Uhlobo lwe-Gantry Umshini Wokubhoboza Nowokugaya we-CNC

I-CNC Gantry Milling And Drilling Machine

I-Gantry Drilling And Milling Machine

Umshini Wokugaya we-CNC Gantry

Isicelo somshini

I-BOSM gantry mobile CNC uchungechunge lwemishini yokugaya ngesivinini esiphezulu kanye nomshini wokugaya isetshenziselwa ikakhulukazi ukubhola nokusebenza kahle kwamapuleti amakhulu, ama-flange amandla omoya, ama-discs, izingxenye zendandatho nezinye izinto zokusebenza ezinogqinsi ngaphakathi kwebanga elisebenzayo. Ukubhoboza emigodini nezimbobo eziyimpumputhe kungenziwa ezingxenyeni zempahla eyodwa kanye nezinto eziyinhlanganisela. Inqubo yokwenza imishini yethuluzi lomshini ilawulwa ngedijithali, futhi ukusebenza kulula kakhulu. Ingakwazi ukubona i-automation, ukunemba okuphezulu, izinhlobo eziningi kanye nokukhiqizwa okukhulu. Ukuze kuhlangatshezwane nezidingo zokucubungula zabasebenzisi abahlukene, inkampani ithuthukise imikhiqizo ehlukahlukene ephothuliwe. Ngaphezu kwamamodeli ajwayelekile, angabuye aklanywe futhi enziwe ngokwezifiso ngokuya ngezidingo zangempela zabasebenzisi.

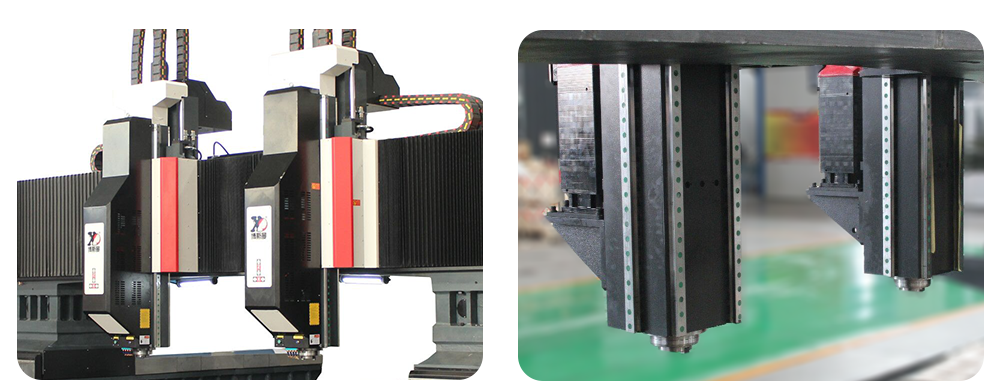

Isakhiwo somshini

Lezi zisetshenziswa ikakhulukazi ziqukethe izinto zokusebenzisa umbhede, i-gantry ehambayo, isihlalo sesihlalo esishibilikayo, ikhanda lamandla okubhola nelokugaya, idivayisi yokuthambisa ezenzakalelayo kanye nedivayisi yokuvikela, idivayisi ejikelezayo yokupholisa, isistimu yokulawula idijithali, isistimu kagesi, njll. i-lead screw pair drive, ithuluzi lomshini linokunemba kokuma okuphezulu nokuphinda ukunemba kokuma.

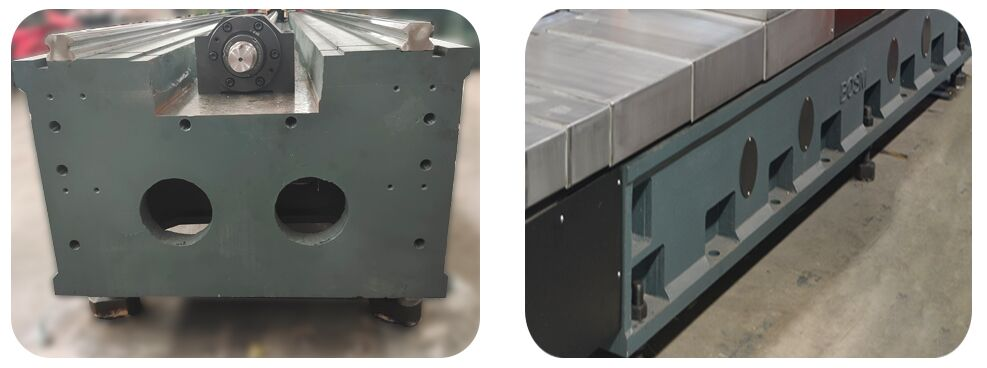

1)Ithebula lokusebenza:

