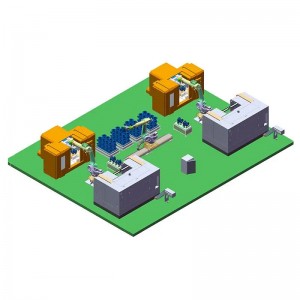

I-CNC Vertical Machining Center

Izici Zomshini

Isikhungo semishini ye-OTURN senziwa ngomzimba wensimbi wensimbi we-Mihanna wekhwalithi ephezulu nokwesekwa okugcwele kwezimbambo, okudonsa ukushaqeka okuphindwe kashumi kunocingo oluvamile lwensimbi. Ama-casting anezimbambo ngaphakathi kwe-fuselage anokumelana nokukhwehlela okuphezulu kakhulu kanye nokumelana nokushaqeka okukhulu. Ngaphezu kwalokho, isikhala sangaphakathi esibanzi sivumela opharetha ukuthi aguqule kalula amathuluzi nezinto zokusebenza. Ngesakhiwo esiqinile esiqinile, sidala unyawo oluncane, kodwa olunembayo oluphezulu kanye nemishini ezenzakalelayo enamagciwane amaningi.

I-Ou Teng isebenzisa amabhrendi aziwayo anokuqina okuphezulu namareyili amaslayidi ahambisana nokunemba. Ubuchwepheshe bayo benqubo bufana nama-bearings okukhiqiza, ane-zero clearance kanye nezici ezithwala nxazonke. Isilayidi esiwumugqa sinokusetshenziswa okuphansi, ukunemba okuphezulu, nesivinini esihamba ngokushesha, esingafika kumamitha angama-48 ngomzuzu.

Umshini ufakwe izibani zokusebenza ezikhanya kakhulu, okulula ukuthi opharetha alayishe futhi ehlise izinto zokusebenza futhi enze izilinganiso. Isibani somsebenzi sinemisebenzi yokuvikela uthuli, ukungangeni kwamanzi kanye nokuvikela ukuqhuma.

Idivayisi yokushintshisana yamathuluzi esheshayo, elula, ethembekile nephila isikhathi eside inikeza ukushintshana kwamathuluzi okubushelelezi futhi okuthembekile. Idizayini yedivayisi yokushintshisana yamathuluzi eyingqayizivele, ikhono lokukhetha amathuluzi kunoma yisiphi isikhundla, ingafinyelelwa ngokushesha ngokulawulwa kwesoftware ye-PLC.

Ukucaciswa

| Into | Iyunithi | V850 | V1160 | V1370 | V1580 |

| Ibanga lomshini | |||||

| Uhambo lwe-X eksisi | mm | 800 | 1100 | 1300 | 1500 |

| Uhambo lwe-Y eksisi | mm | 550 | 600 | 700 | 800 |

| Z ukuhamba eksisi | mm | 550 | 600 | 700 | 700 |

| Ibanga ukusuka ekhaleni lokuphotha kuya etafuleni lokusebenza | mm | 120-670 | 120-720 | 120-820 | |

| Ibanga ukusuka maphakathi ne-spindle ukuya endaweni yethrekhi yekholomu | mm | 595 | 650 | 750 | 865 |

| Ithebula lokusebenza | |||||

| Usayizi wethebula | mm | 1000x550 | 1200x600 | 1400x700 | 1600x800 |

| Umthamo omkhulu webhentshi lokusebenzela | kg | 500 | 800 | ||

| T-slot | mm | 5x18x90 | 5x18x100 | 7x22x110 | 7x22x100 |

| I-spindle | |||||

| Isivinini se-spindle | rpm | 8000 | 6000 | ||

| I-Spindle torque | Nm | 35/47.7 | 47/70 | 140/190 | |

| I-spindle taper | I-BT-40 | I-BT-50 | |||

| Amandla e-spindle | KW | 7.5 | 11 | 15 | |

| Okunye | |||||

| Ubukhulu | mm | 2600x2500x2700 | 3200x2700x3000 | 4180x3050x3187 | 4580x3050x3187 |

| Isisindo somshini | T | 5 | 6.5 | 10 | 15.5 |

Ukucushwa Kwemininingwane

Ukususwa kwe-chip spiral kabili

Idivaysi yokukhipha i-spiral spiral chip ephindwe kabili, eshaywa emshinini wokukhipha i-spiral chip ezinhlangothini zombili zomshini, ingathumela kalula ama-chips ensimbi acutshunguliwe ngaphandle komshini ngokushesha, kunciphise ukumoshakala kwesikhathi okungacutshungulwa ngenxa yokukhishwa kwezinsimbi zensimbi. .

Yonke imishini isebenzisa ukulinganisa kwe-laser, ukuhlolwa kokusika, ukuhlolwa kokusebenza kwesikhathi eside kanye nokuhlolwa okuqinile ngokwezinga le-VDI 3441, ukuze i-eksisi ngayinye ibe nokuphindaphinda okuhle nokuma okunembile, iqinisekisa ukunemba komshini.

Ithuluzi lokulinganisa eliyindilinga i-Renishaw lisetshenziselwa ukulungisa ukuzungeza nokunemba kwejometri yomshini, ngaleyo ndlela ihlola futhi iqinisekise ukunemba okuqondile kwesikhala esinezinhlangothi ezintathu.

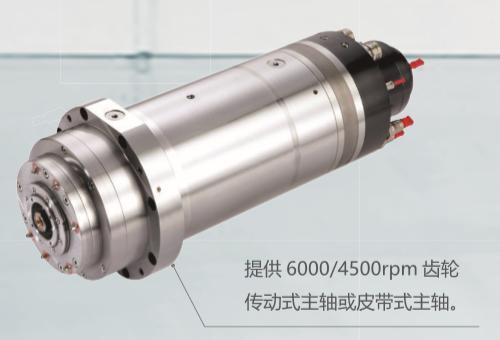

Idizayini yokuphotha yohlobo lomkhono inikeza i-6000/4500rpm yokuphotha eqhutshwa ngegiya noma uhlobo lwebhande lokuphotha, futhi ibhande lokuphotha elinekhala elifushane lisekelwa ngempumelelo umkhono kanye nokuphonswa kwekhanda, ngakho-ke kungathuthukisa kakhulu ukuqina kokuphotha. I-spindle motor ingabonisa izinga eliphezulu lokusika insimbi. Ngesistimu yokupholisa i-spindle, ukunyuka kwezinga lokushisa kwe-bearing kungancishiswa ukuze kunwetshwe impilo ye-spindle.

I-workpiece