5-Axis Vertical Machining Center V5-700B

Uhlolojikelele

Isikhungo somshini we-V5-700 B se-axis emihlanu samukela ukwakheka okuzinzile okumise okuka-C, futhi kufakwe i-spindle kagesi, i-direct-drive turntable ye-CNC kanye nomagazini wamathuluzi njengokujwayelekile, okwazi ukubona ukukhanda ngesivinini esikhulu nokunemba okuphezulu kwezingxenye eziyinkimbinkimbi . Isetshenziswa kabanzi ekucubunguleni okuguquguqukayo nokusebenza kahle kwezinjini zezimoto zamandla amasha, amabhokisi egiya, izinjini, isikhunta, amadivaysi ezokwelapha angamarobhothi neminye imikhiqizo.

Incazelo yemisebenzi nezici

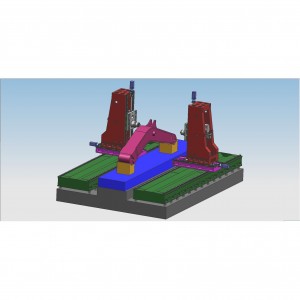

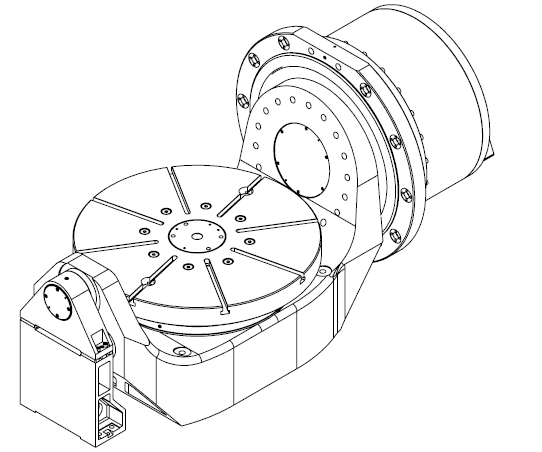

1. Isakhiwo sisonke sethuluzi lomshini

Isikhungo somshini we-V5-700B se-axis emihlanu sithatha isakhiwo esime okume oku-C esizinzile, ikholomu igxilile embhedeni, ipuleti lesilayidi lihamba livundlile eduze kwekholomu (isiqondiso esingu-X), isihlalo sama-slide sihamba ngobude eduze kwepuleti lesilayidi (isiqondiso sika-Y ), futhi isigxobo sinyakaza sibheke phezulu eduze kwesihlalo sama-slide (Z direction). Ithebula elisebenzayo lamukela ukwakheka kwembeleko yesandla esisodwa esizithuthukisile se-direct-drive single-arm, futhi izinkomba zayo ezihlukene zokusebenza sezifinyelele ezingeni eliphezulu lamazwe ngamazwe.

2. Uhlelo lokuphakelayo

I-X, Y, i-Z-axis linear guide rails nezikulufu zebhola zinokungqubuzana okumile okuphansi nokuguqukayo, ukuzwela okuphezulu, ukudlidliza okuphansi ngesivinini esiphezulu, akukho ukukhasa ngesivinini esiphansi, ukunemba kokuma okuphezulu, nokusebenza okuhle kakhulu kwe-servo drive.

I-X, Y, i-Z-axis servo motors ixhunywe ngokuqondile nezikulufu zebhola ezinemba okuphezulu ngokuhlangana, ukunciphisa izixhumanisi ezimaphakathi, ukubona ukudluliswa kwegebe, ukuphakela okuguquguqukayo, ukuma okunembile, nokunemba kokudlulisela okuphezulu.

I-Z-axis servo motor inomsebenzi wamabhuleki. Uma kwenzeka ukuphelelwa amandla, ibhuleki lingakwazi ukubamba i-motor shaft ngokuqinile ukuze ingakwazi ukujikeleza, okudlala indima yokuvikela ukuphepha.

