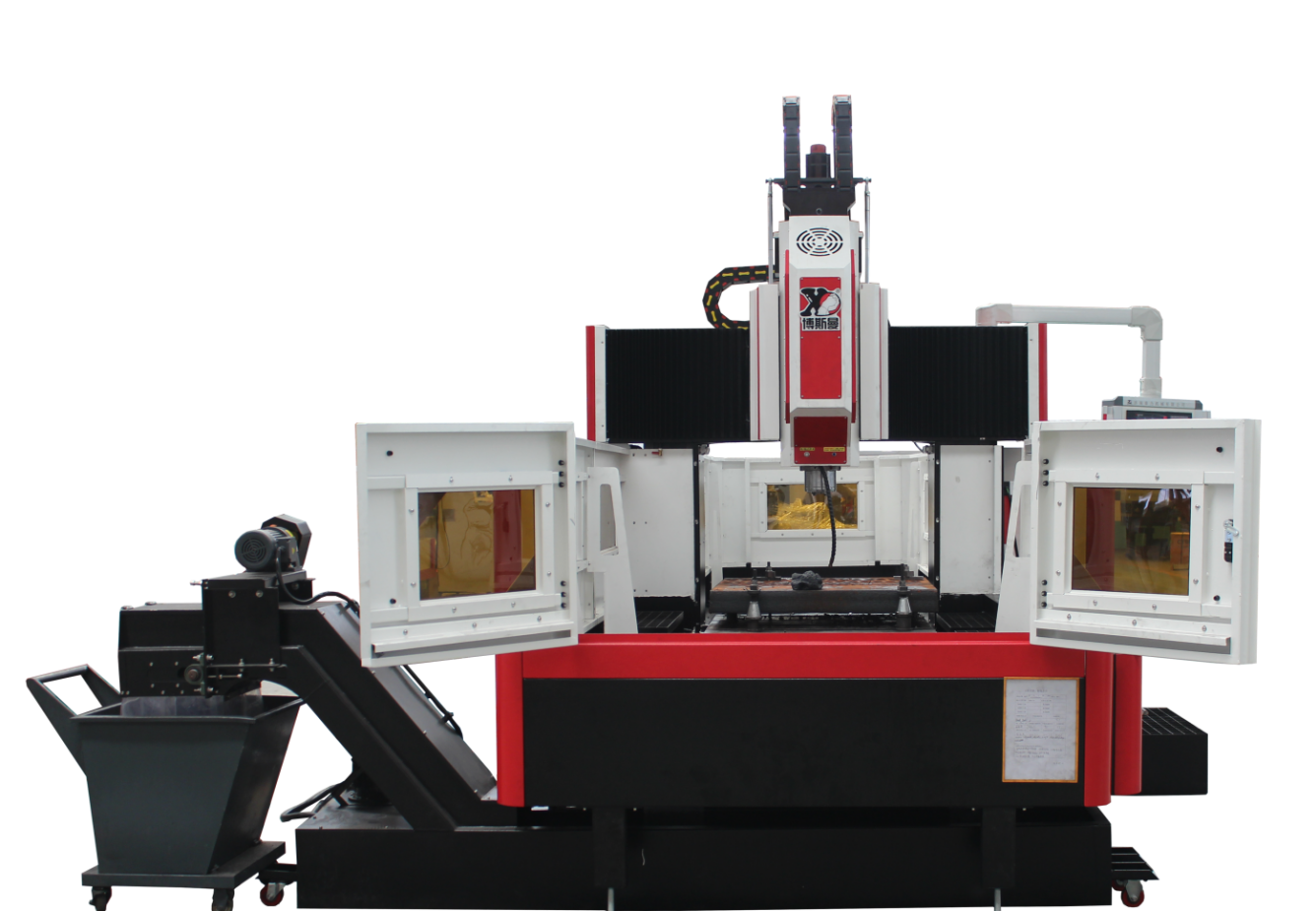

Umshini Wokubhoboza we-Beam CNC Olungisiwe kanye Nokugaya

I-CNC Drilling And Milling Machine

Umsebenzi Womshini Nencazelo Yesici

1) I-CNC gantry drilling kanye nomshini wokugaya iyimishini yokwenza ehlanganisa ubuchwepheshe obuthuthukisiwe obufana nemishini, ugesi, kanye nama-hydraulics. Isetshenziselwa ikakhulukazi ukucubungula isikhunta, ama-flanges, ama-valve, izingxenye zesakhiwo njll. Isetshenziswa kakhulu ekulungiseni nasekuqedeni izingxenye eziyinkimbinkimbi njengamapuleti ahlukahlukene, amabhokisi, amafreyimu, isikhunta njll. embonini yokukhiqiza imishini. Leli thuluzi lomshini lingakwazi ukubona ukunyakaza okuvundlile (i-eksisi ye-Y) nokuma mpo (i-axis engu-Z) kwekhanda lokugaya eliqondile kanye nethebula Ukuxhumanisa kwe-Three-eksisi yokunyakaza kwe-longitudinal (i-eksisi engu-X). Ukucutshungulwa kwezinqubo eziningi ezifana nokugaya, ukubhora, ukubhola, ukuthepha okuqinile, ukulungisa kabusha, kanye nokucwila kungenziwa. Wonke umshini wamukela uhlaka lohlaka lwe-gantry, olunokuqina okuphezulu nokugcinwa kokunemba okuhle. Kuyinketho yokuqala abasebenzisi abangayicubungula.

2) Ukwakheka okuphelele komshini

(1)Isakhiwo sefreyimu yohlobo lwe-gantry engashintshi siyamukelwa, umbhede ulungisiwe, futhi ikholomu ephindwe kabili nombhede kuxhunywe ngamabhawudi. Ithebula lokusebenza lihamba eksisi engu-X phezu kombhede, i-headstock ihamba iye ohlangothini luka-Z phezu kwesihlalo sehhashi, futhi isihlalo sehhashi nesigxobo sekhanda sihamba siye ku-Y ensikeni.

