CNC Horizontal Machining Center

Evundlile Machining Center

I-lathe evundlile

Izici Zomshini

Isikhungo semishini esivundlile esiwuchungechunge H samukela isakhiwo sombhede jikelele esimise okwe-T esithuthuke emhlabeni wonke, ikholomu ye-gantry, isakhiwo sebhokisi elilengayo, ukuqina okuqinile, ukugcinwa kokunemba okuhle, afanele amakhabethe anembayo.

Ukuze kucutshungulwe izingxenye, ukugaya okunobuso obuningi, ukubhola, ukuphinda kufakwe kabusha, kuyisicefe, ukucofa, njll. kungenziwa ekubambeni okukodwa ngasikhathi sinye, umshini usetshenziswa kabanzi ezimotweni, ezokuthutha ngojantshi, indiza, amavalvu, imishini yezimayini, imishini yendwangu. , imishini yepulasitiki, imikhumbi, amandla kagesi neminye imikhakha..

Ukucaciswa

| Into | Iyunithi | H63 | H80 | ||

| Ithebula lokusebenza | Usayizi webhentshi (ubude× ububanzi) | mm | 630×700 | 800×800 | |

| Inkomba yebhentshi lokusebenzela | ° | 1°×360 | |||

| Ifomu le-countertop | 24×M16 Imbobo enezintambo | ||||

| Umthamo omkhulu wethebula lokusebenza | kg | 950 | 1500 | ||

| Ubukhulu bokujika ububanzi betafula lokusebenza | mm | Φ1100 | Φ1600 | ||

| Ukuhamba | Hambisa itafula kwesokunxele nakwesokudla (i-X eksisi) | mm | 1050 | 1300 | |

| I-Headstock ihamba phezulu naphansi (I-eksisi ka-Y) | mm | 750 | 1000 | ||

| Ikholomu iya phambili nangemuva (I-axis Z) | mm | 900 | 1000 | ||

| Ibanga ukusuka kumugqa ophakathi nendawo ukuya endaweni yetafula | mm | 120-870 | 120-1120 | ||

| Ibanga ukusuka ekugcineni kokuphotha kuya enkabeni yetafula lokusebenza | mm | 130-1030 | 200-1200 | ||

| I-spindle | Inombolo ye-spindle taper hole | IS050 7:24 | |||

| Isivinini se-spindle | rpm | 6000 | |||

| Amandla e-spindle motor | Kw | 15/18.5 | |||

| I-torque ephumayo ye-spindle | Nm | 144/236 | |||

|

| Izinga kanye nemodeli yesibambi samathuluzi | I-MAS403/BT50 | |||

| Ukondla | Isivinini esisheshayo (X, Y, Z) | m/min | 24 | ||

| Ukusika isilinganiso sokuphakela (X, Y, Z) | mm/min | 1-20000 | 1-10000 | ||

| Amandla enjini yokuphakelayo (X, Y, Z, B) | kW | 4.0/7.0/7.0/1.6 | 7.0/7.0/7.0 | ||

| Okuphakelayo kwe-torque ye-motor | Nm | X, Z:22;Y:30;B8 | 30 | ||

| I-ATC | Amandla omagazini wethuluzi | PCS | 24 | 24 | |

| Indlela yokushintsha ithuluzi | Uhlobo lwengalo | ||||

| Ubukhulu.Usayizi wethuluzi | Ithuluzi eligcwele | mm | F110×300 | ||

| Eduze ngaphandle kwethuluzi | F200×300 | ||||

| Isisindo sethuluzi | kg | 18 | |||

| Isikhathi sokushintsha ithuluzi | S | 4.75 | |||

|

Abanye | Umfutho womoya | kgf/cm2 | 4; 6 | ||

| Ukucindezela kwesistimu ye-Hydraulic | kgf/cm2 | 65 | |||

| Umthamo wethangi lokuthambisa | L | 1.8 | |||

| Umthamo wethangi likawoyela weHydraulic | L | 60 | |||

| Umthamo webhokisi lokupholisa | L | Izinga:160 | |||

| Ukugeleza kwephampu yokupholisa/ikhanda | l/min,m | Okujwayelekile: 20L/min,13m | |||