3. I-spindle kagesi

I-spindle kagesi yamukela i-spindle kagesi esebenza kahle ngokuzithuthukisa (ilungelo lobunikazi lokusungula: 202010130049.4), futhi isiphetho sifakwe imibhobho yokupholisa ukupholisa ithuluzi. Inezinzuzo zejubane eliphezulu, ukunemba okuphezulu, kanye nokusabela okuphezulu okuguquguqukayo, futhi ingakwazi ukubona ukulawulwa kwesivinini esingenasinyathelo. Isishumeki esakhelwe ngaphakathi sokunemba okuphezulu singabona isitobhi esinembile esiqondiswe ngaphakathi kanye nokuthepha okunzima.

4. Umagazini wamathuluzi

Umagazini wethuluzi le-disc wamukela umagazini wamathuluzi we-BT40 we-manipulator, ongahlalisa amathuluzi angama-24.

5. I-Turntable

I-direct-drive cradle turntable ezithuthukiselwe yona (amalungelo okusungulwa 202010409192.7, 202010408203.X, 2022109170252) ifakwe isifaki khodi sokunemba okuphezulu futhi sipholiswa ngesibandisi samanzi esingashintshi. Inezinzuzo zokuqina okuphezulu, ukunemba okuphezulu, kanye nokuphendula okuphezulu okuguquguqukayo. Ibhentshi lokusebenzela lamukela izikhala ze-T-slots eziyi-8 14mm, ezinomthamo omkhulu wokulayisha ongu-500kg (ovundlile) no-300kg (uqondile)

| Amandla alinganiselwe (kW) | I-torque elinganiselwe (Nm) | Isivinini esilinganiselwe (rpm) | Itorque enkulu (Nm) | Ikalwe okwamanje (A) | |

| I-eksisi ye-B | 13.3 | 2540 | 50 | 4000 | 46.9 |

| I-C eksisi | 3.7 | 700 | 50 | 1400 | 14 |

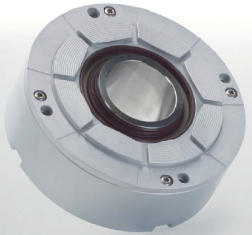

6. Uhlelo lwempendulo ye-loop evaliwe ngokugcwele

X, Y, kanye no-Z ama-ax ahlotshaniswa ne-HEIDENHAIN LC4 uchungechunge lwezikali zegreyithi yenani eliphelele; Amathebula e-B kanye ne-C ajikelezayo ahlomeke ngezishumeki ze-engeli zenani eliphelele le-HEIDENHAIN RCN2000 ukuze kutholakale impendulo evalwe ngokugcwele yama-axes okuphakelayo angu-5, okuqinisekisa ukuthi ithuluzi lomshini linokunemba okuphezulu nokunemba okuphezulu. ukugcinwa kokunemba.

Ifakwe isipholile samanzi sokupholisa izinga lokushisa njalo ukuze kuqinisekiswe ukuthi i-spindle kagesi kanye ne-direct drive turntable kusesimweni esihle sokusebenza futhi kungasebenza kahle isikhathi eside.

Uhlelo lwe-pneumatic luhlungwa ngezingxenye zomoya ukuze kubonakale imisebenzi yokuhlanza nokuvunguza imbobo ye-taper ye-shaft eyinhloko, ukuvikelwa kokuvalwa komoya kwebheringi eyinhloko ye-shaft, nokuphendulela umagazini wamathuluzi nesiphathi samathuluzi.

8. Uhlelo lokuthambisa oluphakathi nendawo

Ibhulokhi yesilayidi yesitimela somhlahlandlela kanye nenathi lesikulufu sebhola zisebenzisa idivayisi yokuthambisa emaphakathi nendawo enamafutha amancane, ehlinzeka ngokugcotshwa okuvamile nobuningi ukuze kuqinisekiswe ukunemba nokuzinza kwesikulufu sebhola kanye nesitimela somhlahlandlela.

