I-CV Series ye-CV ye-axis eyi-Vertical Vertical Machining Centre

Izici

Isingeniso somshini

Uchungechunge lwe-CV yesikhungo se-CV ene-eksisi emihlanu inezici zokuqina okuphezulu, ukunemba okuphezulu nokusebenza kahle kwemishini. Ikholomu ithatha umklamo we-herringbone nge-span enkulu, engathuthukisa kakhulu ukugoba namandla okugoqa kwekholomu; ibhentshi lokusebenzela lithatha ubude be-slider obunengqondo futhi licinywe phezulu, ukuze amandla ebhentshini lokusebenzela afane futhi ukuqina kuthuthukiswe; umbhede wamukela i-trapezoidal cross-section, ukunciphisa Isikhungo sokudonsela phansi sithuthukisa amandla okugubha; wonke umshini usebenzisa ukuhlaziywa kwezinto ezinomkhawulo ukuze udizayine ingxenye ngayinye ukuze unikeze ukuzinza okuphelele okuphelele.

Ukuhamba okusheshayo kwama-axis amathathu okusheshayo kungafinyelela ku-48M/min, isikhathi sokushintsha ithuluzi le-TT singu-2.5S kuphela, umagazini wamathuluzi ulayishwe ngokugcwele ku-24t. Ilungele amamodeli ahlukahlukene we-2D kanye ne-3D concave-convex anomumo oyinkimbinkimbi kanye nemigodi eyinkimbinkimbi nezindawo. Ibuye ilungele ukugaya, ukubhoboza, ukwandisa, isidina, Ukuthepha kanye nezinye izinqubo zokucubungula zifaneleka kakhulu kokubili amaqoqo amancane naphakathi nendawo yokucubungula nokukhiqiza okuhlukahlukene, futhi ingasetshenziswa emigqeni ezenzakalelayo yokukhiqiza ngobuningi.

Ukuboniswa kwesithombe esiguquguqukayo sethrekhi yamathuluzi, isibonisi sesexwayiso esihlakaniphile, ukuzihlola kanye neminye imisebenzi kwenza ukusetshenziswa nokugcinwa kwethuluzi lomshini kube lula futhi kusheshe; Amandla okufunda anyuswa abe yimigqa engu-3000/ngesekhondi, okwenza kube lula ukudluliswa okushesha nangempumelelo kanye nokucutshungulwa ku-inthanethi kwezinhlelo zomthamo omkhulu.

I-RTCP (I-Rotation Tool center Point) yesikhungo somshini esinama-axis amahlanu iwumsebenzi wokulawula iphuzu lamathuluzi. Ngemva kokuvula umsebenzi we-RTCP, isilawuli sizoshintsha kusukela ekulawuleni ekuqaleni ubuso bomphathi wethuluzi ukuya ekulawuleni iphuzu lethiphu yethuluzi. Ithiphu yethuluzi elandelayo inganxephezela umugqa obangelwa i-axis ejikelezayo. Iphutha lokuvimbela ukungqubuzana Kwethuluzi. Ephuzwini elingu-A le-workpiece, umugqa omaphakathi we-eksisi yethuluzi ushintsha ngokuqondile ukusuka endaweni evundlile ukuya endaweni eqondile. Uma iphutha lomugqa lingalungiswa, ithiphu lethuluzi lizochezuka ephuzwini A noma lingene endaweni yokusebenza, lidale ingozi embi. Ngenxa yokuthi ukunyakaza okuqhubekayo kwe-axis ejikelezayo kanye ne-axis ejikelezayo kubangela izinguquko endaweni yephuzu A, indawo yethiphu yasekuqaleni yethuluzi ohlelweni kufanele ilungiswe ukuze kuqinisekiswe ukuthi izixhumanisi zendawo yethiphu yethuluzi zihlala zingashintshile uma ziqhathaniswa nephoyinti A, njengokungathi. ithiphu lethuluzi lihamba nephoyinti A. , leli lithiphu leThuluzi elilandelayo.

