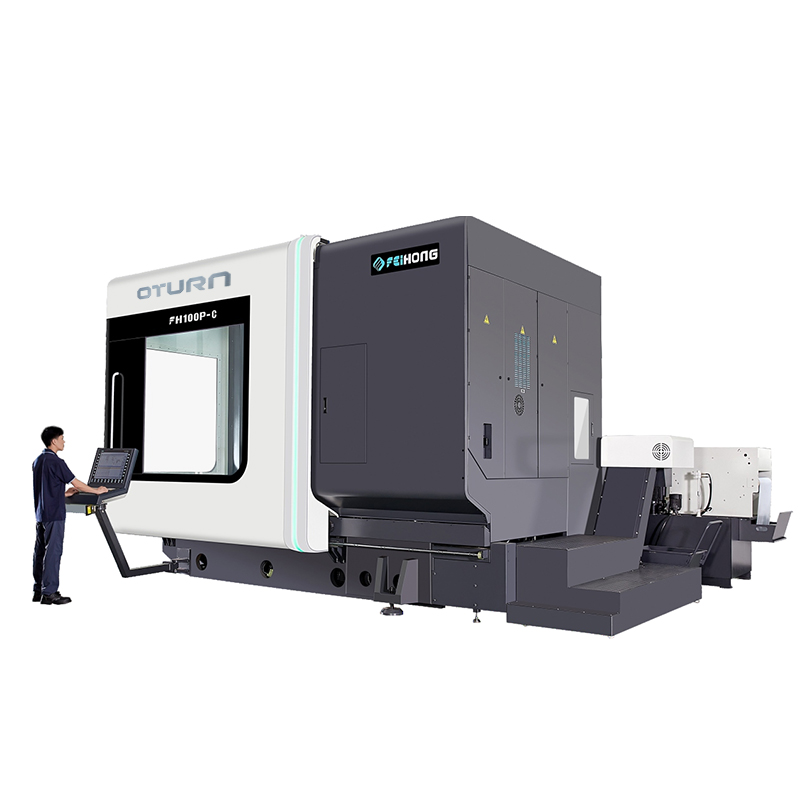

I-Five-axis Machining Centre FH135P

I-axis emihlanukanyekanyeisikhungo somshini

Idrayivu yokupholisa ye-screw engenalutho ye-eksisi ye-XYZ

B\C rotary shaft DD direct drive transmission

Isistimu yokulinganisa inani eliphelele lelophu evaliwe

Ukucushwa okuyinhloko

Ithebula lezinsiza ezijwayelekile (sicela ubhekisele kumsebenzi wesilawuli wengxenye yokulawula ugesi)

| No | Into | Iyunithi | Qty |

| 1. | I-FH mainframe mineral casting | Setha | 1 |

| 2. | Isistimu yokulawula ye-Siemens ONE | Setha | 1 |

| 3. | Bonisa: 21.5 inch touch display panel | Setha | 1 |

| 4. | I-FH five-axis multi-function swing head (B-axis) | Setha | 1 |

| 5. | I-FH-DGZX-28010/42B2 Ukugaya i-spindle kagesi (umsebenzi wokujika onesivikelo) | PC | 1 |

| 6. | I-X/Y/Z I-axis Hollow Cooled Ball Screw | PCS | 3 |

| 7. | I-Milling Direct Drive Rotary Table (C-axis) | Setha | 1 |

| 8. | I-axis ye-B RCN8380 29 bits isifaki khodi esiphelele | PC | 1 |

| 9. | I-C axis RCN2580 28 bits isifaki khodi esiphelele | PC | 1 |

| 10. | INA Roller Linear Amaslayidi | Amasethi | 7 |

| 11. | Isistimu yokupholisa amanzi nge-spindle | Setha | 1 |

| 12. | Isifutho samanzi indandatho yomshini | Setha | 1 |

| 13. | Isifutho samanzi se-crescent yekhanda le-axis emihlanu, ukuvunguza kwe-crescent | Setha | 1 |

