I-CNC Double spindle Ukusebenza okuphezulu 1600-800-1200-1600-2000-3000 uchungechunge

Ukucushwa komkhiqizo

Izici

I-TurretDesignPukusebenza kahle

Isakhiwo esihlanganisiwe esihle se-Y-eksisi siqinile kakhulu, singumsebenzi osindayo, futhi sisebenza kangcono kune-axis Y-interpolation.

·Ukucubungula kahle nokushelela kwekhonta yendiza

·Kulula ukucubungula izindawo ezigobile ezihlanganisiwe namakhonsathi

Uma kuqhathaniswa "ne-interpolation Y", i-"positive Y" inezinzuzo ezisobala ekugayweni kwendiza. Ukunyakaza kwe-"positive Y" Y-axis kuncike ku-X-eksisi futhi kuwukunyakaza kwe-eksisi eyodwa. Ukunyakaza kwe-"interpolation Y" Y-axis ukuhlanganisa umugqa oqondile ngokunyakaza ngesikhathi esisodwa kwe-X-eksisi kanye ne-Y-eksisi. Uma kuqhathaniswa "no-Y omuhle" wokucaba kwendiza yokugaya, ukucutshungulwa kwe-eksisi "positive Y" ngokusobala kuyakhanya futhi kuyashelela.

NgqoDumfulaSi-synchronousEi-lectricSpindle

Ukuqina okuphezulu, i-torque ephezulu, ukusebenza kahle okuphezulu, isiphetho esingcono, ukukhomba okunembe kakhudlwana.

Zonke izingxenye zomshini ezinkulu zenziwe ngensimbi eyinsimbi engu-HT300 enamandla kakhulu okumunca ukushaqeka.

Izici zamathuluzi omshini anama-spindle kagesi e-direct-drive

●Isifaki khodi esikhulayo sikaMagnetic (sine ne-cosine) ukunemba kokumisa: amasekhondi angama-arc angama-20,

Ukunemba kwenkomba ye-C-axis: amasekhondi angama-arc angu-40

● Isivinini sokuphendula esisheshayo sokuqalisa, ukonga isikhathi sethuluzi lomshini nokuthuthukisa ngempumelelo umthamo wokukhiqiza

●Umthwalo omncane wokusika, ukonga amandla nokonga amandla, ukuvikelwa okungcono kwamathuluzi omshini nempilo yesevisi enwetshiwe

●Susa ngokuphumelelayo ukudlidliza kwe-spindle, umphumela omuhle wokulinganisa, isiphetho esihle, futhi uthuthukise isiphetho sezinto zokusebenza

(Izinzuzo zokuphenduka esikhundleni sokugaya, ukubukeka okuqinile, ukuhwaqeka kwendawo engu-Ra 0.2μm)

· Injini yokuphotha ifakwe isistimu yokupholisa ukuze icindezele ithonya lokufuduka okushisayo futhi iqinisekise ukuthi i-spindle iyaqhubeka nokusebenza ezingeni lokushisa elingashintshi.

(Ukunemba kokuphela kwekhala kungaphakathi kuka-0.002mm, kuqinisekisa ukunemba okuzinzile)

· I-back-mounted direct-drive spindle ehambisanayo, ukufakwa nokugcinwa okulula kakhudlwana

· A2-5: 7016AC-ngaphambili ezimbili ezingemuva ezimbili

· A2-6: ngaphambili NN3020+100BAR10S, ngemuva NN3018

I-A2-8: ngaphambili NN3024+BT022B*2, i-NN3022 yangemuva

Kunzima-DutyCi-stIronBaseAnd Cabaphikisayo

Konke ukulingisa kuthuthukiswa kusetshenziswa i-finite element analysis (FEA) ukuze kwehliswe ukuhlanekezela kanye namandla okumunca ukushaqeka. Ukulingisa kochungechunge olukhulu lwezintambo kuqiniswa ngezimbambo ukuze kuthuthukiswe ukuqina kanye nokuzinza kokushisa. I-Compact and symmetric headstock kanye ne-tailstock castings ithuthukisa ukuqina futhi iqinisekise ukunemba kokuma okuphezulu nokuphindaphinda.

