I-Center Drive lathe Yeshubhu enezindonga ezincane

Izingxenye ze-Tube ne-Tube enezindonga ezincane

Isixazululo Sobuchwepheshe

1.Ukuhlaziywa kwenqubo yokucubungula izingxenye ze-cylindrical ezinezindonga ezincane

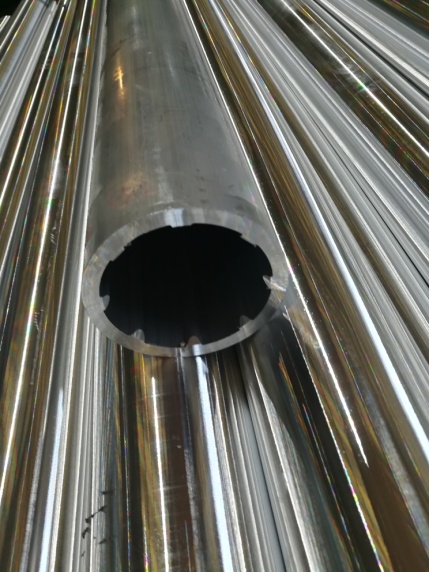

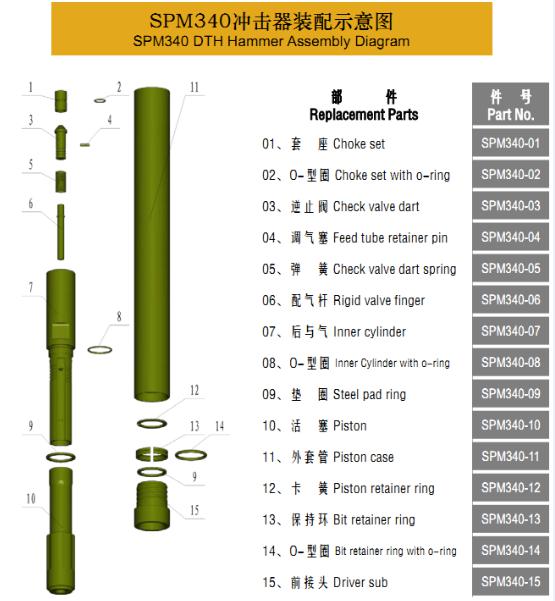

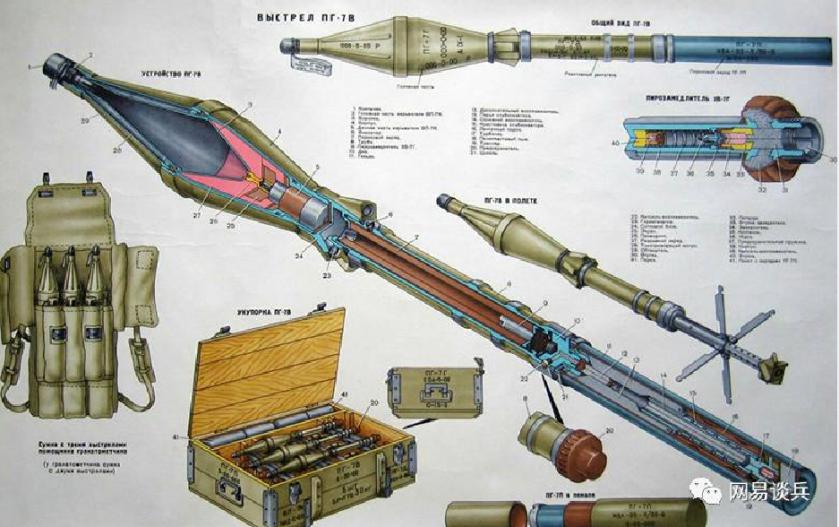

Amashubhu anezindonga ezacile kanye nezingxenye zamashubhu bekulokhu kuyiphuzu elinzima ekwenzeni imishini. Isibonelo: umzimba wesibhamu esibhobozayo wemishini yokubhoboza esetshenziswa emshinini wokumba we-petroleum, igobolondo langaphakathi nangaphandle le-downhole shock absorber, igobolondo langaphakathi nangaphandle lesivikeli sepompo likawoyela, umgqomo wokuphrinta wemishini yokunyathelisa, isigubhu sokuphotha imishini yendwangu, umshini wokudlulisa i-Conveyor roller, ukubhola phansi emgodini kanye nemishini yokuqhumisa

I-casing yangaphandle, njll., kunjalo, ihlanganisa namagobolondo ezinhlamvu zezempi noma zabantu.

