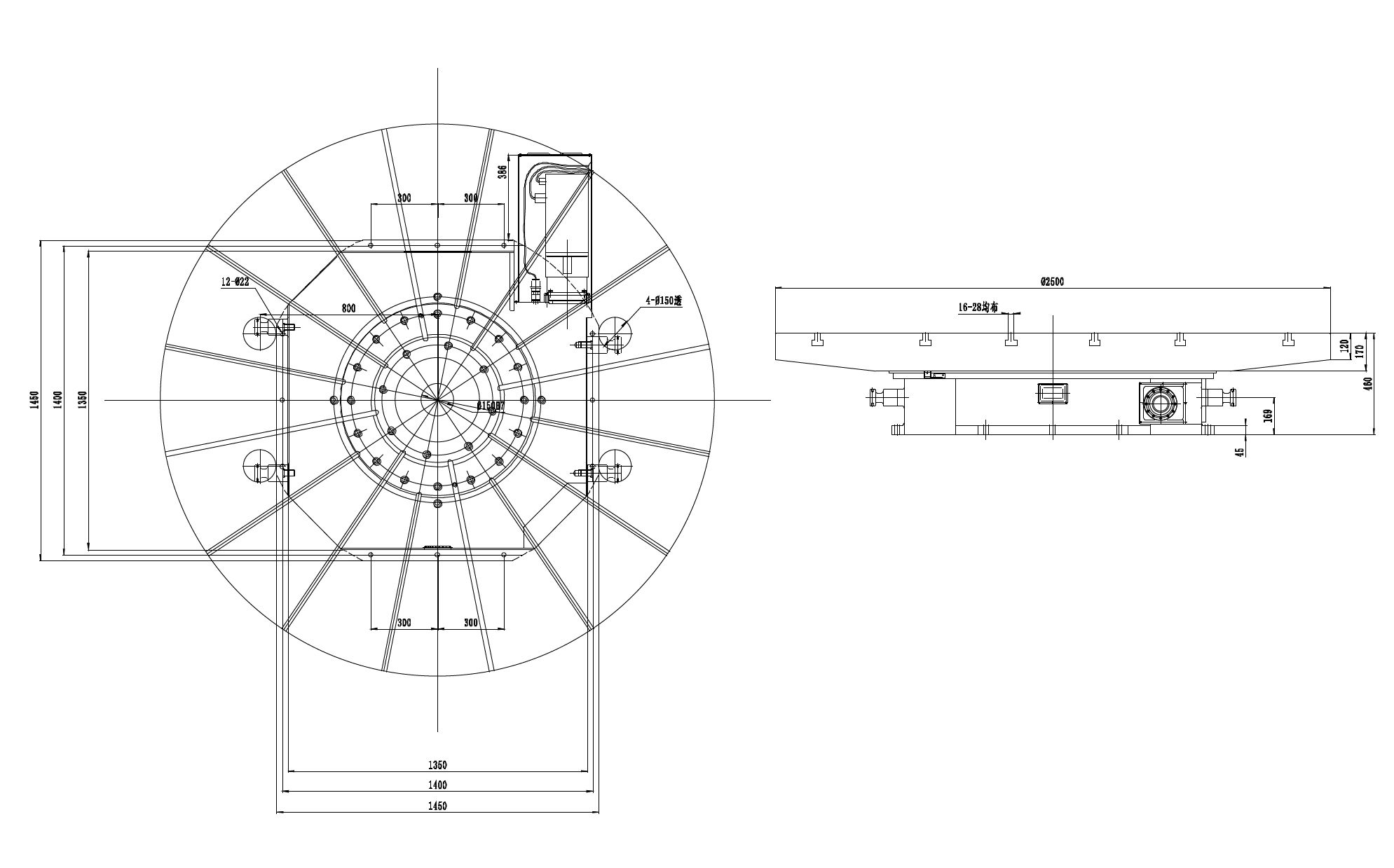

2.1. Itafula lokusebenzisa umbhede: Umbhede wenziwe ngezingxenye zesakhiwo sensimbi eyi-HT250. Iqedwa ngemva kokuthukuthela kwesibili ukuze kususwe ukucindezeleka kwangaphakathi. Inokuqina okuhle okuguquguqukayo nokuma futhi akukho deformation. Ipuleti lokukhomba elinembile lokulawula izinombolo, i-servo drive engu-360° indawo yokubeka inkomba ngokunganaki kanye nokukhiya komoya/uhydraulic, isistimu yokushayela isebenzisa i-AC servo motor ukuze ikhombe ngokuzenzakalelayo ingxenye ye-shaft ejikelezayo engu-360°, futhi ukunemba kwenkomba kuyinkulungwane eyodwa yedigri. Ipuleti lokukhomba libekwe phezulu kombhede, futhi amabhawodi alungisekayo asatshalaliswa phansi kombhede, angalungisa kalula izinga letafula lokusebenza lombhede.

2.2. Ikholomu enyakazayo: Ikholomu yesakhiwo sensimbi enyakazayo iqedwa ngemva kokwelashwa kokufudumeza kwesibili ukuze kususwe ingcindezi yangaphakathi. Inokuqina okuhle okuguquguqukayo nokuma futhi akukho deformation. Isethi yokunemba kwesikulufu sebhola kanye ne-servo motor yenza isilayidi sekholomu sihambe siye ku-Y-eksisi. Isethi yokunemba kwesikulufu sebhola kanye ne-servo motor yenza isilayidi sekholomu sihambe siye ohlangothini lwe-eksisi engu-X. Faka iyunithi yokubhoboza kusilayidi seyunithi. Ukunyakaza kwekholomu kubonakala ngokuzungezisa inadi lebhola kusikulufu sebhola eliqhutshwa injini ye-servo ngokuhlangana.