Umbhede uyi-cast-piece eyodwa, oqedwe ngemva kokwelashwa kokuguga kwesibili kanye nokudlidliza, enokuqina okuhle okuguquguqukayo nokumile futhi akukho kuguqulwa. Kukhona ama-T-slots anesakhiwo sokuqedela esinengqondo endaweni yetafula elisebenzayo lokuhlanganisa ama-workpieces. Isisekelo sombhede sifakwe iziqondiso eziqondile eziqondile ezi-2 (ezi-4 nhlangothi zombili seziphelele), ukuze isilayidi somhlahlandlela sigcizelelwe ngokulinganayo, okuthuthukisa kakhulu ukuqina kwethuluzi lomshini kanye nokuqina kwalo nokumelana nokucindezela. Uhlelo lokushayela lwamukela ama-AC servo motors kanye namapheya e-screw amabhola. I-Side drive yenza i-gantry ihambe iye ohlangothini lwe-X-axis. Amabhawodi alungisekayo asatshalaliswa endaweni engaphansi yombhede, engalungisa kalula izinga letafula lokusebenza lombhede.

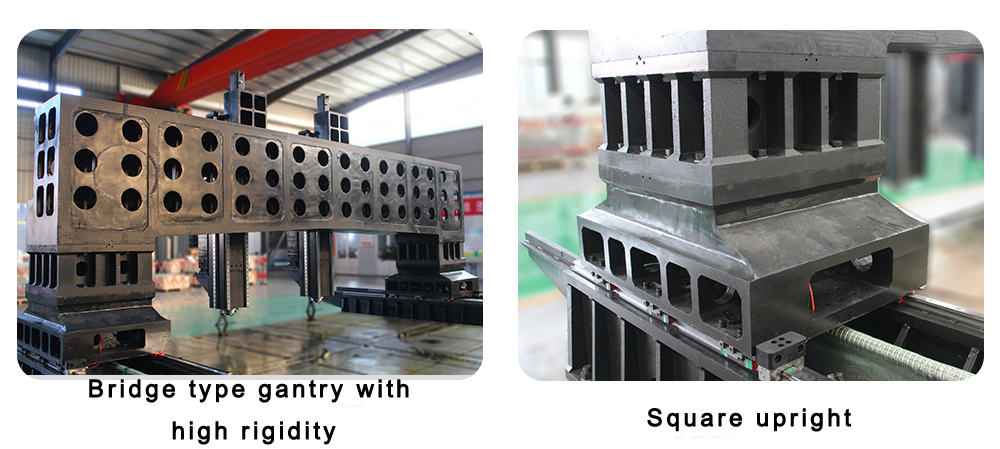

2)Moi-vinggantry:

I-gantry ehambayo iphonswa futhi icutshungulwe ngensimbi empunga (HT250). Amapheya amabili omugqa angama-55# anamandla okuthwala aphezulu afakwe ohlangothini olungaphambili lwe-gantry. Isethi yokunemba kokupheya kwesikulufu sebhola kanye ne-servo motor yenza ikhanda lamandla lishelele ukuze lihambe liye ku-Y-axis, futhi ikhanda lamandla okubhola lifakwa kusilayidi sekhanda lamandla. Ukunyakaza kwe-gantry kubonakala ngokuzungezisa i-screw nut yebhola kusikulufa sebhola esishayelwa yi-servo motor ngokusebenzisa ukuhlanganisa okunembayo.

3)Moi-vingisihlalo sesihlalo:

Isihlalo sehhashi esishelelayo siyisakhiwo sensimbi esakhiwe ngokunemba. Isihlalo sesihlalo esishelelayo sifakwe amaslayidi kajantshi wesitimela we-CNC athwele umthwalo ophezulu kakhulu, isethi yamapheya esikulufu esinembayo kanye nesinciphisi seplanethi esinembe kakhulu esixhunywe kunjini ye-servo, futhi ifakwe isilinda se-nitrogen Balance, bhalansisa isisindo ikhanda lamandla, yehlisa umthwalo wesikulufu sokuhola, inwebe impilo yesikulufu sokuhola, shayela ikhanda lamandla okubhola ukuze liye ohlangothini lwe-axis engu-Z, futhi ubone ukusheshisa ukuya phambili, ukusebenzela phambili, ukuhlehla ngokushesha, nokumisa izenzo ze ikhanda lamandla, ngokuphuka kwe-Chip okuzenzakalelayo, ukususwa kwe-chip, umsebenzi wokumisa isikhashana.