Imininingwane Yezobuchwepheshe

| Into | Igama | Iyunithi | 800MS | 800MSY | 600MS | 600MSY | 1200MS |

| Ukuhamba | Ubukhulu. ukuzungezisa umbhede ububanzi | mm | Φ700 | Φ800 | Φ700 | Φ800 | Φ700 |

| Ubukhulu. ubukhulu bomshini | mm | Φ540 | Φ360 | Φ540 | Φ360 | Φ530 | |

| Ubukhulu. ukuzungezisa isibambi | mm | Φ350 | Φ450 | Φ350 | Φ450 | Φ350 | |

| Ubukhulu. ubude bokucubungula | mm | 770 | 770 | 570 | 570 | 1050 | |

| Ibanga phakathi kwezikhungo ezimbili | mm | 770 | 770 | 570 | 570 | 1030 | |

| ukuphotha Isilinda Chuck | Ikhala lokuphotha | I-ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-8 |

| Isilinda / i-chuck ye-Hydraulic | Intshi | 8'' | 8'' | 8'' | 8'' | 10° | |

| Spindle ngokusebenzisa ububanzi bembobo | mm | Φ79/66 | Φ79/66 | Φ79/66 | Φ79/66 | Φ86 | |

| Ubukhulu. induku ngokusebenzisa ububanzi bembobo | mm | Φ65/52 | Φ66/52 | Φ65/52 | Φ65/52 | Φ76 | |

| I-Spindle Max. isivinini | rpm | 4300 | 4000/4500 | 4300 | 4300 | 2500 | |

| Amandla e-spindle motor | kw | 18/22 | 18/22 | 18/22 | 18/22 | 17 | |

| I-torque ye-spindle motor | Nm | 91-227 | 91/227 | 91-227 | 91-227 | 170/400 | |

| I-sub-spindle Isilinda Chuck

| I-sub-Ikhala lokuphotha | I-ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| I-sub-Isilinda / i-chuck ye-Hydraulic | Intshi | 8” | 8” | 8” | 8” | 8" | |

| I-sub-Spindle ngokusebenzisa ububanzi bembobo | mm | Φ66 | Φ66 | Φ79/66 | Φ66 | Φ66 | |

| I-sub-Ubukhulu. induku ngokusebenzisa ububanzi bembobo | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| I-sub-I-Spindle Max. isivinini | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| I-sub-Amandla e-spindle motor | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| Amapharamitha wokuphakela kwe-eksisi ye-X/ZN/S | Amandla e-X motor | kw | 3 | 3 | 3 | 3 | 3 |

| Y amandla emoto | kw | - | 1.8 | - | 1.8 | - | |

| Z amandla motor | kw | 3 | 3 | 3 | 3 | 3 | |

| Samandla emoto | Kw | 3 | 3 | 3 | 3 | - | |

| Xukuhamba eksisi | mm | 320 | 215 | 315 | 215 | 313 | |

| Yukuhamba eksisi | mm | - | - | - | 100±50 | - | |

| Zukuhamba eksisi | mm | 80 | 820 | 620 | 620 | 1210 | |

| Ukucaciswa kwesitimela se-axis ye-X/Z | spec | 45 roller | 45roller | 45 roller | 45 roller | 45roller | |

| Imininingwane ye-Y axis ujantshi | spec | - | - | - | - | - | |

| S ukuhamba eksisi | mm | 770 | 770 | 570 | 570 | 880 | |

| Xi-eksisi ukuhamba ngokushesha | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Zi-eksisi ukuhamba ngokushesha | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Yi-eksisi ukuhamba ngokushesha | Mm/min | - | 8 | - | 8 | - | |

| Si-eksisi ukuhamba ngokushesha | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Amandla we-Servo Turret nemingcele | Uhlobo lwe-turret yamandla | / | I-Servo turret | I-Servo turret | I-Servo turret | I-Servo turret | I-Servo turret |

