I-CTB ye-CTB yama-axis amahlanu Vertical Machining Centre

Izici

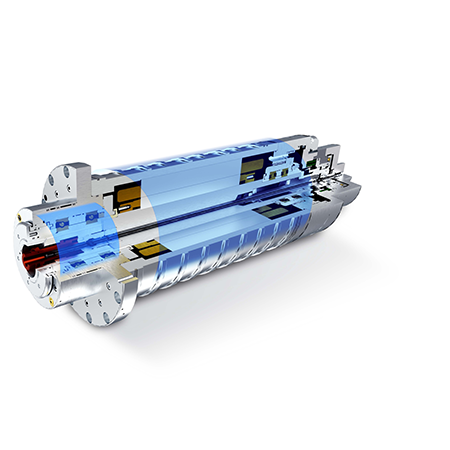

Isingeniso somshini

1.Ukwenza imishini ye-axis emihlanu engabizi ngesikhathi esisodwa

Isakhiwo se-Classic C-type, esifakwe i-spindle kagesi enembayo ethuthukisiwe kanye nethebula elijikelezayo ledrayivu eqondile, uhlelo lwe-CNC olusezingeni eliphezulu, lunikeza ikhwalithi enhle kakhulu. Isekela ama-spindle kagesi ongawakhetha wokucaciswa okuhlukahlukene kanye namatafula aphendukayo kanye nokugaya okujikelezayo okuhlanganisiwe.

2.Direct-drive turntable

I-turntable eyi-direct-drive turntable eyakhiwe ngokwayo yamukela injini ye-torque enembayo ephezulu, igebe lokudlulisela elinguziro, aligugi, futhi ifakwe isishumeki se-engeli esinembe kakhulu.

Uhlelo oluphezulu lwe-CNC lufinyelela ukulawula okunembayo okuphezulu okuguquguqukayo.

I-Swivel Turntable, ukucutshungulwa kokuxhumanisa kwe-axis emihlanu, isisindo esiphezulu se-workpiece engu-150kg-3000kg, kanye nokucutshungulwa kwe-engeli engalungile kungafinyelelwa. I-axis engu-B ifakwe isakhiwo esiyisizayo esinokuqina kosekelo oluqinile.

3.HSK uchungechunge lokuphotha kagesi

I-spindle kagesi yamukela ukusebenza kahle okuphezulu kwe-asynchronous motor yangaphakathi, amabheringi e-ceramic anembe kakhulu, inzwa yokudlidliza, inzwa yokushisa kanye nethuluzi lemisebenzi yokupholisa yangaphakathi iyakhethwa.

4. Uhlelo lokugcoba lusebenzisa ukugcotshwa kwamafutha okuhlala isikhathi eside;

5. Isistimu yokupholisa isebenzisa iphampu yokupholisa egeleza kakhulu ukuze ihlangabezane ngokugcwele nezidingo zokupholisa zamathuluzi okupholisa nezinsimbi zokusebenza. Indawo yokupholisa inqunywa ngokuvumelana nezimo zangempela zezingxenye zokusebenza zomsebenzisi;

6. Uhlelo lokususa ama-chip lusebenzisa umshini wokukhipha i-chip othomathikhi we-chain plate (umugqa ongemuva)

7. Ithuluzi le-ATC elishintsha i-cam box yephephabhuku lamathuluzi lifakwe ukuqapha okuzenzakalelayo kwamazinga kawoyela wokugcoba ukuze kuncishiswe umonakalo omkhulu emishinini ebangelwa izindawo eziyizimpumputhe ekulungisweni kwezandla;

8. Ukwakhiwa kwethuluzi lomshini ukubeka phambili ukunakekelwa.Ukuhlelwa kwezingxenye ezinkulu zaleli thuluzi lomshini kusekelwe esimisweni esivulekile, esilungele ukufakwa, ukulungiswa nokugcinwa, futhi amafasitela okugcina ashiywe kwezinye izingxenye;

9. Ithuluzi lomshini kulula ukulisebenzisa, lisebenze futhi lilondoloze futhi libukeka kahle.Ukusetshenziswa nokunakekelwa kwamathuluzi omshini ngeke kubeke engozini impilo yomuntu noma kungcolise imvelo;

