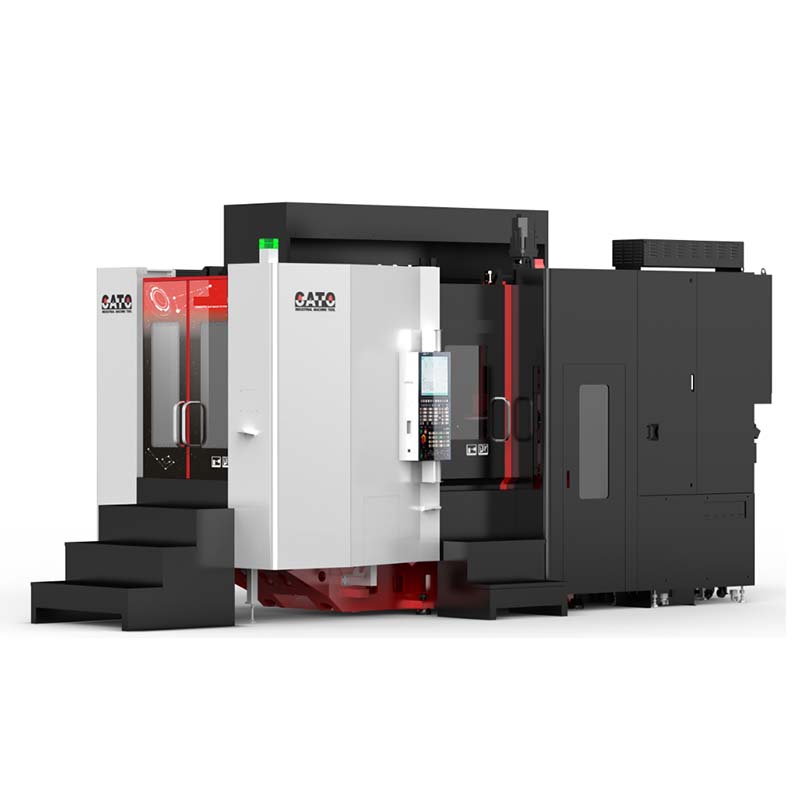

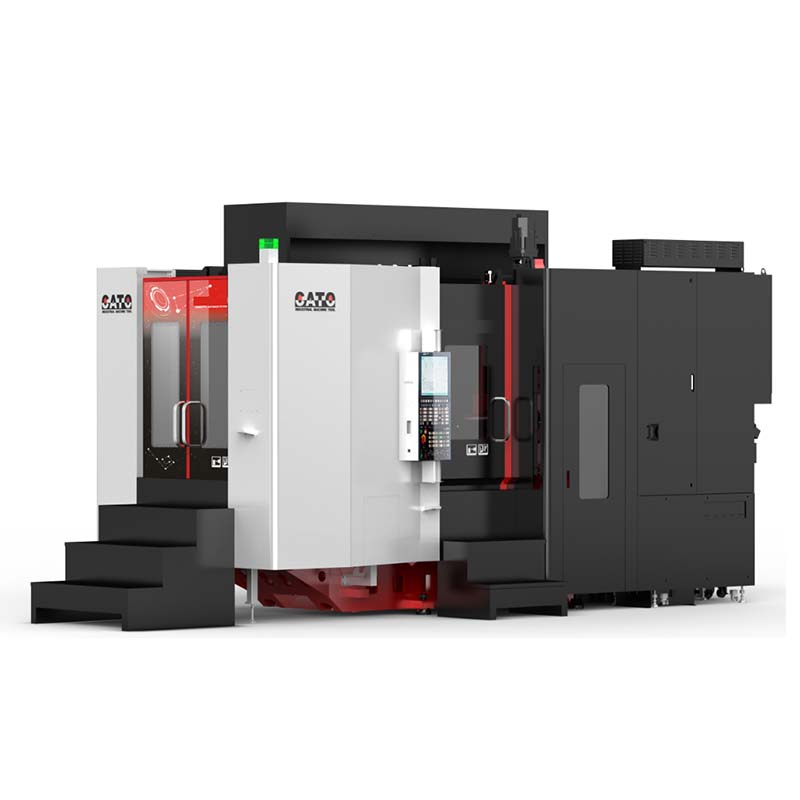

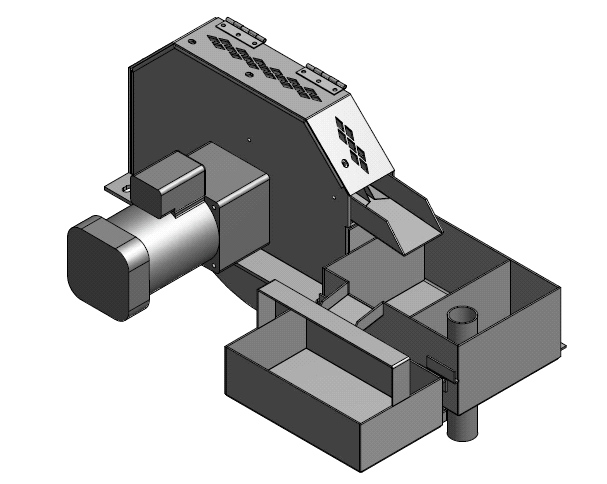

5-eksisi CNC Evundlile Machining Center Enamaphalethi Amabili CP800

1.Izici

Isikhungo semishini esinesivinini esikhulu, esisebenza kahle nesinembayo esivundlile se-CP800T2 esakhiwe yi-CATO Company sinezici zokuqina okuphezulu, ukunemba okuphezulu kanye nokusebenza kahle kwemishini. Isisekelo socezu olulodwa siyamukelwa, futhi umklamo omuhle wesakhiwo se-T wamareyili aphezulu naphansi wesisekelo uqinisekisa ukuqina okuphezulu kwethuluzi lomshini; wonke umshini udlulisa ukuhlaziya kwento enomkhawulo ukuze kuqinisekiswe ukuthi ithuluzi lomshini alidlidlizi ngaphansi kokunyakaza kwesivinini esikhulu, futhi liqinisekisa ukuqina okuhle kakhulu kokusebenza kwesikhathi eside kwawo wonke umshini.

Ngokwamukela ubuchwepheshe obusezingeni eliphezulu obufana nobuchwepheshe bejubane eliphezulu lokuphotha, ubuchwepheshe bokuphakelayo obunesivinini esikhulu, ubuchwepheshe bokushintsha amathuluzi wesivinini esikhulu, nobuchwepheshe besistimu ye-CNC esheshayo, isikhathi sokucubungula sifinyezwa kakhulu, ukusebenza kahle kokucubungula kuyathuthukiswa, kanye nezinhlobonhlobo ezahlukahlukene. izidingo zokukhiqiza ziyahlangatshezwa. Ukufuduka okusheshayo kwe-axis emithathu yi-60 M / min, futhi i-spindle kagesi enesivinini esiphezulu ne-torque ephezulu inciphisa ukusheshisa kanye nesikhathi sokunciphisa i-spindle. Lezi zinkomba zifinyeza kakhulu isikhathi sokungacutshungulwa futhi zithuthukise ukusebenza kahle kokucubungula; isikulufu/isihlalo esithwalayo/i-spindle/DD inhloko yokushwibeka yamukela isistimu yokulawula izinga lokushisa, Iqinisekisa ibhalansi yokushisa ehle kakhulu yezinto zokusebenza, futhi ithuthukise kakhulu ukunemba nokuzinza kwemishini.

