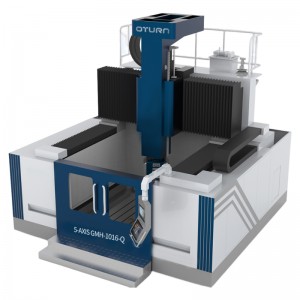

CNC Profile Machining Center

CNC Profile Machining Center

Umshini Wokubhoboza we-CNC

Izici Zomshini

Uchungechunge lwe-Bosm DCImishini yokugaya neyokugaya i-CNCzisetshenziselwa kakhulu ukugaya okusebenzayo kanye nokuthinta izingcezu zokusebenza ezinobubanzi bezinto eziqondile ngaphakathi kwebanga elisebenzayo. Ngokusebenzisa imbobo kanye imbobo eyimpumputhe kungenziwa yabhoboza izingxenye single impahla kanye materials esiyinhlanganisela. Ukucubungula umshini ngesilawuli se-CNC, ukusebenza kulula kakhulu. Ingakwazi ukubona i-automation, ukunemba okuphezulu, izinhlobonhlobo eziningi kanye nokukhiqizwa okukhulu.

Ukuze kuhlangatshezwane nezidingo zokucubungula zabasebenzisi abahlukene, Inkampani yethu ithuthukise imikhiqizo ehlukahlukene eqediwe.Ingase futhi yakhelwe futhi yenziwe ngendlela oyifisayo ngokwezidingo zangempela zabasebenzisi.

Isakhiwo somshini

Izinto ezisetshenziswayo ikakhulukazi zakhiwe itafula lombhede, i-gantry ehambayo, isihlalo sesihlalo esiphathwayo, ukubhola kanye nekhanda lamandla okugaya, idivayisi yokugcoba okuzenzakalelayo kanye nedivayisi yokuvikela, idivayisi yokupholisa ejikelezayo, isistimu yokulawula idijithali, isistimu ye-hydraulic, isistimu kagesi, njll. Ithuluzi lomshini linendawo ephezulu. ukunemba nokunemba kokuma okuphindaphindiwe.

1. Umbhede netafula lokusebenza:

Umbhede womshini uyizingxenye zesakhiwo sensimbi ezishiselwe, futhi ifreyimu eyinhloko icutshungulwa izingxenye zesakhiwo sensimbi. Ngemuva kokuthi ukucindezeleka kwangaphakathi kususwe ukwelashwa kokushisa kokuguga okwenziwayo, kunokuqina okuhle okuguquguqukayo nokumile futhi akukho deformation. Ithebula lokusebenza lenziwe ngensimbi yokuphonsa i-HT250. Ithebula lokusebenza lingasetshenziswai-clamping workpieces. Ingabuye ifakwe i-pneumatic fixture, elula kakhulu futhi eshesha ukuhlanganisa ama-workpieces,. Umthamo omkhulu wokuthwala wethebula lokusebenza yithani elingu-1. Uhlangothi olungaphezulu lwesokunxele lombhede lufakwe mpo lunamapheya alayini anamandla okuthwala aphezulu amabili kanye nerack enembile. I-gantry motor ishayelwa yi-AC servo system kanye ne-rack system in X direction. Ama-bolts alungisekayo asakazwa endaweni engaphansi yombhede, engalungisa kalula izinga letafula lombhede.

2. I-cantilever ehambayo:

I-cantilever gantry ehambayo enesakhiwo se-cast iron icutshungulwa ngemva kokukhipha ukucindezeleka kwangaphakathi ngokwelashwa kokushisa kokuguga okwenziwa, ngokuqina okuhle okuguquguqukayo nokumile futhi akukho deformation. Amapheya amabili ahambayo ahambayo anamandla okuthwala aphezulu afakwa emaceleni angaphambili nangaphezulu e-gantry. Igayidi eginqikayo ewumugqa enomthamo wokuthwala ophakeme kakhulu, isethi yesikulufu esinembayo sebhola kanye ne-servo motor kufakwa phezulu ukuze kwenziwe ipuleti lesilayidi lekhanda lamandla lihambe liye ku-Y-axis. Ikhanda lamandla okubhola lifakwe epuleti lesilayidi lekhanda lamandla. Ukunyakaza kwe-gantry kubonakala ngokuzungezisa isikulufu sebhola esiqhutshwa yi-servo motor ngokusebenzisa ukuhlanganisa.

3. Isihlalo sesihlalo:

Isihlalo esinyakazayo esishelelayo siyilungu lesakhiwo sensimbi. Amapheya amabili ahambayo ahambayo anamandla okuthwala aphakeme kakhulu, isethi yesikulufu esinembayo sebhola kanye ne-servo motor kufakwa esihlalweni esishelelayo ukuze kushayele ikhanda lamandla okubhola ukuze lihambe liye ku-z-eksisi, elikwazi ukubona ukuya phambili ngokushesha, sebenzela phambili, uhlehle ngokushesha futhi umise ikhanda lamandla. Inemisebenzi yokuphulwa kwe-chip okuzenzakalelayo, ukususa ama-chip nokumisa isikhashana.

