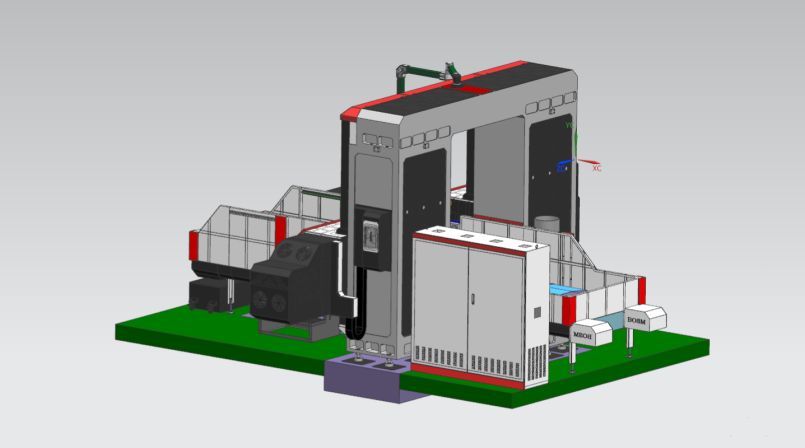

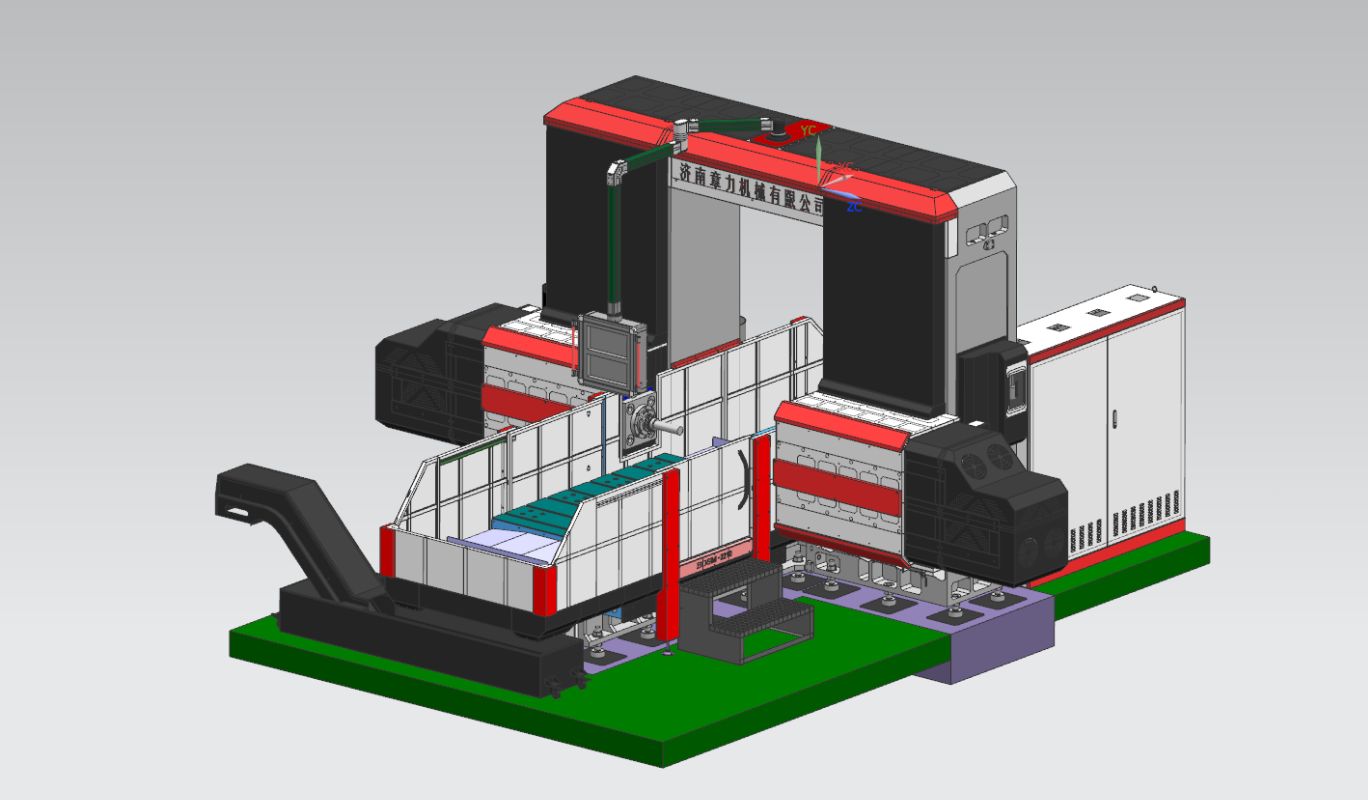

I-BOSM -5020-5Z I-Opposed-Head Boring Machineing Machine

1. Ukusetshenziswa kwezisetshenziswa:

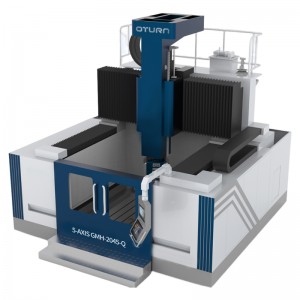

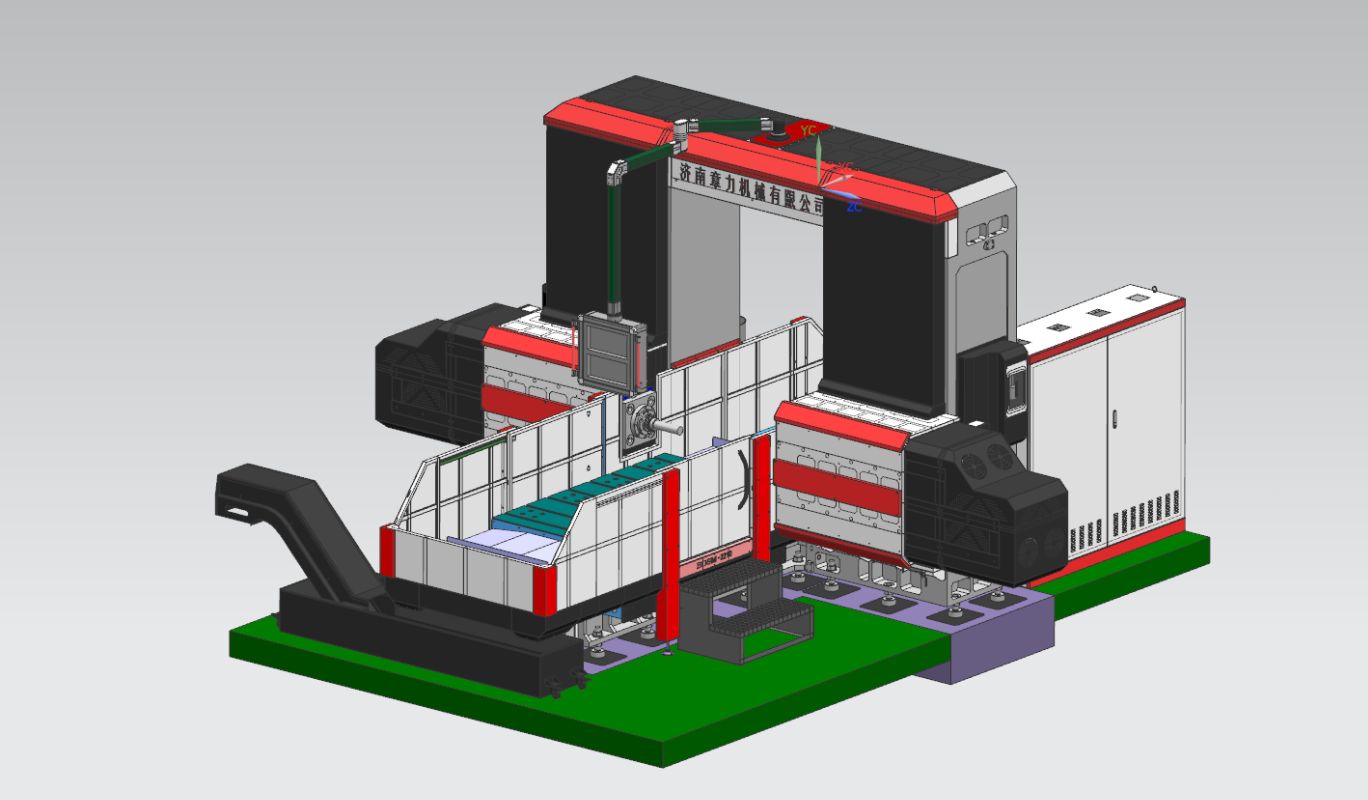

I-BOSM-5020-5Z CNC workbench mobile-double-column head-to-head boring kanye nomshini wokugaya unguMshini okhethekile wemishini yobunjiniyela yemishini yokusebenza elinganayo. Umshini ufakwe ibhentshi elikhethekile eligudlukayo kanye namasethi amabili ezinqama ezivundlile, ezingakwazi ukubona Ukubhoboza, ukugaya, ukubhoreka nokunye ukucutshungulwa kwe-workpiece ngaphakathi kwebanga elisebenzayo le-stroke, i-workpiece ingacutshungulwa endaweni ngesikhathi esisodwa (asikho isidingo i-clamping yesibili), ukulayisha okusheshayo kanye nesivinini sokuthulula, isivinini sokumisa ngokushesha, ukunemba okuphezulu kokucubungula nokusebenza kahle kokucubungula okuphezulu.