(2)Izingxenye ezinkulu ezinkulu zethuluzi lomshini: umbhede, ikholomu, ugongolo, isihlalo sehhashi, nesigxobo sekhanda konke kuyizinto eziqinile ezisansimbi ezisansimbi. Lezi zingxenye ezinkulu zilungiselelwe isofthiwe yekhompyutha ye-3D, enokwakheka okunengqondo kwezimbambo kanye nezinqubo eziphelele zokwelashwa kokushisa ukuze kuqedwe ingcindezi eyinsalela. , Ukuqinisekisa ukuthi wonke umshini unamandla anele, ukuqina nokuzinza okuphezulu, ukusika ukumelana nokudlidliza.

3 )Ibhentshi Lokulala

(1) Umbhede wenziwe ngensimbi eqinile engu-HT250 enamandla amakhulu, kusetshenziswa idizayini yokuthuthukisa eyisizwa ngekhompyutha enezinhlangothi ezintathu, izimbambo zihlelwe ngokufanele, futhi ukuqina namandla kwawo kuyathuthukiswa.

(2) Ipheya ye-X-axis guideway isebenzisa imihlahlandlela yomugqa osindayo engenisiwe, ene-coefficient ephansi eguqukayo nemile, ukuzwela kwetafula eliphezulu, ukudlidliza kwesivinini esiphansi, ukungakhaseki kwesivinini esiphansi, ukunemba kokuma okuphezulu, kanye nokusebenza okuhle kakhulu kwedrayivu ye-servo : ngesikhathi esifanayo, umthamo womthwalo mkhulu, futhi ukumelana nokudlidliza kokusika kuhle. .

(3) I-X-axis drive-injini ye-servo ixhunywe ngesikulufu sebhola ngesinciphisi, esishayela ithebula lokusebenza ukuya emuva naphambili embhedeni ukuze ibone ukunyakaza kokuphakelayo kwe-X kanye nokwelula kusengaphambili isikulufu ukuze kuthuthukiswe Ukuqina.

