I-CNC Double Spindle Turning Center 150MS Series

Ukucushwa komkhiqizo

Ngenisa

1. Yamukela idivayisi yokuphotha kagesi evumelanisiwe yedrayivu eqondile: isifaki khodi esikhulayo samagnetic (sine ne-cosine) ukunemba kokumisa: amasekhondi angama-arc angama-20, ukunemba kwenkomba ye-C-axis: imizuzwana engama-arc angu-40. ①Susa ngempumelelo ukudlidliza kwe-spindle, futhi ukunemba kokuchezuka kwekhala kungaphakathi kuka-0.002MM. Thuthukisa ukuphela kwendawo yokusebenza, ② sebenzisa i-rotor efakwe ngemuva, eyenza ukufakwa nokugcinwa kusheshe, ③ injini yokuphotha ifakwe uhlelo lokupholisa ukuze icindezele umthelela wokugudluzwa okushisayo futhi iqinisekise izinga lokushisa elisebenza njalo le-spindle. Isistimu yokuphotha iye yahlolwa okuqinile kwebhalansi eguquguqukayo. Ukugcinwa kokunemba kwayo okuhle, ukuqina okuphezulu nokusebenza kahle okuphezulu kwenza wonke umshini ungagcini nje ngokuqedela ukuqedela, kodwa futhi wenze imishini enzima kanye nokusika okusindayo kubasebenzisi. Ifaneleka ngokukhethekile ukukhiqizwa ngobuningi bobunjwa obuyinkimbinkimbi kanye nokushelela okuphezulu. umkhiqizo.

2. Ukuqina okuphezulu okuhlanganisiwe komklamo we-servo power turret. Isiza ukushintsha ukusebenza kwethuluzi elisheshayo nelinembile le-servo turret, futhi uma kuhlanganiswe nokugaya amandla kwe-eksisi yamandla esivinini esikhulu, ifinyelela amandla amahle kakhulu okuguqula nokugaya okuhlanganisiwe okucubungula. Isibambi samathuluzi sifakwe nesixhumi esibonakalayo sokufakwa kwe-BMT esiqinile, futhi shaft yokudlulisa amandla ishayelwa yi-servo spindle motor.

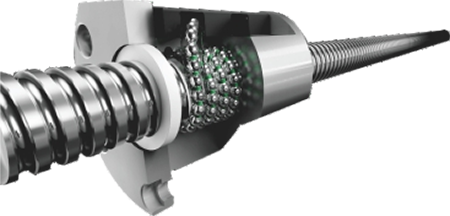

3. Ithuluzi lomshini lifakwe ama-rails angumhlahlandlela kanye nezikulufu zebhola zaphansi ezinembayo ukuze kuqinisekiswe ukunemba okungcono kakhulu nokuqina. I-eksisi ngayinye yamukela ukwakheka kwe-eksisi yokudlulisa okuqondile kanye nendlela yokudluliswa kwe-double-anchor pre-relay, enganciphisa inani lokususwa kwe-thermal futhi Ithuthukise ngokuphawulekayo ukunemba kokucubungula. Ama-rail amaslayidi aqinile, anosayizi omkhulu, anomsebenzi osindayo agcina ukunemba okungaguquki lapho umshini ungaphansi komthelela, futhi ukugudluzwa kushelela futhi kunomsindo ophansi, okunganweba impilo yesevisi.

4. Lo mshini unikeza abasebenzisi uhlelo oluphelele lwe-hydraulic kanye ne-lubrication, besebenzisa amaphampu aphezulu we-hydraulic, ama-valve we-hydraulic nezinye izingxenye ukunciphisa kakhulu izinga lokuhluleka. I-hydraulic kanye ne-lubrication systems yakhelwe ukuthi ibe lula futhi ithembeke. Ithuluzi lomshini lisebenzisa ukuthambisa okuzenzakalelayo komthamo okumaphakathi.

5. Yamukela isilinda esijikelezayo saseTaiwan kanye nedivayisi yokukhipha i-chip ezenzakalelayo. Izinketho zihlukaniswe ngomugqa wangemuva kanye nomugqa oseceleni, okunganciphisa kakhulu amandla okusebenza komsebenzisi futhi kuzuze ukukhiqizwa okuphephile nokusebenza kahle. Izingxenye zokusebenza ezingenhla zingahle zihlelwe ukuthi zilawule, futhi zenzelwe ukuhlukaniswa kwamanzi kawoyela kanye nemishini yokuhlunga yensimbi. Ngesikhathi esifanayo, ukulungiswa okukhethekile okuhlukahlukene kungaklanywa futhi kufakwe ngokuvumelana nezidingo ezikhethekile zabasebenzisi.