1.1 Izingxenye ezijwayelekile

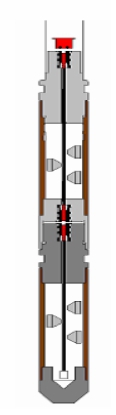

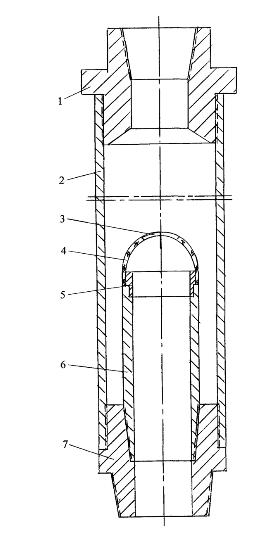

Isakhiwo sesibhamu sokubhoboza: izingxenye eziyinhloko zesibhamu esibhobozayo umzimba wesibhamu, ikhanda lesibhamu, umsila wesibhamu, ilunga eliphakathi nendawo, i-accessory ye-detonation, indandatho yokuvala kanye nesibambi se-cartridge. Izimfuneko zokusebenza eziyisisekelo zesibhamu sokudubula. Njengengxenye eyinhloko ye-perforator yamandla emise okwenzeke, ukusebenza okuyisisekelo kakhulu kwesibhamu esibhobozayo amandla aso emishini. Kuphela uma izici zayo zemishini sezihlangatshezwana nazo, lapho isibhobo samandla esimise okwenzeke singaqinisekiswa Ukungenzeka nokuphepha ngesikhathi sokubhobozwa kwe-downhole.

