I-Center Drive Lathe Ye-Axle

Ukuhlaziywa kobuchwepheshe be-axle yezimoto

I-axle yemoto

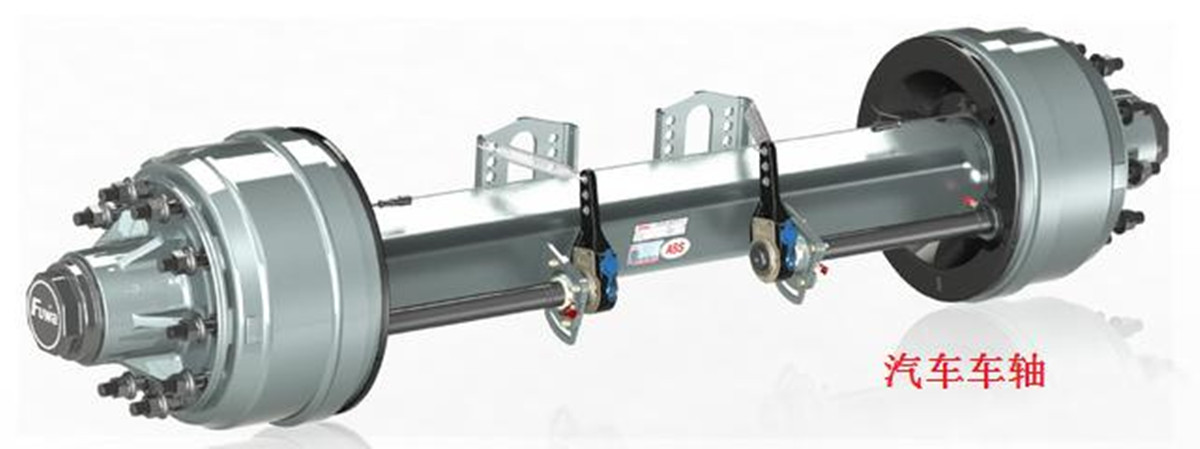

Ama-ekseli anamasondo ezinhlangothini zombili ze-undercarriage (uhlaka) ngokuhlangene abizwa ngokuthi ama-axle ezimoto, kanti ama-ekseli anekhono lokushayela ngokuvamile abizwa ngokuthi ama-ekseli. Umehluko omkhulu phakathi kwakho kokubili ukuthi kukhona idrayivu phakathi kwe-axle (i-axle). Kuleli phepha, i-axle yemoto eneyunithi yokushayela ibizwa ngokuthi i-axle yezimoto, futhi imoto ngaphandle kokushayela ibizwa ngokuthi i-axle yemoto ukukhombisa umehluko.

Ngokukhula kwesidingo sezinto zokuhamba nezokuthutha, ukuphakama kwama-axle ezimoto, ikakhulukazi ama-trailer nama-semi-trailer, kwezokuthutha ngobungcweti kanye nemisebenzi ekhethekile kuya ngokuya kuba sobala, futhi isidingo semakethe sikhule kakhulu.

Lokhu kuhlaziya ubuchwepheshe inqubo machining of the eseli, ithemba ukusiza amakhasimende ukukhetha ofaneleka kakhudlwana umshini CNC.

Ukuhlukaniswa kwe-axle yemoto:

Izinhlobo zama-axles zihlukile ngokohlobo lwebhuleki, futhi zihlukaniswe zibe: ama-axle ama-disc brake, ama-axle ama-drum brake, njll.

Ngokusho kobukhulu besakhiwo sobubanzi be-shaft, ihlukaniswe yaba: i-axle yaseMelika, i-axle yesiJalimane; njll.

Ngokusho komumo nesakhiwo, ihlukaniswe yaba:

konke: i-axle yeshubhu eyisikwele eqinile, i-asire yeshubhu eyisikwele engenalutho, i-asi eyindilinga eyindilinga;

umzimba ohlukanisiwe: inhloko ye-shaft + ishubhu le-shaft welding elingenalutho.

