BOSM -Horizontal Counter Drilling kanye Boring Machine

1. Ukusetshenziswa kwezisetshenziswa:

I-BOSM counter drilling counter drilling kanye nomshini oyisicefe wumshini okhethekile wenkampani yakho ukucubungula amakepisi we-tower crane.Umshini ufakwe amasethi ama-2 okubhola avundlile kanye namakhanda amandla ayisicefe, angabona ukubhoboza, ukugaya kanye nesicefe sezinto zokusebenza ngaphakathi kwebanga le-stroke elisebenzayo.Ukusika nokunye ukucubungula, isivinini sokumisa imishini siyashesha, ukunemba kokucubungula kuphezulu, nokusebenza kahle kokucubungula kuphezulu.

2. Izici zesakhiwo sezisetshenziswa:

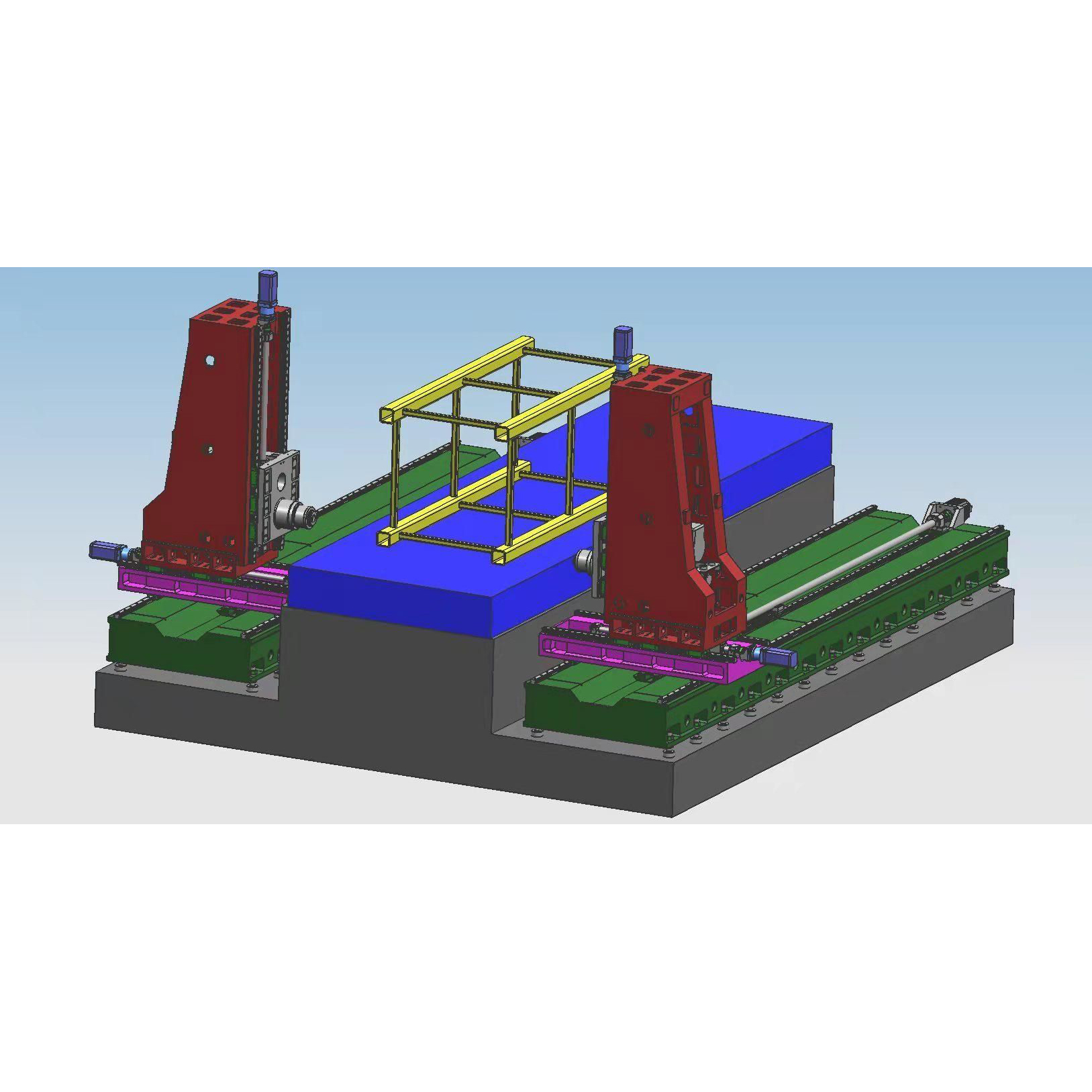