9. Isistimu yokugcoba umoya kawoyela

I-spindle kagesi ifakwe idivayisi yokugcoba komoya kawoyela engenisiwe ukuze igcobe ngokugcwele futhi ipholise i-spindle. Inzwa ihlonyiselwe ukunikeza i-alamu yokugcoba okungavamile, iqinisekisa ngempumelelo ukuthi i-spindle ingasebenza ngokuzinzile ngesivinini esiphezulu isikhathi eside.

10. Uhlelo lokulinganisa i-workpiece

Ithuluzi lomshini lifakwe i-HEIDENHAIN TS460 touch probe kanye nesamukeli sesignali engenantambo, esingafakwa ku-spindle ngohlelo lokushintsha ithuluzi okwenziwa ngesandla noma oluzenzakalelayo ukuze kuqashwe imisebenzi yokuqondanisa ucezu lokusebenza, ukukalwa kocwecwe lokusebenza kanye nokusetha iphuzu lokusethwa ngaphambilini, kanye nokuphindaphinda kwesilinganiso ≤ 1um (isivinini sokuhlola 1 m/min), izinga lokushisa lokusebenza ngu-10°C kuya ku-40°C. I-HEIDENHAIN touch probe iqaliswa ukushintsha kokubona. I-stylus isebenzisa i-bearing yamaphoyinti amathathu ukuze kuqinisekiswe indawo ekahle yesifunda samahhala. Ayigqoki ngesikhathi sokusetshenziswa, inokuphindaphinda okungaguquki futhi izinzile isikhathi eside.

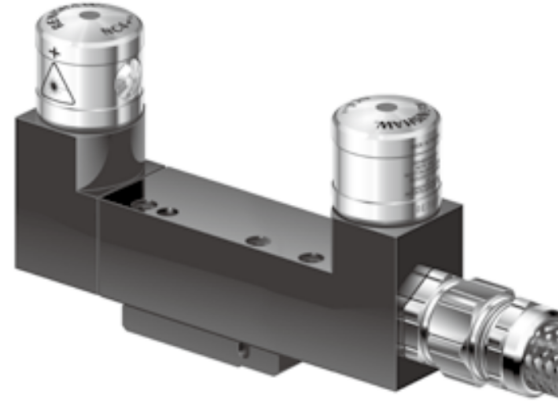

11. Uhlelo lokulinganisa lwamathuluzi

Ithuluzi lomshini lifakwe ithuluzi lokusetha ithuluzi le-laser ye-Renishaw NC4, ukuphindaphinda kokulinganisa kungu-±0.1um, kanti izinga lokushisa elisebenzayo lingu-5°C kuya ku-50°C.

12. Ukulinganisa ukunemba kweeksisi ezinhlanu

Ithuluzi lomshini lifakwe amabhola okulinganisa e-KKH asuka e-HEIDENHAIN, kanye nama-TS series probes, ukuze kufinyelelwe ukulinganisa okunembayo kwe-eksisi yokuzungezisa ithuluzi lomshini, ukunciphisa amaphutha phakathi nokunyakaza kwethuluzi lomshini, kanye nokuzuza ukunemba okuphezulu nokuphindaphinda okuphezulu.

(1) Ukunikezwa kwamandla: 380V±10% 50HZ±1HZ izigaba ezintathu ze-AC

(2) Izinga lokushisa lendawo: 5°C-40°C

(3) Izinga lokushisa eliphezulu: 22°C-24°C

(4) Umswakama ohlobene: 40-75%

(5) Ingcindezi yomthombo womoya: ≥6 ibha

(6) Izinga lokugeleza komthombo wegesi: 500 L/min

15. Ukwethulwa komsebenzi wohlelo lwe-CNC

I-HEIDENHAIN TNC640 CNC uhlelo

(1) Inombolo yezimbazo: kufika ku-24 amalophu okulawula

(2) Inguqulo yesikrini sokuthinta enomsebenzi wokuthinta okuningi

(3) Okokufaka kohlelo: Ingxoxo ye-Klartext kanye nekhodi ye-G (ISO).