4) Ukukhanya

(1) I-crossbeam kanye nekholomu kuhlanganiswe nesakhiwo sefreyimu ye-gantry, kusetshenziswa insimbi enamandla kakhulu ye-HT250, izimbambo zihlelwe ngokufanele, futhi zinokugoba okwanele nokuqiniswa kwe-torsion.

(2) Ipheya yomhlahlandlela womugqa isebenzisa umhlahlandlela osindayo womugqa.

(3) Idrayivu ye-Y-axis-injini ye-servo ixhunywe ngokuqondile nesikulufu sebhola phakathi kokuhlangana, futhi isikulufu sebhola sishayela isihlalo sehhashi ukuze siye kwesokunxele nakwesokudla ebhilini ukuze sibone ukunyakaza kokuphakelayo kwe-Y-axis.

5)Ikhanda

(1) I-headstock isebenzisa umhlahlandlela womugqa we-roller osindayo, onokuqina okuphezulu kokunyakaza, ukunemba kokuma okuphezulu, nokuzinza okuhle kwesivinini esiphansi.

(2) I-Z-axis drive-injini ye-servo ixhunywe ngokuqondile kusikulufa sebhola ngokusebenzisa ukuhlangana, futhi isikulufu sebhola sishayela isigxobo sekhanda ukuthi siye phezulu naphansi kusihlalo ukuze sibone ukuphakela kwe-Z-axis. I-Z-axis motor ine-automatic brake function. Uma kwenzeka ukwehluleka kwamandla, i-motor shaft ibanjwe ngokuqinile ukuze ivimbele ukuthi ingajikelezi.

(3) Iqembu lokuphotha lamukela i-Taiwan Jianchun yokupholisa yangaphakathi enesivinini esiphezulu ngokunemba okuphezulu nokusebenza okuphezulu. I-shaft eyinhloko ibamba ummese nge-butterfly spring ku-shaft eyinhloko ngamandla acindezelayo asebenza esikhonkwaneni sokudonsa sesibambo sethuluzi ngomshini we-broach onezingxenye ezine, futhi ithuluzi elixegayo lisebenzisa indlela yomoya.

6)Isistimu ye-pneumatic

Isetshenziselwa ukukhulula ithuluzi lokuphotha.

7) Ukuvikelwa komshini

Isitimela sombhede (i-X axis) sithatha ikhava yokuvikela yensimbi engenasici;

I-beam guide (Y axis) isebenzisa ukuvikelwa kwesitho esivumelana nezimo.

8) Ukugcoba

(1) X, Y, Z ama-eksisi amathathu amabhere wonke agcotshwe ngamafutha.

(2) X, Y, Z imihlahlandlela yama-eksisi amathathu yonke igcotshwe ngamafutha.

(3) X, Y, Z amapheya wesikulufu sebhola le-eksisi emithathu wonke agcotshwe ngamafutha.

9) Uhlelo lwe-CNC

Uhlelo lwe-CNC lujwayelekile lufakwe uhlelo lokulawula lwe-Beijing Kaiendi nokushayela, olunemisebenzi ephelele nokusebenza okulula; isixhumi esibonakalayo esijwayelekile se-RS-232, isokhethi le-USB nesofthiwe ehlobene.