2. 1. Izingxenye eziyinhloko ze-Umshini

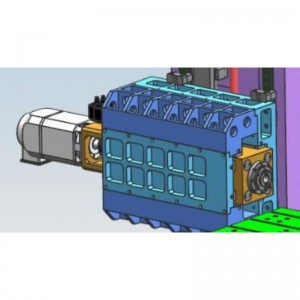

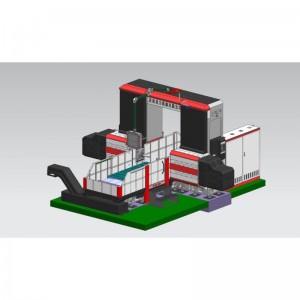

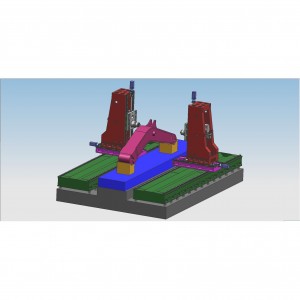

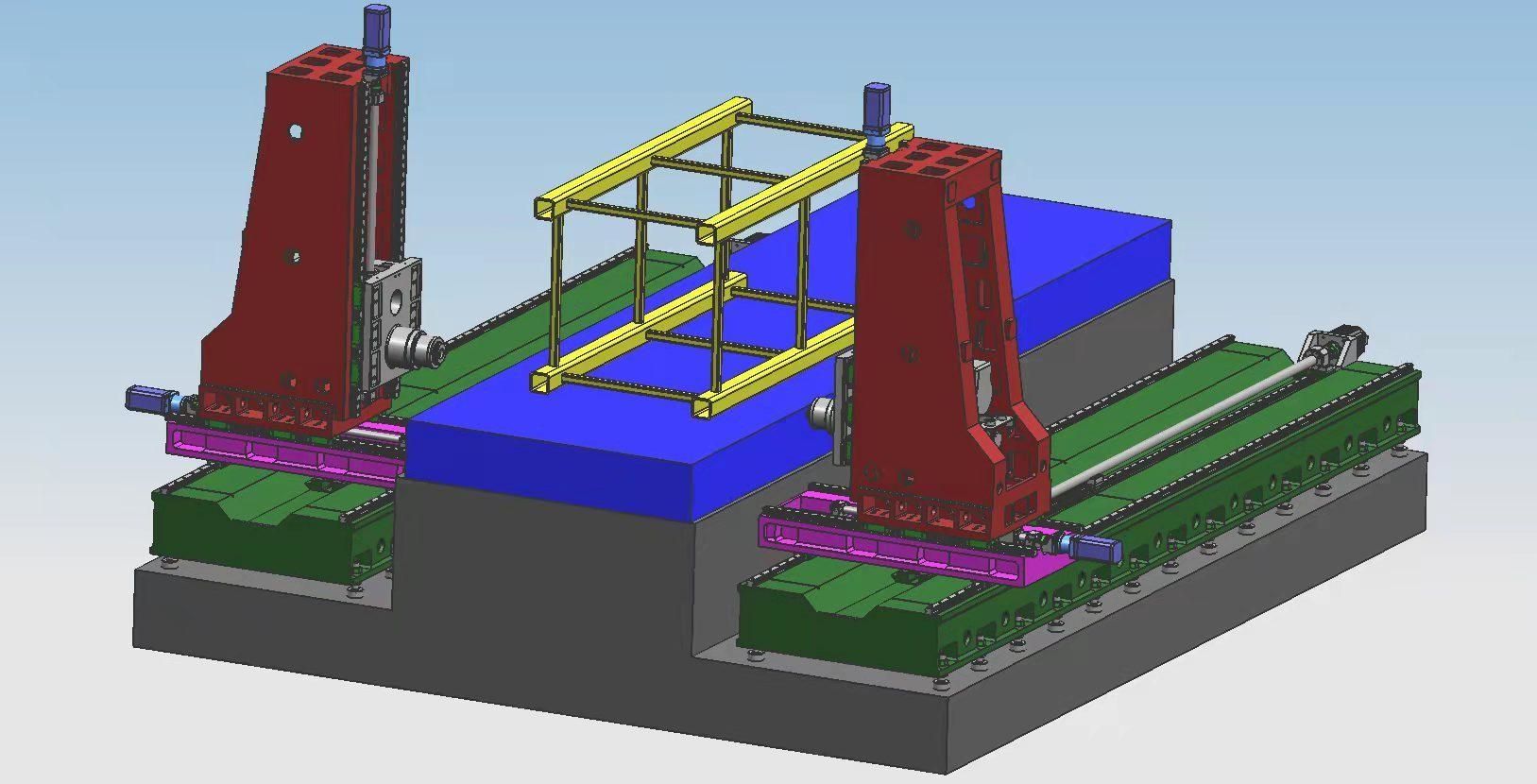

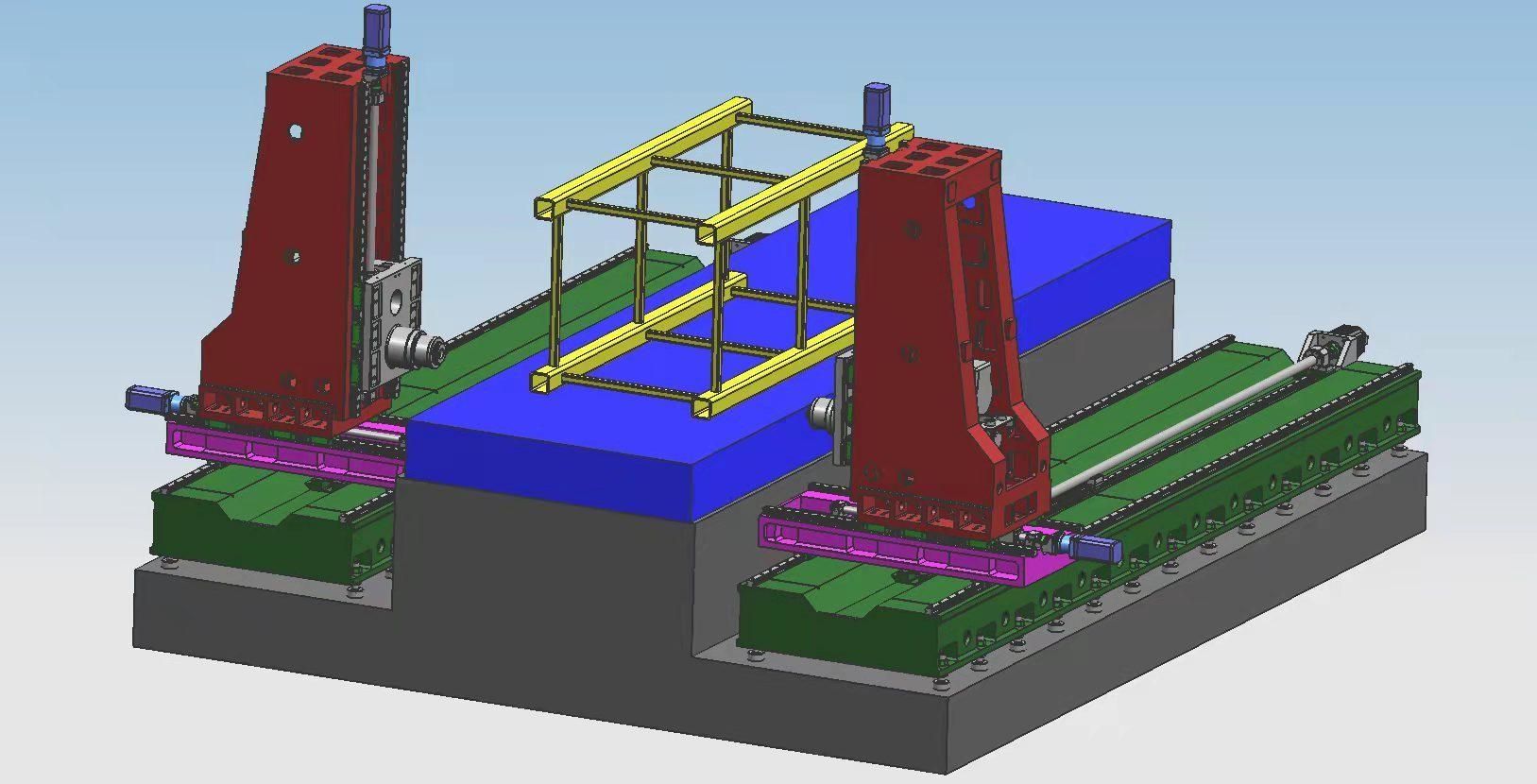

Izingxenye eziyinhloko zomshini: umbhede, itafula lokusebenzela, amakholomu angakwesobunxele nakwesokudla, amahhashi, izinqama, njll., izingxenye ezinkulu zenziwa ngokubunjwa kwesihlabathi se-resin, ikhwalithi ephezulu yensimbi empunga engu-250, ifakwe emgodini wesihlabathi esishisayo→ ukuguga ukudlidliza→kushisa ukuncishiswa kwesithando somlilo→ukuguga kokudlidliza→Ukusebenza kanzima→ukuguga kokudlidliza→ukufakwa kwesithando somlilo→ukuguga kokudlikiza→ukuqeda ukuqeda ngokuphelele ukucindezelwa okungekuhle kwezingxenye nokugcina ukusebenza kwezingxenye kuzinzile.Ibhentshi lokusebenzela lemishini lilungisiwe, futhi amakhanda amandla ezinhlangothini zombili angakwazi ukuhamba ngaphambili nangemuva kwesisekelo;umshini unemisebenzi efana nokubhola, ukubhora, ukucwila, ukuthepha, njll. Indlela yokupholisa yethuluzi ukupholisa kwangaphakathi kanye nokupholisa kwangaphandle.Umshini uqukethe izimbazo eziphakelayo ezi-5, amakhanda amandla okusika ama-2, angavunyelaniswa nezimbazo ezi-5 ngesikhathi esisodwa, noma enze okukodwa.Ukuqondiswa kwe-axial yoMshini kanye nekhanda lamandla kuboniswa esithombeni esingezansi.