Imininingwane Yezobuchwepheshe

| Item Imodeli | Igama | Iyunithi | 150MSY-II | 150MSY-III | 150MS-II | 150MS-III |

| Ukuhamba | Ubukhulu. ukuzungezisa umbhede ububanzi | mm | Ф380 | Ф380 | Ф380 | Ф380 |

| Ubukhulu. ukucubungula ububanzi | mm | Ф100 | Ф100 | Ф100 | Ф100 | |

| Ubukhulu. ukucubungula ububanzi kusiphathi samathuluzi | mm | Ф160 | Ф160 | Ф160 | Ф160 | |

| Ubukhulu. ubude bokucubungula | mm | 150 | 150 | 150 | 150 | |

| I-spindle Isilinda Chuck | Ikhala lokuphotha | / | A2-5 | A2-5 | A2-5 | A2-5 |

| Ubukhulu.isivinini sokuphotha | mm | 5500 | 5500 | 5500 | 5500 | |

| Spindle hydraulic cylinder/colletHydraulic Cylinder/Chuck | rpm | 6" | 6" | 6" | 6" | |

| Idayamitha yembobo yomphimbo Ububanzi bembobo yokuphotha | kw | Ф56 | Ф56 | Ф56 | Ф56 | |

| Ubukhulu.Ububanzi bembobo yebha ye-spindle Ibha ububanzi | Nm | Ф45 | Ф45 | Ф45 | Ф45 | |

| Amandla e-spindle motor | / | 17.5 | 17.5 | 17.5 | 17.5 | |

| Amandla e-spindle motor |

| 62-125 | 62-125 | 62-125 | 62-125 | |

| I-Sub-spindle Chuck | Ikhala le-sub-spindle | / | A2-4 | A2-4 | A2-4 | A2-4 |

| Ubukhulu.isivinini se-sub-spindle | mm | 6000 | 6000 | 6000 | 6000 | |

| I-sub-spindle hydraulic cylinder/collet H | rpm | 5" | 5" | 5" | 5" | |

| I-sub-spindle ngokusebenzisa ububanzi bembobo | Nm | Ф46 | Ф46 | Ф46 | Ф46 | |

| Ubukhulu.Ububanzi bembobo yebha ye-sub-spindle | kw | Ф32 | Ф32 | Ф32 | Ф32 | |

| Amandla kagesi okuphotha aqondise ngqo | / | 11 | 11 | 11 | 11 | |

| Spindle direct drive motor torque |

| 27-66 | 27-66 | 27-66 | 27-66 | |

| X1/Z1/Y/X2/Z2 ipharamitha yokuphakelayo kwe-eksisi | X1/Z1/Y amandla enjini | kw | 1.8/1.2/1.2 | 1.8/1.2/1.2 | 1.8/1.2 | 1.8/1.2 |

| X2/Z2 amandla enjini | mm | 1.2/1.2 | 1.2/1.2 | 1.2/1.2 | 1.2/1.2 | |

| X1/Z1 ukuhamba kwe-eksisi | mm | 135/370 | 135/370 | 135/370 | 135/370 | |

| X2/Z2 uhambo lwe-eksisi | mm/min | 215/400 | 215/400 | 215/400 | 215/400 | |

| Ukunyakaza okusheshayo kwe-eksisi ye-X/Z//Y/S | mm | 30/30/6/30 | 30/30/6/30 | 30/30/30 | 30/30/30 | |

| X1/Z1 uhlobo lwesitimela samaslayidi | mm | Irola35/35 | Irola35/35 | Irola35/35 | Irola35/35 | |

| Uhlobo lwesitimela se-X2/Z2 | mm | Irola30/30 | Irola30/30 | Irola30/30 | Irola30/30 | |

| I-Servo drive Imingcele yokusika | Uhlobo lwe-Turret | ama-pcs | I-BMT45-12T | I-BMT45-12T | I-BMT45-12T | I-BMT45-12T |

| Amandla e-turret | Kw/Nm | 2.2/26Nm | 2.2/26Nm | 2.2/26Nm | 2.2/26Nm | |

| Uhambo lwe-Y eksisi | mm | 80(±40) | 80(±40) |

| 6000 ER20 | |

| Ubukhulu.isivinini somphathi wamathuluzi aqhutshwayo | rpm | 6000 ER20 | 6000 ER20 | 6000 ER20 | 20x20 | |

| Ukucaciswa kwesibambi sethuluzi lobubanzi obungaphandle | mm | 20x20 | 20x20 | 20x20 | Ф32 | |

| Imininingwane yesibambi sethuluzi lobubanzi obungaphakathi | mm | Ф32 | Ф32 | Ф32 | 0.15 | |

| Isikhathi sokushintsha ithuluzi eliseduze | isekhondi | 0.15 | 0.15 | 0.15 | I-BMT40-8T | |

| Amandla we-Servo Turret nemingcele | Uhlobo lwe-turret yamandla | / | I-NC8T | I-BMT40-8T | I-NC8T | 2.2/26Nm |

| Imininingwane yesibambi sethuluzi lobubanzi bangaphandle | mm | 25x25 | 20x20 | 25x25 | 6000 ER20 | |

| Imininingwane yesibambi sethuluzi lobubanzi obungaphakathi | mm | Ф32 | Ф32 | Ф32 | 20x20 | |