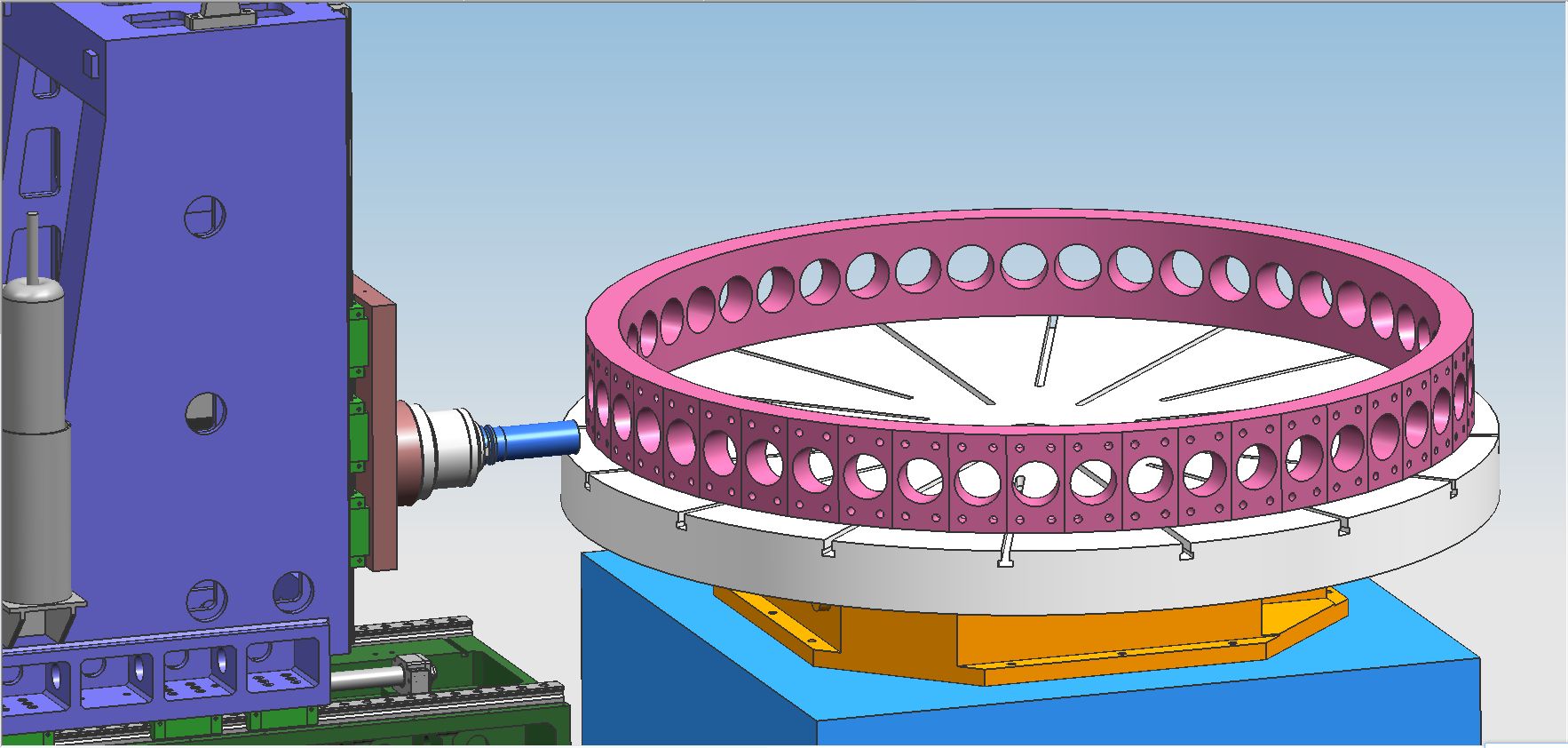

2.3. Isihlalo sehhashi elihambahambayo: Isihlalo sehhashi sifakwe amapheya amabili wesitimela anamandla okuthwala aphezulu, isethi yamapheya eyisikulufu sebhola kanye ne-servo motor, eshayela ikhanda lamandla okubhola ukuthi lihambe liye ohlangothini lwe-Z-eksisi, elingakwazi bona amandla ikhanda phambili ngokushesha, sebenzela phambili, ukuhlehla ngokushesha, yima kanye nezinye izenzo. Inemisebenzi yokuphulwa kwe-chip okuzenzakalelayo, ukususwa kwe-chip nokumisa isikhashana.

2.4. Ikhanda lamandla okumba: Ikhanda lamandla okumba lamukela i-spindle eyimishini yase-Taiwan, futhi i-spindle eqondile ekhethekile ithatha i-angular contact bear, ebona ukuguqulwa kwesivinini esingenasinyathelo ngokudluliswa kwebhande elihambisanayo lamandla aphezulu. Ishayelwa ama-servo motors nezikulufu zebhola. I-Y-axis ingaxhunyaniswa, isebenzise isilawuli se-loop esivaliwe kancane, futhi ingabona imisebenzi yokuhumusha eqondile kanye neyindilinga. I-spindle end iyimbobo ye-taper ye-BT50.

2.5. Idivayisi yokuthambisa ezenzakalelayo kanye nedivayisi yokuvikela:

Lo mshini ufakwe idivayisi yokugcoba ezenzakalelayo, engagcoba ngokuzenzakalelayo amapheya ahambayo njengamareyili angumhlahlandlela, izikulufu zokuhola, namarack. Umshini

I-Z-axis ne-Y-axis ifakwe amakhava okuvikela angangeni uthuli, futhi ama-splash baffles angangeni amanzi afakwe eduze kwetafula lokusebenza.

2.6. Uhlelo olugcwele lokulawula izinombolo zedijithali:

2.6.1. Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

2.6.2. Ifakwe umsebenzi wokuphakamisa ithuluzi, ubude bokuphakamisa ithuluzi bungasethwa kusixhumi esibonakalayo somshini womuntu. Lapho ukubhoboza kufinyelela kulokhu kuphakama, i-drill bit iphakanyiswa ngokushesha phezulu kwe-workpiece, bese ama-chips aphonswa kude, bese idluliselwa ngokushesha endaweni yokubhoboza futhi iguqulelwe ngokuzenzakalelayo ekusebenzeni.