| 14. | Isistimu ye-interlock yokuphepha yomnyango wangaphambili nangaseceleni | Setha | 1 |

| 15. | Ukukhanyisa umgqomo wokusebenza ongangeni manzi | PCS | 2 |

| 16. | Isiteshi samanzi | Setha | 1 |

| 17. | Idivaysi yokugcoba okuphakelayo emaphakathi nendawo | Setha | 1 |

| 18. | I-Operation side yokuhlanza isibhamu samanzi kanye nesibhamu somoya | Setha | 1 |

| 19. | Isistimu yokusika uketshezi (CTS 25bar) | Setha | 1 |

| 20. | Insimbi yeshidi elivikelwe ngokugcwele | Setha | 1 |

| 21. | Ibhokisi lokusebenza | Setha | 1 |

| 22. | Ibhokisi le-air conditioner likagesi | Setha | 1 |

| 23. | I-Siemens electronic handwheel | PC | 1 |

| 24. | Iswishi yokukhulula ithuluzi lokuphotha elisebenza ngonyawo | PC | 1 |

| 25. | Umshini wokukhanya onemibala emithathu | Setha | 1 |

| 26. | 40PCS HSK-A63 ithuluzi omagazini kanye servo ATC uhlelo | Setha | 1 |

| 27. | X/Y/Z isikali sokulinganisa senani lama-eksisi amathathu aphelele | Amasethi | 3 |

| 28. | I-Spiral Chip Roller kanye ne-Rear Chip Conveyor Chip Carriage | Setha | 1 |

