Uchungechunge lwe-TK lwesikhungo semishini esime mpo esinama-eksisi amahlanu

Izici

1.Umphumela omuhle kakhulu wokucubungula

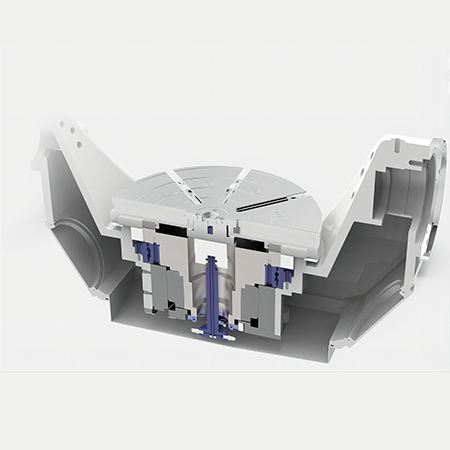

Umbhede wokulingisa obalulekile + i-axis ye-Y enyakazayo + i-high rigidity cradle yenza isizukulwane esisha samathuluzi omshini we-axis emihlanu asezingeni eliphezulu. Ithuluzi lomshini we-CNC we-axis emihlanu lifinyelela ukusebenza kahle okuphezulu kokugaya, ukusebenza okuphezulu kokucubungula nokunemba okwedlulele, kuyilapho liqinile kakhulu futhi lizinzile. Ukusebenza okunamandla okunjalo kuvela emzimbeni wayo ozinze kakhulu kanye nokuhlaziya okucophelela kwe-FEM.

2.Ukuqina okuphezulu nokunemba

3.Ukusebenza okuphezulu okuguquguqukayo

4.Ukuzinza okungenakuqhathaniswa nokunemba okuqhubekayo

Umbhede wokulingisa jikelele unokuzinza okungenakuqhathaniswa; i-beam enyakazayo i-Y-axis + imbeleko eqinile yenza umshini ube nokuqiniswa okungavamile kokusika; isisindo sezingxenye ezihambayo ze-fuselage silungiselelwe ukufeza ukusebenza okunamandla okuphakeme kakhulu.

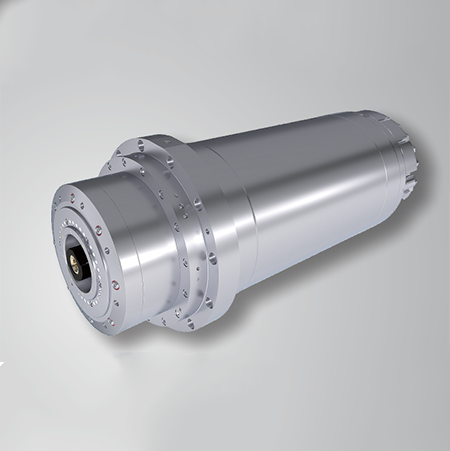

I-5.I-spindle ehlanganisiwe eyenziwe ngokuzimela, ukusebenza kahle okuphezulu nokusebenza okulula

I-6.CNC ubuchwepheshe bokuthuthukiswa okuhlakaniphile

Iminyaka yomkhakha wokusebenzisa imvula yobuchwepheshe be-axis emihlanu inokulawula okuzimele kwe-mechatronics, okwenza amathuluzi omshini azinze futhi athuthukise imisebenzi ehamba phambili embonini.

I-7.Ukugaya / ukuguqula ubuchwepheshe bokucubungula okuhlanganisiwe kufeza ukucubungula okuphelele

Enza ukukhanda okuphelele ethuluzini lomshini owodwa, okuhlanganisa ukugaya nokujika , ngokucindezela okukodwa kuphela okudingekayo , okufakwe ubuchwepheshe bokushayela okuqondile, kanye nesivinini esiphezulu esingu-2000rpm/min. Ijubane lokucubungula liyashesha futhi izindleko ze-logistics ziphansi, okubangelwa ukuntuleka kwesikhathi esiwusizo kanye nemisebenzi eyengeziwe, okuholela ezindlekweni eziphansi zokukhiqiza ucezu olulodwa kanye nokunemba okuphezulu kokucubungula.