Isivikeli sepompo likawoyela

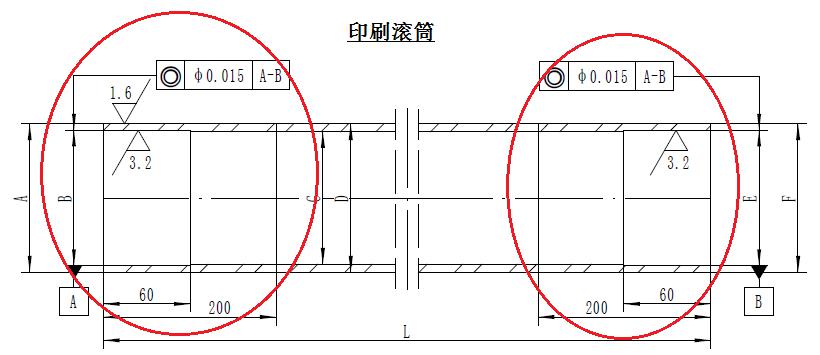

Isilinda sokuphrinta

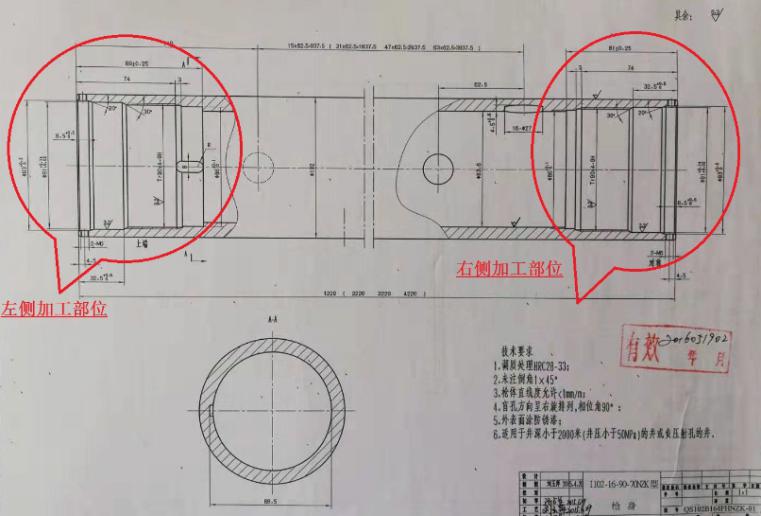

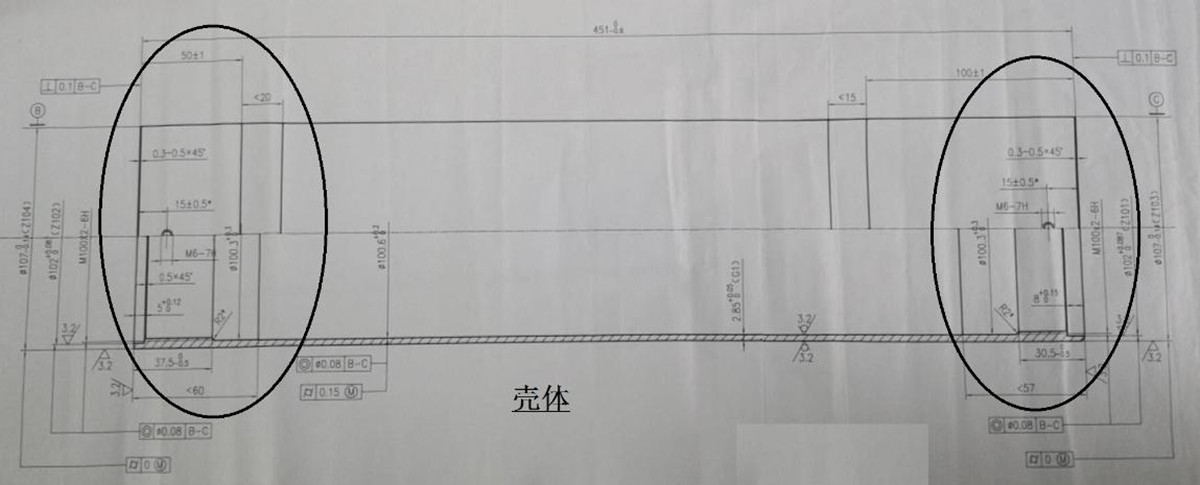

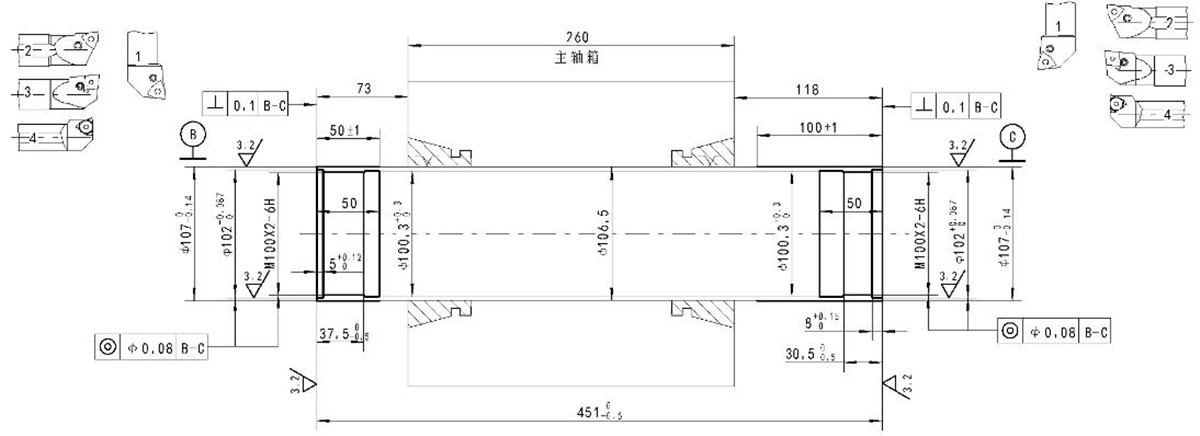

Ukuqhathaniswa kobuchwepheshe obusha nobudala bokucubungula igobolondo

Lolu hlobo lwezingxenye lunento eyodwa olufana ngayo: amapayipi anezindonga ezincane ezakhiwe ngokugingqika noma ukuphotha acutshungulwa ngokuyinhloko emikhawulweni yomibili, isitobhi sembobo yangaphakathi (sokuhlanganiswa), intambo yembobo yangaphakathi (yokuxhuma), indilinga yangaphandle encane, intambo yangaphandle ( uma Kudingeka), ngaphakathi nangaphandle ama-sipes angenalutho kanye ne-chamfer

1.2. Ukuhlaziywa kwenqubo.

1) Ubuchwepheshe bokucubungula bendabuko:

Ngokuvamile, ingxenye eyodwa ye-lathe isetshenziselwa ukubopha, kanti enye iphethe isebenzisa i-tailstock phezulu kwembobo engaphakathi kanye nohlaka lwemoto oluphakathi, bese usebenzisa ifreyimu ephakathi ukusekela, bese ibhoboza imbobo engaphakathi yalesi siphetho. , ubuso bokuphela kwemoto, kanye nomshini ongadingeka ukuze uguqule Izingxenye zesiyingi sangaphandle, noma izingxenye zokubopha ezidingekayo ukuze ujike futhi ujike.

I-Workpiece U-turn: ukusekelwa kwangaphakathi noma umzimba wesilinda esibamba ngaphandle, isitokwe sensimbi esiqinisa ucezu lokusebenza, isokhethi yefreyimu yesikhungo semoto, ukusekelwa kohlaka olumaphakathi, imbobo engaphakathi ephinde yabhoboza, ubuso besiphetho semoto, indilinga yangaphandle.

Uma i-coaxiality yezimbobo zangaphakathi kuzo zombili iziphetho zesilinda iphakeme kancane, ukucubungula kungase kuphindwe izikhathi eziningi.

