I-BOSM-1601 Ephikisayo-Ikhanda Lokugaya Umshini Wokugaya

1. Ukusetshenziswa kwemishini

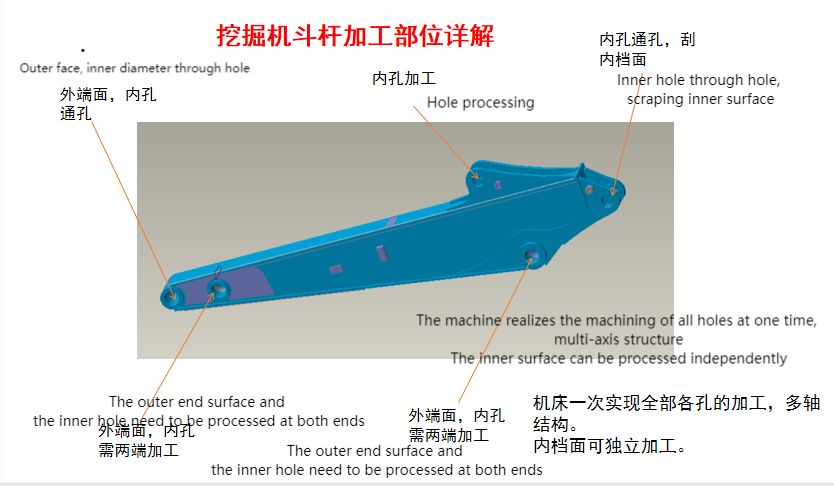

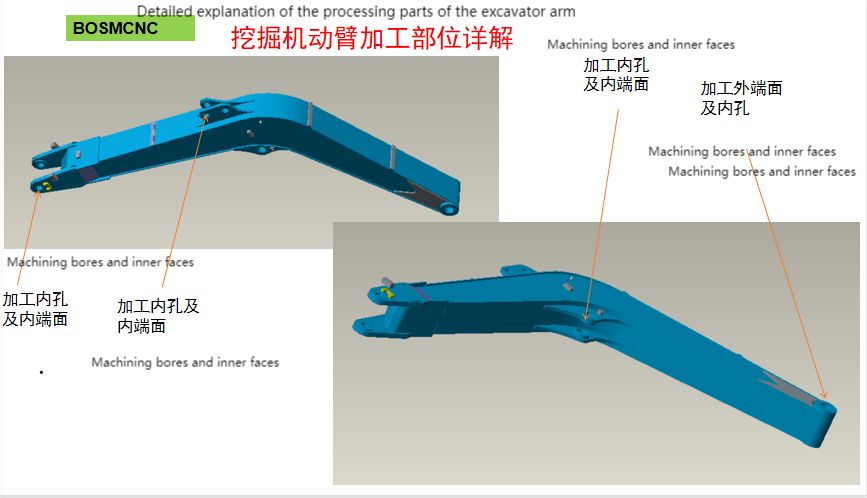

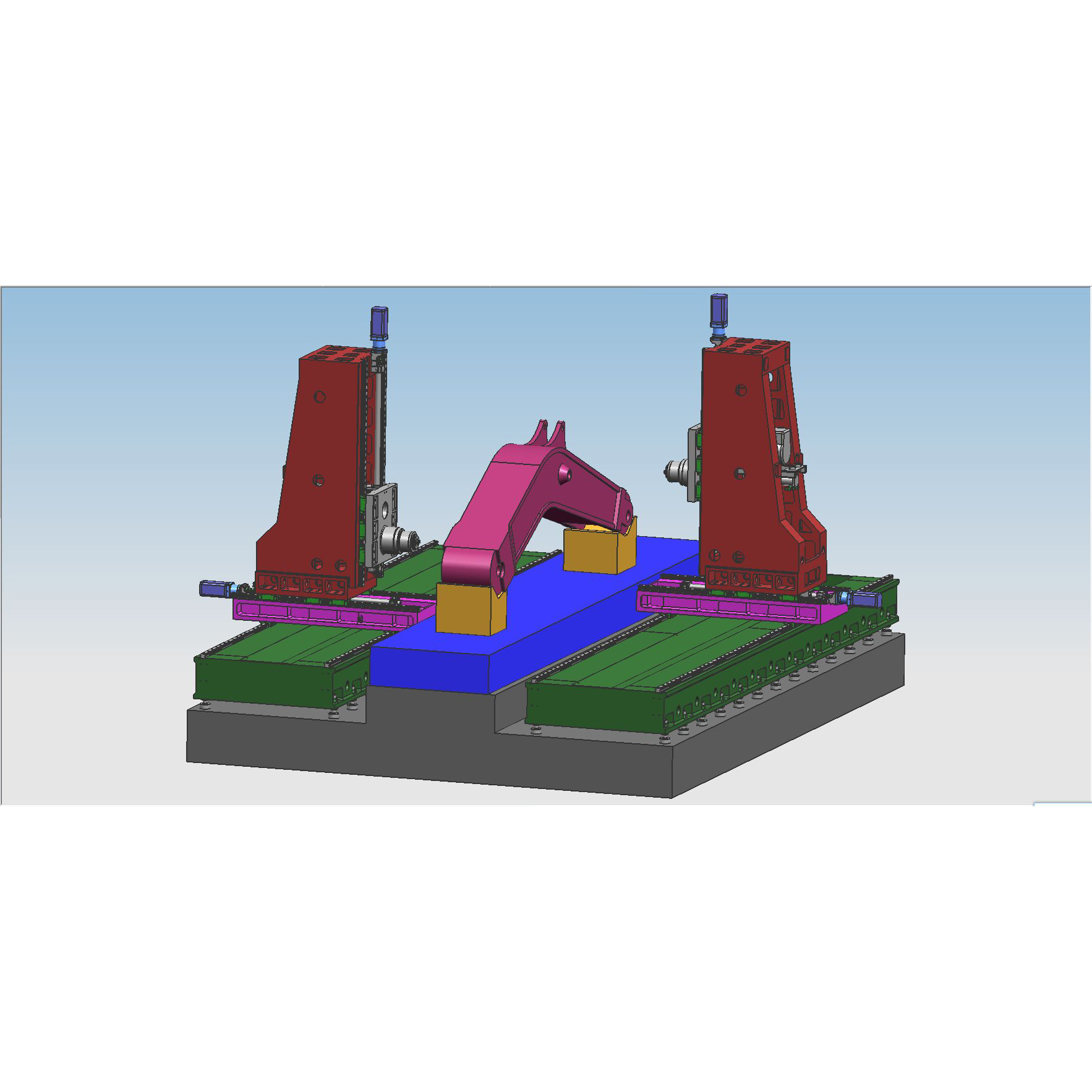

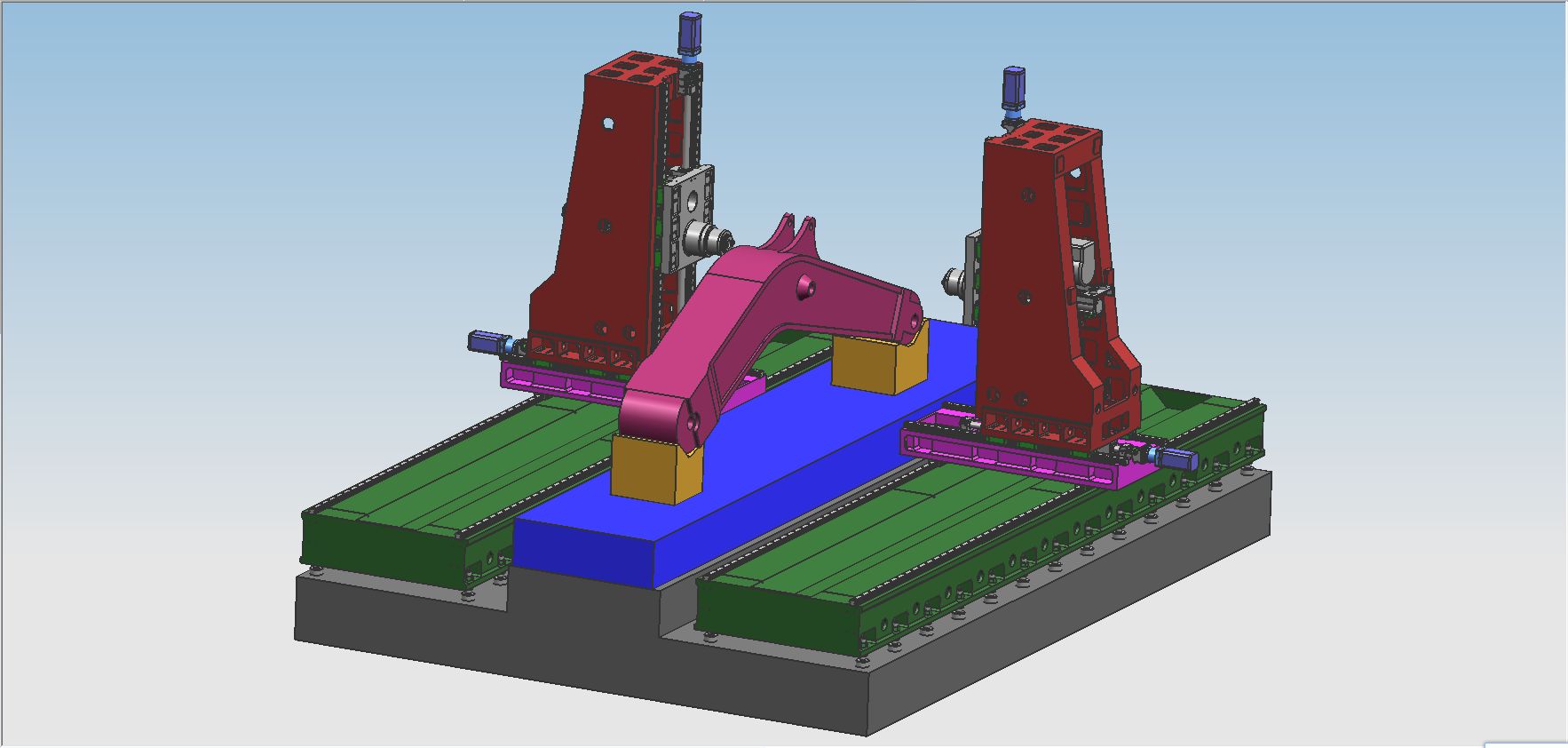

Ikholomu yokulawula izinombolo yeziteshi ezimbili ze-BOSM-1601 ikholomu ephindwe kabili yekholomu yekhanda ukuya ekhanda eyisicefe kanye nomshini wokugaya inguMshini okhethekile wezingcezu zokusebenza ezilinganayo zemishini yokwakha. Umshini ufakwe amakholomu akhethekile agudlukayo namasethi amabili ezinqama ezivundlile, ezingakwazi ukubona Ukubhoboza, ukugaya, ukubhoreka nokunye ukucutshungulwa kwe-workpiece ngaphakathi kwebanga elisebenzayo lokushaywa, i-workpiece ingacutshungulwa endaweni ngesikhathi esisodwa (asikho isidingo sesibili i-clamping), isivinini sokulayisha ngokushesha kanye nokuthulula, isivinini sokumisa ngokushesha, ukunemba okuphezulu kokucubungula nokusebenza kahle kokucubungula.

