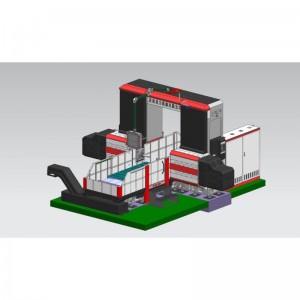

Umshini Wokugaya Osindayo we-CNC

Umshini Wokubhoboza we-CNC Nokugaya

Umshini wokugaya we-CNC onesivinini esikhulu nowokugaya

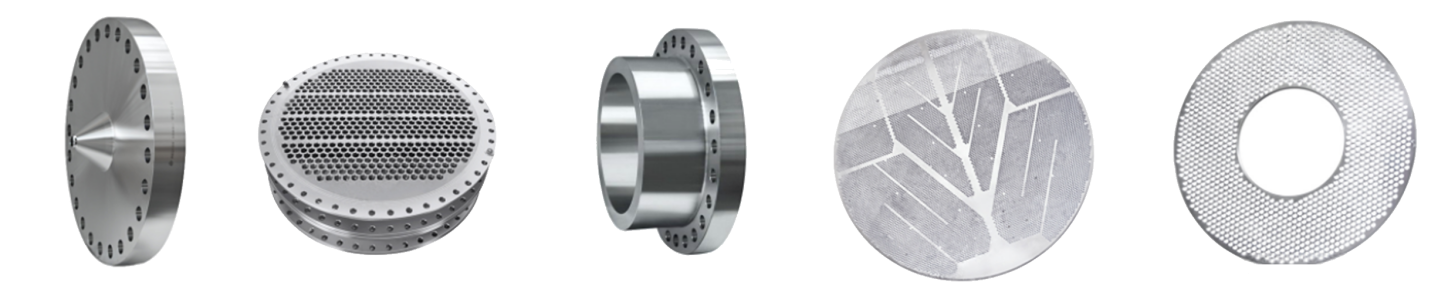

Isicelo somshini

Imishini yokugaya ye-CNC kanye nemishini yokugaya isetshenziselwa ikakhulukazi ukubhola okusebenzayo kwezingcezu zokusebenza ezinogqinsi ngaphakathi kwebanga elisebenzayo elinjengamapuleti, ama-flange, amadiski nezindandatho.Ngezimbobo nezimbobo eziyimpumputhe zingabhobozwa ezinhlotsheni ezahlukene zezinto.Umshini ulawulwa ngedijithali futhi usebenza kalula.Ingakwazi ukufeza i-automation, ukunemba okuphezulu, izinhlobo eziningi, ukukhiqizwa ngobuningi.

Ukuze kuhlangatshezwane nezidingo zokucubungula zabasebenzisi abahlukene, inkampani yethu ithuthukise imishini ehlukahlukene.Ngaphezu kwamamodeli avamile, kungase futhi kube ngokwezifiso ngokuvumelana nezidingo zangempela zamakhasimende.

