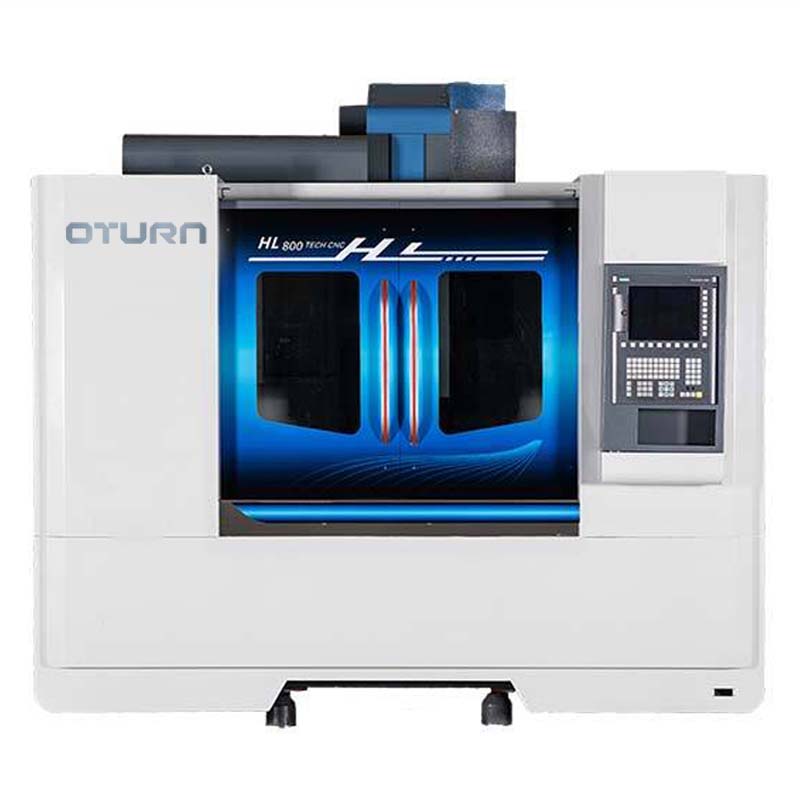

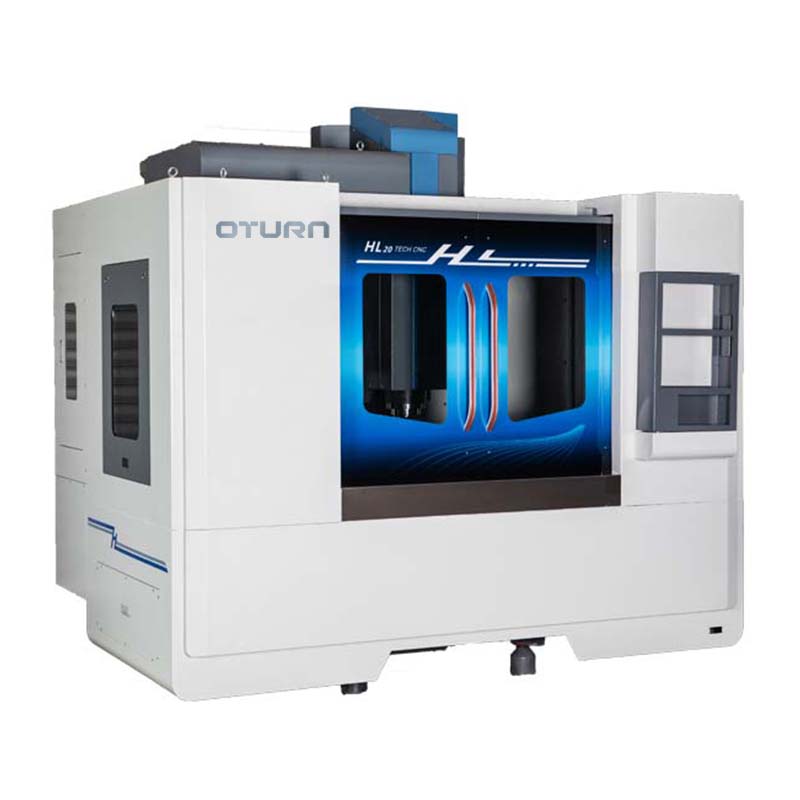

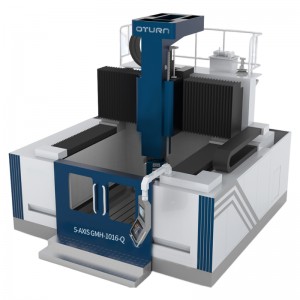

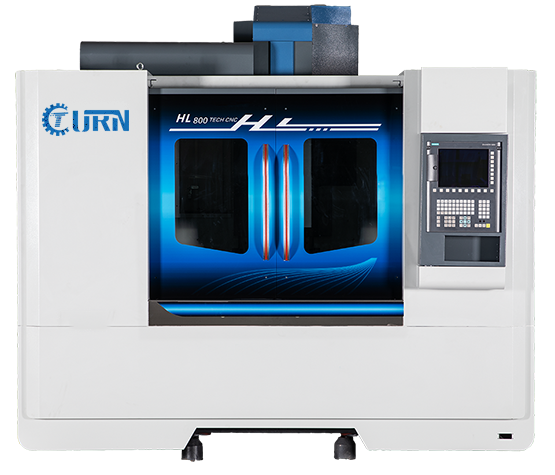

CNC High Qulity Vertical Machining Center

I-HALLERBS iyisikhungo semishini ye-CNC esiphezulu esinembayo ephezulu futhi eqinile, esetshenziselwa ukucubungula umsebenzi odinga