2. Izingxenye eziyinhloko zoMshini

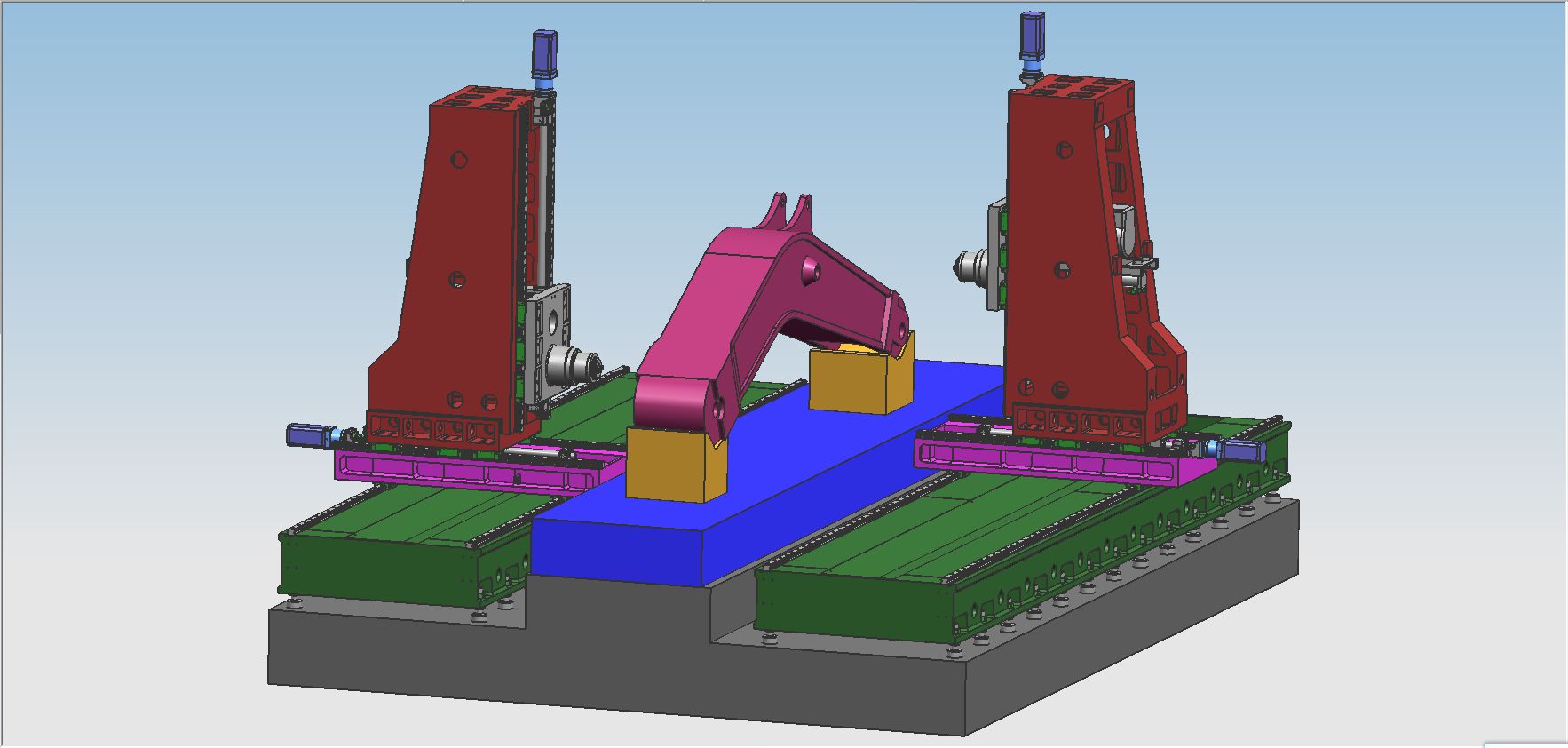

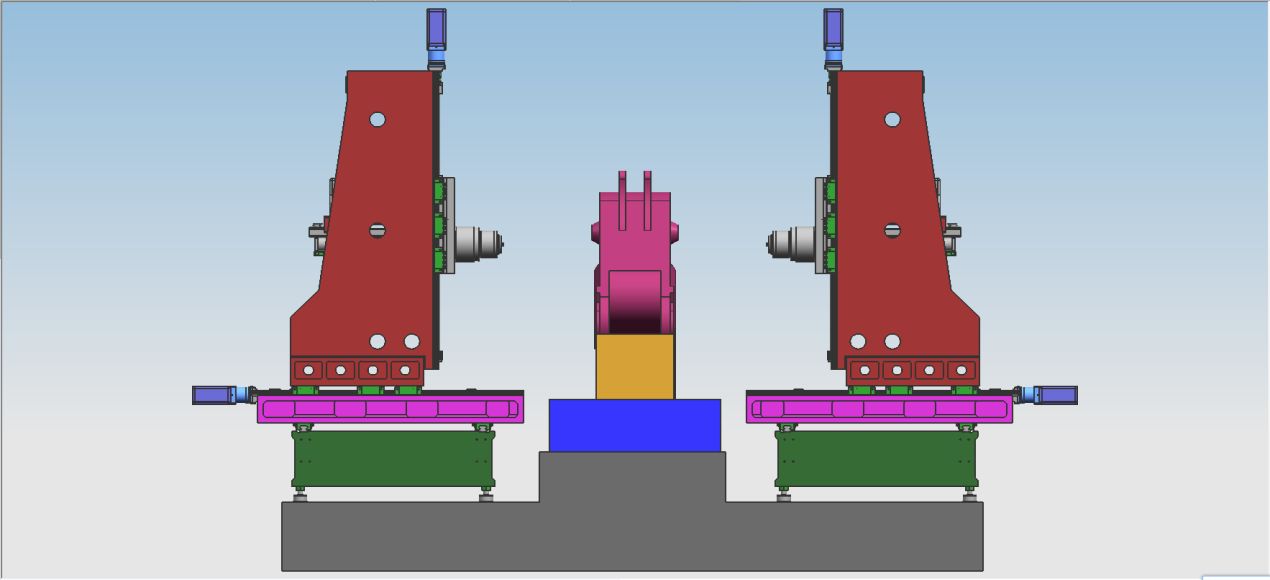

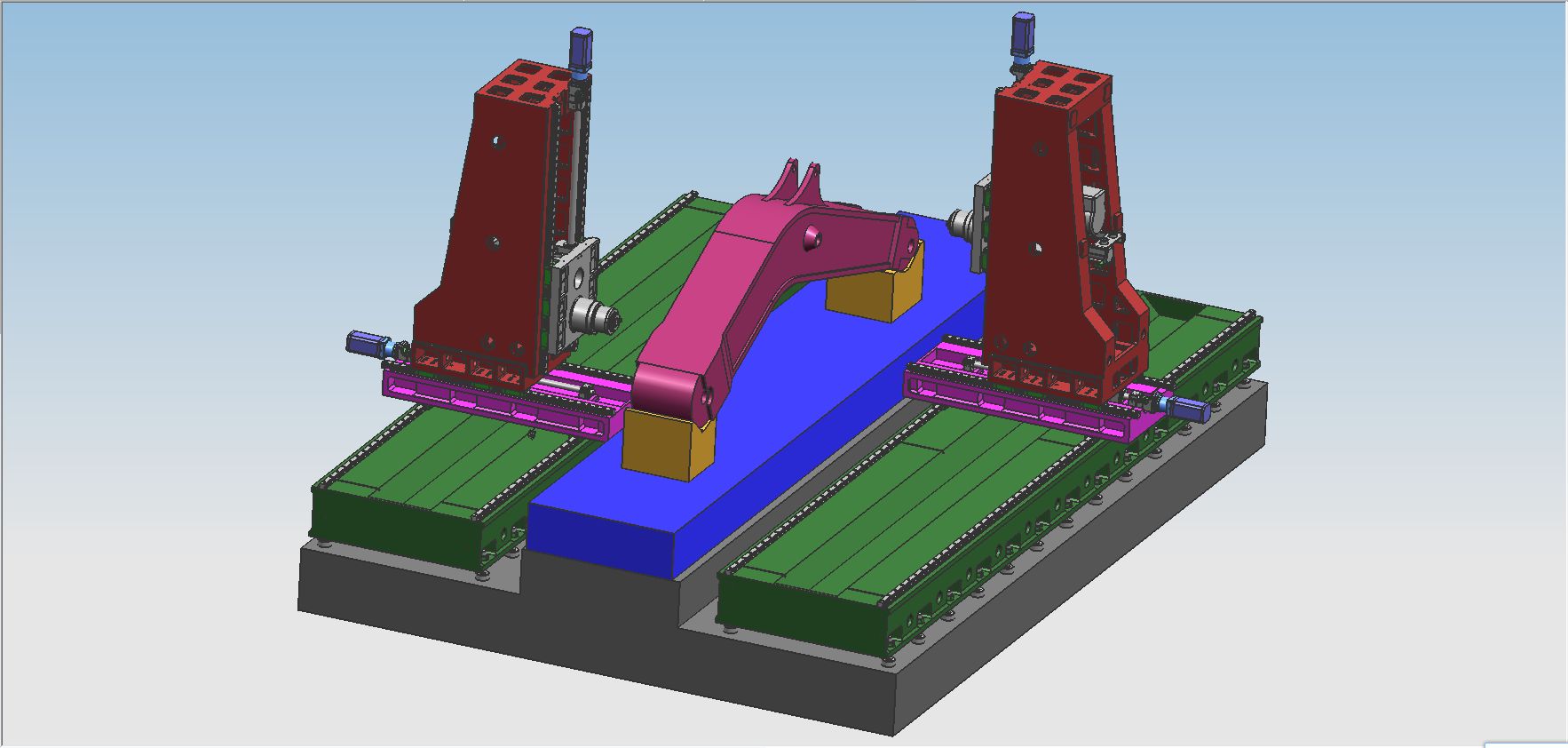

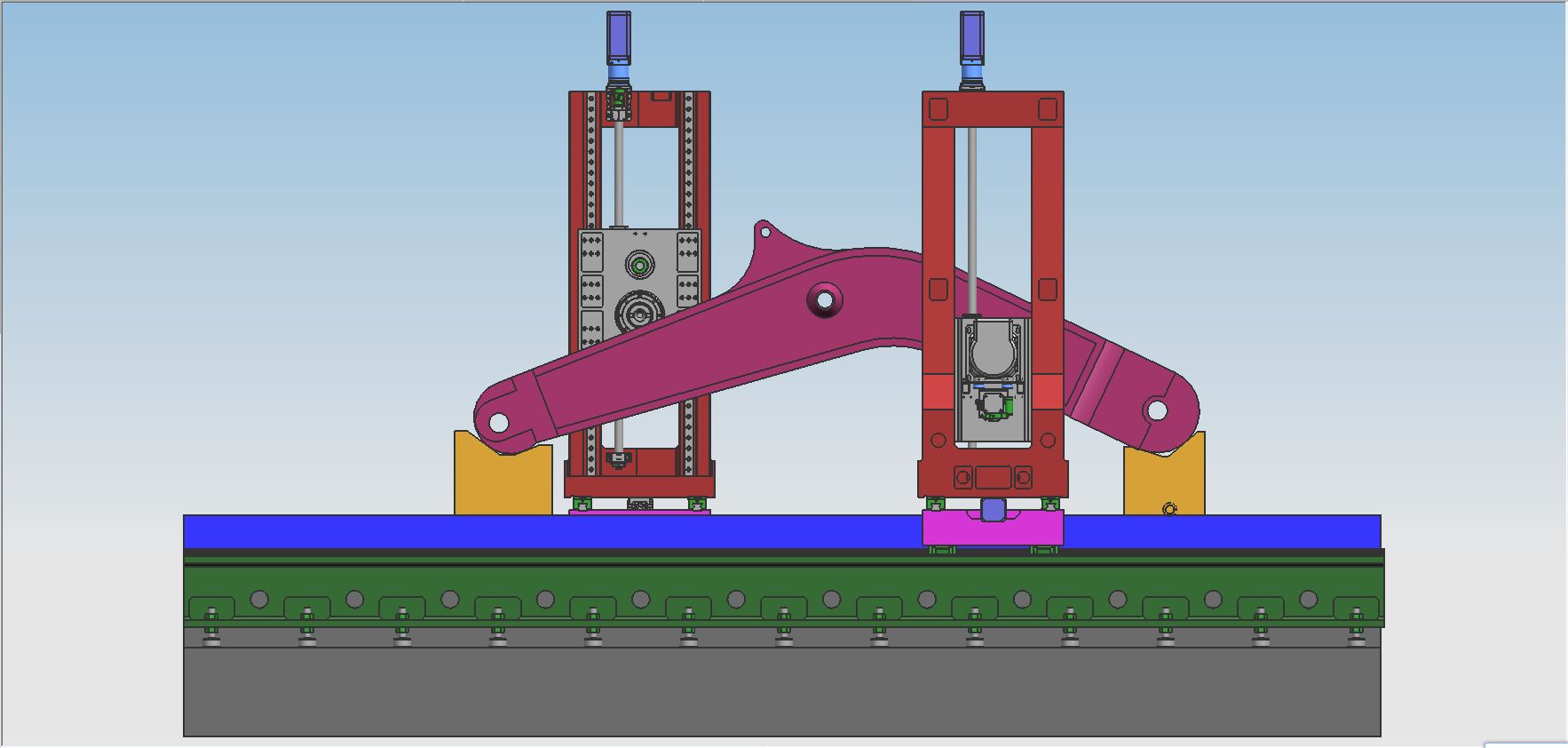

Umbhede, ibhentshi lokusebenzela, amakholomu angakwesobunxele nakwesokudla, imishayo, amahhashi, izinqama nezinye izingxenye ezinkulu zonke zenziwe ngenhlaka yenhlaka, insimbi empunga yezinga eliphezulu engu-250, ifakwe emgodini wesihlabathi esishisayo→ukuguga kokudlidliza→ukuguga kwesithando somlilo esishisayo→ukuguga ukwenza imishini enzima→ ukuguga kokudlidliza→ukushisa kwesithando somlilo esishisayo→ukuguga ukudlidliza→ukuqeda, qeda ngokuphelele ukucindezeleka okungekuhle kwezingxenye, futhi ugcine