Imininingwane Yezobuchwepheshe

| Into | I-TK10 | |

| Amapharamitha we-Linear sxis | X/Y/Z-ukuhamba eksisiububanzi(mm) | 130/100/130 |

|

| X/Y/Z pisihlalo esinembayo esiqondile (mm) | 0.008 |

|

| X/Y/Zrukunemba kokuma kwe-epeat (mm) | 0.005 |

|

| Isivinini sokunqamula ngokushesha se-X/Y/Z-eksisi (m/min) | 15 |

|

| Isivinini sokusika esikhulu se-X/Y/Z-axis (m/min) | 10 |

| Imingcele ye-axis ejikelezayo | B-ibanga lokuhamba le-axis | +20°-125° |

|

| Ibanga lokuhamba le-C-axis | n×360° |

|

| B/Cukunemba kokubeka | 8'' |

|

| B/Crukuma okuphindaphindiwe acubuhlakani | 5'' |

|

| B-isivinini sokunqamula i-axis (rpm/min) | 50 |

|

| C-isivinini sokunqamula i-axis (rpm/min) | 100 |

| Imingcele yomshini | Ubude bethuluzi lomshini (mm) | 2000 |

|

| Unyawo (mm) | 1000*1200 |

|

| Inetha yomshini (T) | 0.9T |

| Amapharamitha asebenzayo | Usayizi osebenzayo (mm) | Ø100 |

|

| Ubukhulu.usayizi we-workpiece (mm) | Ø100*100 |

|

| Ubukhulu.isisindo se-workpiece (kg) | 10 |

|

| Ibanga le-spindle end to table distance(mm) | 90-220 |

| Ipharamitha yomagazini wethuluzi | Amandla omagazini wethuluzi | 20 |

|

| Isikhathi sokushintsha ithuluzi le-TT (s) | 3 |

|

| Ubukhulu.tubude be-ool(mm) | 60 |

|

| Ubukhulu.tuwoyela ububanzi(mm) | Ø20 |

|

| Ubukhulu.tisisindo (kg) | 0.5 |

Imininingwane Yezobuchwepheshe

| Into | TK35 | I-TK50 | TK65 | TK80 | |

| Amapharamitha we-Linear sxis | Ibanga lokuhamba le-X/Y/Z-axis(mm) | 380/420/365 | 520/520/460 | 650/620/520 | 800/800/550 |

| X/Y/Z isihlalo esinembayo sokuma(mm) | 0.004 | 0.004 | 0.005 | 0.005 | |

| X/Y/Z phinda ukunemba kokuma(mm) | 0.003 | 0.003 | 0.004 | 0.004 | |

| X/Y/Z-axis isivinini sokunqamula ngokushesha(m/min) | 30 | 30 | 30 | 30 | |

| X/Y/Z-axis ubuningi. Isivinini sokusika(m/min) | 15 | 15 | 15 | 15 | |

| Imingcele ye-axis ejikelezayo | Ibanga lokuhamba le-axis | ±120° | ±120° | ±120° | ±120° |

| Ibanga lokuhamba le-C-axis | n×360° | n×360° | n×360° | n×360° | |

| Ukunemba kokuma kwe-A/C | 8'' | 8'' | 8'' | 8'' | |

| Ukunemba kokuma okuphindaphindiwe kwe-A/C | 5'' | 5'' | 5'' | 5'' | |

| Isivinini esisheshayo sokunqamula i-axis(rpm/min) | 50 | 30 | 30 | 30 | |

| Isivinini esisheshayo sokunqamula i-C-axis(rpm/min) | 100 | 80 | 100 | 50 | |

| Imingcele yomshini | Ubude bethuluzi lomshini(mm) | 2300 | 2800 | 3300 | 3060 |

| Unyawo(mm) | 1800*3200 | 3600*3220 | 2480*4390 | 4530*2630 | |

| Inetha yomshini(T) | 6 | 10 | 11 | 18.5 | |

| Amapharamitha asebenzayo | Usayizi osebenzayo (mm) | Ø350 | Ø500 | Ø500 | Ø700 |

| T-slot | 6-M10 | 8-M16 | 8-M16 | 8-M18 | |

| Ubukhulu bosayizi we-workpiece(mm) | Ø350*250 | Ø520*410 | Ø650*410 | Ø800*500 | |

| Isisindo se-Max.workpiece(kg) | 100 | 400 | 500 | 500 | |

| Ibanga le-spindle end to table distance(mm) | 110-475 | 170-630 | 170-690 | 180-730 | |

| Ipharamitha yomagazini wethuluzi | Amandla omagazini wethuluzi | 24 | 24 | 24 | 24 |

| Isikhathi sokushintsha ithuluzi le-TT | 3 | 3 | 3 | 3 | |

| Ubude bethuluzi eliphezulu(mm) | 200 | 320 | 320 | 320 | |

| Ubukhulu. ububanzi bezikhundla eziseduze ngaphandle kwamathuluzi(mm) | Ø110 | Ø140 | Ø140 | Ø140 | |