ukunemba okuphezulu kwemishini efana nemoto, i-aerospace, imboni yezempi.

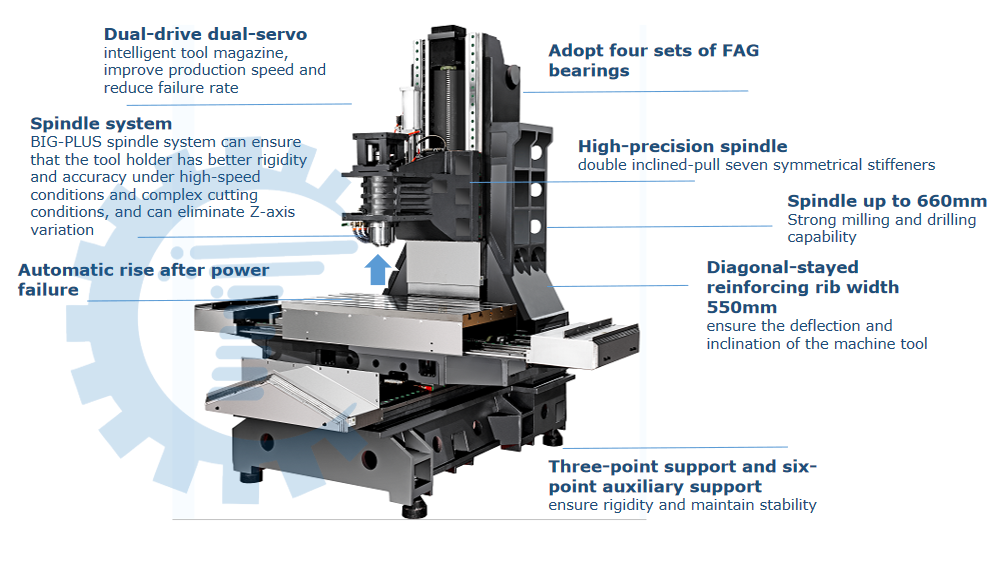

Umshini we-HALLERBS usebenzisa ubuchwepheshe bokusakaza obuthuthukile obuvela eJalimane naseSwitzerland. Kuyisikhungo semishini esime mpo esinesivinini esikhulu, ukunemba okuphezulu, ukusebenza kahle okuphezulu nokuzinza okuphezulu.

