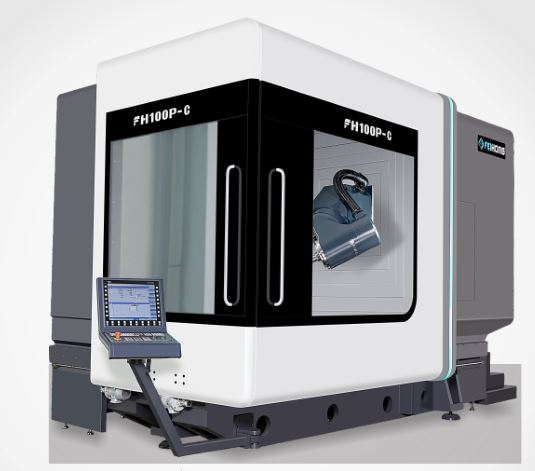

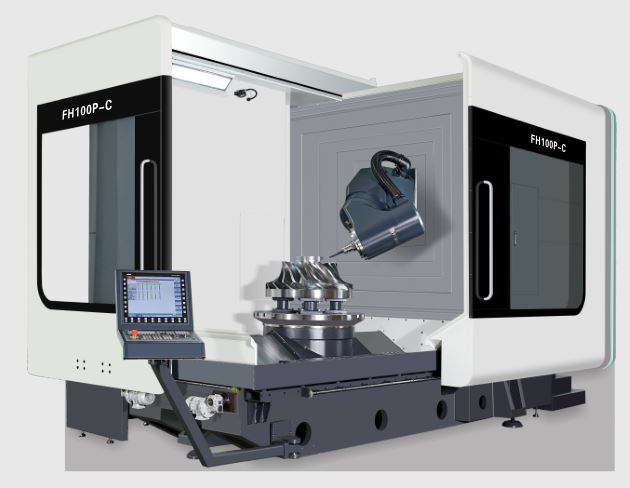

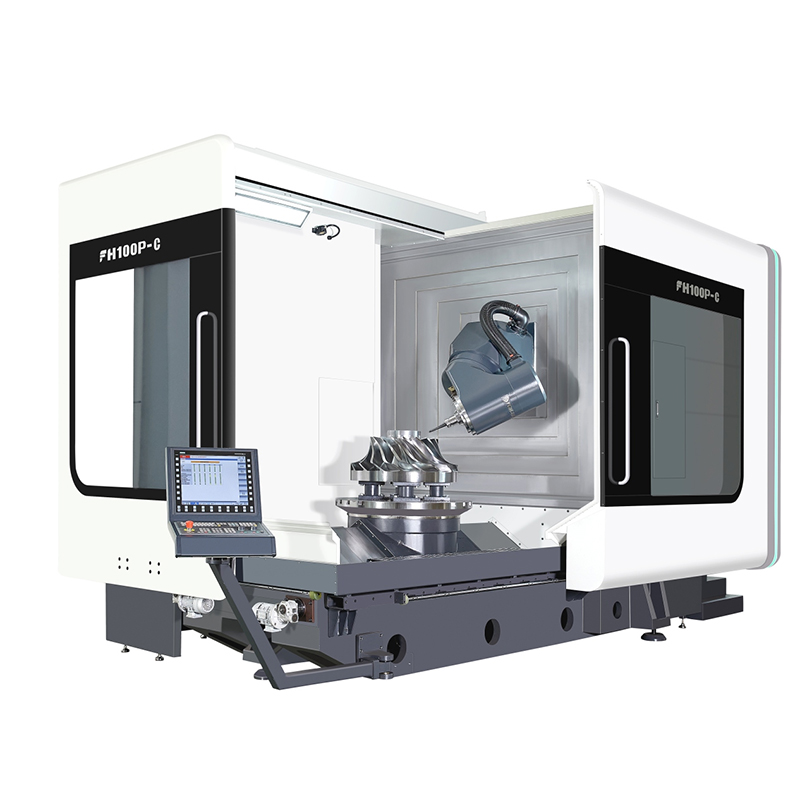

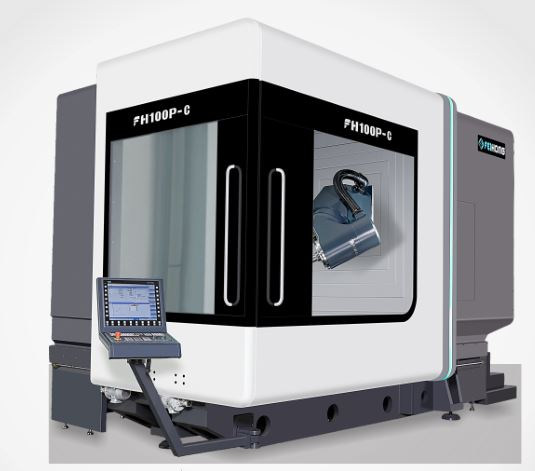

5 Izimbazo Milling Kanyekanye Turning 100P-C

Ububanzi bokunikezwa

Ithebula lezinsiza ezijwayelekile (sicela ubhekisele kumsebenzi wesilawuli wengxenye yokulawula ugesi)

1. Isilawuli se-Siemens 840DSL

2. Ikhanda lokushwibeka le-Brand Own eline-axis emihlanu yemisebenzi eminingi

3. I-spindle kagesi DGZX-24012/34B2-KFHWVJS

4. HSK-A100 40-ithuluzi uhlelo lokushintsha ithuluzi okuzenzakalelayo

5.X/Y/Z isikulufa sebhola lokupholisa esingenalutho

6. Amaslayidi angumugqa wamarola angu-7 (3 ku-X axis, 2 ye-Y/Z axis)—BOSCH REXROTH

7. X/Y/Z irula ye-optical ye-axis emithathu evalwe ngokugcwele

8. Idivayisi yokulawula ukushisa kwebhokisi likagesi

9. Isibandisi se-spindle

10. Idivayisi yokugoqa i-Spiral chip kanye nemoto yangemuva ye-iron chip conveyor iron chip car

11. Amanzi asuka phakathi nendawo yokuphotha, isifutho samanzi se-annular

12. Vuthela umoya phakathi nendawo yokuphotha, bese uphephetha umoya eringini.

13. Inyanga ecwebezelayo enekhanda lezinhlaka ezinhlanu ivunguza amanzi, futhi inyanga ecwebile ivunguza umoya.

14. Uhlobo olu-1 lokukhiyeka kokuphepha kweminyango yokusebenza yangaphambili neseceleni

15. Ithuluzi lokupholisa lokujikeleza kwe-spindle.

16. Isibani se-fluorescent esingangeni manzi