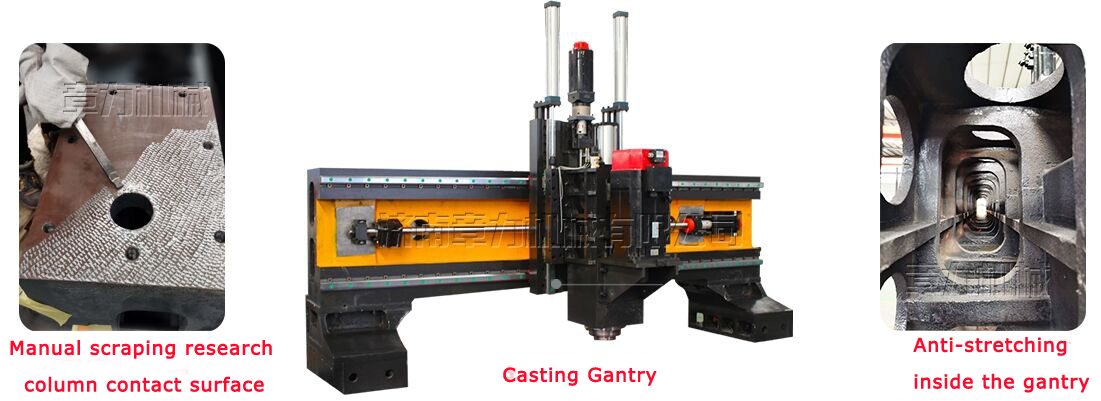

Isakhiwo somshini

Lo mshini ikakhulukazi wakhiwe itafula lombhede, i-gantry ehambayo, isihlalo esihambayo esishelelayo, ukubhola nokuphotha okuphothayo, idivayisi yokugcoba okuzenzakalelayo kanye nedivayisi yokuzivikela, idivayisi yokupholisa ejikelezayo, uhlelo lokulawula lwe-CNC, uhlelo lukagesi nokunye.Ukusekela nokuqondisa komhlahlandlela womugqa kanye nesikulufa sokuhola esinembayo, umshini unokunemba kokuma okuphezulu kanye nokunemba kokuma okuphindaphindiwe.

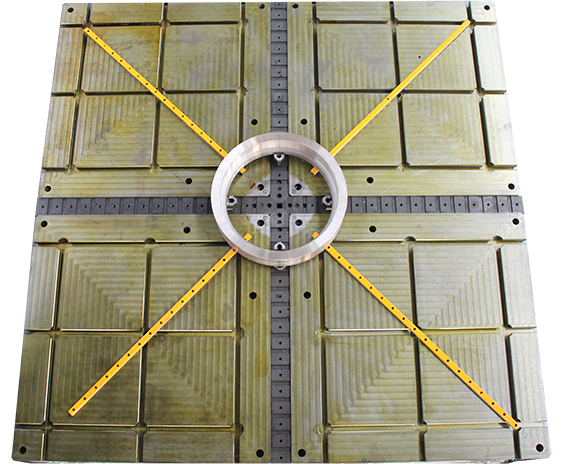

1)Ithebula lokusebenza:

Ithebula elisebenzayo lamukela isakhiwo sokuphonsa, futhi indiza ine-T-slot enesakhiwo sokuqedela esinengqondo sokuhlanganisa ama-workpieces.Ngaphezu kombhede, ama-T-slots ahleliwe.Isistimu yokushayela isebenzisa i-AC servo motor kanye nesikulufu sebhola esinembayo ukushayela nhlangothi zombili ukwenza i-gantry ihambe iqonde ku-Y-eksisi.Amabhawodi alungisekayo asatshalaliswa phansi kombhede, angalungisa kalula izinga letafula lombhede.

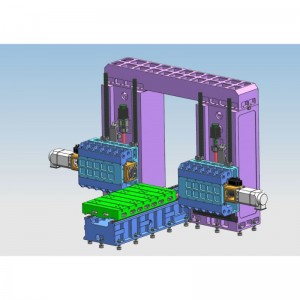

2)Moi-vinggantry:

I-gantry ehambayo ifakwe nge-iron empunga engu-250, futhi amapheya amabili omugqa oginqikayo aphezulu kakhulu afakwe ohlangothini olungaphambili lwe-gantry.Isethi yokunemba kwesikulufu sebhola kanye ne-servo motor yenza ikhanda lamandla lislayidi lihambe liye ohlangothini lwe-X-eksisi.Ikhanda lamandla okubhola lifakwe kusilayidi sekhanda lamandla.Ukunyakaza kwe-gantry kwenziwa yi-servo motor eshayela ucingo lwebhola kusikulufa sebhola ngokusebenzisa ukuhlanganisa okunembayo.