Ukwamukela uhlelo lwe-Siemens 840D, isibonisi se-LCD esingu-19-intshi esikhulu kakhulu, isibonisi esishukumisayo sesithombe se-trajectory yamathuluzi, isibonisi esihlakaniphile sokuxwayisa, ukuzihlola ngokwakho kanye neminye imisebenzi kwenza ukusetshenziswa nokugcinwa kwethuluzi lomshini kube lula futhi kusheshe; indlela yokuxhumana yebhasi enesivinini esikhulu ithuthukisa kakhulu ukucutshungulwa kwedatha yohlelo lwe-CNC Ikhono nokulawula ukusebenza kusiza ukudluliswa okushesha nangempumelelo kanye nokucutshungulwa kwe-inthanethi kwezinhlelo zomthamo omkhulu.

2.Ipharamitha

| Into | Iyunithi | CI-P800T2 | |

| Ukuhamba | Ukuhamba kwe-eksisi ye-X/Y/Z | mm | 800 x 800 x 750 |

| Ukuhamba kwe-B-eksisi | ° | -30 ~ 120 | |

| Ukuhamba kwe-C-axis | ° | 360 | |

| Ibanga ukusuka enkabeni yokuphotha ukuya phezulu kwetafula (i-axis B 90 degrees ovundlile) | mm | 160-910 | |

| Ibanga ukusuka ebusweni bokuphotha kuya phezulu kwetafula (i-axis ye-B engu-0 degree mpo) | mm | -83-667 | |

| Ibanga ukusuka ekugcineni kobuso be-spindle ukuya enkabeni yetafula lokusebenza (i-axis ye-B engu-90 degrees ovundlile) | mm | - 135 ~ 665 | |

| Ibanga ukusuka enkabeni yokuphotha ukuya enkabeni yetafula (i-axis ye-B 0° mpo) | mm | 108-908 | |

| Ibanga eliphezulu lokucubungula | mm | Φ 720 x 910 | |

| Okuphakelayo kwama-eksisi angu-3 | I-eksisi ye-X/Y/Z ihamba ngokushesha | m/min | 60/60/60 |

| Ukusika izinga lokuphakelayo | mm/min | 0-24000 | |

| Itafula elijikelezayo (I-C-eksisi) | Itafula elijikelezayo | ama-pcs | 2 |

| Ububanzi bediski | mm | 500*500 | |

| umthwalo ovumelekile | Kg | 500 | |

| isivinini esikhulu sokujikeleza | Rpm | 40 | |

| Ukuma/Ukuphinda Ukunemba | arc.sec | 15/10 | |

| I-B-eksisi | Isivinini esikhulu sokuzungezisa | Rpm | 60 |

| Ukuma/Ukuphinda Ukunemba | arc.sec | 8/4 | |

| I-spindle | Ukucaciswa kwe-spindle (ukufaka ububanzi/indlela yokudlulisela) | mm | 190 / Kwakhelwe ngaphakathi |