2) Ukusebenzisa ubuchwepheshe bokucutshungulwa kwe-lathe be-CNC obunamaphethelo amabili:

Ukucutshungulwa kokuqukethwe okungenhla kungaqedwa ekubambeni okukodwa, futhi zombili iziphetho zingacutshungulwa ngasikhathi sinye, ezinganciphisi nje kuphela inani lamathuluzi omshini, kodwa futhi kunciphisa ukugeleza kwenqubo nokuphathwa kwezinto ezibonakalayo, futhi kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza. . Njengoba zombili iziphetho zicutshungulwa ngesikhathi esifanayo, i-coaxiality ye-workpiece nayo iqinisekisiwe ngokuthembekile.

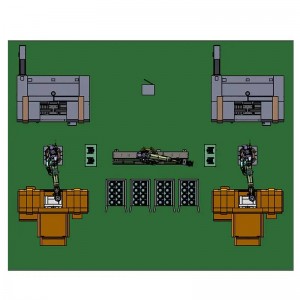

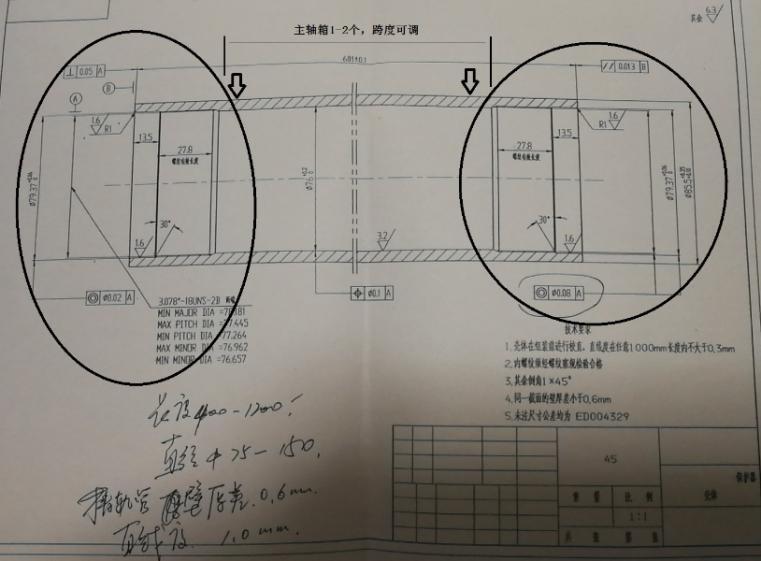

Ngokuqondile: kuye ngobude be-workpiece, i-headstock eyodwa noma ezimbili zingasetshenziswa ukubopha indilinga yangaphandle ye-workpiece. Ububanzi be-clamping kanye nobubanzi be-clamping ye-headstock kunqunywa ngokuhambisana nobubanzi nobude be-workpiece. Ama-turrets amabili ajikelezayo wesiteshi esingu-8/12 Ngesikhathi esisodwa acubungula ubuso bokuphela, imbobo engaphakathi kanye nendilinga yangaphandle kuzo zombili iziphetho. Njengoba inani lamathuluzi angafakwa lanele, lingahlangabezana nezidingo zokucubungula zesikhathi esisodwa zezingxenye eziyinkimbinkimbi.

Uma ingxenye yokugoqa yangaphandle yethuluzi lomshini kulolu chungechunge idinga ukucutshungulwa, sebenzisa ithuluzi lomshini ukuze ubeke kabili phezulu izimbobo zangaphakathi kuzo zombili iziphetho ze-workpiece ukuze ujike noma ugaye indilinga yangaphandle.

Kukhona futhi amakhasimende asebenzisa i-grinder engenamaphakathi ukuze agaye indilinga yangaphandle kusengaphambili, bese esebenzisa i-lathe ye-CNC eneziphetho ezimbili ukucubungula izimbobo zangaphakathi nobuso bokugcina kuzo zombili iziphetho ezidingekayo zenqubo.