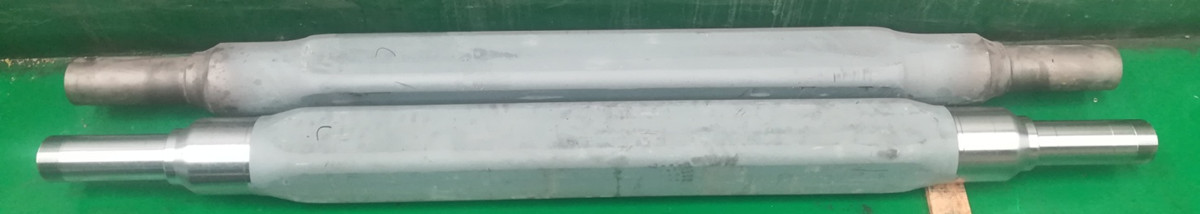

Kusukela kokuqukethwe kokucubungula kwe-axle, ama-axles aqinile futhi angenalutho ahlobene nokukhethwa kwemishini yokucubungula.

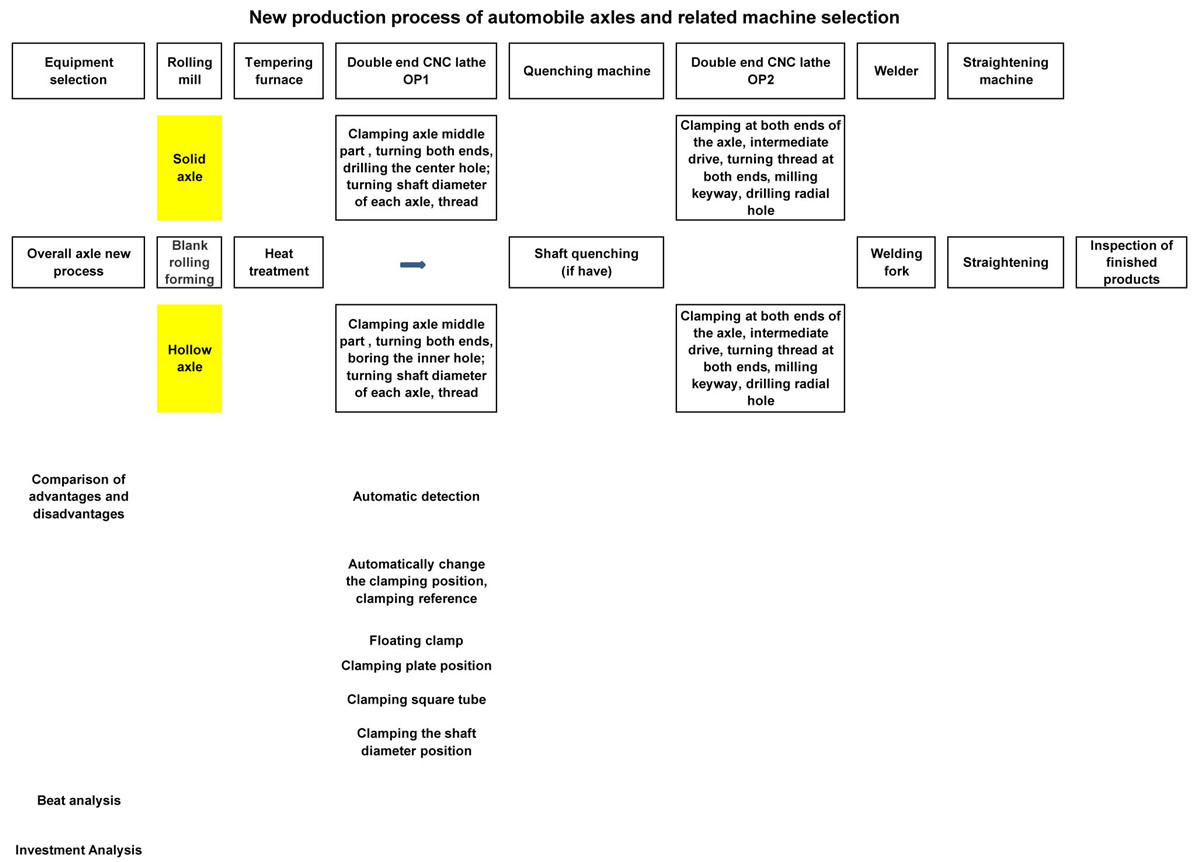

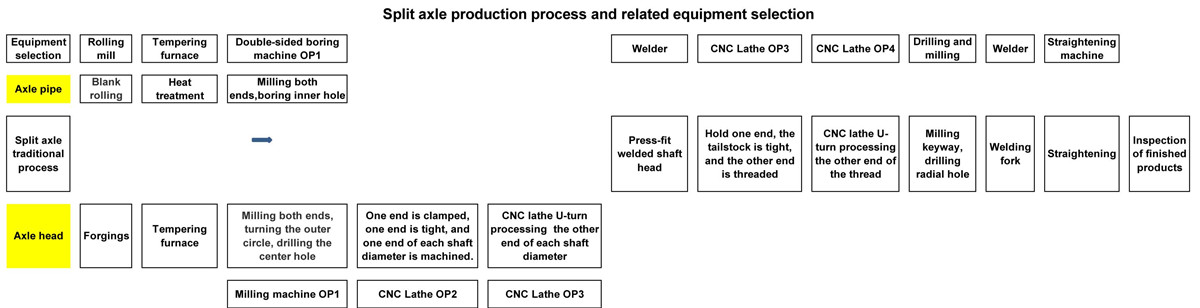

Okulandelayo ukuhlaziya inqubo yokukhiqiza i-ekseli yonke (futhi ihlukaniswe yaba eqinile futhi engenalutho; ishubhu lesikwele neshubhu eliyindilinga), kanye ne-axle ehlukanisiwe (ikhanda le-shaft eliqinile nelingenalutho + ukushiswa kweshubhu le-shaft elingenalutho), Ikakhulukazi, inqubo yomshini ihlaziywa ukuze kukhethwe kangcono umshini ofaneleka kakhulu.

Inqubo yokukhiqiza nomshini wama-ekseli wezimoto:

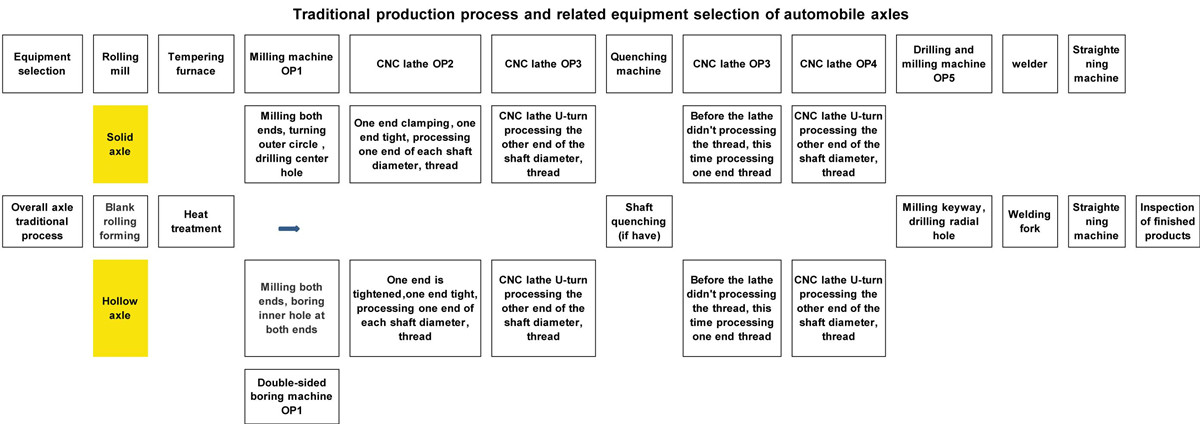

1. Inqubo yokukhiqiza yendabuko ye-asili iyonke:

Kusukela kunqubo yokukhiqiza i-ekseli engenhla, kudingeka okungenani izinhlobo ezintathu zamathuluzi omshini ukuze kuqedelwe umshini: umshini wokugaya noma umshini oyisicefe ozinhlangothi ezimbili, i-CNC lathe, umshini wokubhoboza nowokugaya, kanye ne-CNC lathe idinga ukuphendulwa (amanye amakhasimende ane ekhethiwe i-CNC lathe enamakhanda amabili). Ngokuphathelene nokucutshungulwa kwentambo, uma ububanzi be-shaft bucinywa, bucutshungulwa ngemva kokucisha; uma kungekho ukucisha, kucutshungulwa ku-OP2 naku-OP3, futhi amathuluzi omshini wokulandelana we-OP4 kanye ne-OP5 ayashiywa.