2. Isakhiwo sezisetshenziswa:

2.1. Izingxenye eziyinhloko zoMshini

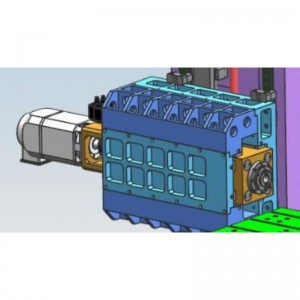

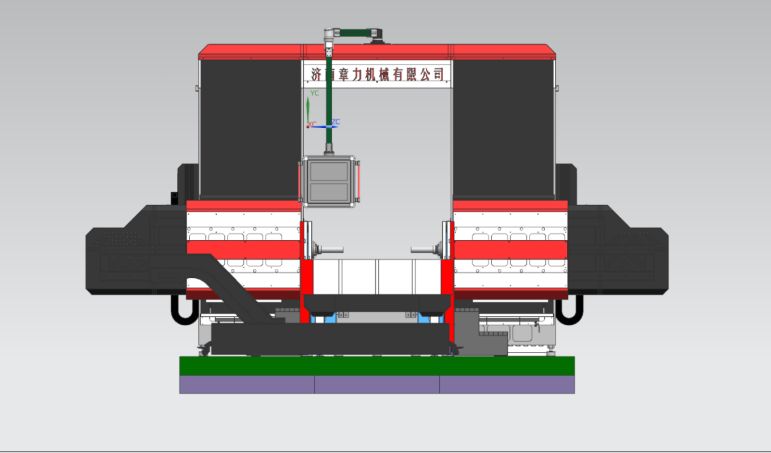

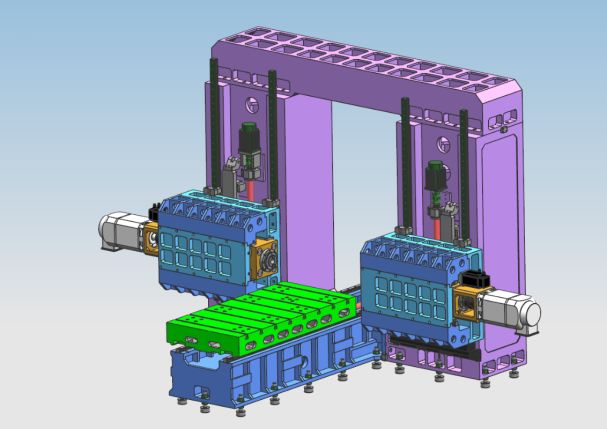

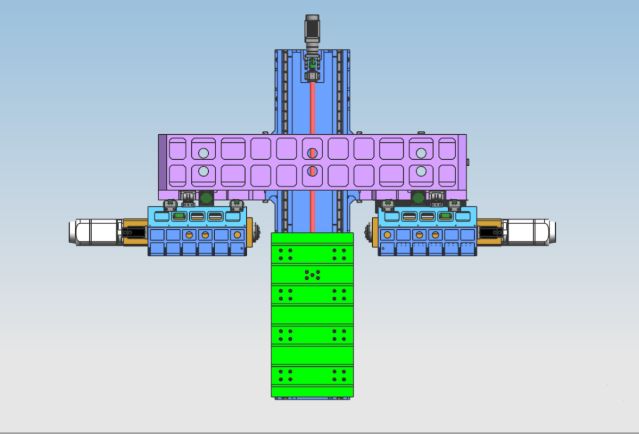

Umbhede, ibhentshi lokusebenzela, amakholomu angakwesobunxele nakwesokudla, imishayo, imishayo ehlanganisa i-gantry, izihlalo, izinqama, njll., zonke zenziwe ngokubunjwa kwesihlabathi se-resin, insimbi empunga yekhwalithi ephezulu engu-250, ifakwe emgodini wesihlabathi esishisayo → ukuguga kokudlidliza → ukufakwa kwesithando somlilo → ukudlidliza Ukuguga→ukusebenza kanzima→ukuguga kokudlidliza→ukufakwa kwesithando somlilo→ukuguga kokudlidliza→ukuqeda, qeda ngokuphelele ukucindezeleka okungekuhle kwezingxenye, futhi ugcine ukusebenza kwezingxenye kuzinzile. Umbhede ongashintshi, amakholomu angakwesokunxele nangakwesokudla, i-gantry, kanye nokunyakaza kwebhentshi lokusebenza; Umshini unokugaya, ukusika okuyisicefe, ukubhola, ukucwila, ukucofa kanye neminye imisebenzi, indlela yokupholisa ithuluzi ukupholisa kwangaphandle, umshini uqukethe izimbazo ezi-5 eziphakelayo, ezikwazi ukubona ukuxhumana kwe-4-eksisi, 5-axis single-action, amakhanda amandla ama-2 , i-axial yoMshini kanye nekhanda lamandla liboniswa esithombeni esingezansi.

2.2. Isakhiwo esiyinhloko sengxenye ye-axial transmission feed

2.2.1. I-X-axis: Ithebula lokusebenza libuyela eceleni eceleni komzila wesitimela wombhede ongashintshi.