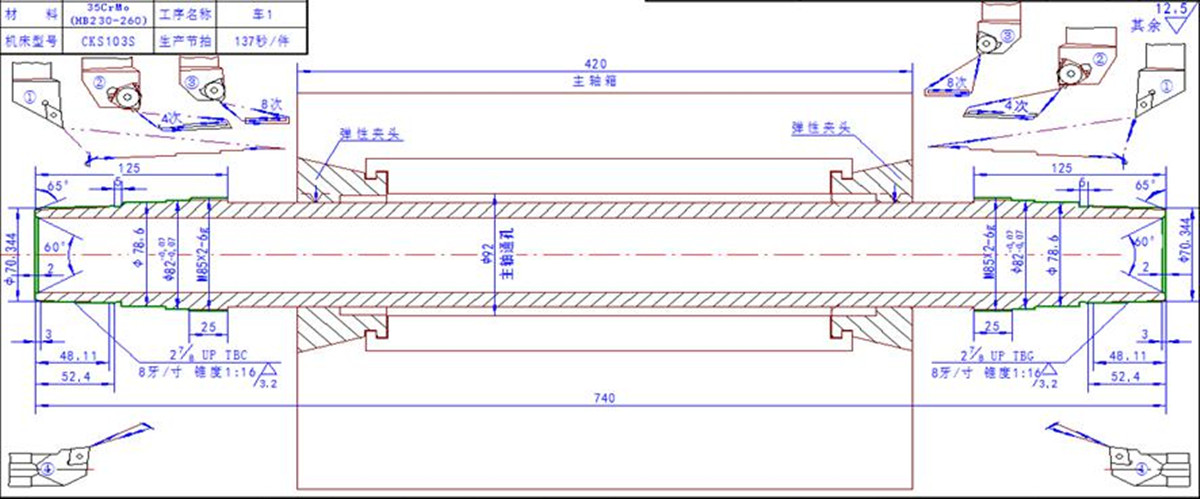

I-3) Amacala ezingxenye eziyisilinda ezicutshungulwe ngamalebula e-CNC aneziphetho ezimbili:

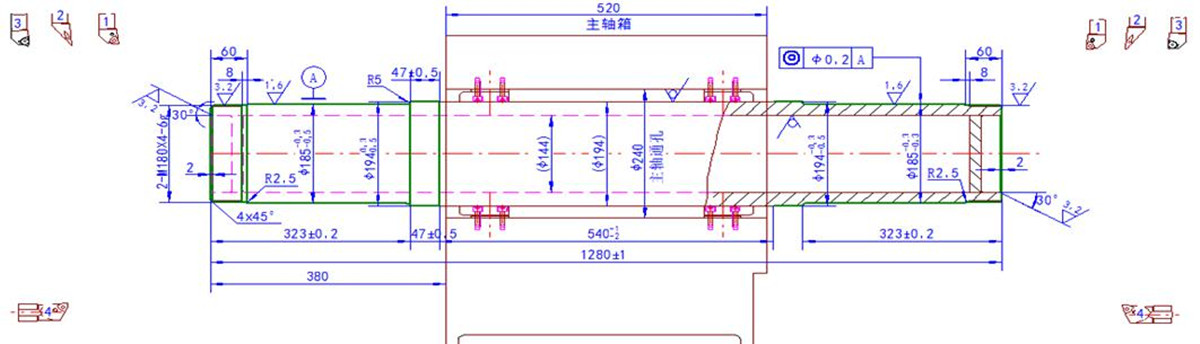

①Icubungula isilinda somshini wokuphrinta, khetha imodeli ye-SCK208S (usebenzisa ibhokisi lokuphotha elikabili).

②Imodeli ye-SCK309S (i-headstock eyodwa) isetshenziselwa ukucubungula i-asi emaphakathi yemoto.

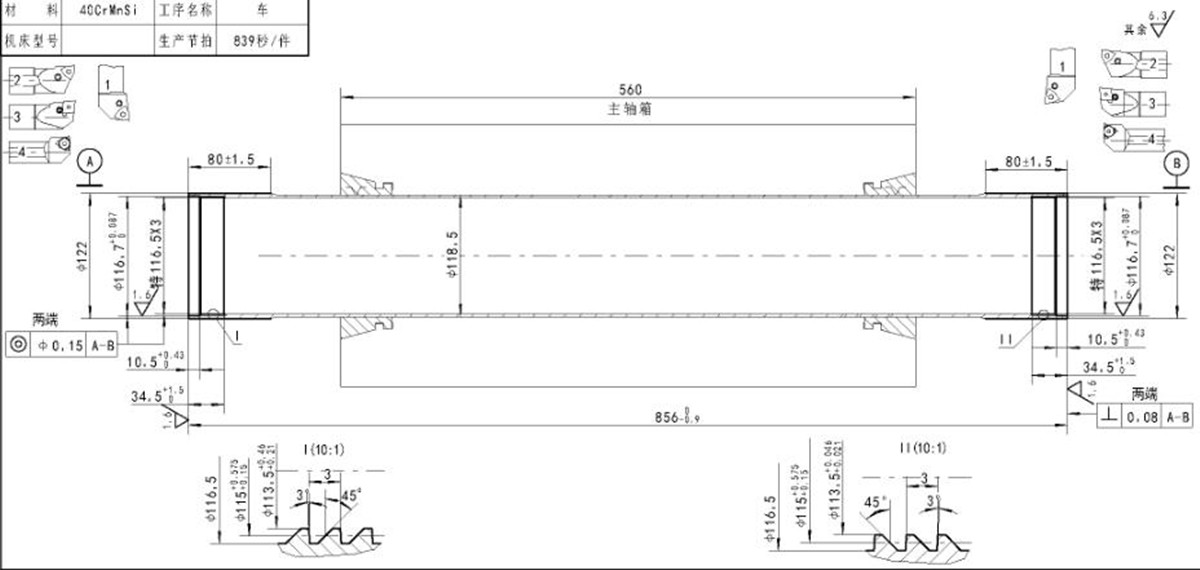

③SCK105S imodeli isetshenziselwa ukucubungula amashubhu amasosha anezindonga ezincane.