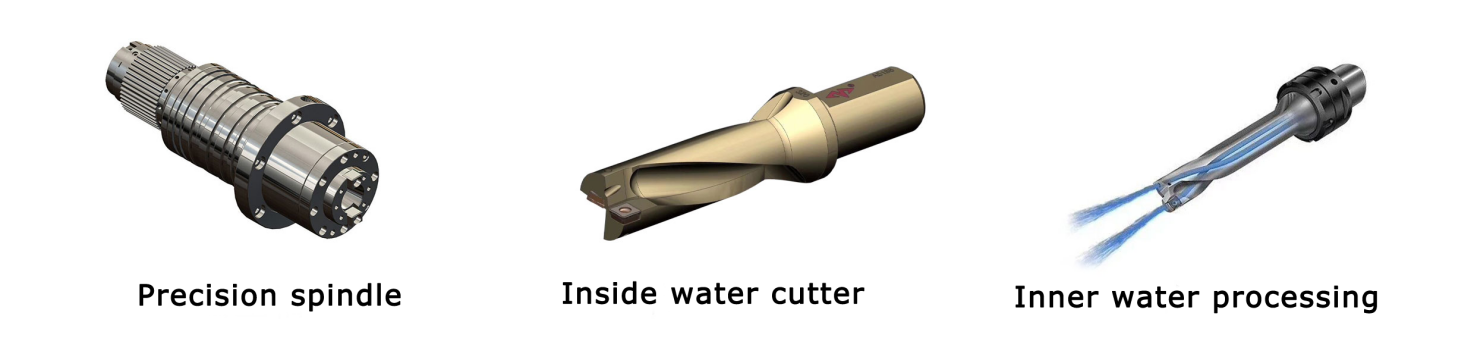

4)Ikhanda lamandla okumba(Spindle):

Ikhanda lamandla okumba lamukela i-servo spindle motor, eshayelwa ukuncishiswa kwebhande le-toothed synchronous ukwandisa i-torque futhi ishayela ukuphotha okuqondile okuzinikele. I-spindle ithatha ezine zokuqala nengemuva imigqa emibili eyisithupha yama-angular contact bearings ase-Japan ukuze kuzuzwe ushintsho lwejubane olungenasinyathelo. I-spindle ifakwe uhlelo lokushintsha ithuluzi lomoya ukwenza ithuluzi Ukushintshwa kuyashesha futhi kulula, futhi okuphakelayo kushayelwa injini ye-servo kanye nesikulufu sebhola. Izimbazo zika-X kanye no-Y zingaxhunywa, kusetshenziswa isilawuli se-loop esivalwe kancane, esikwazi ukubona imisebenzi yokuhumusha ngomugqa neyindilinga. I-spindle end iyimbobo ye-taper ye-BT50, efakwe ijoyinti elijikelezayo le-Italian Rotofors elinesivinini esikhulu, elingasetshenzwa isikhungo sokumba i-U esinesivinini esikhulu.

4.1 Umzimba webhokisi kanye netafula elishelelayo lekhanda lamandla okubhola zenziwe ngokulingisa ukuze kuthuthukiswe ukuqina kwazo nokuzinza, nokunciphisa ukudlidliza nomsindo.

4.2 Ithuluzi lomshini lingasebenza ngesondo lesandla le-elekthronikhi; ukuze wonge isikhathi futhi uthuthukise ukusebenza kahle kokukhiqiza ngesikhathi sokucubungula, ngemuva kokumba imbobo yokuqala yokusetha indawo yokuphakelayo, ukubhoboza izimbobo ezisele zohlobo olufanayo kungafinyelela phambili ngokushesha → umsebenzi kusengaphambili → ukuhlehla okusheshayo Kufanele futhi kube nemisebenzi efana ne-automatic chip. ukuphuka, ukususwa kwe-chip, nokumisa isikhashana.

4.3 Inqama ifakwe isistimu yebhalansi ye-nitrogen ewuketshezi ukuze yehlise umthwalo we-axis engu-Z futhi ikhulise impilo yesevisi yesikulufu se-Z-axis.

4.4 I-Z-axis servo motor isebenzisa i-power-off brake motor, ezobamba ibhuleki lapho ugesi unqanyulwa kungazelelwe ukugwema izingozi ezibangelwa ukuwa kwebhokisi lokuphotha.

4.5 I-Headstock

4.5.1. Ibhokisi le-shaft eliyinhloko lamukela iziqondiso ezine ezisindayo, ezinokuqina okuphezulu kokunyakaza, ukunemba kokuma okuphezulu, nokuzinza okuhle kwesivinini esiphansi.