| I-spindle taper | m/min | A63 | |

| Ubukhulu. Isivinini se-spindle | mm | 18000 | |

| Spindle Motor Power | Kw | 30/35 | |

| I-Spindle Motor Torque | Nm | 72/85 | |

| Ithuluzi | Amandla omagazini wethuluzi |

| 40 T |

| Isikhathi sokushintsha amathuluzi(TT) | s | 7 | |

| Ubukhulu bethuluzi lobubanzi (Ithuluzi eligcwele / Ithuluzi elingenalutho eliseduze) | mm | 80/150 | |

| Ubukhulu. Ubude bethuluzi | mm | 450 | |

| Ubukhulu. Isisindo sethuluzi | Kg | 8 | |

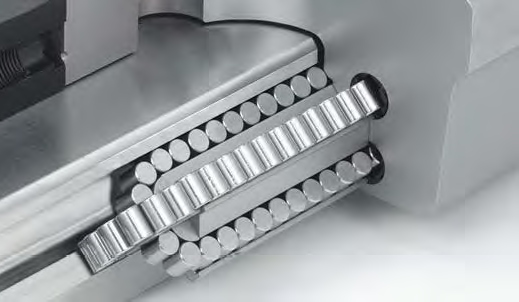

| Umhlahlandlela | Umhlahlandlela we-X-axis (usayizi/inombolo yamaslayidi) |

| 45/2 (I-Roller) |

| Igayidi ye-Y-axis (usayizi/inombolo yamaslayidi) |

| 45/3 (I-Roller) | |

| Z-axis guide (usayizi/inombolo yamaslayidi) |

| 45/2 (I-Roller) | |

| Ezintathu i-eksisi ukudluliswa | Isikulufu sokuhola se-X-axis | N | 2R40x20 |

| Isikulufu sokuhola se-Y-axis | N | 2R40x20 | |

| Isikulufu sokuhola se-Z-axis | N | 2R40x20 | |

| Ukunemba kwama-eksisi amathathu | Ukumisa ukunemba | mm | 0.005 / 300 |

| Phinda ukunemba kokuma | mm | 0.003 / 300 | |

| Isistimu yokugcoba | Umthamo weyunithi yokugcoba | L | 0.7 |

| Uhlobo lokuthambisa |

| Gcoba amafutha | |

| Abanye | Ukufunwa komoya | Kg/cm2 | ≥ 6 |

| Ukugeleza komthombo womoya | mm3/min | ≥ 0.5 | |

| Isisindo | T | 11 | |

3.Ukumisa ukuma

| NO. | Igama |

| 1 | I-Siemens 840D① Indawo egobile enhle kakhulu;②Iphakheji yenqubo yokugaya ye-eksisi emihlanu; ③ Ikhadi le-eksisi emihlanu; ④ Vimbela i-axis ye-B ekuweni; ⑤Ukudluliswa kwedatha ye-USB ne-Ethernet |

| 2 | Umsebenzi wokuthepha kanyekanye |

| 3 | Isistimu yokupholisa engenalutho ye-X/Y/Z |

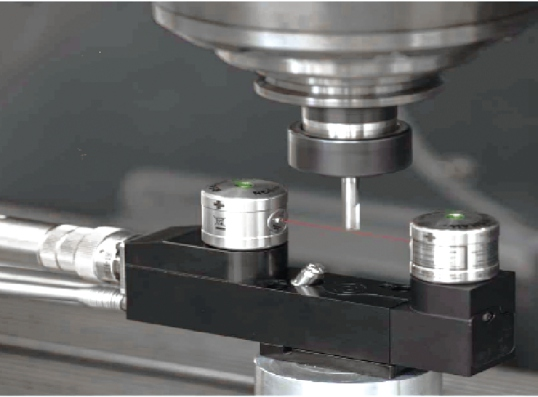

| 4 | Isistimu yokulawula izinga lokushisa kwe-spindle/B-axis |

| 5 | Ukuvikela ukugcwala kwe-spindle |

| 6 | I-APC Double Exchange Workbench |

| 7 | B/C i-axis hydraulic brake system |

| 8 | Ishidi lensimbi elivalwe ngokugcwele |

| 9 | Isistimu yokukhiya umnyango wezokuphepha |

| 10 | Ithuluzi umagazini umnyango othomathikhi |

| 11 | Isistimu yokugcoba amafutha e-automatic |

| 12 | Ukukhanya kokukhanya komsebenzi we-LED |

| 13 | Ukusika izikulufu nhlangothi zombili |

| 14 | Isistimu yokususa i-drum scraper |

| 15 | Isistimu yokufafaza ezungezile |

| 16 | uhlelo lokupholisa |

| 17 | I-CTS (2MPA) |

| 18 | Amathuluzi ajwayelekile namabhokisi amathuluzi |

| Amathuluzi ajwayelekile namabhokisi amathuluzi |