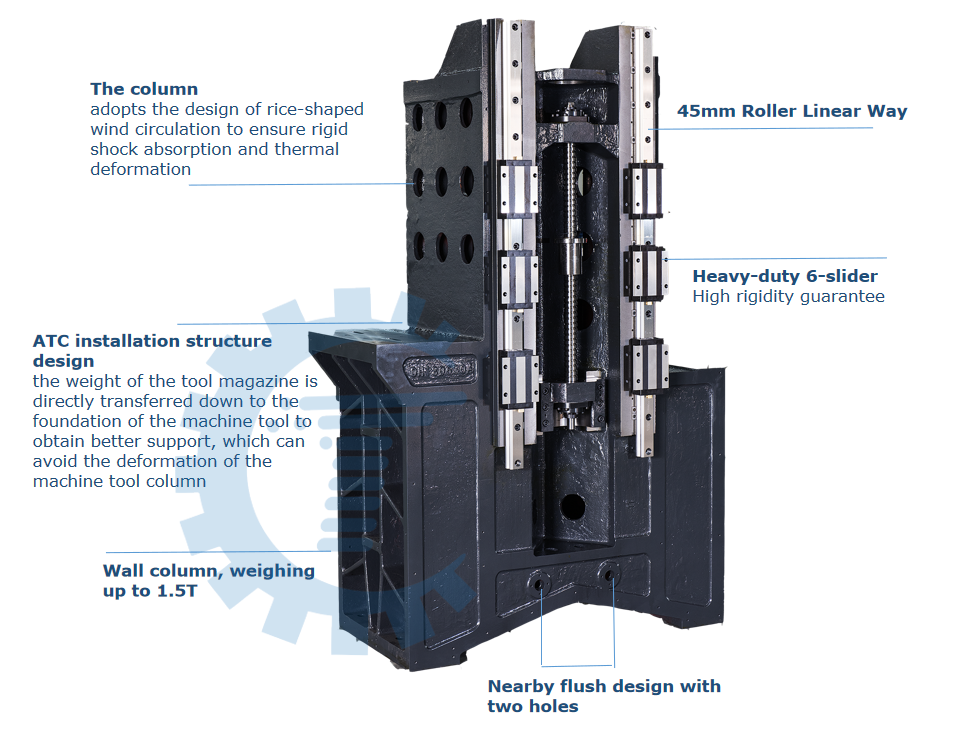

Ikholomu yamukela ukwakheka kokujikeleza komoya okumise okwelayisi ukuze kuqinisekiswe ukumuncwa okuqinile kokushaqeka kanye ne-thermal deformatio, ukwakheka kwesakhiwo sokufakwa kwe-ATC, isisindo somagazini wethuluzi sidluliselwa ngqo phansi esisekelweni somshini ukuthola ukwesekwa okungcono, okungagwema ukuguqulwa kwekholomu yomshini.

Ibhokisi lokuphotha elinemba okuphezulu, ukuthambekela okukabili-donsa izimbambo eziqinisa ukulinganisa eziyi-7 ukuze ukhuphule ukuzinza.

Amaslayidi ayisithupha kanye nesihlalo esibalulekile sesikulufa samantongomane, amasethi ayisithupha ama-bearings, pre-tensioning kabili, ukuma kabili, ukuthuthukisa kakhulu ukwethembeka.

I-X eksisi:35mm; I-eksisi Y:45mm; I-Axis ye-Z: 45mm

Umagazini wethuluzi elihlakaniphile le-dual-drive dual-servo, ithuluzi lishintsha ngokushesha, lithuthukisa isivinini sokukhiqiza futhi linciphise izinga lokuhluleka.