Ukudluliswa kwe-X-axis: I-AC servo motor kanye nesinciphisi seplanethi esinembe kakhulu sisetshenziselwa ukushayela ithebula lokusebenza ngokudluliswa kwesikulufu sebhola ukuze kubonakale ukunyakaza komugqa we-X.

Ifomu lesitimela esiqondisayo: beka izinsimbi ezimbili zomugqa ezinembayo ezinembayo

2.2.2.Y1 i-eksisi: Ikhanda lamandla nenqama kufakwe ngokuqondile ohlangothini olungaphambili lwekholomu, futhi zibuyisela kwesokunxele nakwesokudla eduze kwesitimela somhlahlandlela wekholomu.

I-Y1-axis transmission: I-AC servo motor isetshenziselwa ukushayela isikulufu sebhola ukushayela isihlalo sehhashi ukuze sinyakaze, futhi uqaphele ukunyakaza komugqa we-Y1-axis.

Ifomu lesitimela esiqondisayo: izingcezu ezi-4 zohlobo lwama-45 amalayini omugqa womugqa.

2.2.3.Y2 i-eksisi: Inqama yesibili yekhanda lamandla ifakwe ngokuqondile ohlangothini olungaphambili lwekholomu, futhi ibuyisela kwesokunxele nakwesokudla eduze nomzila we-guide wekholomu.

I-Y2-axis transmission: I-AC servo motor isetshenziselwa ukushayela isikulufu sebhola ukushayela ukunyakaza kwesihlalo sehhashi ukuze kubonakale ukunyakaza komugqa kwe-Y1-eksisi.

Ifomu lesitimela esiqondisayo: izingcezu ezi-4 zohlobo lwama-45 amalayini omugqa womugqa

2.2.4. I-axis ye-Z1: Isihlalo samandla esishelelayo sekhanda lamandla sifakwe sime mpo ohlangothini olungaphambili lwekholomu yesokudla, futhi ibuyisela phezulu naphansi ngakumzila wesitimela wekholomu.

Ukudluliselwa kwe-Z1-axis: I-AC servo motor kanye nesinciphisi seplanethi esinembe kakhulu kusetshenziswa ukushayela inqama ukuze ihambe ngesikulufu sebhola ukuze ibone ukunyakaza komugqa we-Z1-eksisi.