Kusukela enqubweni entsha yokukhiqiza, umshini wokugaya osetshenziselwa umshini (i-asili eqinile) noma umshini wokubhoboza ozinhlangothi ezimbili (i-axle engenalutho) kanye ne-CNC lathe, ukugaya kwendabuko kwe-OP1, i-OP2, ukulandelana kokujika kwe-OP3, ngisho nokubhola nokugaya kwe-OP5 Kungashintshwa. nge-double end CNC lathe OP1.

Kuma-ekseli aqinile lapho i-shaft diameter ingadingi ukucishwa, konke okuqukethwe komshini kungaqedwa ngokusetha okukodwa, okuhlanganisa imisele yokhiye wokugaya kanye nezimbobo zokubhoboza ama-radial. Kuma-ekseli angenalutho lapho i-shaft diameter ingadingi ukucishwa, indinganiso ye-automatic conversion clamping ingabonakala ethuluzini lomshini, futhi okuqukethwe komshini kungaqedwa ngethuluzi lomshini elilodwa.

Khetha amalebula akhethekile e-axle e-CNC aneziphetho ezimbili zomshini ama-ekseli afinyeza kakhulu umzila womshini, futhi uhlobo nenani lamathuluzi omshini akhethiwe nakho kuzoncishiswa.

3.Hlukanisa inqubo yokukhiqiza i-ekseli:

Kusukela kule nqubo engenhla, izinto zokucubungula ze-axle tube ngaphambi kokushisela nazo zingakhethwa njenge-lathe ye-CNC eneziphetho ezimbili. Ukuze kucutshungulwe i-axle ngemva kokushisela, i-lathe ye-CNC ekhethekile yama-axles ane-double-end kufanele kube yisinqumo sokuqala: ukucubungula ngesikhathi esisodwa kuzo zombili iziphetho, ukusebenza kahle okuphezulu kokucubungula kanye nokunemba okuhle kwemishini. Uma ukhiye kanye nembobo ye-radial emikhawulweni yomibili ye-ekseli idinga ukwenziwa ngomshini, umshini ungaphinda ufakwe isibambi samandla ukuze ucubungule ukhiye olandelayo kanye nembobo ye-radial ndawonye.

4.Inzuzo kanye nesici somshini omusha wokukhetha inqubo:

I-1) Ukugxila kwenqubo, ukunciphisa izikhathi zokubopha i-workpiece, ukunciphisa isikhathi sokucubungula esisizayo, usebenzisa ubuchwepheshe bokucubungula ngesikhathi esisodwa kuzo zombili iziphetho, ukusebenza kahle kokukhiqiza kuthuthukiswa kakhulu.

2) Ukuqinisa ngesikhathi esisodwa, ukucutshungulwa ngesikhathi esisodwa kuzo zombili iziphetho kuthuthukisa ukunemba komshini kanye nokuhlangana kwe-axle.

3) Nciphisa inqubo yokukhiqiza, unciphise inzuzo yezingxenye esizeni sokukhiqiza, uthuthukise ukusebenza kahle kokusetshenziswa kwesayithi, futhi usize ukuthuthukisa inhlangano nokuphathwa kokukhiqiza.

I-4) Ngenxa yokusetshenziswa kwemishini yokucubungula ephezulu, ingahlonyiswa ngamadivaysi okulayisha nokukhipha kanye namadivayisi wokugcina ukuze kuzuzwe ukukhiqizwa okuzenzakalelayo ngokugcwele nokunciphisa izindleko zabasebenzi.

I-5) I-workpiece iboshwe endaweni ephakathi, i-clamping inokwethenjelwa, futhi i-torque edingekayo yokusika ithuluzi lomshini yanele, futhi inani elikhulu lokuguqula lingenziwa.

6) Ithuluzi lomshini lingahlonyiswa ngedivayisi yokuthola okuzenzakalelayo, ikakhulukazi i-axle engenalutho, engaqinisekisa ukujiya komfaniswano we-axle ngemuva komshini.