4.5.2. I-Z-axis drive-i-servo motor ixhunywe ngokuqondile kusikulufa sebhola ngokusebenzisa ukuhlangana, futhi isikulufu sebhola sishayela isigxobo sekhanda ukuthi siye phezulu naphansi kwisihlalo sehhashi ukuze sibone okuphakelayo kwe-axis engu-Z. I-Z-axis motor ine-automatic brake function. Uma kwenzeka ukwehluleka kwamandla, i-motor shaft ibanjwe ngokuqinile ukuze ivimbele ukuthi ingajikelezi.

4.5.3. Iqembu lokuphotha lamukela i-Taiwan Jianchun yokuphotha amanzi yangaphakathi enesivinini esiphezulu, esinokunemba okuphezulu nokusebenza okuphezulu. I-shaft eyinhloko ibamba ummese nge-butterfly spring ku-shaft eyinhloko ngamandla acindezelayo asebenza esikhonkwaneni sokudonsa sesibambo sethuluzi ngomshini we-broach onezingxenye ezine, futhi ithuluzi elixegayo lisebenzisa indlela yomoya.

5)Idivayisi yokugcoba okuzenzakalelayo kanye nedivayisi yokuzivikela:

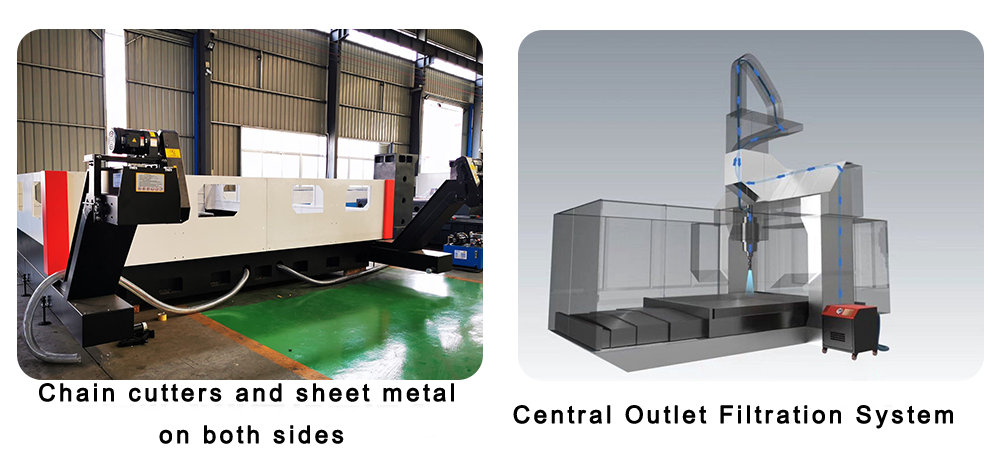

Kukhona i-automatic chip conveyor ezinhlangothini zombili zebhentshi lokusebenzela kanye nesihlungi ekugcineni. I-automatic chip conveyor iwuhlobo lwamaketango ayisicaba. Olunye uhlangothi lufakwe iphampu yokupholisa, futhi i-outlet ixhunywe ohlelweni lokuhlunga amanzi oluphakathi ngepayipi. , Isipholile sigelezela kusidluliseli se-chip, iphampu yokuphakamisa i-chip impompa isipholile kusistimu yesihlungi se-outlet emaphakathi, futhi iphampu yokupholisa enomfutho ophezulu izungeza isipholile esihlungiwe ekupholiseni kokumba ukupholisa nge-spindle. Iphinde ifakwe i-chip transport trolley, elula kakhulu ukuthutha ama-chips. Lokhu okokusebenza kufakwe amasistimu okupholisa amathuluzi angaphakathi nangaphandle. Uma kusetshenziswa ukubhola ngesivinini esikhulu, ukupholisa kwangaphakathi kwethuluzi kusetshenziswa, futhi ukupholisa kwangaphandle kusetshenziselwa ukugaya ukukhanya.

5.1. Isistimu yokuhlunga amanzi ephuma emaphakathi:

Leli thuluzi lomshini lifakwe isistimu yesihlungi samanzi esimaphakathi, esingasefa ngempumelelo ukungcola endaweni epholile. Uhlelo lwangaphakathi lwesifutho samanzi lungavimbela izikhonkwane zensimbi ukuthi zingabambeki ethuluzini phakathi nokucubungula, ukunciphisa ukuguga kwamathuluzi, ukunweba ukuphila kwamathuluzi, futhi kuthuthukise ukuqedwa kwendawo yokusebenza. Iphinikhodi yokukhipha amanzi enomfutho ophezulu wethuluzi ingavikela kahle indawo yokusebenza, ivikele ijoyinti elijikelezayo elinesivinini esikhulu, ivimbele ukungcola ekuvimbeni ilunga elijikelezayo, futhi ithuthukise ikhwalithi yesiqeshana sokusebenza sisonke, futhi ithuthukise ukusebenza kahle komsebenzi.