2.6.3. Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ebanjwa ngesandla yamukela isistimu yokulawula izinombolo futhi ifakwe isixhumi esibonakalayo se-USB kanye nesikrini sekristalu esiwuketshezi se-LCD. Ukuze kube lula ukuhlela, ukugcinwa, ukuboniswa nokuxhumana, okusetshenziswa kubonwa kunemisebenzi efana nengxoxo yomshini womuntu, isinxephezelo samaphutha, ne-alamu ezenzakalelayo.

2.6.4. Imishini inomsebenzi wokuhlola kuqala nokuhlola kabusha indawo yomgodi ngaphambi kokucubungula, futhi ukusebenza kulula kakhulu.

* Ukuze kuqinisekiswe ukuthi kulula ukuphakamisa nokuphakela izindandatho ezinkulu, Umshini awunakho ukuvikeleka kwangaphandle, futhi ukuvikela kwangaphandle kuwukuzikhethela.

3. Umshinisebenzisa imvelo:

Ukunikezwa kwamandla: Izigaba ezintathu ze-AC380V±10%, 50Hz±1 Izinga lokushisa le-Ambient: 0°~ 45°

4.Imingcele yezobuchwepheshe

| Imodeli | I-BOSM-1000 | |

| Ukucubungula okuphezulu usayizi we-workpiece | Ubukhulu obuvumelekile bokuzungezisa ububanzi bocezu lokusebenza (mm) | ≤Φ2000 |

|

Ithebula lokusebenza | Ubukhulu be-worktable (mm) isikwele | □1000 |

| Ubukhulu be-worktable (mm) nxazonke | Φ1200 | |

| Umthwalo omkhulu ovundlile (kg) | 5000 | |

|

Iyunithi Yokubhoboza Inqama Emile | inani) | 1 |

| I-spindle taper | I-BT50 | |

| Ububanzi bokubhoboza (mm) | 2-120 | |

| Ububanzi bediski yokusika (mm) | 200 | |

| Ukuthepha ububanzi (mm) | I-M6-M36 | |

| Ibanga ukusuka ebusweni bokuphotha kuya enkabeni yetafula (mm) | 1000-1600 | |

| Ibanga ukusuka enkabeni yokuphotha ukuya endizeni engaphezulu yetafula (mm) | 100-1100 | |

| Isivinini se-spindle (r/min) | 30-3000 | |

| Amandla e-spindle motor (kw) | 30 | |

| I-workpiece i-axis ejikelezayo (i-axis) | Inombolo enkulu yokuhlukanisa (mm) | 360° |

| Setha inani elincane lokuhlukanisa | 0.001° | |

| A-axis servo motor power (kw) | 4.2 | |

| Ikhanda lamandla liya kwesokunxele nakwesokudla (i-X axis) | I-stroke enkulu (mm) | 2000 |

| Isivinini esihambayo se-X-eksisi (m/min) | 0~8 | |

| I-X-axis servo motor power (kw) | 2.4 | |

| Ikhanda lamandla liya phezulu naphansi (Y axis) | I-stroke enkulu (mm) | 1000 |

| Isivinini sokuhamba se-Y-eksisi (m/min) | 0~8 | |

| I-Y-axis servo motor power (kw) | 2.4 Ibhuleki | |

| Ukunyakaza kwekholomu longitudinal (i-eksisi Z) | I-stroke enkulu (mm) | 600 |

| Isivinini sokuhamba se-Z-eksisi (m/min) | 0~4 | |

| I-Z axis servo motor amandla (kw) | 2.4 | |

| Ukumisa ukunemba | 1000mm | ±0.05 |

| Ukuphindaphinda | 1000mm | ±0.025 |

| Ukunemba kwezinkomba zethebula le-CNC (mm) |

| 15” |

| Ubukhulu bomshini (kuhlanganise nokuvikela) | Ubude (X) × Ububanzi (Z) × Ubude (Y) (mm) | 5300*6000*3400 |

| Isisindo esiphelele (t)okuhlanganisa nokuvikela | (cishe) angu-20 | |