2. 2 Isakhiwo esiyinhloko sengxenye ye-axial transmission feed

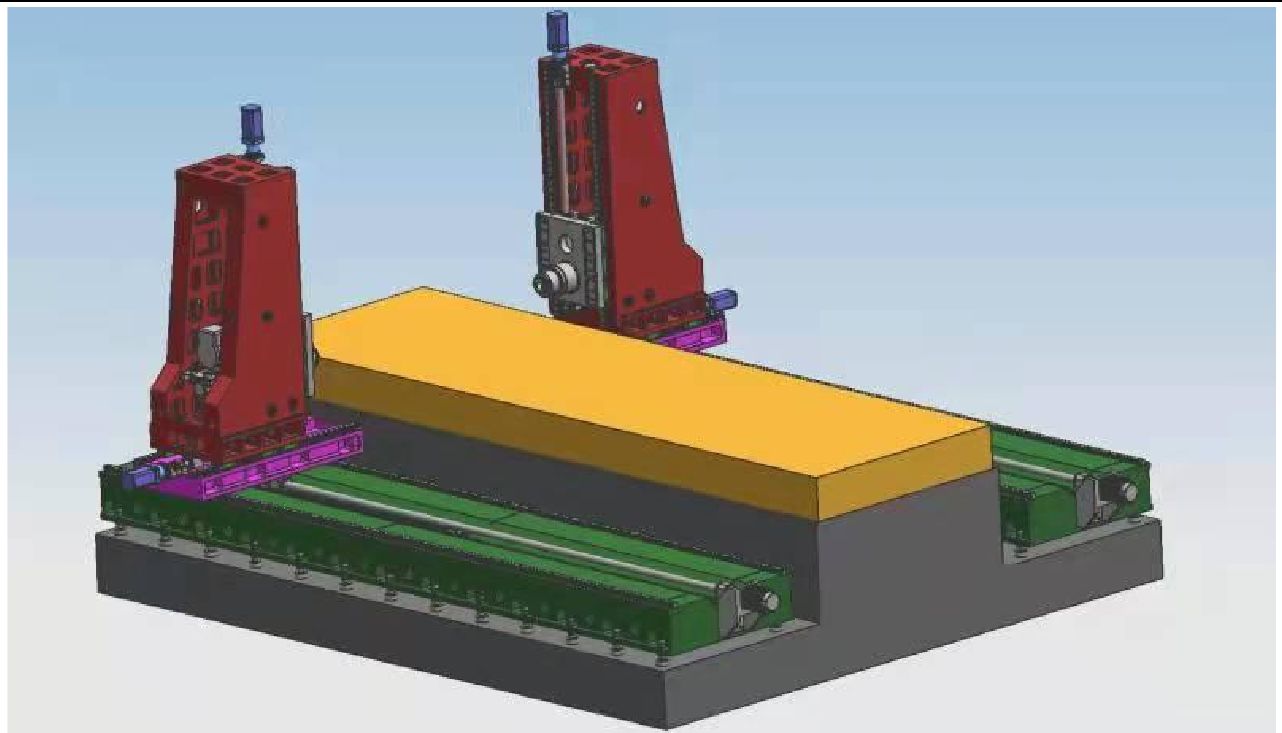

2.2.1 X i-eksisi: Ikhanda lamandla libuyela eceleni eceleni komzila wesitimela wesisekelo.

Idrayivu ye-X1-axis: I-AC servo motor kanye nesinciphisi seplanethi esinembe kakhulu sisetshenziswa ukushayela ikhanda lamandla nge-screw drive ukuze kubonakale ukunyakaza komugqa kwe-X-eksisi.

Ukudluliswa kwe-X2-axis: I-AC servo motor kanye nesinciphisi seplanethi esinembe kakhulu sisetshenziselwa ukushayela ikhanda lamandla ngokudluliswa kwesikulufu sebhola ukuze kubonakale ukunyakaza komugqa we-X-axis.

Ifomu lesitimela esiqondisayo: Ama-rail angumhlahlandlela wokunemba aphezulu afakwe amathayela esisekelweni esinwetshiwe.

2.2 i-eksisi ye-Y1: Ikhanda lamandla libuyisela phezulu naphansi kukholomu.

Idrayivu ye-Y1-axis: Yamukela i-AC servo motor ukushayela ngesikulufu sebhola ukuze ubone ukunyakaza okuqondile kwe-Y1-eksisi.Ifomu lesitimela esiqondisayo: izingcezu ezi-4 zohlobo lwama-45 amalayini omugqa womugqa.

2.2.3 I-eksisi ye-Y2: Ikhanda lamandla libuyisela phezulu naphansi kukholomu.

I-Y2-axis transmission: I-AC servo motor isetshenziselwa ukushayela ngesikulufu sebhola ukubona ukunyakaza komugqa kwe-Y1-axis.