| 29. | I-Renishaw OMP60 Infrared Probe idivayisi | Setha | 1 |

| 30. | Renishaw NC4F230 iyunithi yesethi yamathuluzi | Setha | 1 |

| 31. | Amaphedi ezinga lesisekelo namabhawudi esisekelo | Setha | 1 |

| 32. | Imanuwali yobuchwepheshe | Setha | 1 |

Ipharamitha

| Imodeli | Iyunithi | FH135P |

| Ukuhamba | ||

| Uhambo lwe-X eksisi | mm | 1450 |

| Uhambo lwe-Y eksisi | mm | 1450 |

| Z ukuhamba eksisi | mm | 1000 |

| Ibanga ukusuka ekhaleni lokuphotha ukuya endaweni esebenzayo | mm | 160-1160 |

| Ikhanda lokugaya elivundlile | mm | 30-1030 |

| Okuphakelayo/isivinini esihamba ngokushesha | m/min | 40 |

| Okuphakelayo amandla | KN | 10 |

| Ithebula elijikelezayo (i-C axis) | ||

| Usayizi wethebula elisebenzayo | mm | Ø1400x1300 |

| Max.table load (milling) | kg | 4000 |

| Ithebula lokugaya ubuningi. isivinini | rpm | 50 |

| I-engeli encane yokuhlukaniswa | ° | 0.001 |

| I-torque elinganiselwe | Nm | 1330 |

| I-torque enkulu | Nm | 2630 |

| Ikhanda lokugaya i-CNC (i-axis B) | ||

| Ibanga lokushwiba (0=okuqondile/180=okuvundlile) | ° | - 15 - 180 |

| Ukuhamba ngokushesha kanye nezinga lokuphakelayo | rpm | 50 |

| I-engeli encane yokuhlukaniswa | ° | 0.001 |

| I-torque elinganiselwe | Nm | 1050 |

| I-torque enkulu | Nm | 2130 |

| I-spindle | ||

| Isivinini se-spindle | rpm | 10000 |

| Amandla e-spindle(S1) | Kw | 42/58 |

| I-Spindle torque(S1/S6) | Nm | 215/350 |

| I-spindle taper |

| HSKA100 |

| Umagazini wamathuluzi | ||

| Ithuluzi esibonakalayo |

| HSKA100 |

| Amandla omagazini wethuluzi | PCS | 40 |

| Ithuluzi eliphezulu ububanzi/ubude/isisindo |

| Ø135/300/12 |

| Isikhathi sokushintsha ithuluzi (ithuluzi kuya ithuluzi) | S | 4 |

| Idivayisi yokulinganisa | ||

| I-infrared probe | Yenza kabusha i-OMP60 | |

| Ithuluzi lokuthola ithuluzi endaweni yokucubungula | I-Renishaw NC4F230 | |

| Ukunemba kwesikhundla (ISO230-2 kanye ne-VDI3441) | ||

| X/Y/Z ukunemba kokuma | mm | 0.006 |

| X/Y/Z Phinda ukunemba kokuma | mm | 0.004 |

| Ukunemba kokuma kwe-B/C |

| 8" |

| B/C Phinda ukunemba kokuma |

| 4" |

| Isilawuli se-CNC | ||

| Uhlelo lwe-CNC |

| Siemens EYODWA |

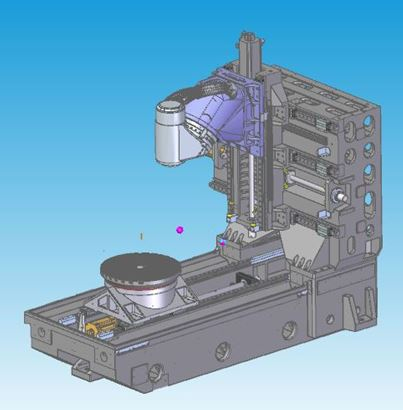

Imininingwane Yomshini Oyinhloko | I-Optimum Rigid Structure Configuration

Izici Zokuklama | Idizayini engcono kakhulu yokuhlaziya ukusakaza kwentambo yomshini

◆Isakhiwo sokuphonsa se-thermosymmetrical sebhokisi eligcwele, kusetshenziswa insimbi yensimbi yezinga eliphezulu ye-Meehanite

◆ Ukwelashwa kokuguga nokwemvelo ukuze kuqedwe ukucindezeleka kwangaphakathi

◆Ukudlidliza kwemvamisa yemvelo yesakhiwo kuqeda ingcindezi yokucubungula izinto

◆Idizayini yekholomu yendawo enkulu futhi eqinile kakhulu kulo lonke udonga ingathuthukisa ngempumelelo ukuqina nokunemba okumile nokuguquguqukayo.

◆Isikulufu sokupholisa esiholayo esinezimbobo ezintathu esinezimbobo ezintathu

I-Spindle kagesi

Izici Zokuklama

◆Ngokwezimpawu zomshini, ucwaningo oluzimele kanye nokuthuthukiswa nokukhiqiza.

◆I-taper hole ye-HSK-A100 yamukelwa kumodeli ye-FH135P.

◆Yamukela uhlelo lokupholisa lwangaphandle lokupholisa okujikelezayo, olungaqinisekisa ngempumelelo ukusetshenziswa kwe-spindle kagesi.