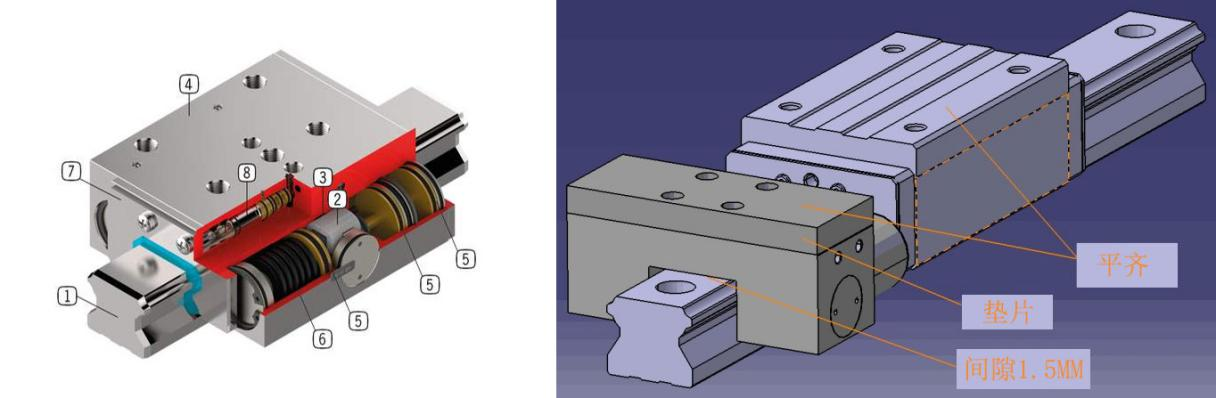

6)I-Linear Clamper:

I-clamp yakhiwe indikimba eyinhloko ye-clamp, ama-actuator, njll. Iyingxenye esebenza kahle kakhulu esetshenziswa ngokuhambisana nokupheya komugqa womugqa ogoqayo. Ngokusebenzisa isimiso sokunwetshwa kwe-wedge block force, ikhiqiza amandla okubamba aqinile; ine-gantry engaguquki, ukuma okunembile, i-anti-vibration kanye nomsebenzi wokuthuthukisa ukuqina.

Inezici ezilandelayo:

Amandla okubamba aphephile futhi athembekile, aqinisa i-eksisi ye-XY enganyakazi phakathi nokubhoboza nokuthepha.

Amandla okubamba aphakeme kakhulu anyusa ukuqina kokuphakelayo kwe-axial futhi avimbele ukukhathazeka okubangelwa ukudlidliza.

Ukusabela okusheshayo, isikhathi sokuphendula sokuvula nokuvala singamasekhondi angu-0.06 kuphela, esingavikela ithuluzi lomshini futhi andise impilo yesikulufu sokuhola.

Indawo ehlala isikhathi eside, ene-nickel-plated, ukusebenza okuhle kwe-anti-rust.

Idizayini yenoveli yokugwema umthelela oqinile lapho uqina.

7)Ukuma kanye nokuqiniswa kwe-workpiece

Ukuze i-workpiece ye-flange eyindilinga iqondaniswe, ingabekwa ngokungafanele epuletini lokusekela eline-T-slots, futhi indawo emaphakathi ikalwa ngesitholi sonqenqema esifakwe embotsheni ye-spindle taper kunoma yimaphi amaphuzu amathathu (ububanzi bangaphakathi noma ububanzi bangaphandle) kucezu lokusebenza. . Ngemuva kwalokho, itholakala ngokuzenzakalelayo ngokubala kohlelo lokulawula izinombolo, olunembile futhi olusheshayo. I-clamping ye-workpiece iboshwe nge-clamp eyakhiwe ipuleti lokucindezela, induku ye-ejector, induku yokubopha kanye ne-cushion block, okulula ukuyisebenzisa.