(4) Uhlelo lwamahhala lwe-FK: sebenzisa ulimi lwengxoxo lwe-Klartext ukwenza uhlelo lwe-FK lwamahhala lwekhonta ngokusekelwa okuyingcaca

(5) Imijikelezo eminingi yokugaya nokumba

(6) Isinxephezelo sethuluzi: isinxephezelo serediyasi yamathuluzi nesinxephezelo sobude bethuluzi. Umjikelezo we-Probe

(7) Ukusika idatha: Ukubalwa okuzenzakalelayo kwejubane lokuphotha, isivinini sokusika, ukondla nge-blade ngayinye kanye nokuphakelayo umbuthano ngamunye

(8) Isivinini esiqhubekayo sokucubungula ikhonta: ngokuhlobene nendlela yesikhungo samathuluzi / isihlobo sonqenqema lwamathuluzi

(9) I-Parallel Run: Uhlelo olusekelwa yizithombe ngenkathi olunye uhlelo lusebenza

10

(11) Ukusondela nokusuka kumakhonsathi: i-tangential noma i-perpendicular/ngezindlela ze-arc

(12) Ukweqa uhlelo: ukuphinda kuvinjwe indlela engaphansi/uhlelo/noma yiluphi uhlelo lungaba umzila ongaphansi

(13) Umjikelezo wamathini: ukubhoboza, ukuthepha (ngohlaka oluntantayo noma ngaphandle kwalo), unxande nomgodi we-arc. Peck drilling, reaming, boring, indawo ebhekene, ukubhola indawo. Ukugaya imicu yangaphakathi neyangaphandle. Ukuqina kwezindawo eziyisicaba nezithambekile. Qedela ukukhanda amaphakethe angama-rectangular nayisiyingi, abaphathi abangonxande nabayisiyingi. Imijikelezo eqinile neyokuqeda yemisele eqondile neyindilinga. Hlela amaphuzu emibuthanweni nasemigqeni. Iphoyinti lohlelo: Ikhodi ye-QR. Contour chain, Contour ephaketheni. I-Contour groove yokugaya i-trochoidal. Umjikelezo wokuqopha: qopha umbhalo noma izinombolo ngomugqa oqondile noma i-arc.

(14) Hlanganisa uguquko: ukuhumusha, ukuzungezisa, ukwenza isibuko, ukukala (i-eksisi ethize).

(15) Uhlelo oluguquguqukayo lwepharamitha ye-Q: umsebenzi wezibalo, ukusebenza okunengqondo, ukusebenza kobakaki, inani eliphelele, okungaguquki þ, ukunganaki, inombolo ephelele noma idesimali, umsebenzi wokubala umbuthano, umsebenzi wokucubungula umbhalo.

(16) Izinsiza zokuhlela: umshini wokubala. Uhlu lwayo yonke imilayezo yamaphutha yamanje. Umsebenzi wosizo obucayi kokuqukethwe kumilayezo yephutha. I-TNCguide: uhlelo losizo oludidiyelwe; i-TNC 640 ibonisa ulwazi ngokuqondile encwadini yomsebenzisi. Usekelo lwezithombe lokuhlelwa komjikelezo. Amabhlogo wokuphawula kanye namabhulokhi amakhulu ezinhlelweni ze-NC.

(17) Ukuthola ulwazi: sebenzisa ngokuqondile isikhundla sangempela ohlelweni lwe-NC.

(18) Imifanekiso yokuqinisekisa uhlelo: Ukulingisa okungokomfanekiso kokusebenza komshini kungenziwa nanoma olunye uhlelo lusebenza. Ukubuka okuphezulu/ukubuka kwezinhlangothi ezintathu/ukubuka kwestereo, nendiza yokucubungula ethambekele/umdwebo womugqa ongu-3-D. Ukukala kwendawo.

19

(20) Izithombe ezisebenza ngohlelo: ukulingiswa kwezithombe zesikhathi sangempela ngenkathi kwenziwa uhlelo lokugaya. ukubuka okuphezulu/ukubuka okuthathu/ukubuka kwesitiriyo.