I-servo spindle motor ekhethekile isetshenziselwa ukumba ikhanda lamandla. I-spindle ekhethekile yokunemba iqhutshwa ibhande le-synchronous elinamazinyo ukuze libone ukuguqulwa kwesivinini esingenasinyathelo esishintshashintshayo. Isiphakeli sishayelwa yi-servo motor kanye nesikulufu sebhola.

I-axis ka-y ingaxhunyaniswa futhi ilawulwe yiluphu evalwe uhhafu, ekwazi ukubona ukuhunyushwa komugqa nokuyisiyingi. Isiphetho se-shaft esiyinhloko i-er taper hole clamping drill noma i-milling cutter, enembayo ephakeme, ukusika isivinini esikhulu, umsebenzi wokushintsha ithuluzi lomoya, ozikhethela umagazini wethuluzi lohlobo lwesigqoko, umthamo wephephabhuku wamathuluzi oyisishiyagalombili, ukuguqulwa kwamathuluzi kulula kakhulu, izinga eliphezulu lokuzishintsha yokucubungula ngesandla.

5. Idivayisi yokuthambisa ezenzakalelayo kanye nedivayisi yokuvikela:

Umshini ufakwe idivayisi yokugcoba ezenzakalelayo, engakwazi ukugcoba ngokuzenzakalelayo amapheya ahambayo njengesitimela esiqondisayo, isikulufu sokuhola kanye nerack. I-x-eksisi kanye ne-Y-eksisi yethuluzi lomshini ifakwe isembozo sokuvikela esivikela uthuli, futhi i-splash baffle engangeni manzi ifakwe eduze kwetafula lokusebenza.

6. Uhlelo Lokulawula lwe-KND:

6.1. Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

6.2. Ngeumsebenzi wokuphakamisa ithuluzi, ubude bokuphakamisa ithuluzi bungasethwa kusixhumi esibonakalayo somshini womuntu. Uma ubhoboza lokhu kuphakama, i-drill bit iphakanyiselwa ngokushesha phezulu kwendawo yokusebenza, bese i-chip iphonswa, bese iya phambili ngokushesha endaweni yokubhoboza bese iguqulwa ngokuzenzakalelayo ibe kusengaphambili komsebenzi.

6.3. Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ephathwa ngesandla ifakwe uhlelo lwe-CNC, isixhumi esibonakalayo se-USB nesikrini se-LCD. Ukuze kube lula ukuhlela, ukugcinwa, ukubonisa nokuxhumana, isixhumi esibonakalayo somsebenzisi sinemisebenzi yengxoxo yomshini womuntu, isinxephezelo samaphutha kanye ne-alamu ezenzakalelayo.

6.4. Imishini inomsebenzi wokubuka kuqala nokubheka kabusha indawo yembobo ngaphambi komshini, ngakho-ke ukusebenza kulula kakhulu.

Ukucaciswa

| Imodeli | I-BOSM-DC60050 | |

| Ubukhulu. usayizi we-workpiece | Ubude × ububanzi (mm) | 2600×500 |

| Ikhanda lamandla lokumba iRam elimile | Ubuningi (ucezu) | 1 |

| Imbobo ye-spindle taper | I-BT40 | |

| Ububanzi bokubhoboza (mm) | Φ2-Φ26 | |

| Isivinini se-spindle (R / min) | 30 ~ 3000 | |

| Amandla e-spindle (kw) | 15 | |

| Ibanga phakathi kwekhala lokuphotha kanye netafula lokusebenza (mm) | 150-650 mm | |

| I-X-axis (i-lateral travel) | I-stroke enkulu (mm) | 500 |

| Isivinini esihambayo se-X-eksisi (M / min) | 0~9 | |

| I-X-axis servo motor power (kw) | 2.4*1 | |

| I-Y-eksisi(ukunyakaza kwekholomu longitudinal) | I-stroke enkulu (mm) | 2600 |

| Isivinini esihambayo se-Y-eksisi (M / min) | 0~9 | |

| Amandla we-y-axis servo motor (kw) | 2.4*1 | |

| I-axis engu-Z(Ukunyakaza kokuphakelayo kwenqama okuqondile) | I-stroke enkulu (mm) | 500 |