| Isamba somthamo kagesi | kVA | 40 | 65 | ||

| Isisindo somshini | kg | 12000 | 14000 | ||

|

| Uhlelo lwe-CNC | I-Mistubishi M80B | |||

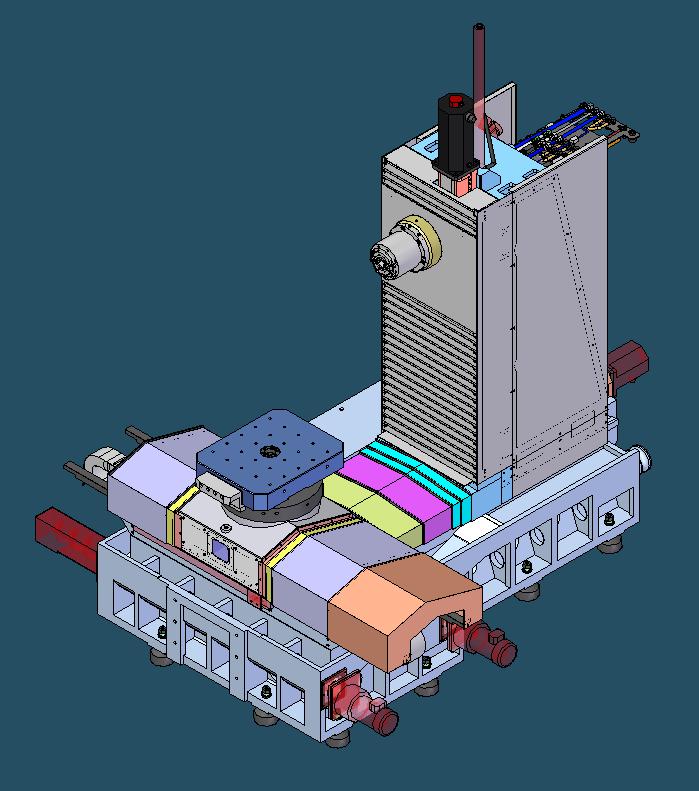

Ukucushwa Okuyinhloko

Umshini ngokuyinhloko wakhiwe isisekelo, ikholomu, isihlalo sehhashi, ithebula lenkomba, ithebula lokushintshanisa, i-headstock, ukupholisa, ukugcoba, isistimu ye-hydraulic, ikhava yokuvikela evalwe ngokugcwele kanye nesistimu yokulawula izinombolo.Umagazini wamathuluzi ungafakwa nge-disc noma uhlobo lweketango.