3)Moi-vingisihlalo sesihlalo:

Isihlalo sokushelela esihambayo siyingxenye yesakhiwo sensimbi enembile.Amaslayidi amabili wesitimela we-NC womthamo omkhulu kakhulu kanye nesethi yamapheya eyisikulufu esinembayo kanye nesinciphisi seplanethi esinembe kakhulu kuxhunywe ku-servo motor ukushayela ikhanda lamandla okubhola.Ukuhamba nge-Z-axis kungabona phambili ngokushesha, ukusebenzela phambili, ukuhlehlisa ngokushesha, nokuma kwekhanda lamandla.Ngokuphulwa kwe-chip okuzenzakalelayo, ukususwa kwe-chip, imisebenzi yokumisa okwesikhashana.

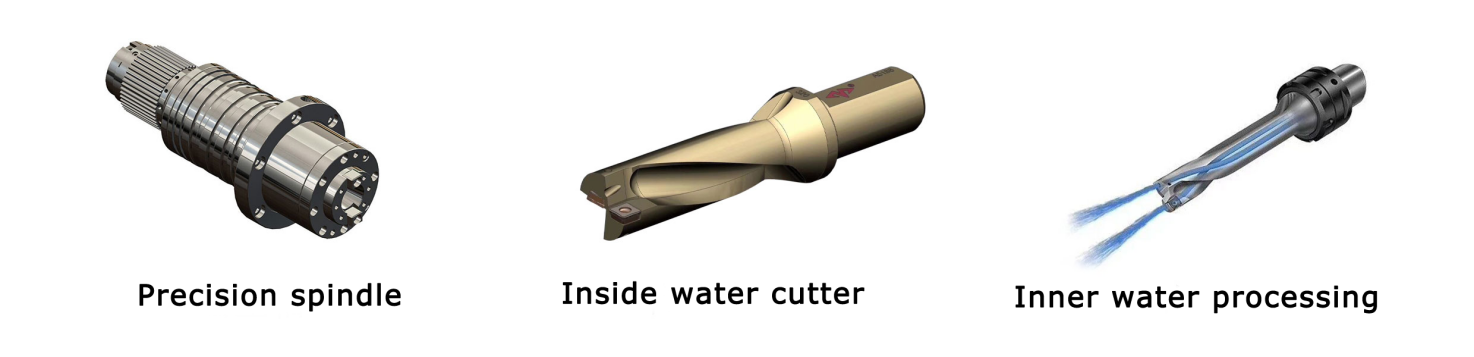

4)Ikhanda lamandla okumba(Spindle):

Ikhanda lamandla okumba lisebenzisa i-servo spindle motor, eshayela ukuphotha okunembayo okuzinikele ngokwehlisa izinga lebhande le-synchronous elinamazinyo ukuze kwandiswe i-torque.I-spindle isebenzisa ama-angular angaphambili amathathu, amabili, kanye nama-angular angama-angular ase-Japan ukuze kuzuzwe ushintsho lwejubane olunganyatheli.Ukushintshwa okusheshayo nokulula, okuphakelayo kushayelwa yi-servo motor nesikulufu sebhola.Izimbazo zika-X kanye no-Y zingaxhunywa, futhi isilawuli seluphu esivalwe kancane sisetshenziselwa ukufeza imisebenzi yokuhumusha ewumugqa neyindilinga.

I-spindle end iyimbobo ecijile ye-BT40, efakwe i-Rotorfoss high-speed rotary joint esuka e-Italy, engasebenzisa i-U drill enesivinini esikhulu (i-drill enobudlova) kanye ne-core drill bit ukukhipha amanzi. qaphela ukucubungula imbobo ejulile futhi uvikele ithuluzi ukuze unciphise izindleko zokusebenzisa.

5)Idivayisi yokuthambisa ezenzakalelayo kanye nedivayisi yokuvikela:

njengama-guide rails, izikulufu zokuhola, ama-rack, njll., ngaphandle kwamakhona afile ukuze kuqinisekiswe impilo yesevisi yethuluzi lomshini.I-X-axis kanye ne-Y-axis yethuluzi lomshini ifakwe izembozo zokuvikela ezivikela uthuli, futhi onogada be-splash abangenamanzi bafakwe eduze kwebhentshi lokusebenza.