Ifomu lesitimela esiqondisayo: 2 65 uhlobo lwama-linear guide rails

2.2.5.Z2 i-eksisi: Isihlalo sesihlalo seslayidi sekhanda lamandla sifakwe sime sibheke ngaphambili kwekholomu yesokudla, futhi sibuyisela phezulu naphansi ngakumzila wesitimela wekholomu.

Ukudluliselwa kwe-Z1-axis: I-AC servo motor kanye nesinciphisi seplanethi esinembe kakhulu sisetshenziswa ukushayela inqama ukuze ihambe ngesikulufu sebhola ukuze ibone ukunyakaza komugqa we-Z2-eksisi.

Ifomu lesitimela esiqondisayo: 2 65 uhlobo lwama-linear guide rails

Ikholomu yokusakaza yekhwalithi ephezulu ye-HT250 izingcezu ezingu-2 zohlobo lwama-65 omzila osindayo womugqa womugqa

Inhloko yamandla eyisicefe neyokugaya (okuhlanganisa nekhanda lamandla 1 no-2) iyinqama yesikwele esiyinhlanganisela, futhi isiqondiso esinyakazayo siqondiswa ama-rails angu-4 we-linear roller guide. Idrayivu isebenzisa i-AC servo motor ukushayela ukunemba kwesikulufa sebhola. Umshini ufakwe ibha yebhalansi ye-nitrogen. , Yehlisa umthamo wokuthwala wekhanda lomshini kusikulufa kanye ne-servo motor. I-Z-axis motor ine-automatic brake function. Uma kwenzeka ukuphelelwa amandla, ibhuleki elizenzakalelayo lizobamba i-motor shaft ngokuqinile ukuze lingakwazi ukujikeleza. Lapho usebenza, lapho i-drill bit ingathinti i-workpiece, izodla ngokushesha; lapho i-drill bit ithinta i-workpiece, izoshintshela ngokuzenzakalelayo kokuphakelayo okusebenzayo. Lapho i-drill bit ingena ku-workpiece, izoshintsha ngokuzenzakalelayo ekubuyiseleni emuva ngokushesha; lapho ukuphela kwe-drill bit kushiya ucezu lokusebenza futhi ifinyelela indawo emisiwe, izothuthela endaweni elandelayo yembobo ukuze ibone ukujikeleza okuzenzakalelayo. Futhi ingabona imisebenzi yokubhoboza imbobo eyimpumputhe, ukugaya, ukukhwabanisa, ukuphulwa kwe-chip, ukususwa kwe-chip okuzenzakalelayo, njll., okuthuthukisa ukukhiqizwa kwabasebenzi.

Ikhanda lamandla enqama yesikwele elingu-500mm lisebenzisa iziqondiso ezilandelanayo esikhundleni sokufaka okuvamile ukuze kuthuthukiswe kakhulu ukunemba komhlahlandlela kuyilapho igcina ukuqina kwenqama eyisikwele.

2.3. Ukususwa kwe-chip nokupholisa

Kukhona ama-spiral chain chain chip conveyor afakwe nhlangothi zombili ngaphansi kwebhentshi lokusebenza, futhi ama-chips angadluliselwa ngokuzenzakalela kusidlulisi se-chip ekugcineni ngezigaba ezimbili zamapuleti a-spiral kanye namaketango ukuze kutholakale ukukhiqizwa okuphucuzekile. Kunepompo yokupholisa ethangini lokupholisa le-chip conveyor, engasetshenziselwa ukupholisa kwangaphandle kwethuluzi ukuze kuqinisekiswe ukusebenza nempilo yesevisi yethuluzi, futhi okokupholisa kungagaywa kabusha.

3. Uhlelo olugcwele lokulawula izinombolo zedijithali:

3.1. Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

3.2. Ifakwe umsebenzi wokuphakamisa ithuluzi, ibanga lokuphakamisa ithuluzi lingasethwa kusixhumi esibonakalayo somshini womuntu. Uma ibanga selifinyelelwe, ithuluzi liphakanyiswa ngokushesha, bese ama-chips elahlwa kude, bese lidluliselwa ngokushesha endaweni yokubhoboza bese liguqulwa ngokuzenzakalelayo lisebenze.