Ifomu lesitimela esiqondisayo: izingcezu ezi-4 zohlobo lwama-45 amalayini omugqa womugqa.

2.2.4 i-eksisi ye-Z1: Ikhanda lamandla libuyela emuva naphambili kwisihlalo sehhashi.

I-Z1-axis transmission: I-AC servo motor kanye nesinciphisi seplanethi esinembe kakhulu sisetshenziselwa ukushayela ukunyakaza ngesikulufu sebhola ukuze kubonakale ukunyakaza komugqa we-axis ye-Z1.

2.2.5 i-eksisi ye-Z2: Ikhanda lamandla libuyela emuva naphambili kwisihlalo sehhashi.

Ukudluliselwa kwe-Z2-axis: I-AC servo motor kanye nesinciphisi seplanethi esinembe kakhulu sisetshenziswa ukushayela ukunyakaza ngesikulufu sebhola ukuze kubonakale ukunyakaza komugqa we-Z2-eksisi.

2.3. Ukususwa kwe-chip nokupholisa

Kukhona ama-flat chain chip conveyor afakwe nhlangothi zombili ngaphansi kwebhentshi lokusebenzela, futhi amashiphu ensimbi angakhishelwa kusidlulisi se-chip ekugcineni ukuze kutholakale ukukhiqizwa okuphucuzekile.Kunepompo yokupholisa ethangini lokupholisa le-chip conveyor, engasetshenziselwa ukupholisa kwangaphakathi + ukupholisa kwangaphandle kwethuluzi ukuze kuqinisekiswe ukusebenza nempilo yesevisi yethuluzi, futhi okokupholisa kungagaywa kabusha.