Lo msebenzi unamazinga angu-0 ~ 9, izinga lesi-9 liwukunemba okuphezulu kakhulu, kuyilapho izinga loku-1 - 8 linxephezela iphutha lokubuyela emuva le-servo, futhi linikeza indlela yokucubungula ukushelela okufanele.

Ukucutshungulwa kwe-Three-dimensional enesivinini esikhulu nokunemba okuphezulu

I-spindle enesivinini esikhulu, isilawuli semishini ye-arc ye-3D singakwazi ukufunda kusengaphambili ama-blocks angu-2000 kanye nokulungiswa kwendlela eshelelayo yomshini wejubane eliphezulu nokunemba okuphezulu.

High Rigidity Isakhiwo

Thuthukisa indlela yesakhiwo futhi ulungiselele isabelo ukuze uthuthukise ukuqina komshini. Umumo wethuluzi lomshini nekholomu kanye nokulungiselelwa kokwaba kuwumumo ofaneleka kakhulu ngokuhlaziywa kwe-CAE. Izinyathelo ezihlukahlukene ezithuthukisiwe ezingabonakali ngaphandle zibonisa ikhono lokusika elizinzile ijubane lokuphotha elingakwazi ukulibonisa.

Imininingwane Yezobuchwepheshe

| Into | iyunithi | I-CV200 | I-CV300 | I-CV500 | |

| Ukuhamba

| X/Y/Z uhambo lwe-eksisi | mm | 500×400×330 | 700*600*500 | 700×600×500 |

| Ibanga ukusuka ebusweni bokuphela kokuphotha kuya endaweni ekwazi ukusebenza | mm | 100-430 | 150-650 | 130-630 | |

| Ibanga ukusuka enkabeni yokuphotha ukuya endaweni yesitimela yekholomu | mm | 412 | 628 | 628 | |

| Ibanga eliphakeme kakhulu phakathi kwesikhungo sokuphotha esingu-A-eksisi esingu-90° kanye nendawo yediski ye-C-axis | mm | 235 | 360 | 310 | |

| 3 i-eksisi feed

| I-X/Y/Z i-eksisi ehamba ngokushesha | m/min | 48/48/48 | 48/48/48 | 36/36/36 |

| Ukusika izinga lokuphakelayo | mm/min | 1-24000 | 1-24000 | 1-24000 | |

| I-spindle

| Ukucaciswa kwe-spindle (ububanzi bokufaka/imodi yokudlulisela) | mm | 95/ngqo | 140/Ngqo | 140/Ngqo |

| I-spindle taper | mm | I-BT30 | I-BT40 | I-BT40 | |

| Isivinini se-spindle | r/min | 12000 | 12000 | 12000 | |

| Amandla e-spindle motor (aqhubekayo/S3 25%) | kW | 8.2/12 | 15/22.5 | 15/22.5 | |

| I-Spindle Motor Torque (Iyaqhubeka/S3 25%) | Nm | 26/38 | 47.8/71.7 | 47.8/71.7 | |

| Umagazini wamathuluzi

| Amandla kamagazini | T | 21T | 24T | 24T |

| Isikhathi sokushintsha ithuluzi (TT) | s | 2.5 | 4 | 4 | |

| I-Max.Tool diameter(ithuluzi eligcwele/ithuluzi elingenalutho) | mm | 80 | 70/120 | 70/120 | |

| Ubude be-Max.Tool | mm | 250 | 300 | 300 | |

| Ubukhulu. Isisindo sethuluzi | kg | 3 | 8 | 8 | |

| Umhlahlandlela

| Umhlahlandlela we-X-axis (usayizi/inombolo yezilayidi) | mm | 30/2 | 35/2 roller | 45/2 roller |