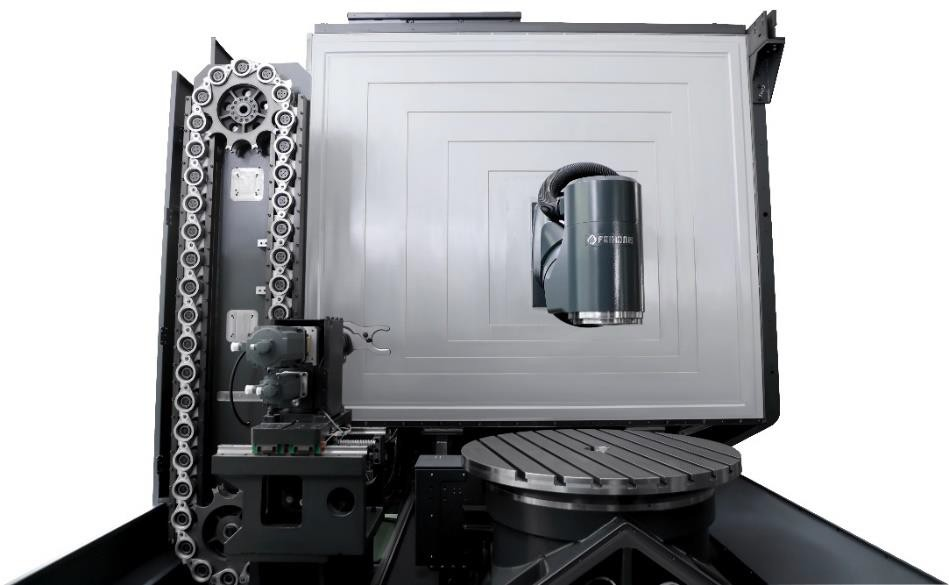

Ikhanda lokugaya i-CNC (i-axis B)

Izici Zokuklama

◆ Ukuklama nokukhiqiza okuzimele.

◆Iketango elakhelwe ngaphakathi le-DD motor zero transmission akukho mklamo wokuhlehla.

◆Izici zokusheshisa okuphezulu.

◆Isikhathi esifushane kakhulu phakathi kwephuzu lekhala lethuluzi lokuphotha kanye nendawo yokusekela yesakhiwo sibona ukuqina okukhulu kokusika.

◆Ukuzala kwe-YRT enkulu kuthuthukisa ukuqina.

◆ Ifakwe i-HEIDENHAIN RCN8380 yochungechunge oluphelele lwesistimu yokukala yesifaki khodi esijikelezayo, isilawuli se-loop evaliwe ngokugcwele, ukuze kuqinisekiswe ukunemba okungcono kakhulu.

◆ Idizayini yesistimu yokupholisa ye-B-eksisi yehlisa ukudluliswa kokushisa.

Ithebula elijikelezayo (ithebula le-C-axis)

Izici Zokuklama

◆ Ukuklama nokukhiqiza okuzimele.

◆Iketango elakhelwe ngaphakathi le-DD motor zero transmission akukho mklamo wokuhlehla.

◆Izici zokuphendula zokusheshisa nokuhlehliswa okuphezulu.

◆Ukuzala kwe-YRT enkulu kukhulisa ukuqina.

◆I-torque enkulu yokushayela elinganiselwe, ukumisa nokucutshungulwa ngokuma kwetafula kanye nedivayisi yokubopha

◆ Hlangana nezidingo zokugaya, unciphise ukuphathwa kwe-workpiece futhi uthuthukise ukunemba komkhiqizo.

◆Ifakelwe isistimu yokulinganisa ye-HEIDENHAIN enembe kakhulu ye-rotary, isilawuli se-loop evaliwe ngokuphelele ukuze kuqinisekiswe ukunemba okungcono kakhulu.

◆Ukwakheka kwesistimu yokupholisa ukunciphisa ukudluliswa kokushisa.

Isistimu yokulawula

Izici zokukhetha

◆Khetha umsingathi wokulawula i-NCU730.3B ngokuxhumanisa ama-eksisi amahlanu (bona ithebula lomsebenzi ukuze uthole imininingwane yokucushwa kwesistimu)

◆Ngomsebenzi we-RTCP

◆Khetha i-Siemens S120 drive enamandla okulayisha ngokweqile izikhathi ezi-3 kanye ne-1FT series motor enezici eziphezulu ze-kinematic

◆Khetha i-TCU30.3+ICP427E njengomsingathi osebenzisanayo we-HMI, i-IPC inejubane eliphezulu lekhompyutha nendawo yokugcina ephezulu

Uhlelo lokushintsha ithuluzi oluzenzakalelayo

Izici Zokuklama

◆ Ukuklama nokukhiqiza okuzimele.

◆ Ukukhetha ithuluzi kanye noshintsho lwamathuluzi sebenzisa i-servo motor ukulawula isenzo esibulalayo, esizinzile nesinembile.