④Ngokucubungula amashubhu amasosha anezindonga ezincane, khetha imodeli ye-SCK103S

⑤ Imodeli ye-SCK105S ikhethelwa ukucubungula amapayipi kawoyela emishini kaphethiloli.

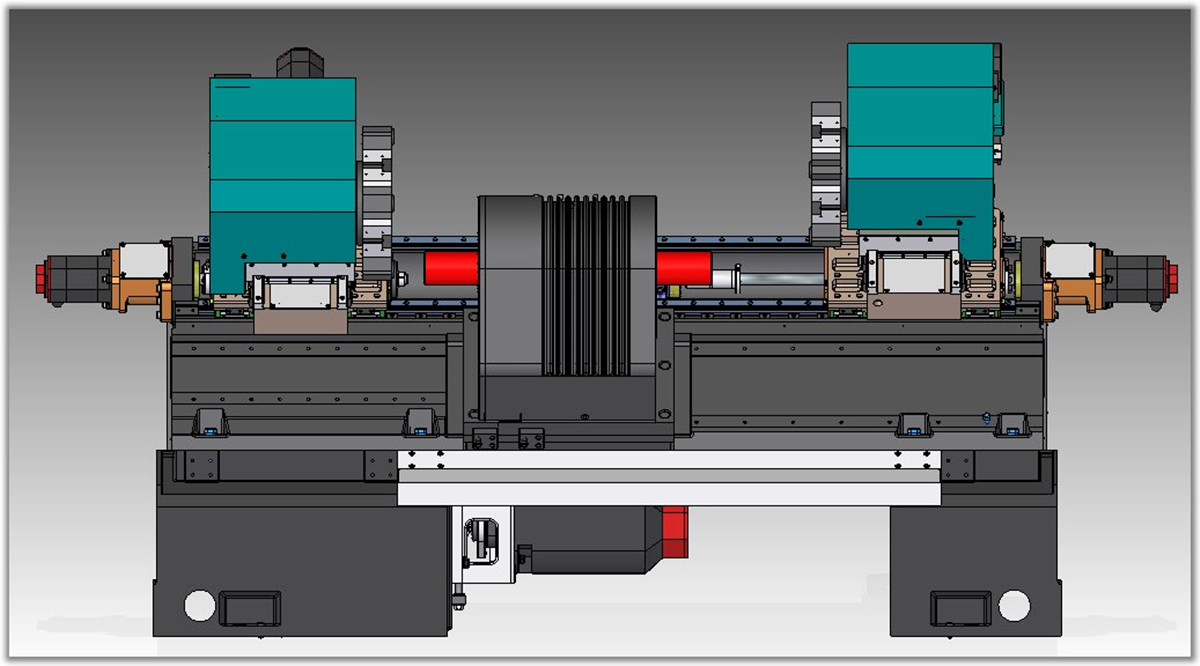

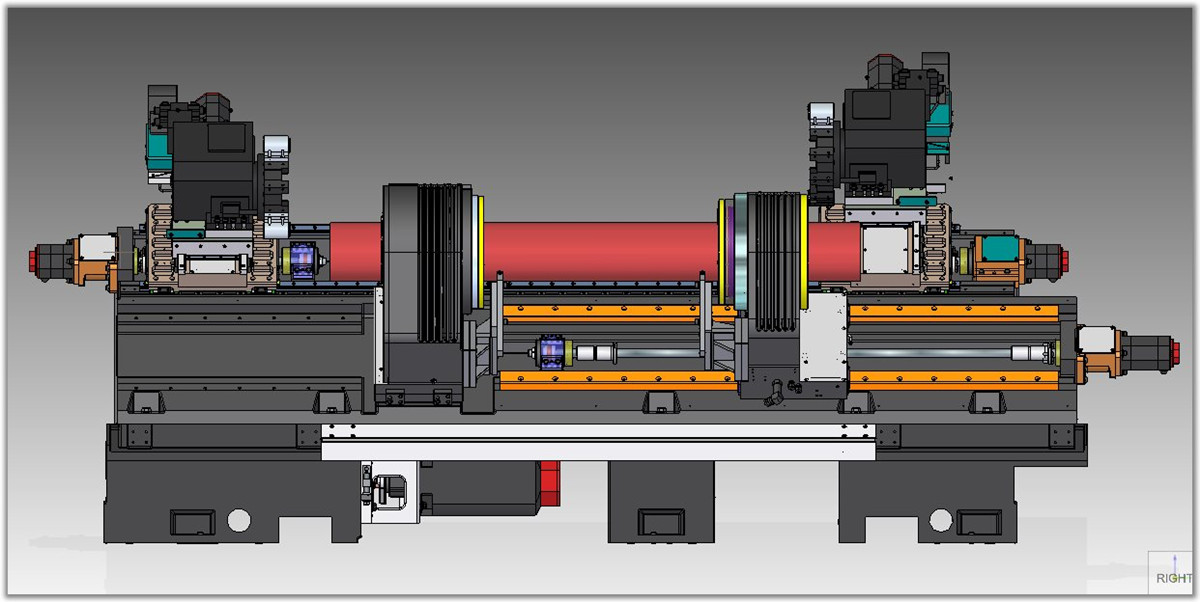

I-SCK Series Isingeniso se-CNC Lathe esiphetha kabili

■ I-double-end surface specialised CNC lathe iwuhlobo lwemishini yokukhiqiza esezingeni eliphezulu nenembayo ephezulu. Ingakwazi ngesikhathi esisodwa ukuqedela indilinga yangaphandle, ubuso bokugcina kanye nembobo yangaphakathi yezingxenye ezimbili zohlelo lokusebenza ekubambeni okukodwa. Uma kuqhathaniswa nenqubo yendabuko yokubopha izingxenye kabili nokuphenduka, inezinzuzo zokusebenza kahle kokukhiqiza, i-coaxiality enhle nokunemba okuphezulu kwezingxenye ezicutshunguliwe.

Njengamanje, kunezinhlobo ezingaphezu kwezingu-10 zamamodeli, ububanzi be-clamping: φ5-φ250mm, ubude bokucubungula: 140-3000mm; uma kucatshangelwa ngokukhethekile izingxenye zegobolondo le-tube, ububanzi be-clamping bungafinyelela ku-φ400 mm.

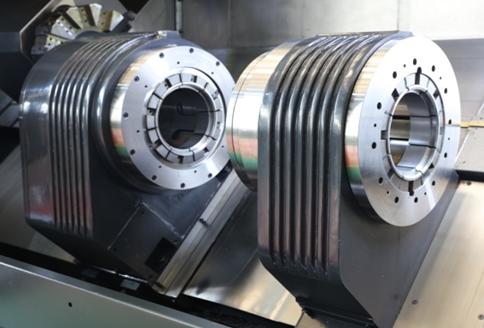

■ Wonke umshini unesakhiwo semibhede ethambekele engama-450, enokuqina okuhle nokususwa kwe-chip. Ibhokisi lokuphotha eline-intermediate drive kanye nomsebenzi wokubopha lihlelwe phakathi nombhede, futhi izindawo zokuphumula ezimbili zamathuluzi zihlelwa nhlangothi zombili zebhokisi lokuphotha.