(21) Isikhathi sokucubungula: Bala isikhathi sokucubungula kumodi yokusebenza "yokugijima kokuhlola". Ibonisa isikhathi samanje somshini kumodi yokusebenza ethi "Program Run".

(22) Buyela ku-contour: bonisa isikhathi samanje sokucubungula kumodi yokusebenza "esebenzayo yohlelo". Ukuphazamiseka kohlelo, ukuhamba nokubuyela ku-contour.

(23) Ukuphathwa kwephoyinti okusethiwe: ithebula lokulondoloza noma yiliphi iphuzu elisethiwe.

(24) Ithebula lomsuka: amathebula omsuka amaningi, asetshenziselwa ukulondoloza umsuka ohlobene wocezu lokusebenza.

(25) Ukusetjenziswa kwe-3-D: Ukulawula Ukunyakaza Kwekhwalithi Ephezulu Ye-Smooth Jerk

(26) Vimba isikhathi sokucubungula: 0.5 ms

(27) Ukulungiswa kokokufaka nesinyathelo sokubonisa: 0.1 μm

(28) Umjikelezo wokulinganisa: ukulinganisa kwe-probe. Isinxephezelo mathupha noma esizenzakalelayo sokungaqondani kahle kocezu lokusebenza. Setha amaphuzu asethiwe ngokuzenzela noma ngokuzenzakalelayo. Ithuluzi kanye workpiece kungalinganiswa ngokuzenzakalelayo.

(29) Isinxephezelo sephutha: iphutha le-eksisi ewumugqa nengaqondile, ukuhlehla, i-engeli ebukhali ehlehlayo yokunyakaza okuyindilinga, iphutha lokuhlehla, ukunwetshwa kokushisa. ukungqubuzana okumile, ukungqubuzana kokuslayida.

(30) Isixhumi esibonakalayo sedatha: RS-232-C/V.24, kufika ku-115 kbit/s. Ukusebenzelana kwedatha okunwetshiwe kwephrothokholi ye-LSV2, sebenzisa isofthiwe ye-HEIDENHAIN TNCremo noma i-TNCremoPlus ukuze usebenzise ukude i-TNC ngokusebenzisa lesi sikhombimsebenzisi sedatha. 2 x Gigabit Ethernet 1000BASE-T isixhumi esibonakalayo. 5 x izimbobo ze-USB (imbobo ye-USB engu-1 ngaphambili 2.0, izimbobo ezi-4 ze-USB 3.0).

(31) Ukuxilongwa: Amathuluzi okuxilonga aqukethwe ngokwawo okuxazulula inkinga ngokushesha nakalula.

(32) Isifundi se-CAD: bonisa amafayela efomethi ye-CAD evamile.

Ipharamitha eyinhloko

| Into | Iyunithi | Ipharamitha | |

| Ithebula lokusebenza | I-diameter esebenzayo | mm | Φ700 |

| Ubukhulu bomthwalo ovundlile | kg | 500 | |

| Ubukhulu bomthwalo oqondile | kg | 300 | |

| T-slot | mm | 8×14 | |

| Icubungula ububanzi | Ibanga phakathi kobuso bokuphela kwe-spindle kanye nobuso bokuphela kwetafula lokusebenza (Ubukhulu) | mm | 600 |

| Ibanga phakathi kobuso bokuphela kwe-spindle kanye nobuso bokuphela kwetafula lokusebenza (Min) | mm | 150 | |