| Igayidi ye-Y-eksisi (ubukhulu/ubuningi bezilayidi) |

| 30/2 | 35/2 roller | 45/2 roller | |

| Umhlahlandlela we-axis (ubukhulu/ubuningi bezilayidi) |

| 30/2 | 35/2 roller | 45/2 roller | |

|

Isikulufu

| Isikulufu se-X-axis |

| Φ28×16 | Φ40×16 | Φ40×16 |

| Isikulufu se-Y-axis |

| Φ28×16 | Φ40×16 | Φ40×16 | |

| Isikulufu se-axis Z |

| Φ32×16 | Φ40×16 | Φ40×16 | |

| Ukunemba

| Ukumisa ukunemba | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Ukuphindaphinda | mm | ±0.003/300 | ±0.003/300 | ±0.003/300 | |

| 5 ekseni

| Indlela ye-Turntable drive |

| Moter ngqo | I-roller cam | i-roller cam |

| I-diameter eguqukayo | mm | Φ200 | Φ300*250 | φ500*400 | |

| Isisindo somthwalo esivumelekile se-turntable (evundlile/ethambekile) | kg | 40/20 | 100/70 | 200 | |

| I-A/C-eksisi ubuningi. isivinini | rpm | 100/230 | 60/60 | 60/60 | |

| Ukuma kwe-axis/ukuphindaphinda | arc-sec | 10/6 | 15/10 | 15/10 | |

| Ukuma/ukuphindaphinda kwe-C-eksisi | arc-sec | 8/4 | 15/10 | 15/10 | |

| Ukuthambisa

| Umthamo weyunithi yokugcoba | L | 1.8 | 1.8 | 1.8 |

| Uhlobo lwesihlukanisi samafutha |

| ivolumu | Gcoba amafutha | ivolumu | |

| Abanye

| Ukufunwa komoya | kg/c | ≥6 | ≥6 | ≥6 |

| Ukugeleza komthombo womoya | mm3/min | ≥0.2 | ≥0.4 | ≥0.4 | |

| umthamo webhethri | I-KVA | 10 | 22.5 | 26 | |

| Isisindo somshini (Buphelele) | t | 2.9 | 7 | 8 | |

| Ubukhulu Bemishini (L×W×H) | mm | 1554×2346×2768 | 2248*2884*2860 | 2610×2884×3303 | |

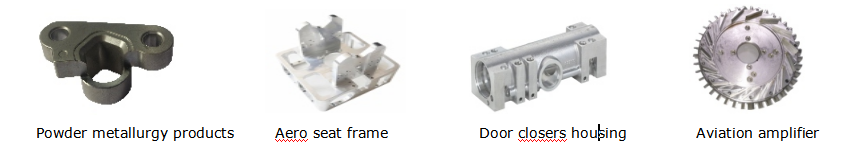

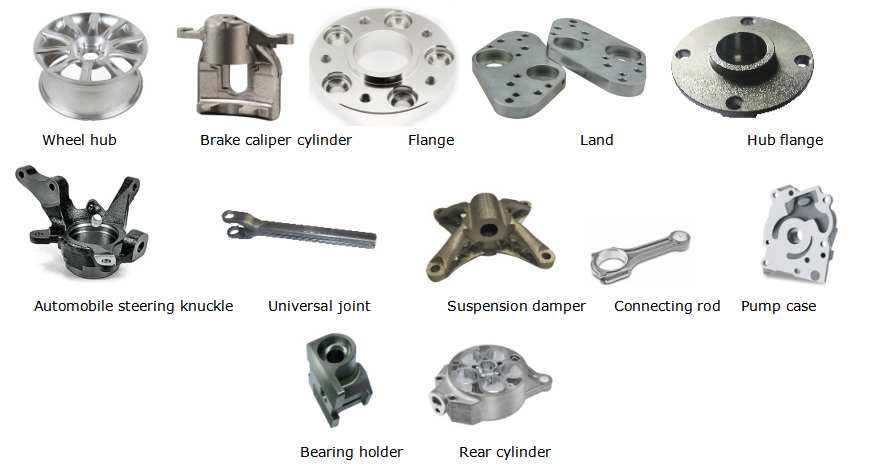

Icubungula Isibonelo

1.Imboni Yezimoto

2.Ukulungiswa okuqondile

3.Imboni yezempi