ukusebenza kwezingxenye kuzinzile. Umshini unemisebenzi efana nokugaya, ukubhora, ukubhola, ukucwila, ukuthepha, njll., futhi indlela yokupholisa ithuluzi ukupholisa kwangaphandle , Umshini uqukethe ama-ax okuphakelayo angu-6, angakwazi ukubona ukuxhumana kwe-axis engu-4 kanye nesenzo esisodwa se-axis engu-6. Kunamakhanda amandla angu-2. Ukuqondiswa kwe-axial yoMshini kanye nekhanda lamandla kuboniswa esithombeni esingezansi.

2.1Isakhiwo esiyinhloko sengxenye ye-axial transmission feed

2.1.1 X1/X2 i-eksisi:Ikholomu ibuyela ngobude eduze komzila wesitimela wombhede ongashintshi.

Ukudluliswa kwe-X-axis: Ishayelwa futhi ilawulwa yi-AC servo motor, isinciphisi seplanethi esinembe kakhulu sishayela amakholomu amabili ukuze ahambe ngokulandelana ku-X-eksisi ngokusebenzisa ipheya yokudlulisa isikulufu sebhola.

Ifomu likajantshi wesitimela: Imizila emibili yomugqa enembayo enembayo ibekwe isicaba. Ibanga lokunemba lesikulufu sebhola kupheya yokudlulisela ngu-C5.

2.1.2 i-eksisi ye-Y1/Y2:Amakhanda amandla ayisicefe kanye nagaywayo I, II kanye namakholomu awo afakwe ngokulandelana kuma-high-power guide rails nhlangothi zombili, futhi abuyiselana eduze kwama-base guide rails eduze kwezimbazo ze-Y1 kanye ne-Y2. I-AC servo motor isetshenziselwa ukushayela nokulawula ipheya yokudlulisa isikulufu sebhola, ukuhudula isihlalo sehhashi ukuze unyakaze, futhi ubone ukunyakaza komugqa ku-eksisi ye-Y.

Ifomu lesitimela somhlahlandlela: 4 amalayini womugqa oqondile + i-ball screw drive. Ibanga lokunemba lesikulufu sebhola kupheya yokudlulisa ngu-C5, futhi isilawuli se-semi-closed-loop siyamukelwa.

2.1.3 i-eksisi ye-Z1/Z2:Amakhanda anamandla ayisicefe futhi agaywayo I, II kanye nezihlalo zazo ezishelelayo zifakwe zibheke phezulu emaphethelweni angaphambili amakholomu nhlangothi zombili, futhi zibuyiselana eduze nezimbazo ze-Z1 ne-Z2 phezulu naphansi kumareyili womhlahlandlela wekholomu.

I-Z1-axis transmission: I-AC servo motor isetshenziselwa ukushayela nokulawula isinciphisi seplanethi esinembe kakhulu kanye ne-ball screw transmission pair, futhi inqama ishayelwa ukuze ihambe ngokulandelana ku-axis ye-Z.