17. Idivayisi yesiteshi seHydraulic

18. I-Renishaw OMP60 Infrared Probe Unit

19. I-Renishaw Laser Tool Setter

20. Ithuluzi lokuthambisa eliphakathi nendawo eliphakathi nendawo

21. Ukusebenza ohlangothini lokuhlanza isibhamu samanzi kanye nesixhumi esibonakalayo somoya

22. Ukusika uhlelo lokupholisa uketshezi

23. Ishidi lensimbi elivikelwe ngokugcwele

24. Ibhokisi lokusebenza

25. Ibhokisi likagesi lifakwe i-air conditioner

26. Siemens electronic handwheel

27. Iswishi yokukhulula ithuluzi lokuphotha elisebenza ngonyawo

28. Amaphedi ezinga lesisekelo namabhawodi esisekelo

29. Amathuluzi okulungisa namabhokisi amathuluzi

30. Ibhukwana lobuchwepheshe

Ipharamitha

| Into | Uni | I-FH100P-C |

| Uhambo lwe-X eksisi | mm | 1000 |

| Uhambo lwe-Y eksisi | mm | 1150 |

| Z ukuhamba eksisi | mm | 1000 |

| Ibanga ukusuka ekhaleni lokuphotha ukuya endaweni yetafula lomsebenzi | mm | 160-1160 |

| Ikhanda lokugaya elivundlile | mm | 30-1030 |

| Okuphakelayo/isivinini esihamba ngokushesha | m/min | 40 |

| Okuphakelayo amandla | KN | 10 |

| Ithebula elijikelezayo (i-C axis) | ||

| Usayizi wethebula elisebenzayo | mm | Ø1050 |

| Max.table load (isigayo) | kg | 4000 |

| Max.table load (ukujika) | kg | 3000 |

| Ithebula le-Rotray | rpm | 45 |

| Ukugaya/ukuguqula itafula lokulungisa (ukugaya inhlanganisela nokuphenduka) | rpm | 500 |