3.Uhlelo olugcwele lokulawula izinombolo zedijithali:

3.1.Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

3.2.Ngomsebenzi wokuphakamisa ithuluzi, ibanga lokuphakamisa ithuluzi lingasethwa kusixhumi esibonakalayo somshini womuntu.Uma ibanga selifinyelelwe, ithuluzi lizophakanyiswa ngokushesha, bese ama-chips azolahlwa kude, bese adlulela phambili ngokushesha endaweni yokubhoboza futhi aguqulelwe ngokuzenzakalelayo ukusebenza.

3.2.Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ephathwa ngesandla yamukela isistimu yokulawula izinombolo futhi ifakwe isixhumi esibonakalayo se-USB nesibonisi sekristalu esiwuketshezi se-LCD.Ukuze kube lula ukuhlela, ukugcinwa, ukuboniswa nokuxhumana, okusetshenziswa kubonwa kunemisebenzi efana nengxoxo yomshini womuntu, isinxephezelo samaphutha, ne-alamu ezenzakalelayo.

3.2.. Izinto zokusebenza zinomsebenzi wokuhlola kuqala nokuhlola kabusha indawo yembobo ngaphambi kokucubungula, futhi ukusebenza kulula kakhulu.

4.Ukugcoba okuzenzakalelayo

Ukunemba komshini amapheya kaloliwe womugqa, amapheya wesikulufu sebhola anemba kanye namanye amapheya anyakazayo anembe kakhulu afakwe amasistimu okugcoba azenzakalelayo.Ipompo yokugcoba ezenzakalelayo ikhipha uwoyela ocindezelayo, futhi igumbi likawoyela we-lubricator lobuningi lingena emafutheni.Lapho igumbi likawoyela ligcwele uwoyela futhi ingcindezi yesistimu ikhuphukela ku-1.4 ~ 1.75Mpa, inkinobho yokucindezela ohlelweni ivaliwe, iphampu iyama, futhi i-valve yokukhipha ilayishwa ngesikhathi esifanayo.Lapho umfutho kawoyela emgwaqeni wehla ngaphansi kuka-0.2Mpa, isigcobo somthamo siqala ukugcwalisa indawo yokugcoba bese siqedela ukugcwaliswa kwamafutha okukodwa.Ngenxa yenani eliqondile lamafutha anikezwa i-oiler quantitative kanye nekhono lokubona ingcindezi yesistimu, ukunikezwa kukawoyela kunokwethenjelwa futhi kuqinisekisa ukuthi kukhona ifilimu yamafutha ebusweni be-kinematic pair ngayinye, enciphisa ukungqubuzana nokuguga futhi ivimbele umonakalo. esakhiweni sangaphakathi esibangelwa ukushisa ngokweqile., ukuqinisekisa ukunemba nokuphila koMshini.

5. Umshinisebenzisa imvelo:

Ukunikezwa kwamandla: Izigaba ezintathu AC380V±10%, 50Hz±1 izinga lokushisa le-Ambient: -10°~ 45°

6.Imibandela yokwamukela:

I-JB/T10051-1999 "Izicaciso Ezijwayelekile Zobuchwepheshe Zomshini Wokusika Wamanzi we-Metal Cutting Machines"

7.Imingcele yezobuchwepheshe:

| Imodeli | 2050-5Z | |

| Ubukhulu bosayizi womsebenzi wokucubungula | Ubude × ububanzi × ubude (mm) | 5000×2000×1500 |

| usayizi wedeski elisebenzayo | Ubude X Ububanzi (mm) | 5000*2000 |

| I-Power head base direction travel | Iya emuva naphambili (mm) | 5000 |

| Amandla ikhanda phezulu naphansi | Ukushaywa kwenqama phezulu naphansi (mm) | 1500 |

|

Uhlobo lwenqama oluvundlile lokumba ikhanda lamandla Ikhanda lamandla 1 2 | Ubuningi (2 ama-pcs) | 2 |

| I-spindle taper | I-BT50 | |

| Ububanzi bokubhoboza (mm) | Φ2-Φ60 | |

| Ukuthepha ububanzi (mm) | I-M3-M30 | |

| Isivinini se-spindle (r/min) | 30 ~ 3000 | |

| Amandla e-Servo spindle motor (kw) | 22*2 | |

| Uhambo lwesokunxele nakwesokudla (mm) | 600 | |

| Ukunemba kokuma kwe-Bidirectional | 300mm*300mm | ±0.025 |

| Ukunemba kokuma kokuphinda kabili kwezinhlangothi ezimbili | 300mm*300mm | ±0.02 |