| Isiteshi samathuluzi | / | I-BMT55 | I-BMT55MY | I-BMT55 | I-BMT55MY | I-BMT65 | |

| M amandla motor | kw | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | |

| I-torque ye-M axis motor | Nm | 35 | 35 | 35 | 35 | 47.8 | |

| Ikhanda lamandla Max. isivinini | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Imininingwane yesibambi sethuluzi lobubanzi bangaphandle | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Imininingwane yesibambi sethuluzi lobubanzi obungaphakathi | mm | Φ40 | Φ50 | Φ40 | Φ40 | Φ50 | |

| Isikhathi sokushintsha ithuluzi eliseduze | isekhondi | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Ukumisa ukunemba | / | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Phinda ukunemba kokuma | / | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | |

| Imingcele ye-Tailstock | I-hydraulic tailstock ehlelekayo | / | - | - | - | - | - |

| I-Tailstock Max. ukuhamba | mm | - | |||||

| Ububanzi bemikhono | mm | - | |||||

| Ukuhamba ngemikhono | mm | - | |||||

| I-sleeve taper | / | - | |||||

| Ubukhulu | Izilinganiso sezizonke | m | 3100*2250*2100 | 3500*2250*2100 | 3100*2110*1800 | 3100*2250*2100 | 3900*2400*2100 |

| Isisindo somshini cishe. | kg | 5600 | 7000 | 5500 | 5600 | 7600 | |

| Okunye | Ukusika umthamo we-tank fluid | L | 250 | 250 | 250 | 250 | 300 |

| Amandla epompo yamanzi okupholisa | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Ivolumu yebhokisi leyunithi ye-Hydraulic | L | 40 | 40 | 40 | 40 | 40 | |

| Amandla kawoyela wephampu kawoyela weHydraulic | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Umthamo wethangi likawoyela wokugcoba | L | 2 | 2 | 2 | 2 | 2 | |

| Amandla e-automatic lubrication futha motor | kw | 50 | 50 | 50 | 50 | 50 |

| Into | Igama | Iyunithi | 1200MSY | 1600MS | 1600MSY | 2000MS | 2000MSY |

| Ukuhamba | Ubukhulu. ukuzungezisa umbhede ububanzi | mm | Φ800 | Φ700 | Φ800 | Φ700 | Φ800 |

| Ubukhulu. ubukhulu bomshini | mm | Φ400 | Φ530 | Φ400 | Φ530 | Φ400 | |

| Ubukhulu. ukuzungezisa isibambi | mm | Φ450 | Φ350 | Φ450 | Φ350 | Φ450 | |

| Ubukhulu. ubude bokucubungula | mm | 970 | 1450 | 1370 | 2030 | 2030 | |

| Ibanga phakathi kwezikhungo ezimbili | mm | 1030 | 1030 | 1030 | 2030 | 2030 | |

| ukuphotha Isilinda Chuck | Ikhala lokuphotha | I-ASA | A2-8 | A2-8 | A2-8 | A2-8 | A2-8 |

| Isilinda / i-chuck ye-Hydraulic | Intshi | 10" | 10° | 10" | 10" | 10" | |

| Spindle ngokusebenzisa ububanzi bembobo | mm | Φ86 | Φ86 | Φ86 | Φ86 | Φ86 | |

| Ubukhulu. induku ngokusebenzisa ububanzi bembobo | mm | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | |

| I-Spindle Max. isivinini | rpm | 2500 | 2500 | 2500 | 2500 | 2500 | |

| Amandla e-spindle motor | kw | 17 | 17 | 17 | 17 | 17 | |

| I-torque ye-spindle motor | Nm | 170/400 | 170/400 | 170/400 | 170/400 | 170/400 | |

| I-sub-spindle Isilinda Chuck

| I-sub-Ikhala lokuphotha | I-ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| I-sub-Isilinda / i-chuck ye-Hydraulic | Intshi | 8* | 8" | 8* | 8" | 8* | |

| I-sub-Spindle ngokusebenzisa ububanzi bembobo | mm | Φ66 | Φ66 | Φ66 | Φ66 | Φ66 | |