| I-engeli encane yokuhlukaniswa | ° | 0.001 |

| I-torque elinganiselwe | Nm | 1330 |

| I-torque enkulu | Nm | 2630 |

| Ikhanda lokugaya i-CNC (i-axis B) | ||

| Ibanga lokushwiba(0=Okuqondile/180=Izinga) | ° | - 15 - 180 |

| Ukuhamba okusheshayo kanye nesivinini sokudla | rpm | 103 |

| I-engeli encane yokuhlukaniswa | ° | 0.001 |

| I-torque elinganiselwe | Nm | 1050 |

| I-torque enkulu | Nm | 2130 |

| I-Spindle (i-turning and milling) | ||

| Isivinini se-spindle | rpm | 10000 |

| Amandla e-spindle | Kw | 42/58 |

| I-Spindle torque | Nm | 215/350 |

| I-spindle tapre |

| HSKA100 |

| Ibanga ukusuka esikhungweni se-spindle ukuya ugongolo guideway surface | mm | 1091.5 |

| Imodeli | Iyunithi | I-FH100P-C |

| Umagazini wamathuluzi | ||

| Ithuluzi esibonakalayo |

| HSKA100 |

| Amandla omagazini wethuluzi | PCS | 40 |

| I-Max.tool diameter/ubude/isisindo |

| Ø135/300/12 |

| Ukushintsha ithuluzi(Ithuluzi ukuya) | S | 2 |

| Idivayisi yokulinganisa | ||

| I-infrared probe | I-Rensishaw OMP60 | |

| Ithuluzi lokuthola ithuluzi endaweni yokucubungula | I-Rensishaw NC4F230 | |

| Umthamo wokucubungula | ||

| I-Max.drilling diameter(Insimbi emaphakathi) |

| Ø50 |

| I-Max.tapping diameter(Insimbi emaphakathi) |

| M40 |

| I-Max.milling diameter(Insimbi emaphakathi) |

| 250 |

| Ukunemba (ISO230-2 kanye ne-VDI3441) | ||

| X/Y/Z ukunemba kokuma | mm | 0.006 |

| X/Y/Z Phinda ukunemba kokuma | mm | 0.004 |

| Ukunemba kokuma kwe-B/C |

| 8" |

| B/C Phinda ukunemba kokuma | 4" | |

| Isistimu yokulawula |

| I-Siemens840D |

| Ubude bomshini(Umshini ojwayelekile) | mm | 3650 |

| Indawo okuhlalwa kuyo umshini omkhulu (L*W) | mm | 5170x3340 |

| Indawo okuhlalwe kuyo umagazini wamathuluzi(L*W) | mm | 1915x1400 |

| Indawo okuhlalwa kuyo i-chip conveyor(L*W) | mm | 3120x1065 |

| Indawo ehlala ithangi lamanzi(L*W) | mm | 1785x1355 |

| Indawo ephelele ephelele yokuqedela umshini (L*W) | mm | 6000x3750 |

| Isisindo somshini | Kg | 21000 |

Umshini CNCisilawuli

| Isistimu yokulawula | I-Siemens 840DSL (imoto nokushayela) | ||

| Inombolo yezimbazo zokulawula | 5-axis ukugaya kanyekanye nokuphenduka ngasikhathi sinye (i-NC axis + spindle, BC axis) | ||

| Ukulawula ngesikhathi esisodwa kwezimbazo ezi-5 Ukugaya ngesikhathi esisodwa nokuphenduka | i-eksisi yokuma | Okujwayelekile X, Y, Z, B, C | |

| ukutolika | umugqa oqondile | X, Y, Z, B, C izimbazo (X, Y, Z, B, C zinganxeshezelwa) | |

| i-arc | X, Y, Z, B, C izimbazo (X, Y, Z, B, C zinganxeshezelwa) | ||

| Iyunithi yemiyalelo encane | 0.001um | ||

| ubuncane beyunithi yokulawula | 0.1nm | ||

| Bonisa | 19LCD | ||

| Imoto | Amandla okulayishwa okuphindwe kathathu ngesifaki khodi esiphelele (indawo yesifaki khodi ayilokothi ilahleke) | ||

| Umsebenzi wokuxhumana wangaphandle | I-Ethernet ne-RS232C interface | ||

| Imodi yokusebenza | I-MDI, Okuzenzakalelayo, Imanuwali, Isondo Lesandla, Umsuka (absolute), REPOS | ||