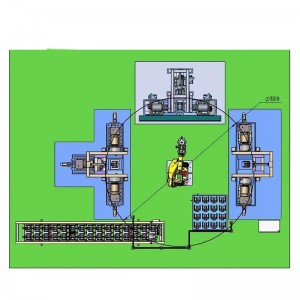

Uhlelo Lokuhlunga

Leli thuluzi lomshini lifakwe isistimu yesihlungi samanzi esimaphakathi, esingasefa ngempumelelo ukungcola endaweni epholile. Uhlelo lwangaphakathi lwesifutho samanzi lungavimbela izikhonkwane zensimbi ukuthi zingabambeki ethuluzini phakathi nokucubungula, ukunciphisa ukuguga kwamathuluzi, ukunweba ukuphila kwamathuluzi, futhi kuthuthukise isiphetho sendawo yokusebenza. Iphinikhodi yokukhipha amanzi yethuluzi elinomfutho ophezulu lingavikela kahle ingaphezulu lengxenye yokusebenza, livikele ijoyinti elijikelezayo elinesivinini esikhulu, livimbele ukungcola ekuvimbeni ijoyinti elijikelezayo, futhi lithuthukise ikhwalithi iyonke yesiqeshana sokusebenza futhi lithuthukise ukusebenza kahle komsebenzi. (Qaphela isithombe isithombe esibonakalayo sesistimu yokuhlunga)

Ukucaciswa

| Imodeli | I-BOSM-DPH2016 | I-BOSM-DPH2022 | I-BOSM-DPH2625 | I-BOSM-DPH4026 | |

| Usayizi wokusebenza(mm) | 2000*1600 | 2000*2000 | 2500*2000 | 4000*2200 | |

| I-Max.loading(Kg) | 7000 | 7000 | 7000 | 7000 | |

| I-T Slot(mm) | 8*22 | 8*22 | 8*22 | 8*22 | |

| Ubuningi bokuhamba kwe-table-X axis(mm) | 2200 | 2200 | 2600 | 4000 | |

| Umkhawulo wokuhamba we-table-Y axis(mm) | 1600 | 2200 | 2500 | 2600 | |

| I-spindle maximum stroke-Z axis(mm) | 600 | 600 | 600 | 600/1000 | |

| Ibanga ukusuka ekugcineni kokuphotha kuya kuthebula lokusebenza(mm) | Ubuningi | 800 | 800 | 800 | 800 |

| Ubuncane | 200 | 200 | 200 | 200 | |

| Tapper (7:24) | I-BT50 | I-BT50 | I-BT50 | I-BT50 | |

| Isivinini se-spindle(r/min) | 30 ~ 3000/60 ~ 6000 | 30 ~ 3000/60 ~ 6000 | 30 ~ 3000/60 ~ 6000 | 30 ~ 3000/60 ~ 6000 | |

| Amandla e-spindle motor (Kw) | 22 | 22 | 22 | 22 | |

| Ubukhulu. I-U-drill(mm) | φ90 | φ90 | φ90 | φ90 | |

| Ukuthepha okukhulu(mm) | M36 | M36 | M36 | M36 | |

| Ukusika ibanga lesivinini sokuphakelayo | 1 ~ 4000 | 1 ~ 4000 | 1 ~ 4000 | 1 ~ 4000 | |

| Ukunyakaza okusheshayo(m/min) | 2008/8/8 | 2008/8/8 | 2008/8/8 | 2008/8/8 | |

| Ukusetshenziswa kwamazinga kazwelonke GB/T18400.4(m/min) | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm | |

| Isisindo(T) | 16.5 | 21 | 24 | 40 | |

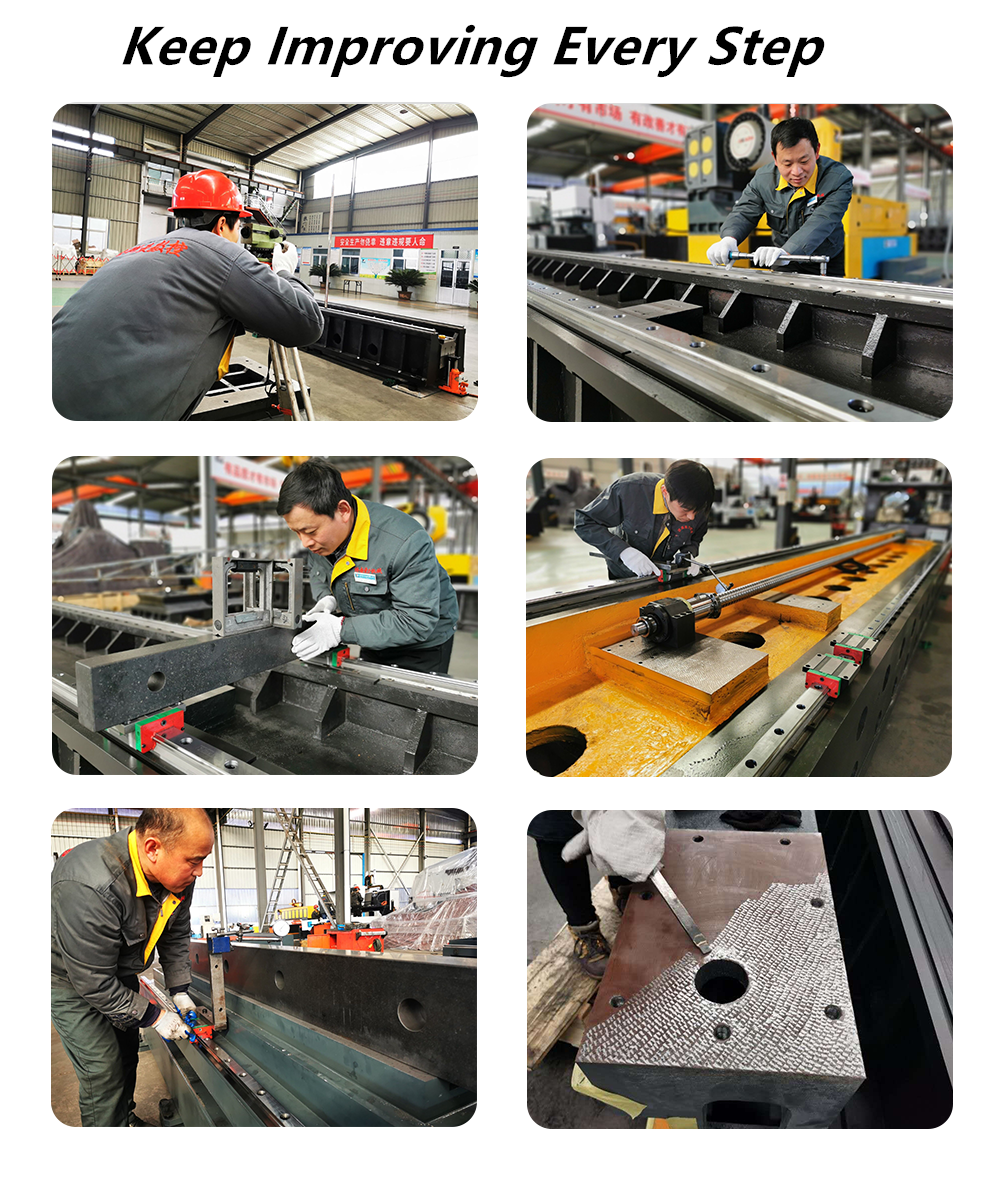

Ukuhlolwa Kwekhwalithi

Umshini ngamunye we-Bosman ulinganiswa nge-laser interferometer evela enkampanini ye-RENISHAW yase-United Kingdom, ehlola ngokunembile futhi inxephezele amaphutha e-pitch, ukuhlehla, ukunemba kokuma, nokunemba kokuma okuphindaphindiwe ukuze kuqinisekiswe ukuguquguquka komshini, ukuzinza okumile, kanye nokunemba kokucubungula. . Ukuhlolwa kwebha yebhola Umshini ngamunye usebenzisa isihloli sebha yebhola esivela enkampanini yaseBrithani i-RENISHAW ukuze ulungise ukunemba kwendingilizi yeqiniso kanye nokunemba komshini wejometri, futhi wenze izivivinyo zokusika eziyindilinga ngesikhathi esifanayo ukuze kuqinisekiswe ukunemba komshini we-3D womshini kanye nokunemba kwendingilizi.