| I-sub-Ubukhulu. induku ngokusebenzisa ububanzi bembobo | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| I-sub-I-Spindle Max. isivinini | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| I-sub-Amandla e-spindle motor | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| Amapharamitha wokuphakela kwe-eksisi ye-X/ZN/S | Amandla e-X motor | kw | 3 | 3 | 3 | 3 | 3 |

| Y amandla emoto | kw | 1.8 | - | 1.8 | - | 1.8 | |

| Z amandla motor | kw | 3 | 3 | 3 | 3 | 3 | |

| Samandla emoto | Kw | - | 3 | 3 | 3 | 3 | |

| Xukuhamba eksisi | mm | 235 | 313 | 235 | 313 | 235 | |

| Yukuhamba eksisi | mm | 100±50 | - | 120±60 | - | 120±60 | |

| Zukuhamba eksisi | mm | 1100 | 1620 | 1500 | 2220 | 2100 | |

| Ukucaciswa kwesitimela se-axis ye-X/Z | spec | 45roller | 45 roller | 45 roller | 45 roller | 45 roller | |

| Imininingwane ye-Y axis ujantshi | spec | - | - | - | - | - | |

| S ukuhamba eksisi | mm | 880 | 880 | 880 | 2030 | 2030 | |

| Xi-eksisi ukuhamba ngokushesha | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Zi-eksisi ukuhamba ngokushesha | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Yi-eksisi ukuhamba ngokushesha | Mm/min | 8 | - | 8 | - | 8 | |

| Si-eksisi ukuhamba ngokushesha | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Amandla we-Servo Turret nemingcele | Uhlobo lwe-turret yamandla | / | I-Servo turret | I-Servo turret | I-Servo turret | I-Servo turret | I-Servo turret |

| Isiteshi samathuluzi | / | I-BMT65MY | I-BMT65 | I-BMT65MY | I-BMT65 | I-BMT65MY | |

| M amandla motor | kw | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |

| I-torque ye-M axis motor | Nm | 47.8 | 47.8 | 47.8 | 47.8 | 47.8 | |

| Ikhanda lamandla Max. isivinini | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Imininingwane yesibambi sethuluzi lobubanzi bangaphandle | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Imininingwane yesibambi sethuluzi lobubanzi obungaphakathi | mm | Φ50 | Φ50 | Φ50 | Φ50 | Φ50 | |

| Isikhathi sokushintsha ithuluzi eliseduze | isekhondi | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Ukumisa ukunemba | / | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Phinda ukunemba kokuma | / | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | |

| Imingcele ye-Tailstock | I-hydraulic tailstock ehlelekayo | / | - | - | - | - | - |

| I-Tailstock Max. ukuhamba | mm | - | - | - | - | - | |

| Ububanzi bemikhono | mm | - | - | - | - | - | |

| Ukuhamba ngemikhono | mm | - | - | - | - | - | |

| I-sleeve taper | / | - | - | - | - | - | |

| Ubukhulu | Izilinganiso sezizonke | m | 3900*2400*2100 | 4300*2110*2100 | 4300*2110*2100 | 4300*2110*2100 | 4300*2110*2100 |

| Isisindo somshini cishe. | kg | 7800 | 8400 | 8500 | 8400 | 8500 | |

| Okunye | Ukusika umthamo we-tank fluid | L | 300 | 350 | 350 | 350 | 350 |

| Amandla epompo yamanzi okupholisa | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Ivolumu yebhokisi leyunithi ye-Hydraulic | L | 40 | 40 | 40 | 40 | 40 | |

| Amandla kawoyela wephampu kawoyela weHydraulic | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Umthamo wethangi likawoyela wokugcoba | L | 2 | 2 | 2 | 2 | 2 | |

| Amandla e-automatic lubrication futha motor | kw | 50 | 50 | 50 | 50 | 50 |

| Into | Igama | Iyunithi | 3000MS | 3000MSY | 600MSY | 800MSY | 1200I-MSY |

| Ukuhamba | Ubukhulu. ukuzungezisa umbhede ububanzi | mm | Φ700 | Φ800 | Φ800 | Φ800 | Φ800 |