3.3. Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ebanjwa ngesandla yamukela isistimu yokulawula izinombolo futhi ifakwe isixhumi esibonakalayo se-USB nesibonisi sekristalu esiwuketshezi se-LCD. Ukuze kube lula ukuhlela, ukugcinwa, ukuboniswa nokuxhumana, okusetshenziswa kubonwa kunemisebenzi efana nengxoxo yomshini womuntu, isinxephezelo samaphutha, ne-alamu ezenzakalelayo.

3.4. Imishini inomsebenzi wokuhlola kuqala nokuhlola kabusha indawo yembobo ngaphambi kokucubungula, futhi ukusebenza kulula kakhulu.

4. Ukugcoba okuzenzakalelayo

Ukunemba komshini amapheya kaloliwe womugqa, amapheya wesikulufu sebhola anemba kanye namanye amapheya anyakazayo anembe kakhulu afakwe amasistimu okugcoba azenzakalelayo. Ipompo yokugcoba ezenzakalelayo ikhipha uwoyela ocindezelayo, futhi igumbi likawoyela we-lubricator lobuningi lingena emafutheni. Ngemuva kokuthi igumbi likawoyela ligcwaliswe ngamafutha, lapho ingcindezi yesistimu ikhuphukela ku-1.4-1.75Mpa, inkinobho yokucindezela ohlelweni ivaliwe, ipompo iyama, futhi i-valve yokukhipha imithwalo ngesikhathi esifanayo. Lapho umfutho kawoyela emgwaqeni wehla ngaphansi kuka-0.2Mpa, isigcobo somthamo siqala ukugcwalisa indawo yokugcoba bese siqedela ukugcwaliswa kwamafutha okukodwa. Ngenxa yokuhlinzekwa okunembile kwamafutha omjovo kawoyela omningi kanye nokutholwa kwengcindezi yesistimu, ukunikezwa kukawoyela kunokwethenjelwa, kuqinisekisa ukuthi kukhona ifilimu kawoyela ebusweni bepheya ngayinye ye-kinematic, ukunciphisa ukungqubuzana nokuguga, nokuvimbela umonakalo isakhiwo sangaphakathi esibangelwa ukushisa ngokweqile. , ukuqinisekisa ukunemba nokuphila koMshini. Uma kuqhathaniswa nepheya yesitimela sikamhlahlandlela oslayidayo, ipheya yesitimela esigingqikayo esetshenziswa kulo Mshini inochungechunge lwezinzuzo:

①Ukuzwela kokunyakaza kuphezulu, i-coefficient yokungqubuzana yesitimela esigingqikayo incane, kuphela 0.0025~0.01, futhi amandla okushayela ehle kakhulu, okulingana kuphela no-1/10 wemishini evamile.

② Umehluko phakathi kokungqubuzana okuguquguqukayo nokumile mncane kakhulu, futhi ukusebenza kokulandelela kuhle kakhulu, okungukuthi, isikhawu sesikhathi phakathi kwesiginali yokushayela kanye nesenzo somshini sifushane kakhulu, esiza ekuthuthukiseni isivinini sokuphendula nokuzwela uhlelo lokulawula izinombolo.

③Ilungele ukunyakaza komugqa onesivinini esikhulu, futhi isivinini sayo esisheshayo cishe siphakeme ngokuphindwe ka-10 kunaleso samareyili omhlahlandlela.

④ Ingakwazi ukubona ukunyakaza okungenazikhala futhi ithuthukise ukuqina kokunyakaza kwesistimu yemishini.

⑤Ikhiqizwe abakhiqizi abangochwepheshe, inokunemba okuphezulu, ukuguquguquka okuhle nokulungisa kalula.

5.Ukuhlolwa kwe-laser yama-axis amathathu:

Umshini ngamunye we-Bosman ulinganiswa yi-laser interferometer yenkampani ye-RENISHAW e-United Kingdom ukuze ihlole ngokunembile futhi inxephezele iphutha le-pitch, ukuhlehla, ukunemba kokuma, ukuphinda ukunemba kokuma, njll., ukuze kuqinisekiswe ukuguquguquka, ukuzinza nokucubungula ukunemba kwe umshini . Ukuhlolwa kwe-Ballbar Umshini ngamunye usebenzisa ibha yebhola evela enkampanini yaseBrithani i-RENISHAW ukuze ulinganise ukunemba kwendingilizi yeqiniso kanye nokunemba komshini wejometri, futhi wenze ukuhlolwa kokusika okuyisiyingi ngesikhathi esifanayo ukuze kuqinisekiswe ukunemba komshini we-3D nokunemba okuyindilinga komshini.