Imininingwane Yezobuchwepheshe

| Into | Iyunithi | I-V5-320B | I-V5-630B | I-V5-1000A | ||||

| Ithebula | ||||||||

| Ububanzi | mm | 320 | 630 | 1000 | ||||

| Ubukhulu. umthwalo ovundlile | kg | 150 | 500 | 3000 | ||||

| Ubukhulu. umthwalo oqondile | 100 | 300 | 2000 | |||||

| T-slots (inombolo X ububanzi) | Cha. X mm | 8X10H8 | 8X14H8 | 5x18 | ||||

| Ibanga lomshini | ||||||||

| Ibanga ukusuka ekhaleni lokuphotha | Ubukhulu.(mm) | 430 | 550 | 1080 | ||||

| endaweni yetafula | Ubuncane.(mm) | 100 | 150 | 180 | ||||

| I-X-eksisi | mim | 450 | 600 | 1150 | ||||

| I-Y-eksisi | mm | 320 | 450 | 1300 | ||||

| I-Z-eksisi | mm | 330 | 400 | 900 | ||||

| I-B-eksisi | . | -35~ +110 | -35~ +110 | -150~ +130 | ||||

| I-C-eksisi | . | n X 360 | n X 360 | n X 360 | ||||

| I-spindle | ||||||||

| Isiphathi samathuluzi |

| I-BT30 | HSKE40 | I-BT40 | I-HSKA63 | I-BT50 | HSKA100 | |

| Donsa istudi |

| I-MAS403 BT30-I |

| I-MAS403 BT40-I |

| I-MAS403 BT50-I |

| |

| Isivinini esilinganiselwe | rpm | 12000 | 17500 | 1800 | 2000 | 1500 | ||

| Ubukhulu. isivinini | 24000 | 32000 | 12000 | 18000 | 10000 | |||

| I-torque ephumayo ye-motorized spindle (S1/S6) | Nm | 12/15.5 | 6/8.2 | 69/98 | 72/88 | 191/236 | ||

| Amandla okukhipha i-spindle anemoto (S1/S6) | kW | 15/19.5 | 11/15 | 13/18.5 | 15/18.5 | 30/37 | ||

| Hlanganisa i-eksisi | ||||||||

| Ukunqamula ngokushesha | I-X-eksisi |

m/min | 36 | 36 | 25 | |||

| I-Y-eksisi | 36 | 36 | 25 | |||||

| I-Z-eksisi | 36 | 36 | 25 | |||||

| Ubukhulu. isivinini | I-B-eksisi | rpm | 100 |

| 15 | |||

| I-C-eksisi | 80 |

| ||||||

| 130 | 80 | 30 | ||||||

| Ukushintsha ithuluzi okuzenzakalelayo | ||||||||

| Uhlobo | Uhlobo lwediski | Uhlobo lwediski | I-Horizontal chain type servo ithuluzi elishintshashintshayo | |||||

| Ukukhetha ithuluzi | Isimiso sokusondelana se-Bidirectional

| Isimiso sokusondelana se-Bidirectional

| Isimiso sokusondelana se-Bidirectional | |||||

| Amandla | T | 24/30 | 24 | 30 | ||||

| Ubukhulu. ubude bethuluzi | mm | 200 | 300 | 400 | ||||

| Ma ithuluzi isisindo | kg | 3.5 | 8 | 20 | ||||

| Idayamitha yediski enkulu | Igcwele | mm | 65 | 80 | 125 | |||

|

| Izikhundla eziseduze azinalutho | 125 | 150 | 180 | ||||

| Ukunemba | ||||||||

| Amazinga Okusebenzisa | I-GB/T 20957 | I-GB/T 20957 | I-GB/T 20957 | |||||

| Ukumisa ukunemba | I-eksisi ye-X/Y/Z | mm

| 0.006 | 0.007 | 0.08 | |||

|

| I-eksisi ye-B/C | “ | 6 | 6 | 8 | |||

| Ukuphindaphinda | I-eksisi ye-X/Y/Z | mm | 0.004 | 0.005 | 0.006 | |||

| I-eksisi ye-B/C | “ | 4 | 4 | 6 | ||||

| Isisindo | kg | 4000 | 6500 | 33000 | ||||

| Amandla | I-KVA | 45 | 45 | 80 | ||||

| Ubukhulu bebonke (LXWXH) | mm | 3460 X 3000X 2335 | 4000 X 4000X 3200 | 7420X4800X4800 | ||||

Ukucubungula Amacala

Izingxenye Zefoni Ephathwayo

Izingxenye Zesakhiwo

Imihlobiso

Ama-Impellers

Ibhuloho Plating

Imizimba ye-Valve