6)CNC Control System:

6.1 Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

6.2 Ngomsebenzi wokuphakamisa ithuluzi, ubude bokuphakamisa ithuluzi bungasethwa kusixhumi esibonakalayo somshini womuntu.Uma ubhoboza kulokhu kuphakama, i-drill bit iphakanyiswa ngokushesha phezulu kwe-workpiece, bese i-chip iphonswa, bese idluliselwa ngokushesha endaweni yokubhoboza futhi iguqulelwe ngokuzenzakalelayo emsebenzini.

6.3Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ebanjwa ngesandla yamukela isistimu yokulawula izinombolo, futhi ifakwe isixhumi esibonakalayo se-USB nesibonisi sekristalu esiwuketshezi se-LCD.Ukuze kube lula ukuhlela, ukugcinwa, ukuboniswa nokuxhumana, okusetshenziswa kubonwa kunemisebenzi efana nengxoxo yomshini womuntu, isinxephezelo samaphutha, ne-alamu ezenzakalelayo.

6.4Umshini unomsebenzi wokuhlola kuqala nokubheka kabusha indawo yomgodi ngaphambi kokucubungula, futhi ukusebenza kulula kakhulu.

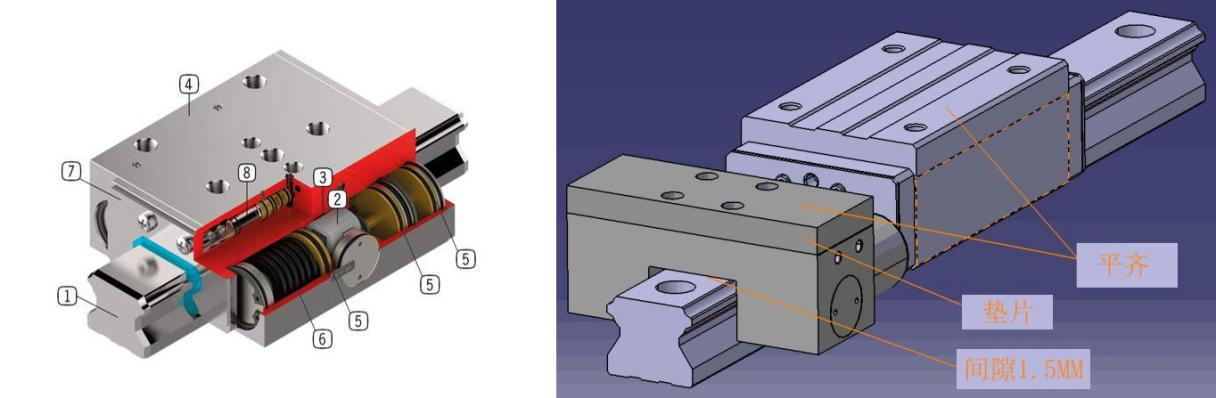

7)I-clamp kaloliwe

I-clamp yakhiwe ngomzimba we-clamp kanye ne-actuator.Kuyingxenye esebenza kahle kakhulu esetshenziswa nepheya yomugqa womugqa ogoqayo.Ikhiqiza amandla okugoqa aqinile ngomgomo wokunwetshwa kwebhulokhi emise okukanxantathu.Izici ezandisa ukuqina.

Izici:

- Amandla okubamba aphephile futhi athembekile, abamba i-eksisi ye-XY enganyakazi phakathi nokubhoboza nokuthepha.

- Amandla okubamba aphezulu kakhulu, akhuphula ukuqina kokuphakelayo kwe-axial, futhi avimbele ukunyakaza okuncane okubangelwa ukudlidliza.

- Ukuphendula okusheshayo, isikhathi sokuphendula sokuvula nokuvala amasekhondi angu-0.06 kuphela, okuvikela ithuluzi lomshini futhi kuthuthukisa impilo yesikulufu.

- Indawo ehlala isikhathi eside, ene-nickel-plated, ukusebenza okuhle kwe-anti-rust.

Idizayini yenoveli yokugwema umthelela oqinile lapho ubamba.