■ Ngokusebenzisa isistimu yokulawula yamashaneli amabili, izindawo zokuphumula zamathuluzi ezimbili zingaxhunywa ne-spindle ngesikhathi esisodwa noma ngokuhlukene ukuze kuqedelwe ukucubungula ngesikhathi esisodwa noma ukucutshungulwa okulandelanayo kwazo zombili iziphetho zengxenye.

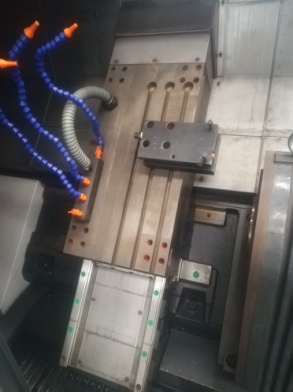

■I-servo feed axis ngayinye isebenzisa isikulufu sebhola esithule kakhulu, futhi ukuhlangana okunwebekayo kuxhumeke ngokuqondile, kunomsindo ophansi, ukunemba kokuma okuphezulu kanye nokunemba kokubeka okuphezulu okuphindaphindayo.

■ Ngokobude bokucutshungulwa kwama-workpieces ahlukene, ama-headstocks angama-1-2 aphakathi nendawo angafakwa. Phakathi kwazo, ibhokisi lokuphotha eliyinhloko lesobunxele lilungisiwe, futhi ibhokisi le-sub spindle elingakwesokudla lishayelwa yi-servo motor ukuhambisa isikulufu sebhola siye ngaku-Z. Ingasebenzisa kuphela i-headstock ukuze ibambe ukuze iqedele ukucutshungulwa kwezingxenye ezimfushane; ingase futhi isebenzise ama-headstocks amabili ukuze ibambene ndawonye ukuze iqedele ukucutshungulwa kwezingxenye ezinde.