8)Idivayisi yokugcoba ngokuzenzakalelayo

Leli thuluzi lomshini lifakwe i-Taiwan's original volumetric partial lubrication lubrication device, engakwazi ukugcoba ngokuzenzakalelayo amapheya ahlukahlukene anyakazayo njengama-guide rails, izikulufu zokuhola, amarack, njll., ngaphandle kweziphetho ezifile, futhi iqinisekise impilo yesevisi yethuluzi lomshini. Ama-rails aqondisayo ezinhlangothini zombili zombhede womshini afakwe izembozo zokuzivikela zensimbi engenasici, futhi izinhlangothi zombili zekhanda lamandla e-gantry ezihambayo zifakwe izembozo zokuzivikela eziguquguqukayo. Onogada be-splash abangangeni amanzi bafakwe eduze kwetafula lokusebenza, futhi ulayini wepayipi lamanzi uvikelwe iketango lokudonsa lepulasitiki. Ikhethini elithambile le-PVC elikhanyayo lifakwe eduze kwe-spindle.

9)Isilawuli esigcwele sedijithali se-CNC:

9.1. Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

9.2. Ngomsebenzi wokuphakamisa ithuluzi, ubude bokuphakamisa ithuluzi bungasethwa kusixhumi esibonakalayo somshini womuntu. Uma ubhoboza lokhu kuphakama, i-drill bit iphakanyiselwa ngokushesha phezulu kwe-workpiece, bese i-shavings, bese iya phambili ngokushesha endaweni yokubhoboza bese iguqulwa ngokuzenzakalelayo ibe yisiphakeli somsebenzi.

9.3. Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ephathwa ngesandla yamukela isistimu yokulawula izinombolo, futhi ifakwe isixhumi esibonakalayo se-USB nesibonisi sekristalu esiwuketshezi se-LCD. Ukuze kube lula ukuhlela, ukugcinwa, ukuboniswa nokuxhumana, okusetshenziswa kubonwa kunemisebenzi efana nengxoxo yomshini womuntu, isinxephezelo samaphutha, ne-alamu ezenzakalelayo.

9.4. Imishini inomsebenzi wokuhlola kuqala nokuhlola kabusha indawo yembobo ngaphambi kokucubungula, okulula kakhulu ukusebenza.

10)Isitholi se-Optical edge:

Imishini ifakwe isitholi se-photoelectric edge, esingathola isikhundla se-workpiece kalula futhi ngokushesha.

1) Faka isitholi sonqenqema ku-spindle chuck yethuluzi lomshini, bese uzungezisa kancane kancane i-spindle ukuze ulungise ukugxila kwayo.

2) Hambisa i-spindle ngesondo lesandla, ukuze unqenqema lwebhola lensimbi yesitholi sonqenqema lithinte ucezu lokusebenza kancane, futhi ukukhanya okubomvu kuvuliwe. Ngalesi sikhathi, i-spindle ingayiswa phambili nangemuva ngokuphindaphindiwe ukuze kutholwe iphoyinti elingcono kakhulu lapho unqenqema lwebhola lensimbi lesitholi sonqenqema lithinta ucezu lokusebenza. .

3) Rekhoda amanani e-eksisi u-X no-Y aboniswe uhlelo lwe-CNC ngalesi sikhathi, bese ugcwalisa ikhompuyutha.

4) Thola amaphuzu amaningi okuthola ngale ndlela

11)I-alamu yokugqoka ithuluzi

I-alamu yokugqoka ithuluzi ithola ngokuyinhloko ukusebenza kwenjini yokuphotha. Uma i-current idlula inani elisethiwe, idivayisi ihlulela ngokuzenzakalelayo ukuthi ithuluzi ligugile, futhi i-spindle izohoxisa ithuluzi ngokuzenzakalelayo ngalesi sikhathi, futhi uhlelo oluzenzakalelayo luzophela. Khumbuza opharetha ukuthi ithuluzi seligugile.

12)I-alamu yezinga lamanzi aphansi

1) Uma isipholile esisefini sisezingeni eliphakathi, isistimu ixhumeka ngokuzenzakalelayo enjini ukuze iqale, futhi okokupholisa ku-chip conveyor kugeleza ngokuzenzakalelayo kusihlungi. Uma ifika ezingeni eliphezulu, injini iyayeka ukusebenza ngokuzenzakalelayo.

I-2) Uma i-coolant kusihlungi isezingeni eliphansi, isistimu izokwazisa ngokuzenzakalelayo i-gauge yezinga, i-spindle izohoxisa ithuluzi ngokuzenzakalelayo, futhi umshini uzoyeka ukusebenza.

13) Umsebenzi wenkumbulo yokucisha amandla

Ngenxa yokuma kokusebenza okubangelwa ukuhluleka kwamandla kungazelelwe, lo msebenzi ungathola ngokushesha futhi kalula indawo yembobo yokugcina ebhodliwe ngaphambi kokuhluleka kwamandla. Ama-opharetha angaqhubekela esinyathelweni esilandelayo ngokushesha, alondoloze isikhathi sokusesha.