7) Kuma-ekseli angenalutho, lapho izimbobo zangaphakathi emikhawulweni yomibili yesilandeleli se-OP1 seziqediwe, ikhasimende lendabuko lizosebenzisa isiphetho esisodwa ukuphakamisa isigxivizo kanye nesiphetho esinye ukusebenzisa i-tailstock ukuqinisa ucezu lokusebenza ukuze lujike, kodwa ubukhulu umgodi ongaphakathi uhlukile. Ngembobo encane engaphakathi, ukuqina kokuqina akwanele, i-torque yokuqina ephezulu ayanele, futhi ukusika okuphumelelayo akukwazi ukuqedwa..

Kulathe olusha olunobuso obubili, i-axle engenalutho, lapho izimbobo zangaphakathi kuzo zombili iziphetho zemoto seziqediwe, umshini ushintsha ngokuzenzakalelayo imodi yokubopha: iziphetho ezimbili zisetshenziselwa ukuqinisa ucezu lokusebenza, futhi idrayivu ephakathi intanta into yokusebenza. ukudlulisa i-torque.

I-8) I-headstock ene-workpiece eyakhelwe ngaphakathi ye-hydraulic clamping ingahanjiswa ohlangothini lwe-Z lomshini. Ikhasimende lingakwazi ukubamba indawo eshubhu lesikwele esimaphakathi (ishubhu eliyindilinga), indawo yepuleti elingezansi kanye nendawo yobubanzi be-shaft ye-asi njengoba kudingeka.

5. Isiphetho:

Uma kubhekwa lesi simo esingenhla, ukusetshenziswa kwama-lathe e-CNC aneziphetho ezimbili emshinini wama-ekseli wezimoto kunezinzuzo ezibalulekile kunezinqubo zendabuko. Kuwubuchwepheshe obuthuthukisiwe bokukhiqiza obungakwazi ukuthatha indawo yamathuluzi omshini wendabuko ngokwenqubo yokukhiqiza kanye nesakhiwo somshini.

Ingxenye emaphakathi ye

6.Icala lekhasimende le-Axle

Isethulo esikhethekile se-Axle CNC ye-lathe eyisipesheli

Ibanga lokucubungula i-ekseli: ∮50-200mm, □50-150mm, ubude bokucubungula: 1000-2800mm