| ngokohlelo | Umhleli wolimi we-ISO eku-inthanethi | ||

| Umthamo omkhulu wesitoreji sokuhlela we-PLC | 2048 KB | ||

| Umsebenzi wokuhumusha | Imigqa eqondile, imibuthano phakathi nendawo, ama-spirals, izindawo ezinhle, izilungiselelo zesivinini esikhulu, njll. | ||

| Inombolo yokususwa kwamathuluzi | 512 amaqembu | ||

| Ukukhulisa isondo lesandla | 0.1/0.01/0.001mm | ||

| Ubuncane bokusetha namayunithi anyakazayo | 1um/X,Y,Z | ||

| ukulondoloza idatha | Idatha yememori ayisoze yalahleka lapho kucishwa amandla | ||

| isilinganiso sokuphakelayo | 0%-150% | ||

| Ukukhulisa phambili ngokushesha | 0%-100% | ||

| Okokufaka nokukhiphayo | I-Ethernet kanye ne-RS232C interface, ikhadi le-CF, ikhophi yasenqolobaneni ye-USB | ||

| ulimi lokubonisa | IsiShayina nesiNgisi | ||

Ubuningi bokucushwa obujwayelekile

| No | Igama lensiza | iyunithi | Qty |

| 1 | unyawo lokulawula ukushintsha | setha | 1 |

| 2 | I-Hydraulic clamping mechanism | setha | 1 |

| 3 | Idivayisi Yokugcobisa Ephakathi | setha | 1 |

| 4 | uhlelo lokupholisa | setha | 1 |

| 5 | isibani esisebenzayo | setha | 1 |

| 6 | Ukukhanya okunemibala emithathu | setha | 1 |

| 7 | ibhuloho elivundlile | Ama-PC | 1 |

| 8 | Ukulungiswa kwamathuluzi omshini | setha | 1 |

| 9 | Iphakheji Yethuluzi Elijwayelekile | setha | 1 |

| 10 | Ilokhi yomnyango wezokuphepha | setha | 1 |

| 11 | isisekelo kit | setha | 1 |

| 12 | Faka ithuluzi lokulungisa | setha | 1 |

| 13 | Ukuthepha okuqinile kanye nokuma kwamaphuzu amaningi okuphotha | setha | 1 |

| 14 | Umshini wokuhambisa isikulufu kanye nomshini wokukhipha ama-chip othomathikhi | setha | 1 |

| 15 | Isistimu ye-hydraulic ejwayelekile | setha | 1 |

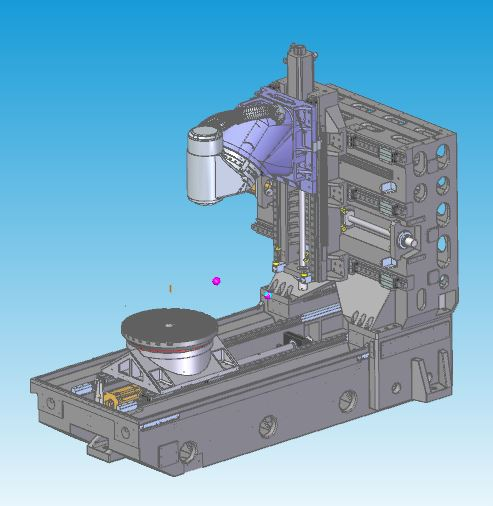

Izici Zokuklama | Idizayini engcono kakhulu yokuhlaziya ukusakaza kwentambo yomshini

Ibhokisi eligcwele lesakhiwo sokusakaza se-thermosymmetric, kusetshenziswa insimbi yensimbi yezinga eliphezulu ye-Meehanna

Ukushisa kanye nokwelashwa kokuguga kwemvelo ukuze kuqedwe ukucindezeleka kwangaphakathi

Ukudlidliza kwemvamisa yemvelo yesakhiwo kuqeda ingcindezi yokucubungula izinto

Idizayini yekholomu yendawo enkulu eqinile enodonga olugcwele, ithuthukisa ngempumelelo ukuqina nokunemba okumile nokuguquguqukayo

Idrayivu yokupholisa eyisikulufu esinama-eksisi amathathu

Ikhanda lokugaya i-CNC (i-axis B)

Izici Zokuklama

Eyakhelwe ngaphakathi i-DD motor zero transmission chain akukho mklamo wokubuyela emuva

Izici zokusheshisa okuphezulu

Isikhathi esifushane kakhulu phakathi kwephuzu lekhala lethuluzi lephoyinti lokuphotha kanye nendawo yokusekela yesakhiwo sibona ukuqina okukhulu kokusika.