Ifomu likajantshi wesitimela: 2 izakhiwo zikaloliwe eziwumugqa womugqa ziyamukelwa. Ibanga lokunemba lesikulufu sebhola kupheya yokudlulisela ngu-C5.

2.2 Ukususwa kwe-chip nokupholisa

Kukhona ama-spiral chain chain chip conveyor afakwe nhlangothi zombili ngaphansi kwebhentshi lokusebenza, futhi ama-chips angadluliselwa ngokuzenzakalela kusidlulisi se-chip ekugcineni ngezigaba ezimbili zamapuleti a-spiral kanye namaketango ukuze kutholakale ukukhiqizwa okuphucuzekile. Kunepompo yokupholisa ethangini lokupholisa le-chip conveyor, engasetshenziselwa ukupholisa kwangaphandle kwethuluzi ukuze kuqinisekiswe ukusebenza nempilo yesevisi yethuluzi, futhi okokupholisa kungagaywa kabusha.

3. Uhlelo olugcwele lokulawula izinombolo zedijithali:

3.1. Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

3.2. Ifakwe umsebenzi wokuphakamisa ithuluzi, ibanga lokuphakamisa ithuluzi lingasethwa kusixhumi esibonakalayo somshini womuntu. Uma ibanga selifinyelelwe, ithuluzi liphakanyiswa ngokushesha, bese ama-chips elahlwa kude, bese lidluliselwa ngokushesha endaweni yokubhoboza bese liguqulwa ngokuzenzakalelayo lisebenze.

3.3. Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ebanjwa ngesandla yamukela isistimu yokulawula izinombolo futhi ifakwe isixhumi esibonakalayo se-USB nesibonisi sekristalu esiwuketshezi se-LCD. Ukuze kube lula ukuhlela, ukugcinwa, ukuboniswa nokuxhumana, okusetshenziswa kubonwa kunemisebenzi efana nengxoxo yomshini womuntu, isinxephezelo samaphutha, ne-alamu ezenzakalelayo.

3.4. Imishini inomsebenzi wokuhlola kuqala nokuhlola kabusha indawo yembobo ngaphambi kokucubungula, futhi ukusebenza kulula kakhulu.

4. Ukugcoba okuzenzakalelayo

Ukunemba komshini amapheya kaloliwe womugqa, amapheya wesikulufu sebhola anemba kanye namanye amapheya anyakazayo anembe kakhulu afakwe amasistimu okugcoba azenzakalelayo. Ipompo yokugcoba ezenzakalelayo ikhipha uwoyela ocindezelayo, futhi igumbi likawoyela we-lubricator lobuningi lingena emafutheni. Ngemuva kokuthi igumbi likawoyela ligcwaliswe ngamafutha, lapho ingcindezi yesistimu ikhuphukela ku-1.4-1.75Mpa, inkinobho yokucindezela ohlelweni ivaliwe, ipompo iyama, futhi i-valve yokukhipha imithwalo ngesikhathi esifanayo. Lapho umfutho kawoyela emgwaqeni wehla ngaphansi kuka-0.2Mpa, isigcobo somthamo siqala ukugcwalisa indawo yokugcoba bese siqedela ukugcwaliswa kwamafutha okukodwa. Ngenxa yokuhlinzekwa okunembile kwamafutha omjovo kawoyela omningi kanye nokutholwa kwengcindezi yesistimu, ukunikezwa kukawoyela kunokwethenjelwa, kuqinisekisa ukuthi kukhona ifilimu kawoyela ebusweni bepheya ngayinye ye-kinematic, ukunciphisa ukungqubuzana nokuguga, nokuvimbela umonakalo isakhiwo sangaphakathi esibangelwa ukushisa ngokweqile. , ukuqinisekisa ukunemba nokuphila koMshini. Uma kuqhathaniswa nepheya yesitimela sikamhlahlandlela oslayidayo, ipheya yesitimela esigingqikayo esetshenziswa kulo Mshini inochungechunge lwezinzuzo:

① Ukuzwela kokunyakaza okuphezulu, i-coefficient yokungqubuzana yesitimela somhlahlandlela incane, kuphela 0.0025-0.01, futhi amandla okushayela ehle kakhulu, okulingana kuphela no-1 womshini ojwayelekile. /10.

② Umehluko phakathi kokungqubuzana okuguquguqukayo nokumile mncane kakhulu, futhi ukusebenza kokulandelela kuhle kakhulu, okungukuthi, isikhawu sesikhathi phakathi kwesiginali yokushayela kanye nesenzo somshini sifushane kakhulu, esiza ekuthuthukiseni isivinini sokuphendula nokuzwela isistimu yokulawula izinombolo.③Ifanele ukunyakaza komugqa onesivinini esikhulu, futhi isivinini sayo esisheshayo cishe siphindwe izikhathi ezingu-10 kunaleso somzila wezinsimbi ezishelelayo. ④ Ingakwazi ukubona ukunyakaza okungenazikhala futhi ithuthukise ukuqina kokunyakaza kwesistimu yemishini. ⑤Ikhiqizwe abakhiqizi abangochwepheshe, inokunemba okuphezulu, ukuguquguquka okuhle nokulungisa kalula.