| Ubukhulu. ubukhulu bomshini | mm | Φ530 | Φ400 | Φ320 | Φ320 | Φ320 | |

| Ubukhulu. ukuzungezisa isibambi | mm | Φ350 | Φ450 | Φ450 | Φ450 | Φ450 | |

| Ubukhulu. ubude bokucubungula | mm | 3030 | 3030 | 510 | 710 | 970 | |

| Ibanga phakathi kwezikhungo ezimbili | mm | 3030 | 3030 | 570 | 770 | 1030 | |

| ukuphotha Isilinda Chuck | Ikhala lokuphotha | I-ASA | A2-8 | A2-8 | A2-6 | A2-6 | A2-8 |

| Isilinda / i-chuck ye-Hydraulic | Intshi | 10" | 10" | 8" | 8" | 10" | |

| Spindle ngokusebenzisa ububanzi bembobo | mm | Φ86 | Φ86 | Φ79/66 | Φ79/66 | Φ86 | |

| Ubukhulu. induku ngokusebenzisa ububanzi bembobo | mm | Φ76 | Φ76 | Φ66/52 | Φ66/52 | Φ76 | |

| I-Spindle Max. isivinini | rpm | 2500 | 2500 | 4300 | 4300 | 2500 | |

| Amandla e-spindle motor | kw | 17 | 17 | 18/22 | 18/22 | 17 | |

| I-torque ye-spindle motor | Nm | 170/400 | 170/400 | 91-227 | 91/227 | 170/400 | |

| I-sub-spindle Isilinda Chuck

| Ikhala le-Sub-Spindle | I-ASA | A2-6 | A2-6 | A2-6 | A2-6 | A2-6 |

| I-Sub-Hydraulic cylinder/chuck | Intshi | 8" | 8* | 8" | 8" | 8* | |

| I-Sub-Spindle ngokusebenzisa ububanzi bembobo | mm | Φ66 | Φ66 | Φ66 | Φ66 | Φ66 | |

| I-Sub-Max. induku ngokusebenzisa ububanzi bembobo | mm | Φ52 | Φ52 | Φ52 | Φ52 | Φ52 | |

| I-Sub-Spindle Max. isivinini | rpm | 4300 | 4300 | 4300 | 4300 | 4300 | |

| Amandla e-Sub-Spindle motor | kw | 18/22 | 18/22 | 18/22 | 18/22 | 18/22 | |

| Amapharamitha wokuphakela kwe-eksisi ye-X/ZN/S | Amandla e-X motor | kw | 3 | 3 | 3 | 3 | 3 |

| Y amandla emoto | kw | - | 1.8 | 1.8 | 1.8 | 1.8 | |

| Z amandla motor | kw | 3 | 3 | 3 | 3 | 3 | |

| S motor amandla | Kw | 3 | 3 | - | 3 | 3 | |

| Uhambo lwe-X eksisi | mm | 313 | 235 | 210 | 210 | 210 | |

| Uhambo lwe-Y eksisi | mm | - | 120±60 | 120±50 | 120±50 | 120±60 | |

| Z ukuhamba eksisi | mm | 3220 | 3100 | 620 | 820 | 1100 | |

| Ukucaciswa kwesitimela se-axis ye-X/Z | spec | 45 roller | 45 roller | 45 roller | 45 roller | 45 roller | |

| Imininingwane ye-Y axis ujantshi | spec | - | - | - | - | - | |

| S ukuhamba eksisi | mm | 3080 | 3080 | - | 770 | 880 | |

| Ukunyakaza okusheshayo kwe-eksisi ye-X | Mm/min | 24 | 24 | 8 | 8 | 8 | |

| I-axis engu-Z ihamba ngokushesha | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| I-eksisi engu-Y ihamba ngokushesha | Mm/min | - | 8 | 8 | 8 | 8 | |

| Ukunyakaza okusheshayo kwe-eksisi | Mm/min | 24 | 24 | 24 | 24 | 24 | |

| Amandla we-Servo Turret nemingcele | Uhlobo lwe-turret yamandla | / | I-Servo turret | I-Servo turret | I-Servo turret | I-Servo turret | I-Servo turret |