Amabheringi amakhulu e-YRT akhuphula ukuqina

Ifakwe isistimu yokulinganisa ye-HEIDENHAIN enembayo ephezulu, isilawuli seluphu evalwe ngokugcwele ukuze kuqinisekiswe ukunemba okungcono kakhulu.

Idizayini yesistimu yokupholisa ye-spindle ne-B-axis ukunciphisa ukudluliswa kokushisa

Ithebula elijikelezayo (i-C axis)

Izici Zokuklama

Eyakhelwe ngaphakathi i-DD motor zero transmission chain akukho mklamo wokubuyela emuva

Ukusheshisa okuphezulu kanye nezici zokuphendula zokwehlisa amandla

Amabheringi amakhulu e-YRT akhuphula ukuqina

I-torque enkulu yokushayela elinganiselwe, ukuma nokucutshungulwa ngokuma kwetafula kanye nedivayisi yokubopha

Hlangana nezidingo ezimbili zokucubungula zokugaya nokugaya, ukunciphisa ukuphatha izingcezu zokusebenza futhi uthuthukise ukunemba komkhiqizo

Ifakwe isistimu yokulinganisa ye-HEIDENHAIN enembayo ephezulu, isilawuli seluphu evalwe ngokugcwele ukuze kuqinisekiswe ukunemba okungcono kakhulu.

Idizayini yesistimu yokupholisa ukunciphisa ukudluliswa kokushisa

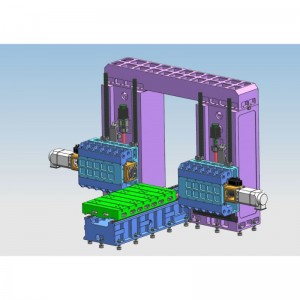

Isetha samathuluzi esiphakanyiswayo

Izici Zokuklama

Ifakwe i-Ransishaw NC4F230 isethi yamathuluzi e-laser engathinteki ukuze uthole ukunemba okuphezulu

Ukusetha ithuluzi okuzenzakalelayo emshinini, isibuyekezo esizenzakalelayo sesinxephezelo samathuluzi

Idivayisi yokusetha ithuluzi ingaphakanyiswa futhi yehliswe ukuze konge isikhala sendawo yokucubungula

Idizayini yensimbi yeshidi evalwe ngokugcwele ivikela isethi yamathuluzi emanzini nensimbi ngesikhathi sokucubungula

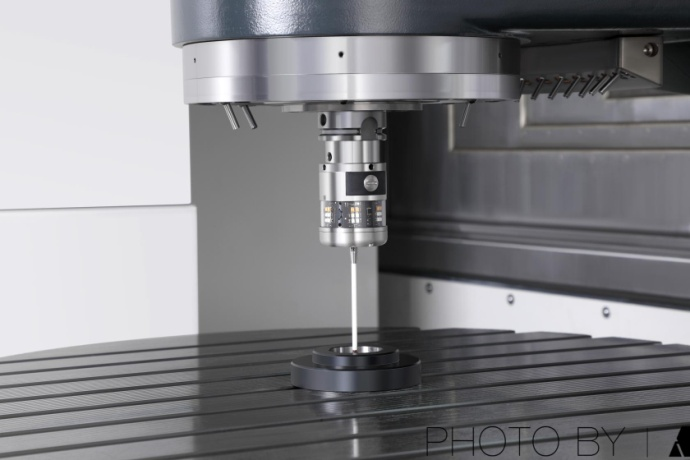

I-infrared probe

Izici Zokuklama

Ifakwe i-Ransishaw OMP60 optical touch probe

Ukuqondanisa komshini wokusebenza emshinini nokuhlolwa kosayizi, kunciphisa amaphutha okuhlola okwenziwa ngesandla, kuthuthukisa ukunemba komkhiqizo nokusebenza kahle kokucubungula

90% ukonga ngesikhathi sosizo emshinini