◆ Kuhlanganiswe nomsebenzi wokuphatha ithuluzi we-Siemens ONE, ukuphathwa kwethuluzi okuphumelelayo.

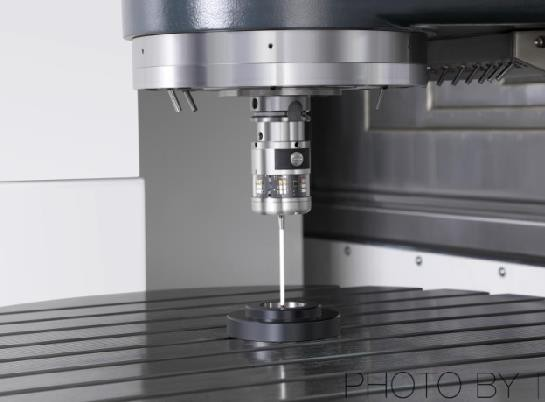

Isetha samathuluzi esiphakanyiswayo

Izici Zokuklama

◆Ifakwe isethi yamathuluzi ye-Ransishaw NC4F230R ngokunemba okuphezulu.

◆ Ukulungiselelwa kwamathuluzi okuzenzakalelayo emshinini, ukubuyekezwa okuzenzakalelayo kwesinxephezelo sethuluzi.

◆Idivayisi yokusetha ithuluzi ingaphakanyiswa futhi yehliswe ukuze konge isikhala sendawo yokucubungula.

◆ Idizayini yensimbi yeshidi evalwe ngokugcwele ukuvikela isethi yamathuluzi ekonakalisweni ngamanzi nensimbi ngesikhathi sokucubungula.

I-infrared probe

Izici Zokuklama

◆Ifakwe i-Renishaw OMP60 Infrared Probe Unit.

◆Ukuqondanisa komshini wokusebenza emshinini nokuhlolwa kosayizi kunganciphisa amaphutha okuhlola okwenziwa ngesandla futhi kuthuthukise ukunemba komkhiqizo nokusebenza kahle kokucubungula.

◆90% yokonga ngesikhathi sosizo ebhodini.

Ukubukeka

Idizayini yekhava yochungechunge lwesikhungo semishini ye-FH ene-axis emihlanu ithobelana nezindinganiso eziqinile zokuphepha ze-CE. Ishidi lensimbi eliminyene ngokugcwele livimbela opharetha ukuthi angangeni endaweni yokusebenza ngephutha ngesikhathi sokucubungula, futhi ngesikhathi esifanayo kuvimbela ukusetshenziswa koketshezi olunomfutho ophezulu wokusika noma ama-chips emshinini, ngaphandle kwe-nameplate yesixwayiso. , Umnyango wokusebenza ubuye ufakwe inkinobho yokuphepha ukuvimbela izingozi ngesikhathi sokusebenza noma ukulungiswa. Futhi inefasitela elikhulu lokulunguza, elilungele opharetha ukuqonda ukusebenza nokucutshungulwa komshini.

Ukuhlanza

Sebenzisa isembozo se-telescopic kanye neshidi lensimbi lokuvikela ukuze uvikele ama-chips akhiqizwa ngesikhathi sokusebenza, ugweme ukusika ama-splash futhi ubangele ukulimala kwezinye izindlela.

Ukukhanyisa

Indawo yokusebenza ifakwe izibani ezimbili ze-LED, futhi ukukhanya kokukhanyisa kugcinwa ngaphezu kwe-800LUX, kuhlinzeka indawo efanelekile yokusebenza ekhanyayo ku-opharetha.

Ukusebenza

Uhlangothi lokusebenza lufakwe umnyango wokuslayida wohlobo oluhlukanisiwe, olunikeza isikhala esikhulu sokuvula, esilungele ukuthi i-workpiece ilayishwe ngokukhululekile futhi ilayishwe kusuka ezinhlangothini ezintathu usebenzisa i-crane.