■Ibhokisi lokuphotha lihlanganisa izingxenye ezinhlanu zesistimu yokuphotha, ama-clamp, isilinda sokubopha, isistimu yokusabalalisa uwoyela kanye nedivayisi yokushayela, nesakhiwo esihlangene nokusebenza okuthembekile. Amadivaysi okubamba wonke aqhutshwa ngamanzi, futhi amandla okubamba angahlangabezana nezidingo zetorque ephezulu yokujika.

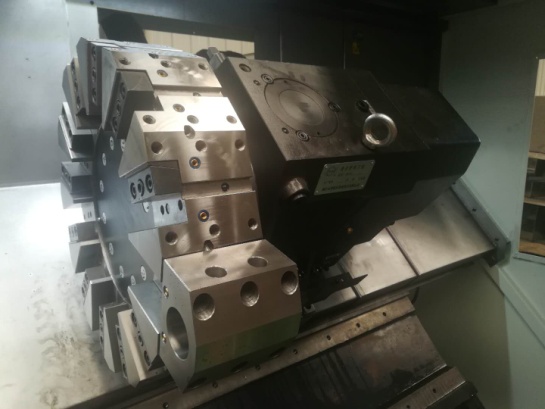

■ Izinto ezilungiswayo zifakwa ebhokisini lokuphotha. Isakhiwo se-fixtures sihlanganisa uhlobo lwe-collet ene-clamp ephakathi kanye ne-clamp emaphethelweni amabili, kanye ne-clamp ephakathi kanye ne-clamp ephethe imihlathi emibili.

Uma kubhekwa izici zokuguquguquka ezilula zokubopha izingxenye ze-cylindrical ezinodonga oluncane, izinsimbi ze-collet zivame ukusetshenziswa. Ama-clamp ashayelwa i-cylinder piston ukuze azenze zigxumeke ukuze kubonakale ukuthi i-chuck iyaxega noma iyaqina. I-deformation ye-elastic chuck ingu-2-3mm (ububanzi) . I-chuck ibopha ingxenye ebophayo yengxenye kuyo yonke isiqondiso esiyindilinga, amandla okubamba ayafana, futhi ukuguqulwa kwengxenye kuncane. Lapho ukunemba okungaphezulu kwengxenye yokugoqa kuhle, kuzoba nokunemba okuphezulu kokugoqa. Ngesikhathi esifanayo, kubalulekile ukunciphisa ukuguqulwa kwezingxenye ukwenza izingxenye zibe ne-overhang efanele.

■Uma izingxenye zinencazelo enkulu yobubanzi, uzipho lokulungisa lungafakwa esakhiweni se-chuck. Uzipho olulungisayo uzipho oluthambile, olugxile kububanzi obungaphakathi be-clamp. Ngaphambi kokusetshenziswa, inokunemba okuphezulu kwe-clamping nokushintshwa okusheshayo nokulula.

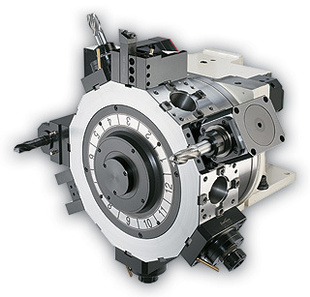

■Umshini usebenzisa idizayini eyimojuli, futhi ungaba nezinhlobonhlobo zezakhiwo, ukucushwa kanye nezinhlanganisela zokusebenza ngokuya ngezidingo zomsebenzisi. Kunezinketho eziningi zokuthunyelwe kwamathuluzi, njengohlobo lwethuluzi lomugqa, uhlobo lwe-turret kanye ne-turret yamandla. Izindawo zokuphumula ezimbili zamathuluzi zingaxhunywa ku-spindle ngesikhathi esisodwa noma ngokuhlukene ukuze kuqedelwe ukucubungula okuhambisanayo noma okulandelanayo kwazo zombili iziphetho zengxenye.

Inhlanganisela yesibambi samathuluzi: isibambi samathuluzi esikabili; ithuluzi lemigqa emibili; umnikazi wethuluzi lamandla; ithuluzi lomugqa wesokunxele+ isibambi sethuluzi sakwesokudla; isibambi sethuluzi esingakwesokunxele + ithuluzi lomugqa wesokudla.

■Ithuluzi lomshini livalwe ngokugcwele futhi livikelwe, lifakwe izinto zokuthambisa ezizenzakalelayo kanye nezisetshenziswa ezizenzakalelayo zokususa ama-chip, ngokusebenza kahle kokuvikela, ukubukeka okuhle, ukusebenza okulula nokunakekelwa okufanele.

■Ithuluzi lomshini lingahlonyiswa ngohlaka olusekelayo, isisetshenziswa esisizayo sokulayisha nokukhipha, kanye nedivayisi yokulayisha nokuthulula ngokuzenzakalelayo. Bona ividiyo nezithombe zomshini.