| I-X eksisi | mm | 700 | |

| Y eksisi | mm | 550 | |

| Z eksisi | mm | 450 | |

| I-eksisi ye-B | ° | -35~+110 | |

| I-C eksisi | ° | 360 | |

| I-spindle | I-Taper | I-BT40 | I-BT40 |

| Isivinini esilinganiselwe | rpm | 2000 | |

| Ubukhulu. isivinini | rpm | 15000 | |

| I-torque ye-S1/S6 | Nm | 72/88 | |

| Amandla e-spindle motor S1/S6 | KW | 15/18.5 | |

| I-eksisi | Isivinini sokunqamula esisheshayo esingu-X | m/min | 36 |

| I-axis engu-Y Isivinini sokunqamula esisheshayo | m/min | 36 | |

| I-Z eksisi Isivinini esisheshayo sokunqamula | m/min | 36 | |

| I-axis ye-B Max. isivinini | rpm | 80 | |

| I-C eksisi Max. isivinini | rpm | 80 | |

| Amandla e-axis motor ye-X/Y/Z | Kw | 3.6/3.6/2 | |

| Amandla e-axis motor ye-B/C | Kw | 13.3 / 3.7 | |

| I-torque elinganiselwe nge-eksisi ye-B/C | Nm | 2540/700 | |

| Umagazini wamathuluzi | Uhlobo |

| Uhlobo lwediski |

| Indlela yokukhetha ithuluzi |

| Ukukhethwa kwethuluzi eliseduze kwezinhlangothi ezimbili | |

| Amandla | T | 30 | |

| Ubukhulu. ubude bethuluzi | mm | 300 | |

| Ubukhulu. isisindo sethuluzi | kg | 8 | |

| Ubukhulu. I-cutter disc diameter (Ithuluzi Eligcwele) | mm | φ80 | |

| Ubukhulu bobubanzi bediski yokusika (Ithuluzi eliseduze elingenalutho) | mm | φ150 | |

| Ukunemba | Imibandela yokuphoqelela |

| I-GB/T20957.4 (ISO10791-4) |

| Ukunemba kokuma(X/Y/Z) | mm | 0.008/0.008/0.008 | |

| Ukunemba kokuma(B/C) |

| 7″/7″ | |

| Ukunemba kokuma okuphindaphindiwe | I-X-eksisi/Y-eksisi/Z-eksisi | mm | 0.006/0.006/0.006 |

| I-B-eksisi/C-eksisi |

| 5″/5″ | |

| Isisindo | kg | 8000 | |

| Amandla | I-KVA | 45 | |

Uhlu Lokucushwa Okujwayelekile

| Cha. | Igama |

| 1 | Izingxenye eziyinhloko (okuhlanganisa umbhede, ikholomu, ipuleti lesilayidi, isihlalo sama-slide, isigxobo) |

| 2 | X, Y, Z isistimu yokuphakelayo yama-eksisi amathathu |

| 3 | I-Single Arm Cradle Turntable BC630 |

| 4 | I-spindle kagesi BT40 |

| 5 | Uhlelo lokulawula ugesi (okuhlanganisa iKhabhinethi kagesi, imojula yokuphakela amandla, imojula ye-servo, i-PLC, iphaneli yokusebenza, isibonisi, iyunithi ephathwa ngesandla, isiyolisi somoya sekhabhinethi kagesi, njll.) |

| 6 | Isikali sokulinganisa: HEIDENHAIN |

| 7 | Uhlelo lweHydraulic |

| 8 | Isistimu ye-pneumatic |

| 9 | Isistimu yokugcoba emaphakathi |

| 10 | Isistimu yokugcoba umoya kawoyela |

| 11 | I-chip conveyor, ithangi lamanzi, umqoqi we-chip: RAL7021 okumpunga okumnyama |

| 12 | Isipholile samanzi |

| 13 | Idivayisi yokulinganisa i-Workpiece: HEIDENHAIN TS460 |

| 14 | Ithuluzi lokusetha ithuluzi: Renishaw NC4 |

| 15 | Ukulinganisa ukunemba kwama-eksisi amahlanu: HEIDENHAIN KKH |

| 16 | Unogada wesitimela |

| 17 | Ithuluzi lomshini ikhava yokuvikela iyonke |

| 18 | Ngokusekelwe endaweni eyodwa yokusetshenziswa kwesofthiwe ye-HPMILL ngemva kokucubungula, bopha ikheli lendawo lekhompuyutha |

| 19 | Umsebenzi wokunxephezela we-spindle elongation |