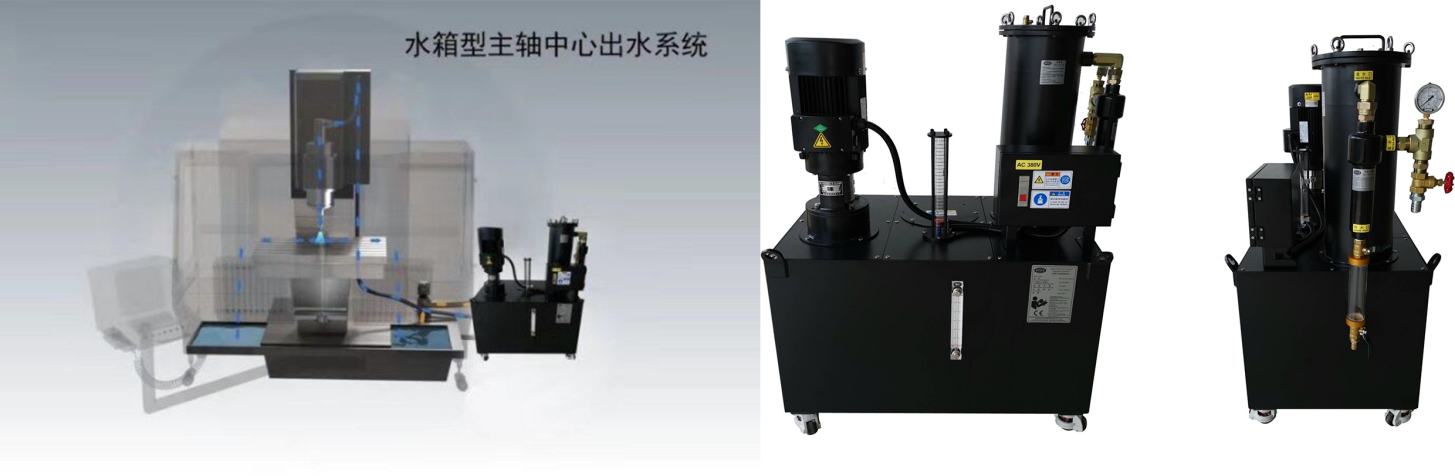

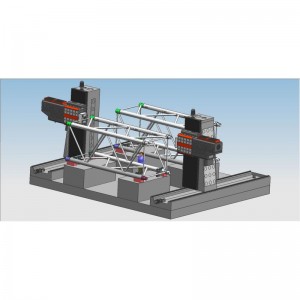

8)Isikhiphi se-chip esizenzakalelayo kanye nedivayisi yokupholisa ejikelezayo:

I-automatic chip remover ihlelwa ngemuva kwebhentshi lomsebenzi futhi isihlungi sihlelwa ekugcineni.I-automatic chip remover iwuhlobo lwamaketango ayisicaba, futhi iphampu yokupholisa ifakwe ohlangothini olulodwa.I-outlet ye-chip ixhunywe ohlelweni oluphakathi lokuhlunga amanzi.Isipholile sigelezela ku-chip ejector.Iphampu yokuphakamisa i-chip ejector ishayela isipholile kusistimu yokuhlunga amanzi emaphakathi.Iphampu yokupholisa enomfutho ophezulu izungeza isipholile esihlungiwe sokusika nokupholisa.Futhi ifakwe i-chip yokuthutha i-trolley, elula kakhulu ukuthutha ama-iron chips.Lo mshini ufakwe uhlelo lokupholisa lwangaphakathi nangaphandle lwabasiki.Lapho ubhoboza ngesivinini esikhulu, abasiki bapholiswa ngamanzi angaphakathi nangaphandle ngesikhathi sokugaya ukukhanya.