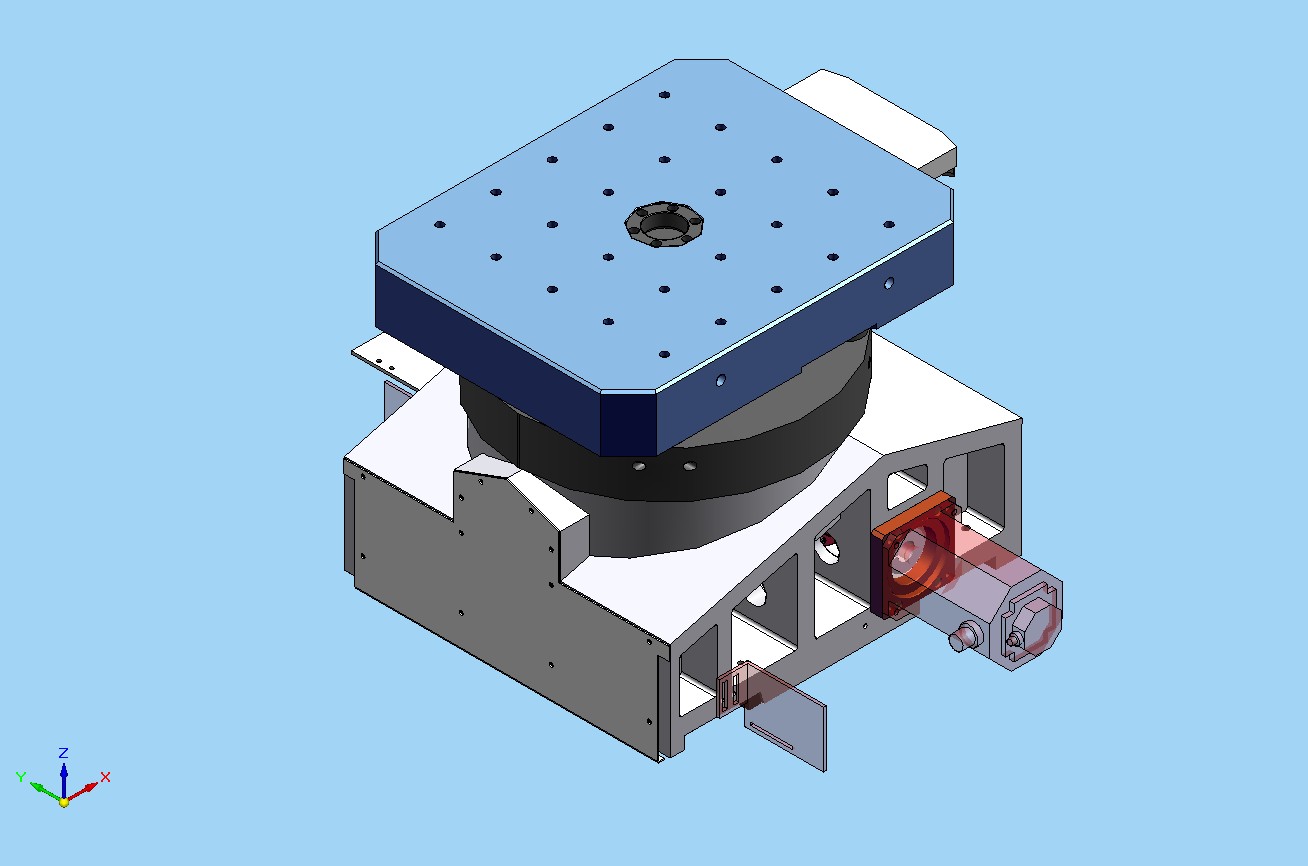

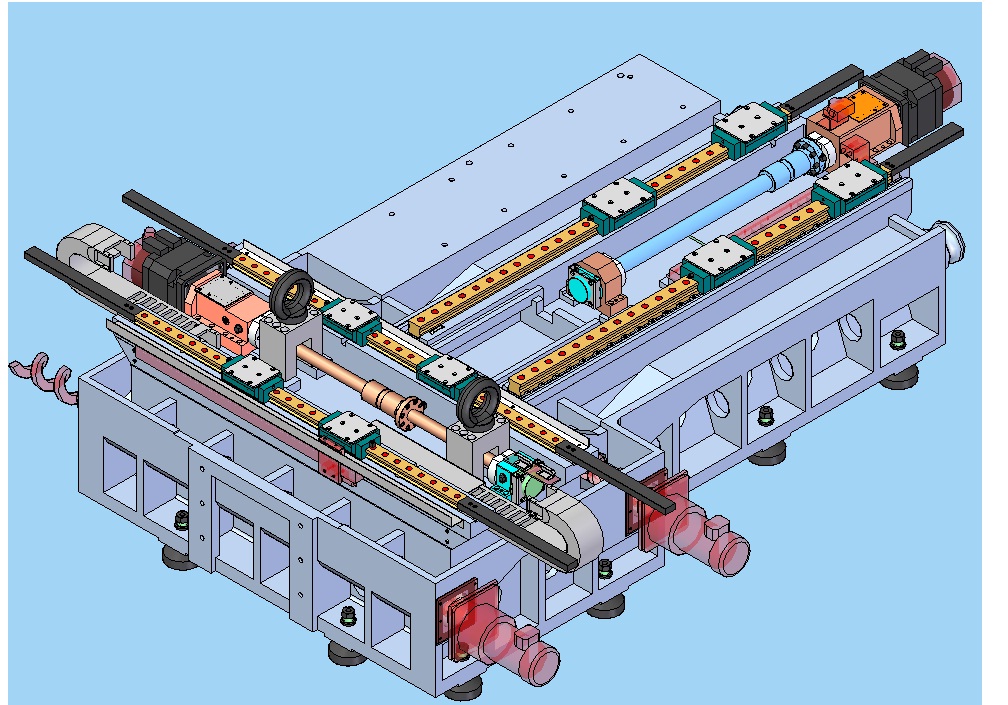

Isisekelo

Ukuze kuthuthukiswe ukusebenza kwe-anti-vibration, umbhede womshini ovundlile uhlongozwa ukuthi wamukele isakhiwo esimise okwe-T esihlanekezelwe esinokumelana nokudlidliza okungcono kakhulu emhlabeni, ngesakhiwo esivaliwe esimise okwebhokisi, kanye nemibhede yangaphambili nangemuva kuhlanganisiwe.Umbhede ufakwe izindiza ezimbili eziyisethenjwa zokufakwa komhlahlandlela ohambayo wokunyakaza kwetafula lokusebenza kanye nekholomu.Uma kucatshangelwa ukusebenziseka kalula kokukhishwa kwe-chip kanye nokuqoqwa kwezinto ezipholile, kuhlelwe ukusetha imitshingo ye-chip ezinhlangothini zombili zombhede.

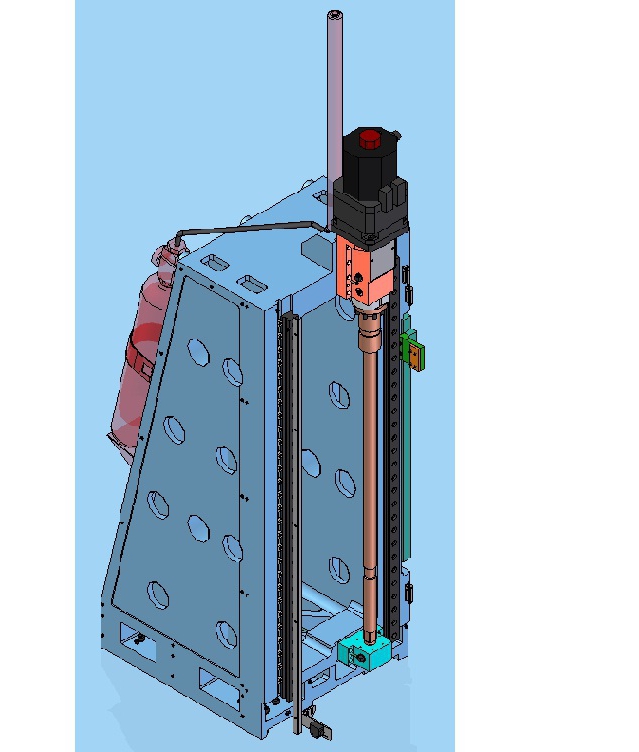

Ikholomu