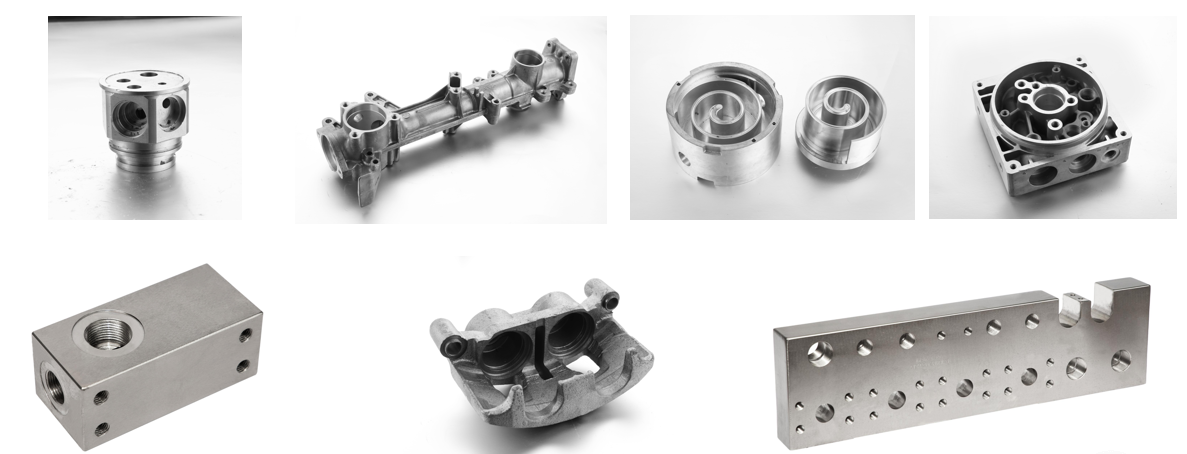

Ukucubungula izixazululo ezifanele ama-workpiece ahlukene ezimbonini eziningi:

I-Aerospace/Automobile/Medical/Energy/Traffic Construction/Agriculture/ Mold/3Cindustry/5Gindustry/Military/ Engineering/Etc.