Ukuhlolwa kwe-laser yama-axis amathathu:

Umshini ngamunye we-Bosman ulinganiswa ne-laser interferometer yenkampani yaseBrithani i-RENISHAW, futhi uhlola ngokunembile futhi unxephezele iphutha le-pitch, ukuhlehla, ukunemba kokuma, ukuphinda ukunemba kokuma, njll., ukuze kuqinisekiswe ukuguquguquka, ukuzinza okuqinile kanye nokunemba kokucubungula komshini. . Ukuhlolwa kwe-Ballbar Umshini ngamunye usebenzisa ibha yebhola yenkampani yaseBrithani i-RENISHAW ukulinganisa ukunemba kwendingilizi yangempela kanye nokunemba komshini kwejiyomethri. Ngesikhathi esifanayo, ukuhlolwa kokusika okuyindilinga kwenziwa ukuze kuqinisekiswe ukunemba komshini we-3D womshini kanye nokunemba kwendilinga.

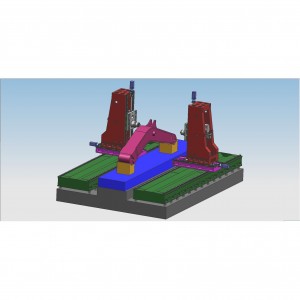

Isakhiwo seplathifomu, i-workpiece clamping, izidingo zokususwa kwe-chip ezizenzakalelayo

1. Ipulatifomu eyinhloko (ama-pcs angu-1): Isiqephu sokusebenza se-T-slot clamping. Kokubili indawo yokuphela engaphezulu kanye nendawo eseceleni yesikhulumi esikhulu ingasetshenziswa njengokucubungula izindawo zokuma.

2. Ipulatifomu yokucwila (ama-pcs angu-1): (uhlangothi lufakwe uhlaka olusizayo lokucindezela ukucindezela, futhi phezulu kufakwe isembozo sokuzivikela esigcwele, esiklanywe futhi sifakwe umdayisi), indawo eyinhloko yokubeka i-workpiece nemiyalo yokucubungula:

Ukucutshungulwa kwekhava yevalvu: ukumiswa kweplatifomu engezansi (isibambo esisekela esiphansi kanye nezingxenye zokusebenza ezinosayizi abahlukene), ipuleti lokucindezela eliphezulu lilungiswa ngokucindezela noma umdayisi uklama idivayisi yokugoqa phezulu ezenzakalelayo.

Ukucutshungulwa komzimba we-valve: ukuma kweplatifomu engezansi (izibambo ezisekela phansi nezinsimbi zosayizi abahlukene), izibambo eziseceleni zekholomu eyisisizi yeplathifomu ephansi kanye nezinduku zokukhipa ezimise okwe-L ziyacindezelwa futhi ziyalungiswa noma umdayisi uklama okuzenzakalelayo okungaphezulu. idivayisi yokubopha.

Ukucaciswa

| Imodeli | I-BOSM-DS3030 | I-BOSM-DS4040 | I-BOSM-DS5050 | I-BOSM-DS6060 | |

| Usayizi Wokusebenza | ubude*ububanzi | 3000*3000 | 4000*4000 | 5000*5000 | 6000*6000 |

| Inhloko Yokubhoboza Emile | I-spindle taper | I-BT50 | |||

| Ububanzi Bokubhoboza (mm) | φ96 | ||||

| Ukuthepha Ububanzi(mm) | M36 | ||||

| Isivinini se-Spindle (r/min) | 30 ~ 3000/60 ~ 6000 | ||||

| Spindle Motor Power (kw) | 22/30/37 | ||||

| Spindle Nose To Table Distance | Ngokusho kwesisekelo | ||||

| Phinda Ukunemba Kokumisa (X/Y/Z) | X/Y/Z | ±0.01/1000mm | |||

| Isistimu yokulawula | KND/GSK/SIEMENS | ||||

| Ithuluzi Lomagazini | Ithuluzi lomagazini we-Okada elinamathuluzi angu-24 njengokuzithandela | ||||

Ukuhlolwa Kwekhwalithi

Umshini ngamunye we-Bosman ulinganiswa nge-laser interferometer evela enkampanini ye-RENISHAW yase-United Kingdom, ehlola ngokunembile futhi inxephezele amaphutha e-pitch, ukuhlehla, ukunemba kokuma, nokunemba kokuma okuphindaphindiwe ukuze kuqinisekiswe ukuguquguquka komshini, ukuzinza okumile, kanye nokunemba kokucubungula. . Ukuhlolwa kwebha yebhola Umshini ngamunye usebenzisa isihloli sebha yebhola esivela enkampanini yaseBrithani i-RENISHAW ukuze ulungise ukunemba kwendingilizi yeqiniso kanye nokunemba komshini wejometri, futhi wenze izivivinyo zokusika eziyindilinga ngesikhathi esifanayo ukuze kuqinisekiswe ukunemba komshini we-3D womshini kanye nokunemba kwendingilizi.