| Isikhathi sokushintsha ithuluzi eliseduze | isekhondi | 0.15 | 0.15 | 0.15 | Ф25 | |

| Ubukhulu | Indawo okuhlalwa kuyo Approx. | mm | 2.2x2.1x1.7 | 2.2x2.1x1.7 | 2.2x2.1x1.7 | 0.15 |

| Isisindo somshini Cishe. | kg | 3500 | 3500 | 3200 | 2.2x2.1x1.7 | |

| Okunye | Ukusika umthamo we-tank fluid | L | 180 | 180 | 180 | 3500 |

| Ivolumu yebhokisi leyunithi ye-Hydraulic | L | 40 | 40 | 40 | 180 | |

| Amandla kawoyela wephampu kawoyela weHydraulic | kw | 1.5 | 1.5 | 1.5 | 40 | |

| Umthamo wethangi likawoyela wokugcoba | L | 2 | 2 | 2 | 1.5 | |

| Amandla e-automatic lubrication futha motor | W | 50 | 50 | 50 | 2 | |

| Amandla epompo yamanzi okupholisa | W | 750 | 750 | 750 | 50 |

Izici zokucushwa

Kalula nakakhuluTo Use And MinsimbiPenamandla

●Idizayini ethuthukiswe ngokugcwele

● Ifakwe i-HMI

●Ihlonyiswe nge-CNC yakamuva ye-FANUC kanye nobuchwepheshe be-servo

●Kulinganiswe ngemisebenzi yomuntu siqu

●Umthamo wenkumbulo owandisiwe

KalulaOf Use

Vimbela ukungasebenzi komshini kungazelelwe ngokulungiswa kokuvikela

● Imisebenzi yokubikezela iphutha elicebile

Thola kalula indawo enephutha futhi unciphise isikhathi sokutakula

●Imisebenzi yokuxilonga/yokunakekela

Ukusebenza okuphezulu kokucubungula

KufushanisiweCycleTimi

●Ubuchwepheshe bokucubungula obusezingeni eliphezulu

Thola ukucutshungulwa kwekhwalithi ephezulu

Ubuchwepheshe bokucubungula obusezingeni eliphezulu

●Ukuxilongwa/umsebenzi wokunakekela

PhezuluOperationRwadla

Hlala usekela imisebenzi ehlukahlukene endaweni yokucubungula

●FANUC

Okwenziwe kube ngokwakhoSukreniIs EasierTo Use

●Ukusebenza komuntu siqu okujwayelekile

Izinyathelo emkhakheni we-IoT

●Usekelo lwenhlobonhlobo yamanethiwekhi akusayithi

THKBkonkeSabasebenzi

·Ibanga le-C3, kusetshenziswa isikulufu sebhola esinembayo esiphezulu, esinokulayisha kuqala amantongomane kanye nokwelashwa kokugxilisa isikulufu ukuze kuqedwe kusengaphambili ukuhlehla emuva kanye nokwenyuka kwezinga lokushisa, okubonisa ukuma okuhle kakhulu nokunemba kokuphindaphinda.

·Servo motor drive eqondile yokunciphisa iphutha lokubuyela emuva.

THKRollerLungekhoGuide

·Izinga le-P lezinga eliphezulu lokunemba kwe-SRG, ibanga lokunemba legayidi elinguziro, ukusikwa kwe-arc, ukusikwa kwe-bevel, ukuthungwa kwendawo akufani ngokuqhathaniswa. Ifanele ukusebenza ngesivinini esiphezulu, inciphisa kakhulu amandla okushayela amahhashi adingekayo kumathuluzi omshini.

·Ukugingqika esikhundleni sokushelela, ukulahlekelwa ukushwibilika okuncane, ukusabela okubucayi, ukunemba kokuma okuphezulu. Ingakwazi ukuthwala umthwalo endleleni ehambayo ngesikhathi esifanayo, futhi indawo yokuxhumana yethrekhi isathintana namaphuzu amaningi ngesikhathi somthwalo, futhi ukuqina kokusika ngeke kuncishiswe.

·Kulula ukuhlanganisa, ukushintshashintsha okuqinile, kanye nesakhiwo esilula sokuthambisa; inani lokugqoka lincane kakhulu futhi impilo yesevisi yinde.

I-SKFBicici/OilingMane

·Umshini wokuthambisa ozenzakalelayo uhlangabezana nezidingo zezinhlelo zokusebenza ezahlukahlukene, ulungele izimo zokusebenza ezahlukahlukene, imikhiqizo ethembekile, ukusetshenziswa okuvumelana nezimo.

·Hlangana nezidingo zokuthwala ukugcotshwa kumazinga okushisa aphezulu, ukudlidliza okuqinile nendawo eyingozi.

Iphuzu ngalinye lokugcoba lisebenzisa i-volumetric proportional distributor ukulawula inani lokuthambisa, futhi umshini ungalawulwa yi-PLC ukuze unikeze uwoyela ngokunembile.