6. Indawo yokusetshenziswa komshini:

6.1. Izidingo zendawo yokusetshenziswa kwezisetshenziswa

Ukugcina izinga elingaguquki lezinga lokushisa le-ambient kuyisici esibalulekile sokwenza imishini enembile.

(1) Izidingo ezitholakalayo zokushisa kwe-ambient zingu-10°C kuya ku-35°C, lapho izinga lokushisa lendawo liku-20°C, umswakama kufanele ube ngu-40% kuya ku-75%.

(2) Ukuze kugcinwe ukunemba okumile koMshini phakathi kwebanga elishiwo, izinga lokushisa elifanele le-ambient liyadingeka ukuthi libe ngu-15°C kuya ku-25°C, futhi umehluko wezinga lokushisa akufanele weqe ±2°C/24h.

6.2. I-voltage yokuphakelwa kwamandla: izigaba ezi-3, 380V, phakathi kwebanga lokuguquguquka kwe-voltage ± 10%, imvamisa yokuphakelwa kwamandla: 50HZ.

6.3. Uma i-voltage endaweni osetshenziswayo ingazinzile, Umshini kufanele ufakwe ugesi ozinzile ukuze kuqinisekiswe ukusebenza okuvamile koMshini.

6.4. Umshini kufanele ube nendawo ephansi enokwethenjelwa: intambo yaphansi iyintambo yethusi, ububanzi bocingo akufanele bube ngaphansi kuka-10mm², futhi ukumelana nomhlaba kufanele kube ngaphansi kuka-4 ohms.

6.5. Ukuze kuqinisekiswe ukusebenza okuvamile kwemishini, uma umoya ocindezelwe womthombo womoya awukwazi ukuhlangabezana nezidingo zomthombo womoya, isethi yedivayisi yokuhlanza umthombo womoya (ukukhipha umswakama, ukwehlisa, ukuhlunga) kufanele yengezwe ngaphambi kokungena komoya. yoMshini.

6.6. Gcina okokusebenza kude nelanga eliqondile, ukudlidliza nemithombo yokushisa, amajeneretha anemvamisa ephezulu, imishini yokushisela kagesi, njll., ukuze ugweme ukwehluleka kokukhiqizwa komshini noma ukulahlekelwa ukunemba koMshini.

7.Amapharamitha wobuchwepheshe:

| Imodeli | 5020-5Z | |

| Ubukhulu bosayizi womsebenzi wokucubungula | Ubude × ububanzi × ubude (mm) | 5000×2000×2500 |

| Okuphakelayo okuphezulu kwe-Gantry | Ububanzi (mm) | 2300 |

| usayizi wedeski elisebenzayo | Ubude X Ububanzi (mm) | 5000*2000 |

| Ukuhamba kwetafula | Ibhentshi lokusebenza liya emuva naphambili (mm) | 5000 |

| Izinqama ezimbili phakamisa phezulu naphansi | Ukushaywa kwenqama phezulu naphansi (mm) | 2500 |

| Inqama evundlile yohlobo lwamandla ekhanda ikhanda elilodwa elilodwa | Ubuningi (2) | 2 |

| Inqama evundlile yohlobo lwamandla ekhanda ikhanda elilodwa elilodwa | I-spindle taper | I-BT50 |

| Isivinini se-spindle (r/min) | 30 ~ 5000 | |

| Amandla e-Servo spindle motor (kw) | 37*2 | |

| Ibanga eliphakathi kwezikhungo zeziphetho zekhala lezinsimbi ezimbili zokuphotha (mm) | 1500-2500mm | |

| Ukushaya kwesobunxele nesokudla kwenqama eyodwa (mm) | 500 | |

| Ukushaywa kwesobunxele nesokudla kwenqama ephindwe kabili (mm) | 1000 | |

| Ukunemba kokuma kwe-Bidirectional | 300mm*300mm | ±0.025 |

| Ukunemba kokuma kokuphinda kabili kwezinhlangothi ezimbili | 300mm*300mm | ±0.02 |

| Isisindo esiphelele (t) | (cishe) 55 | Isisindo esiphelele (t) |