Indawo yokusebenzisa ithuluzi lomshini

1.1 Izidingo zemvelo yezinto zokusebenza

Ukugcina izinga elingaguquki lezinga lokushisa le-ambient kuyisici esibalulekile sokwenza imishini enembile.

(1) Izinga lokushisa le-ambient elitholakalayo ngu- -10 ℃ ~ 35 ℃. Lapho izinga lokushisa le-ambient lingama-20 ℃, umswakama kufanele ube ngu-40 ~ 75%.

(2) Ukuze kugcinwe ukunemba okumile kwethuluzi lomshini ngaphakathi kwebanga elishiwo, izinga lokushisa elifanele le-ambient liyadingeka ukuthi libe ngu-15 ° C kuya ku-25 ° C nomahluko wokushisa.

Akufanele idlule ± 2 ℃ / 24h.

1.2 I-voltage yokuphakelwa kwamandla: 3-isigaba, 380V, ukushintshashintsha kwamandla kagesi ngaphakathi ± 10%, imvamisa yokuphakelwa kwamandla: 50HZ.

1.3 Uma i-voltage endaweni esetshenziswayo ingazinzile, ithuluzi lomshini kufanele lifakwe ugesi olawulwayo ukuze kuqinisekiswe ukusebenza okuvamile kwethuluzi lomshini.

1.4. Ithuluzi lomshini kufanele libe nomhlabathi othembekile: intambo yaphansi iyintambo yethusi, ububanzi bocingo akufanele lube ngaphansi kuka-10mm², futhi ukumelana nomhlabathi kungaphansi kuka-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuvamile kwemishini, uma umoya ocindezelwe womthombo womoya wehluleka ukuhlangabezana nezidingo zomthombo womoya, isethi yamadivayisi okuhlanza umthombo womoya (ukukhipha umswakama, ukwehlisa, ukuhlunga) kufanele kwengezwe ngaphambi kokukhishwa kwemishini. ukungena komoya womshini.

1.6. Izinto ezisetshenziswayo kufanele zigcinwe kude nelanga eliqondile, ukudlidliza nemithombo yokushisa, futhi kude namajeneretha anemvamisa ephezulu, imishini yokushisela kagesi, njll., ukuze kugwenywe ukwehluleka kokukhiqiza umshini noma ukulahlekelwa ukunemba komshini.

Ngaphambi Nangemuva Kwesevisi

1) Ngaphambi Kwesevisi

Ngokutadisha isicelo nolwazi oludingekayo oluvela kumakhasimende bese impendulo konjiniyela bethu, ithimba le-Bossman Technical linesibopho sokuxhumana nobuchwepheshe namakhasimende kanye nokwakhiwa kwezixazululo, ukusiza ikhasimende ekukhetheni isixazululo esifanele somshini kanye nemishini efanelekile.

2) Ngemva Kwesevisi

A.Umshini onewaranti yonyaka owodwa futhi okhokhelwe ukunakekela impilo yonke.

B. Phakathi nenkathi yewaranti yonyaka owodwa ngemva kokuba umshini ufikile echwebeni lapho uya khona, i-BOSSMAN izohlinzeka ngezinsizakalo zokunakekela zamahhala nezifika ngesikhathi zamaphutha ahlukahlukene angenziwanga umuntu emshinini, futhi ibuyisele ngesikhathi zonke izinhlobo zezingxenye zomonakalo ongenziwanga ngumuntu mahhala. yenkokhiso . Ukwehluleka okwenzeka ngesikhathi sewaranti kuzolungiswa ngezindleko ezifanele.

Ukusekelwa kwe-C.Technical emahoreni angama-24 ku-inthanethi, i-TM, i-Skype, i-E-mail, ukuxazulula imibuzo ehlobene ngesikhathi. uma ingeke ixazululwe, i-BOSSMAN izohlela ngokushesha ukuthi unjiniyela wangemuva kokuthengisa afike esizeni ukuze alungiswe, umthengi udinga ukukhokhela i-VISA, amathikithi ezindiza kanye nendawo yokuhlala.

Isizinda Sekhasimende