Indawo yokusebenzisa ithuluzi lomshini

1.1 Izidingo zemvelo yezinto zokusebenza

Ukugcina izinga elingaguquki lezinga lokushisa le-ambient kuyisici esibalulekile sokwenza imishini enembile.

(1) Izinga lokushisa le-ambient elitholakalayo ngu--10℃ ~35 ℃. Lapho izinga lokushisa le-ambient lingu-20℃, umswakama kufanele ube ngu-40~75%.

(2) Ukuze ugcine ukunemba okumile kwethuluzi lomshini ngaphakathi kwebanga elishiwo, izinga lokushisa elifanele le-ambient liyadingeka ukuthi libe ngu-15° C ku25° C ngomehluko wezinga lokushisa

Akufanele idlule± 2 ℃/ 24h.

1.2 I-voltage yokuphakelwa kwamandla: 3-isigaba, 380V, ukushintshashintsha kwamandla kagesi ngaphakathi± 10%, imvamisa yokunikezwa kwamandla: 50HZ.

1.3 Uma i-voltage endaweni esetshenziswayo ingazinzile, ithuluzi lomshini kufanele lifakwe ugesi olawulwayo ukuze kuqinisekiswe ukusebenza okuvamile kwethuluzi lomshini.

1.4. Ithuluzi lomshini kufanele libe nomhlabathi othembekile: intambo yaphansi iyintambo yethusi, ububanzi bocingo akufanele bube ngaphansi kuka-10mm.², futhi ukumelana komhlabathi kungaphansi kuka-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuvamile kwemishini, uma umoya ocindezelwe womthombo womoya wehluleka ukuhlangabezana nezidingo zomthombo womoya, isethi yamadivayisi okuhlanza umthombo womoya (ukukhipha umswakama, ukwehlisa, ukuhlunga) kufanele kwengezwe ngaphambi kokukhishwa kwemishini. ukungena komoya womshini.

1.6. Izinto ezisetshenziswayo kufanele zigcinwe kude nelanga eliqondile, ukudlidliza nemithombo yokushisa, futhi kude namajeneretha anemvamisa ephezulu, imishini yokushisela kagesi, njll., ukuze kugwenywe ukwehluleka kokukhiqiza umshini noma ukulahlekelwa ukunemba komshini.

Ngaphambi Nangemuva Kwesevisi

1) Ngaphambi Kwesevisi

Ngokutadisha isicelo nolwazi oludingekayo oluvela kumakhasimende bese impendulo konjiniyela bethu, ithimba le-Bossman Technical linesibopho sokuxhumana nobuchwepheshe namakhasimende kanye nokwakhiwa kwezixazululo, ukusiza ikhasimende ekukhetheni isixazululo esifanele somshini kanye nemishini efanelekile.

2) Ngemva Kwesevisi

A.Umshini onewaranti yonyaka owodwa futhi okhokhelwe ukunakekela impilo yonke.

B. Phakathi nenkathi yewaranti yonyaka owodwa ngemva kokuba umshini ufikile echwebeni lapho uya khona, i-BOSSMAN izohlinzeka ngezinsizakalo zokunakekela zamahhala nezifika ngesikhathi zamaphutha ahlukahlukene angenziwanga umuntu emshinini, futhi ibuyisele ngesikhathi zonke izinhlobo zezingxenye zomonakalo ongenziwanga ngumuntu mahhala. yenkokhiso . Ukwehluleka okwenzeka ngesikhathi sewaranti kuzolungiswa ngezindleko ezifanele.

Ukusekelwa kwe-C.Technical emahoreni angama-24 ku-inthanethi, i-TM, i-Skype, i-E-mail, ukuxazulula imibuzo ehlobene ngesikhathi. uma ingeke ixazululwe, i-BOSSMAN izohlela ngokushesha ukuthi unjiniyela wangemuva kokuthengisa afike esizeni ukuze alungiswe, umthengi udinga ukukhokhela i-VISA, amathikithi ezindiza kanye nendawo yokuhlala.

Isizinda Sekhasimende