5. Indawo yokusetshenziswa komshini:

5.1. Izidingo zemvelo zokusetshenziswa kwemishini

Ukugcina izinga elingaguquki lezinga lokushisa le-ambient kuyisici esibalulekile sokwenza imishini enembile.

(1) Izidingo ezitholakalayo zokushisa kwe-ambient zingu-10°C kuya ku-35°C, lapho izinga lokushisa lendawo liku-20°C, umswakama kufanele ube ngu-40% kuya ku-75%.

(2) Ukuze kugcinwe ukunemba okumile koMshini ngaphakathi kwebanga elishiwo, izinga lokushisa elifanele le-ambient liyadingeka ukuthi libe ngu-15°C kuya ku-25°C, kanye nomehluko wezinga lokushisa.

Akufanele idlule ±2°C/24h.

5.2 I-voltage yokuphakelwa kwamandla: 3-isigaba, 380V, ngaphakathi kwebanga lokuguquguquka kwe-voltage ± 10%, imvamisa yokunikezwa kwamandla: 50HZ.

5.3 Uma i-voltage endaweni yokusebenza ingazinzile, Umshini kufanele ufakwe ugesi ozinzile ukuze kuqinisekiswe ukusebenza okuvamile koMshini.

5.4 Umshini kufanele ube nendawo ephansi enokwethenjelwa: intambo yaphansi iyintambo yethusi, ububanzi bocingo akufanele bube ngaphansi kuka-10mm², futhi ukumelana nomhlabathi kuncane kube ngu-4 ohms.

5.5 Ukuze kuqinisekiswe ukusebenza okuvamile kwemishini, uma umoya ocindezelwe womthombo womoya awukwazi ukuhlangabezana nezidingo zomthombo womoya, kufanele ufakwe emshinini.

Engeza isethi yedivayisi yokuhlanza umthombo womoya (ukukhipha umswakama, ukwehlisa, ukuhlunga) ngaphambi komoya.

5.6 Gcina okokusebenza kude nelanga eliqondile, ukudlidliza nemithombo yokushisa, amajeneretha amaza aphezulu, imishini yokushisela kagesi, njll., ukuze ugweme ukwehluleka kokukhiqizwa komshini noma ukulahlekelwa ukunemba koMshini.

6. Imingcele yezobuchwepheshe

| Imodeli | 1601 | |

| Icubungula usayizi wesiqeshana somsebenzi | Ubude × ububanzi × ubude (mm) | 16000×1000×1500 |

| Okuphakelayo okuphezulu komshini | Ububanzi (mm) | 1300 |

| Usayizi wedeski elisebenzayo | Ubude X Ububanzi (mm) | 16000*1000 |

| Ukuhamba kwekholomu | Ikholomu iya emuva naphambili (mm) | 1600 |

| Spindle up and down | Uhambo oluya phezulu naphansi (mm) | 1500 |

| Ubude ukusuka enkabeni yokuphotha kuya endizeni yetafula | 100-1600 mm | |

| I-spindle yamandla aphezulu evundlile amandla ikhanda elilodwa amabili | Ubuningi (2) | 2 |

| I-spindle taper | I-BT50 | |

| I-Broach | Ukuphequlula okuzenzakalelayo, ushintsho lwethuluzi okwenziwa ngesandla | |

| Ububanzi be-Cutter (mm) | ≤Φ200 | |

| Ukuthepha ububanzi (mm) | I-M3-M30 | |

| Isivinini se-spindle (r/min) | 30 ~ 3000 | |

| Amandla e-Servo spindle motor (kw) | 30*2 | |

|

| Ibanga lokuhamba kwesokunxele nakwesokudla phakathi kweziphetho ezimbili zokuphotha | 400-1600 mm |

| Ukuhamba kwesokunxele nakwesokudla kwamakholomu aphindwe kabili (mm) | 600 ngamunye | |

| Ukupholisa Ithuluzi | Ukupholisa kwangaphakathi, ukupholisa kwangaphandle | |

| Ukunemba kokuma kwe-Bidirectional | 300mm | ±0.032 |

| Ukunemba kokuma kokuphinda kabili kwezinhlangothi ezimbili | 300mm | ±0.025 |

| Ubukhulu bomshini | Ubude × ububanzi × ubude (mm) | Ngokwemidwebo (uma kukhona izinguquko enqubweni yokuklama, sizokwazisa) |

| Isisindo esiphelele (t) | 72T | |