I-alamu yamanzi aphansi

1) Uma into epholisayo kusihlungi ikuleveli yoketshezi emaphakathi, isistimu ixhuma ngokuzenzakalelayo injini ukuze iqale, futhi into epholisayo kusikhiphi se-chip igeleza ngokuzenzakalelayo iye kusihlungi.Lapho izinga eliphezulu le-liquid lifinyelelwa, injini iyayeka ukusebenza ngokuzenzakalelayo.

2) Uma okokupholisa kusihlungi kusezingeni eliphansi, isistimu izokwazisa ngokuzenzakalelayo igeji yeleveli ye-liquid, i-spindle izohoxisa ithuluzi ngokuzenzakalelayo, futhi umshini uzomisa umsebenzi.

9)I-Central Outlet Filtration System:

Umshini ufakwe isistimu yokuhlunga amanzi emaphakathi njengejwayelekile, engahluza ngempumelelo ukungcola okukupholisa.Uhlelo lwamanzi lwesifutho lwangaphakathi lungavimbela izikhonkwane zensimbi ukuthi zingahlangani ethuluzini ngesikhathi sokucubungula, ukunciphisa ukuguga kwamathuluzi, ukunweba impilo yamathuluzi, ukuthuthukisa isiphetho sendawo yokusebenza, Iphinikhodi yokukhipha amanzi enengcindezi ephezulu yethiphu ye-blade ingavikela kahle ingaphezulu le-workpiece, vikela ijoyinti le-rotary elinesivinini esiphezulu, uvimbele ukungcola ekuvimbeni ilunga elijikelezayo, futhi uthuthukise ikhwalithi iyonke ye-workpiece nokusebenza kahle komsebenzi.

10)Isikulufu sebhola kanye nesihlalo esihlanganisiwe semoto:

Isisekelo semoto siwumkhiqizo ogxile kakhulu oxhuma isikulufu sebhola kanye nenjini.I-angular contact paired bear (ibanga lokunemba C5) ihlanganiswe ukuze kuthuthukiswe ukunemba nokuqinisekisa ukucaciswa kwe-axial eyiziro yesikulufu sebhola lapho injini iya phambili futhi ihlehla.Ifaneleka ngokukhethekile imishini yesivinini esikhulu.

Ukunemba komhlangano: isikulufu sebhola kanye nenjini kufakwa endaweni eyodwa ngesisekelo semoto.Yehlisa iphutha lokugxila le-motor shaft kanye ne-ball screw shaft, lilawule kokuthi plus noma susa 0.01mm, futhi perpendicularity yobuso bokuphela ngu-0.01.

11)Itafula elinezinzipho ezine(ongakukhetha)

Ithebula lokusebenza lemishini yokuzenzela ifakwe i-hydraulic self-centering chuck enemihlathi emine.I-workpiece ingafakwa phakathi ngokuzenzakalela ku-clamp eyodwa ngaphandle kokuzulazula kwe-workpiece ngayinye ukuze kutholwe isikhungo.I-clamping iyashesha futhi ifanelekile.

Rarulula inkinga yokuthi ucezu lomsebenzi olunesiyingi sokukhomba esingaphansi kuka-1600 mm ububanzi luboshelwa ngokucindezela ipuleti ngemva kokuphakelwa bese ubheka isikhungo, esidla isikhathi esincane futhi esithatha isikhathi eside sokubopha kunesikhathi sokucubungula.

I-chuck yemihlathi emine egxilile ngokuzimele ithuthukiswe ngokushaywa komhlathi omkhulu yenza kube nzima ukuthi ucezu lokusebenza luthinte umhlathi lapho ubamba.Isakhiwo se-strip esine-pad sisetshenziswa.Ixazulula isimo sokuthi imihlathi ye-hydraulic noma ye-pneumatic inokuhamba okuncane emakethe futhi ama-workpieces amakhulu azothinta imihlathi lapho ephakamisa, edala umonakalo kuma-chucks.

Imihlathi emine ebhentshini lokusebenza isesitayelani esihlakazekayo, futhi ukukhishwa kwebhentshi langemuva kuyinkundla evamile ene-T-groove yayo.