| Isivinini esihambayo se-axis engu-Z (M / min) | 0~8 | |

| I-Z-axis servo motor power (kw) | 1×2.4 ngebhuleki | |

| Ubukhulu bomshini | Ubude × ububanzi × ukuphakama (mm) | 5400×2180×2800 |

| Ukumisa ukunemba | X/Y/Z | ±0.05/300mm |

| Ukuma kokunemba okuphindaphindiwe | X/Y/Z | ±0.025/300mm |

| Isisindo esiphelele (t) | 4.5 | |

Ukuhlolwa Kwekhwalithi

Umshini ngamunye ulinganiswa nge-laser interferometer evela enkampanini yase-United Kingdom RENISHAW, ehlola ngokunembile futhi inxephezele amaphutha e-pitch, ukuhlehla, ukunemba kokuma, nokunemba kokuma okuphindaphindiwe ukuze kuqinisekiswe ukuguquguquka, ukuzinza komshini, nokunemba kokucubungula. . Ukuhlolwa kwebha yebhola Umshini ngamunye usebenzisa isihloli sebha yebhola esivela enkampanini yaseBrithani i-RENISHAW ukuze ulungise ukunemba kwendingilizi yeqiniso kanye nokunemba komshini wejometri, futhi wenze izivivinyo zokusika eziyindilinga ngesikhathi esifanayo ukuze kuqinisekiswe ukunemba komshini we-3D womshini kanye nokunemba kwendingilizi.

Indawo yokusebenzisa ithuluzi lomshini

1.1 Izidingo zemvelo yezinto zokusebenza

Ukugcina izinga elingaguquki lezinga lokushisa le-ambient kuyisici esibalulekile sokwenza imishini enembile.

(1) Izinga lokushisa le-ambient elitholakalayo ngu- -10 ℃ ~ 35 ℃. Lapho izinga lokushisa le-ambient lingama-20 ℃, umswakama kufanele ube ngu-40 ~ 75%.

(2) Ukuze kugcinwe ukunemba okumile kwethuluzi lomshini ngaphakathi kwebanga elishiwo, izinga lokushisa elifanele le-ambient liyadingeka ukuthi libe ngu-15 ° C kuya ku-25 ° C nomahluko wokushisa.

Akufanele idlule ± 2 ℃ / 24h.

1.2 I-voltage yokuphakelwa kwamandla: 3-isigaba, 380V, ukushintshashintsha kwamandla kagesi ngaphakathi ± 10%, imvamisa yokuphakelwa kwamandla: 50HZ.

1.3 Uma i-voltage endaweni esetshenziswayo ingazinzile, ithuluzi lomshini kufanele lifakwe ugesi olawulwayo ukuze kuqinisekiswe ukusebenza okuvamile kwethuluzi lomshini.

1.4. Ithuluzi lomshini kufanele libe nomhlabathi othembekile: intambo yaphansi iyintambo yethusi, ububanzi bocingo akufanele lube ngaphansi kuka-10mm², futhi ukumelana nomhlabathi kungaphansi kuka-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuvamile kwemishini, uma umoya ocindezelwe womthombo womoya wehluleka ukuhlangabezana nezidingo zomthombo womoya, isethi yamadivayisi okuhlanza umthombo womoya (ukukhipha umswakama, ukwehlisa, ukuhlunga) kufanele kwengezwe ngaphambi kokukhishwa kwemishini. ukungena komoya womshini.

1.6. Izinto ezisetshenziswayo kufanele zigcinwe kude nelanga eliqondile, ukudlidliza nemithombo yokushisa, futhi kude namajeneretha anemvamisa ephezulu, imishini yokushisela kagesi, njll., ukuze kugwenywe ukwehluleka kokukhiqiza umshini noma ukulahlekelwa ukunemba komshini.

Ngaphambi Nangemuva Kwesevisi

1) Ngaphambi Kwesevisi

Ngokutadisha isicelo nolwazi oludingekayo oluvela kumakhasimende bese impendulo konjiniyela bethu, ithimba le-Bossman Technical linesibopho sokuxhumana nobuchwepheshe namakhasimende kanye nokwakhiwa kwezixazululo, ukusiza ikhasimende ekukhetheni isixazululo esifanele somshini kanye nemishini efanelekile.

2) Ngemva Kwesevisi

A.Umshini onewaranti yonyaka owodwa futhi okhokhelwe ukunakekela impilo yonke.

B. Phakathi nenkathi yewaranti yonyaka owodwa ngemva kokuba umshini ufikile echwebeni lapho uya khona, i-BOSSMAN izohlinzeka ngezinsizakalo zokunakekela zamahhala nezifika ngesikhathi zamaphutha ahlukahlukene angenziwanga umuntu emshinini, futhi ibuyisele ngesikhathi zonke izinhlobo zezingxenye zomonakalo ongenziwanga ngumuntu mahhala. yenkokhiso . Ukwehluleka okwenzeka ngesikhathi sewaranti kuzolungiswa ngezindleko ezifanele.

Ukusekelwa kwe-C.Technical emahoreni angama-24 ku-inthanethi, i-TM, i-Skype, i-E-mail, ukuxazulula imibuzo ehlobene ngesikhathi. uma ingeke ixazululwe, i-BOSSMAN izohlela ngokushesha ukuthi unjiniyela wangemuva kokuthengisa afike esizeni ukuze alungiswe, umthengi udinga ukukhokhela i-VISA, amathikithi ezindiza kanye nendawo yokuhlala.

Isizinda Sekhasimende