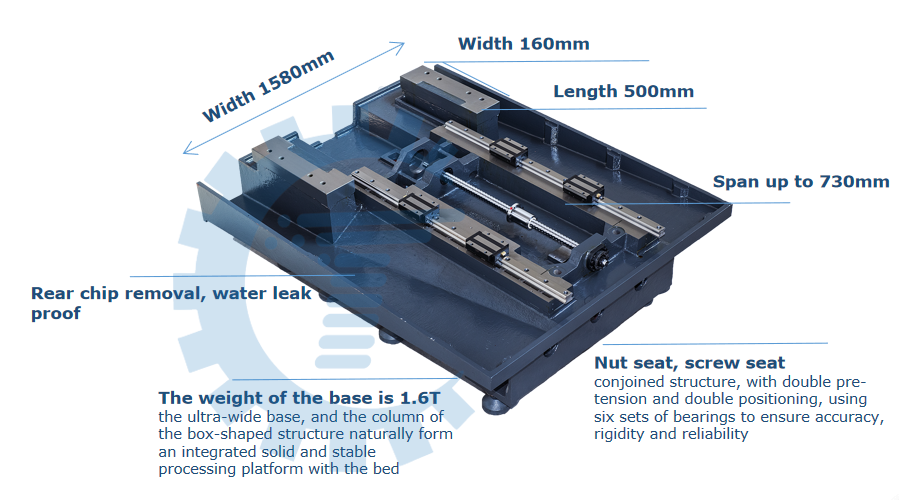

Umzimba Wombhede

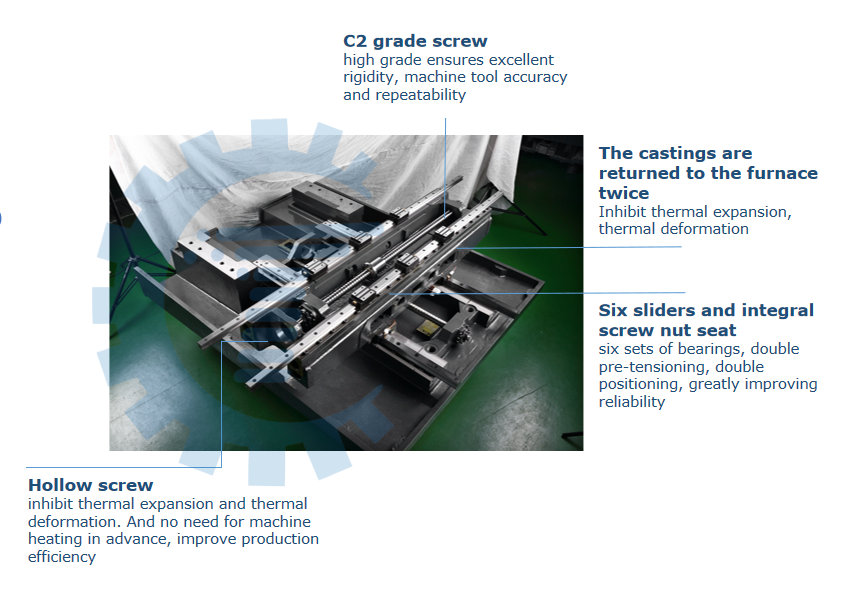

Isikulufu

Umshini Wokugcwalisa

Ikholomu

Ulwazi Lobuchwepheshe

| Imininingwane | Iyunithi | I-HL-8 | I-HL-8HS | I-HL-8SS | HL-11 | I-HL-11HS | I-HL-11SS |

| Ukuhamba | |||||||

| I-X eksisi | mm | 800 | 800 | 800 | 1100 | 1100 | 1100 |

| Y eksisi | mm | 500 | 500 | 500 | 500 | 500 | 500 |

| Z eksisi | mm | 600 | 600 | 600 | 600 | 600 | 600 |

| Ikhala lokuphotha libheke etafuleni | mm | 200-800/250-850/320-920 | |||||

| I-Spindle Center kuya ku-Column Plate | mm | 512 | 512 | 512 | 512 | 512 | 512 |

| Ibhentshi lokusebenzela | |||||||

| Ubude | mm | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 |

| Ububanzi | mm | 480 | 480 | 480 | 480 | 480 | 480 |

| Ukuthwala itafula | KG | 950 | 1700 | 1200 | 950 | 1700 | 1200 |

| Usayizi we-T-groove | mm | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 |

| I-spindle | |||||||

| Isivinini se-spindle | I-BT40 | I-BT40 | I-BT40 | I-BT40 | I-BT40 | I-BT40 | |

| Isivinini esikhulu sokuphotha | rpm | 8000belt/12000ukuxhuma okuqondile | |||||

| Amandla e-spindle motor | KW | 11/15 | 15/18.5 | 13.5/12 | 11/15 | 15/18.5 | 13.5/12 |

| Ukugcoba nge-spindle | NM | 191/118 | 118 | 250/126 | 191/118 | 118 | 250/126 |

| Amapharamitha we-eksisi | |||||||

| Izinga lokuphakelayo elisheshayo(X/Y) | m/min | 48/48/36 | 64/64/64 | 72/72/64 | 48/48/36 | 64/64/50 | 72/72/55 |

| I-X/Y/Z I-Axis Servomotor | KW | 3.0/3.0/3.0 | 4.0/4.0/4.0 | 3.0/3.0/5.2 | 3.0/3.0/3.0 | 4.0/4.0/4.0 | 3.0/3.0/5.2 |

| Ukunemba | |||||||

| Ukumisa ukunemba | mm | 0.008 | 0.006 | 0.006 | 0.008 | 0.006 | 0.006 |

| Ukunemba kokuma okuphindaphindiwe | mm | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 |

| Ukushintsha Ithuluzi Okuzenzakalelayo | |||||||

| Amandla omagazini wethuluzi | PCS | 24(30 Uma uthanda) | 24(30 Uma uthanda) | 24(30 Uma uthanda) | 24(30 Uma uthanda) | 24(30 Uma uthanda) | 24(30 Uma uthanda) |

| Ubukhulu bethuluzi lobubanzi | mm | 80 | 80 | 80 | 80 | 80 | 80 |

| Ubude bethuluzi obukhulu | mm | 300 | 300 | 300 | 300 | 300 | 300 |

| Isisindo sethuluzi esiphezulu | KG | 8 | 8 | 8 | 8 | 8 | 8 |

| Isikhathi sokushintsha ithuluzi | isekhondi | 2.5 | 2.5 | 2.2 | 2.5 | 2.5 | 2.2 |

| Isisindo Somshini | KG | 7600 | 7600 | 7600 | 8000 | 8000 | 8000 |

| Imfuneko yengcindezi encane | Indawo yokuphuzela utshwala | 5 | 5 | 5 | 5 | 5 | 5 |