Ukucaciswan

| Imodeli | I-BOSM-DT1010 | I-BOSM-DT2010 | I-BOSM-DT2016 | I-BOSM-DT2525 | |

| Usayizi wokusebenza | Ubude*Ububanzi (mm) | 1000x1000 | 2000x1000 | 2000x1600 | 2500x2500 |

| Inhloko Yokubhoboza Emile | I-spindle taper | BT40/BT50 | BT40/BT50 | BT40/BT50 | BT40/BT50 |

| Ububanzi bokubhoboza (mm) | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | |

| Ukuthepha ububanzi (mm) | M24/M36 | M24/M36 | M24/M36 | M24/M36 | |

| Isivinini se-spindle (r/min) | 30 ~ 3000 | 30 ~ 3000 | 30 ~ 3000 | 30 ~ 3000 | |

| Amandla e-spindle (Kw) | 15/22 | 15/22 | 15/22 | 15/22 | |

| Ibanga ukusuka ekugcineni okungaphansi kwe-spindle ukuya endaweni yokusebenza (mm) | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | |

| Phinda Ukunemba Kokumisa (X/Y/Z) | X/Y/Z | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm |

| Isisindo esiphelele (T) | 8.5 | 11 | 13.5 | 16.5 | |

| Ithuluzi lomagazini | Umagazini wethuluzi lomugqa | ||||

Ukuhlolwa Kwekhwalithi

Umshini ngamunye we-Bosman ulinganiswa nge-laser interferometer evela enkampanini ye-RENISHAW yase-United Kingdom, ehlola ngokunembile futhi inxephezele amaphutha e-pitch, ukuhlehla, ukunemba kokuma, nokunemba kokuma okuphindaphindiwe ukuze kuqinisekiswe ukuguquguquka komshini, ukuzinza okumile, kanye nokunemba kokucubungula..Ukuhlolwa kwebha yebhola Umshini ngamunye usebenzisa isihloli sebha yebhola esivela enkampanini yaseBrithani i-RENISHAW ukuze ulungise ukunemba kwendingilizi yeqiniso kanye nokunemba komshini wejometri, futhi wenze izivivinyo zokusika eziyindilinga ngesikhathi esifanayo ukuze kuqinisekiswe ukunemba komshini we-3D womshini kanye nokunemba kwendingilizi.

Ngaphambi Nangemuva Kwesevisi

1) Ngaphambi Kwesevisi

Ngokutadisha isicelo nolwazi oludingekayo oluvela kumakhasimende bese impendulo konjiniyela bethu, ithimba le-Bossman Technical linesibopho sokuxhumana nobuchwepheshe namakhasimende kanye nokwakhiwa kwezixazululo, ukusiza ikhasimende ekukhetheni isixazululo esifanele somshini kanye nemishini efanelekile.

2) Ngemva Kwesevisi

A.Umshini onewaranti yonyaka owodwa futhi okhokhelwe ukunakekela impilo yonke.

B. Phakathi nenkathi yewaranti yonyaka owodwa ngemva kokuba umshini ufikile echwebeni lapho uya khona, i-BOSSMAN izohlinzeka ngezinsizakalo zokunakekela zamahhala nezifika ngesikhathi zamaphutha ahlukahlukene angenziwanga umuntu emshinini, futhi ibuyisele ngesikhathi zonke izinhlobo zezingxenye zomonakalo ongenziwanga ngumuntu mahhala. yenkokhiso .Ukwehluleka okwenzeka ngesikhathi sewaranti kuzolungiswa ngezindleko ezifanele.

Ukusekelwa kwe-C.Technical emahoreni angama-24 ku-inthanethi, i-TM, i-Skype, i-E-mail, ukuxazulula imibuzo ehlobene ngesikhathi.uma ingeke ixazululwe, i-BOSSMAN izohlela ngokushesha ukuthi unjiniyela wangemuva kokuthengisa afike esizeni ukuze alungiswe, umthengi udinga ukukhokhela i-VISA, amathikithi ezindiza kanye nendawo yokuhlala.

Isizinda Senkampani