| Ubukhulu. ububanzi bamathuluzi okusika aseduze(mm) | Ø65 | Ø80 | Ø80 | Ø80 | |

| Isisindo (kg) se-Max. | 6 | 6 | 6 | 6 | |

Imininingwane Yezobuchwepheshe

| Into | TK20 | TK1000 | |

| Amapharamitha we-Linear sxis

| Ibanga lokuhamba le-X/Y/Z-axis(mm) | 250/250/250 | 1100/1100/700 |

| X/Y/Z isihlalo esinembayo sokuma(mm) | 0.008 | 0.006 | |

| X/Y/Z phinda ukunemba kokuma(mm) | 0.005 | 0.005 | |

| X/Y/Z-axis isivinini sokunqamula ngokushesha(m/min) | 15 | 30 | |

| X/Y/Z-axis ubuningi. Isivinini sokusika(m/min) | 10 | 15 | |

| Imingcele ye-axis ejikelezayo

| Ibanga lokuhamba le-axis | ±125° | ±120° |

| Ibanga lokuhamba le-C-axis | n×360° | n×360° | |

| Ukunemba kokuma kwe-A/C | 8'' | 8'' | |

| Ukunemba kokuma okuphindaphindiwe kwe-A/C | 5'' | 5'' | |

| Isivinini esisheshayo sokunqamula i-axis(rpm/min) | 50 | 30 | |

| Isivinini esisheshayo sokunqamula i-C-axis(rpm/min) | 100 | 100 | |

| Imingcele yomshini

| Ubude bethuluzi lomshini(mm) | 2010 | 4000 |

| Unyawo(mm) | 1750*1290 | 3200*4200 | |

| Inetha yomshini(T) | 2.3 | 25 | |

| Amapharamitha asebenzayo

| Usayizi osebenzayo (mm) | Ø200 | Ø800 |

| T-slot |

| Uhlobo lwe-M18T slot eqondile | |

| Ubukhulu bosayizi we-workpiece(mm) | Ø200*200 | Ø1100*700 | |

| Isisindo se-Max.workpiece(kg) | 30 | 2500 | |

| Ibanga le-spindle end to table distance(mm) | 60-310 |

| |

| Ipharamitha yomagazini wethuluzi

| Amandla omagazini wethuluzi | 16 | 40 |

| Isikhathi sokushintsha ithuluzi le-TT | 3 | 4 | |

| Ubude bethuluzi eliphezulu(mm) | 125 | 450 | |

| I-Max.tool diameter(mm) | 40 | Ø200 | |

| Isisindo (kg) se-Max. | 1 | 20 | |

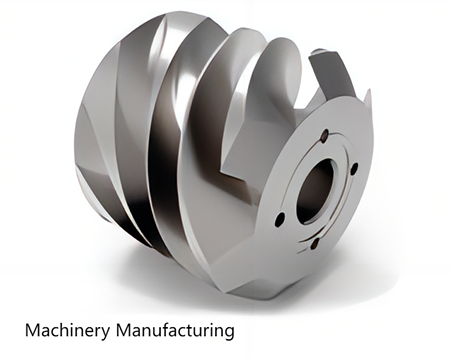

Icubungula Isibonelo

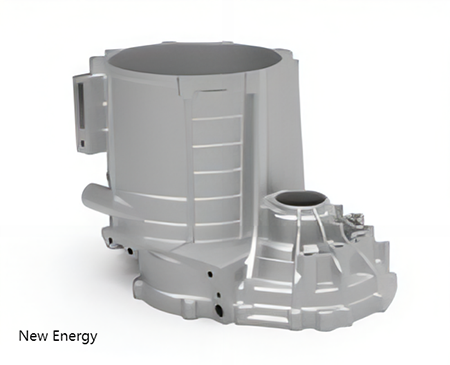

1.Amandla Amasha

2.Imishini Yezokwelapha

3.Imboni Yemikhumbi

4.IsikhuntaIumkhakha

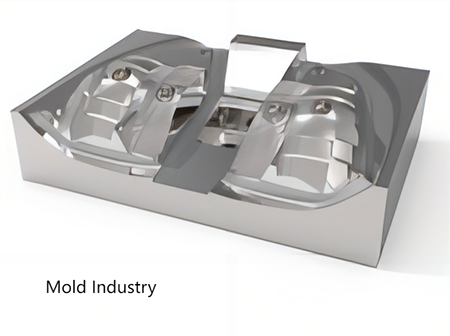

5.MubuhlunguMukwenza izinto

6.I-Aerospace