Ikholomu eqondile yomshini ovundlile ihlelelwe ukuthi yamukele uhlaka oluyikholomu ephindwe kabili evaliwe yohlaka olulinganayo, olunezimbambo ze-annular ezinde neziphambanayo ezihlelwe emgodini.Kuzo zombili izinhlangothi zekholomu, kunezindawo ezihlangene zokufakwa komhlahlandlela wokugoqa womugqa wokuhamba kwe-headstock (indawo yereferensi yokufaka yomhlahlandlela womugqa).Ekuqondeni mpo (i-Y-direction) yekholomu, ngaphezu kwama-rails angumhlahlandlela wokunyakaza kwe-headstock, kukhona futhi isikulufu sebhola kanye nesihlalo sokuhlanganisa i-motor phakathi kwama-rails amabili aqondisayo ashayela i-headstock ukuya phezulu naphansi.Izihlangu zensimbi ezingenasici ezihamba ngesivinini esiphezulu zibhekwa ezinhlangothini zombili zekholomu.Izinsimbi zomhlahlandlela nezikulufu zokuhola zivikelekile futhi zivikelekile.

Itafula elijikelezayo

Ithebula lokusebenza libekwe kahle futhi likhiywe i-servo, kanti iyunithi yenkomba encane ingu-0.001°