| Isiteshi samathuluzi | / | I-BMT65 | I-BMT65MY | I-BMT55MY-16T | I-BMT55MY-16T | I-BMT55MY-16T | |

| M amandla motor | kw | 7.5 | 7.5 | 5.5 | 5.5 | 7.5 | |

| I-torque ye-M axis motor | Nm | 47.8 | 47.8 | 35 | 35 | 47.8 | |

| Ikhanda lamandla Max. isivinini | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Imininingwane yesibambi sethuluzi lobubanzi bangaphandle | mm | 25*25 | 25*25 | 25*25 | 25*25 | 25*25 | |

| Imininingwane yesibambi sethuluzi lobubanzi obungaphakathi | mm | Φ50 | Φ50 | Φ50 | Φ50 | Φ50 | |

| Isikhathi sokushintsha ithuluzi eliseduze | isekhondi | 0.2 | 0.2 | 0.15 | 0.15 | 0.15 | |

| Ukumisa ukunemba | / | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Phinda ukunemba kokuma | / | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | |

| Imingcele ye-Tailstock | I-hydraulic tailstock ehlelekayo | / | - | - | - | - | - |

| I-Tailstock Max. ukuhamba | mm | - | - | - | - | - | |

| Ububanzi bemikhono | mm | - | - | - | - | - | |

| Ukuhamba ngemikhono | mm | - | - | - | - | - | |

| I-sleeve taper | / | - | - | - | - | - | |

| Ubukhulu | Izilinganiso sezizonke | m | 6200*2300*2160 | 6200*2300*2160 | 3100*2250*2100 | 3500*2250*2100 | 3900*2400*2100 |

| Isisindo somshini cishe. | kg | 15000 | 15000 | 5600 | 7000 | 7800 | |

| Okunye | Ukusika umthamo we-tank fluid | L | 485 | 485 | 250 | 250 | 300 |

| Amandla epompo yamanzi okupholisa | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Ivolumu yebhokisi leyunithi ye-Hydraulic | L | 40 | 40 | 40 | 40 | 40 | |

| Amandla kawoyela wephampu kawoyela weHydraulic | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Umthamo wethangi likawoyela wokugcoba | L | 2 | 2 | 2 | 2 | 2 | |

| Amandla e-automatic lubrication futha motor | kw | 50 | 50 | 50 | 50 | 50 |

Isingeniso sokucushwa

I-FANUC CNC

PhezuluPukuzungezaPukusebenza kahle

I-FANUC0Uhlelo lwe-i-TF PLUS lunobuchwepheshe obunamandla bokucubungula okuphezulu nobuchwepheshe obukhaliphile bokulawula i-servo; ubuchwepheshe bokucubungula okuphezulu bunciphisa isikhathi sokucutshungulwa okulandelanayo kwamasignali angaphandle ngokusho kokusheshisa nokunciphisa isimo sesenzo futhi kwandise ukusetshenziswa kwamakhono e-servo, ngaleyo ndlela kunciphisa isikhathi somjikelezo wohlelo lokucubungula; ukulawulwa kwe-servo okuhlakaniphile kubhekisela eqenjini lomsebenzi wokulawula i-servo elingakwazi ukuzilungiselela futhi lilungise ngesikhathi sangempela njengezimo zethuluzi lomshini njengokushintsha komthwalo nokushisa, ukufeza ukucubungula okuphezulu nokunemba okuphezulu.

PhezuluEaseOf Use

I-FANUC0Uhlelo lwe-i-TF PLUS lunenkumbulo yohlelo olunamandla amakhulu, ikhadi le-CF lingasetshenziswa njengememori yohlelo, uhlelo lwe-USB lungenziwa ngokuchofoza okukodwa, umsebenzi we-CNC-QSSR usiza amathuluzi omshini ngokushesha futhi kalula ukungenisa amarobhothi, kanye nohlelo lokuzikhethela lwe-IHMI inikeza ukwesekwa okuphelele komsebenzi endaweni yokucubungula, futhi inikeza ulwazi lwamathuluzi okuphatha okudidiyelwe, ukubikezela isikhathi sokucubungula, ukuhlela inkhulumomphendvulwano, ukugwema ukungqubuzana kwemishini, ukucutshungulwa kokuqoqwa kwedatha, ukuphathwa kokugcinwa kokugcinwa kanye neminye imisebenzi edingekayo kunqubo ngayinye "yokuhlela", "ukucubungula" kanye "nokuthuthukiswa".

PhezuluOperationRwadla

I-IOlinki ne-FSSB ye-FANUC Oi-TF PLUS inemisebenzi ecebile yokuthola amaphutha, enganquma ukwehluleka kwamandla emojula ye-I/O noma i-servo amplifier kanye nendawo yokunqanyulwa kwekhebula lokuxhumana. Ngaphezu kwalokho, i-I/Olinki ingakwazi ukubona umjikelezo omfushane ophumayo wephuzu ngalinye le-DO; ngaphezu kwalokho, umsebenzi wokuxilongwa kwephutha ungathola ulwazi oluhlukahlukene lokuxilonga esikrinini se-CNC esiza ukwahlulela isimo sesistimu lapho i-alamu yenzeka, kusiza abasebenzisi ukulungisa ngokushesha indawo yenkinga.

THKBkonkeSabasebenzi

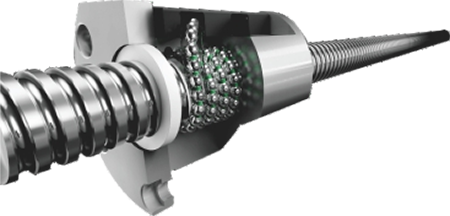

·Ibanga le-C3, kusetshenziswa isikulufu sebhola esinembayo esiphezulu, esinokulayisha kuqala amantongomane kanye nokwelashwa kokugxilisa isikulufu ukuze kuqedwe kusengaphambili ukuhlehla emuva kanye nokwenyuka kwezinga lokushisa, okubonisa ukuma okuhle kakhulu nokunemba kokuphindaphinda.

·Servo motor drive eqondile yokunciphisa iphutha lokubuyela emuva.

THKRollerLungekhoGuide

·Izinga le-P lezinga eliphezulu lokunemba kwe-SRG, ibanga lokunemba legayidi elinguziro, ukusikwa kwe-arc, ukusikwa kwe-bevel, ukuthungwa kwendawo akufani ngokuqhathaniswa. Ifanele ukusebenza ngesivinini esiphezulu, inciphisa kakhulu amandla okushayela amahhashi adingekayo kumathuluzi omshini.

·Ukugingqika esikhundleni sokushelela, ukulahlekelwa ukushwibilika okuncane, ukusabela okubucayi, ukunemba kokuma okuphezulu. Ingakwazi ukuthwala umthwalo endleleni ehambayo ngesikhathi esifanayo, futhi indawo yokuxhumana yethrekhi isathintana namaphuzu amaningi ngesikhathi somthwalo, futhi ukuqina kokusika ngeke kuncishiswe.

·Kulula ukuhlanganisa, ukushintshashintsha okuqinile, kanye nesakhiwo esilula sokuthambisa; inani lokugqoka lincane kakhulu futhi impilo yesevisi yinde.

I-SKFBicici/OilingMane

·Umshini wokuthambisa ozenzakalelayo uhlangabezana nezidingo zezinhlelo zokusebenza ezahlukahlukene, ulungele izimo zokusebenza ezahlukahlukene, imikhiqizo ethembekile, ukusetshenziswa okuvumelana nezimo.

·Hlangana nezidingo zokuthwala ukugcotshwa kumazinga okushisa aphezulu, ukudlidliza okuqinile nendawo eyingozi.

Iphuzu ngalinye lokugcoba lisebenzisa i-volumetric proportional distributor ukulawula inani lokuthambisa, futhi umshini ungalawulwa yi-PLC ukuze unikeze uwoyela ngokunembile.