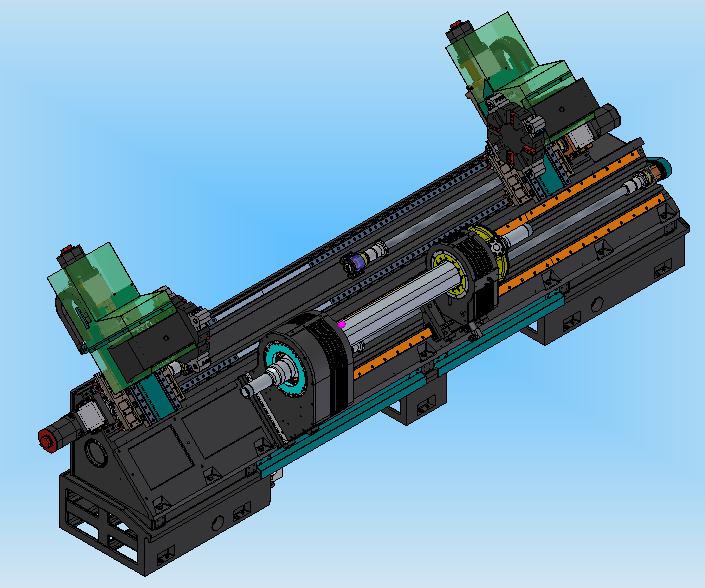

Isakhiwo somshini nesingeniso sokusebenza

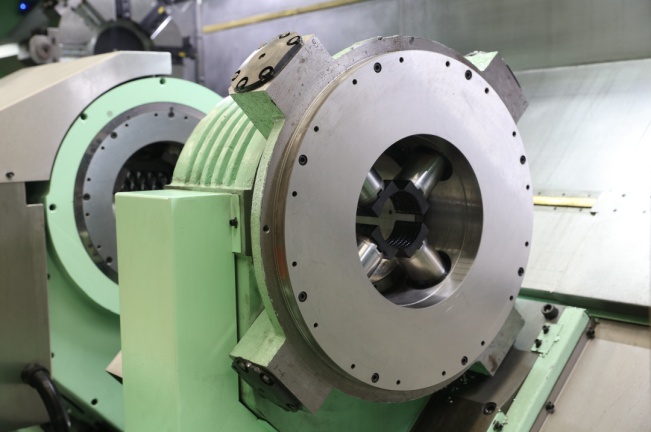

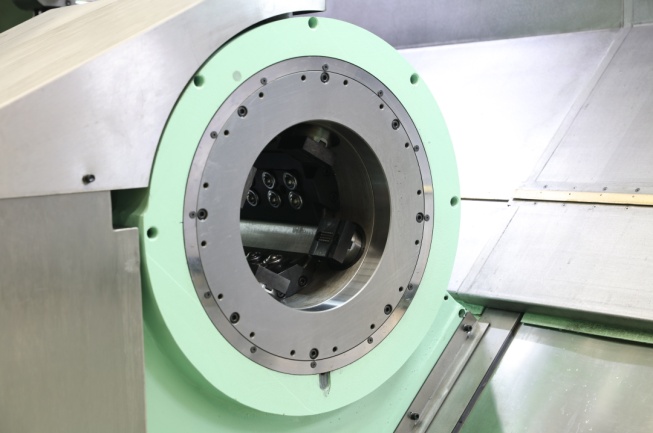

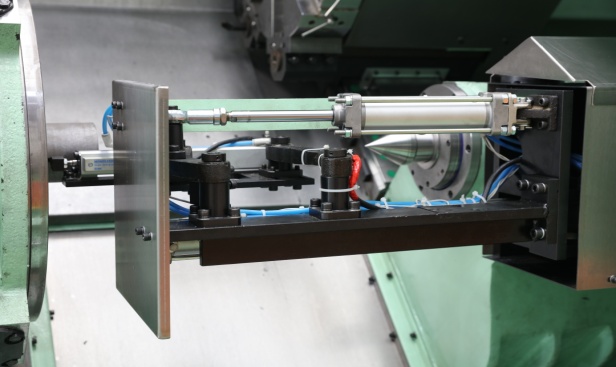

Ithuluzi lomshini lamukela umbhede ongu-45° otshekile, onokuqinile okuhle nokuphuma kalula kwe-chip. I-headstock enomsebenzi we-intermediate drive clamping ihlelwa phakathi nombhede, futhi izibambi zamathuluzi ezimbili zihlelwe nhlangothi zombili zebhokisi lokuphotha. Ubude obuncane bokubopha bomshini bungu-1200mm kanti ubude bomshini womshini bungama-2800mm. Umhlahlandlela wokugoqa uyamukelwa, futhi i-servo feed shaft ngayinye ithatha isikulufu sebhola esithulisa kakhulu, futhi ukuhlanganisa okunwebekayo kuxhumeke ngokuqondile, futhi umsindo uphansi, ukunemba kokuma kanye nokunemba kokuma okuphindaphindiwe kuphezulu.

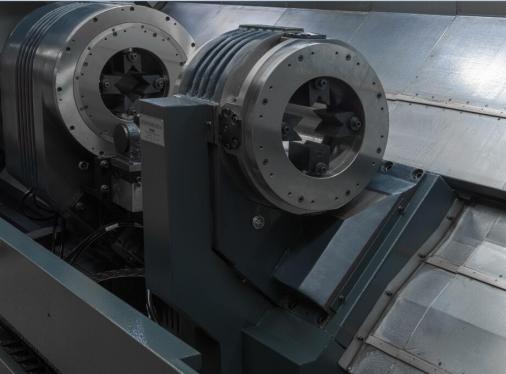

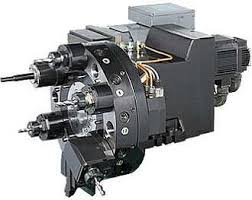

■Umshini ufakwe uhlelo lokulawula lwamashaneli amabili. Izibambi zamathuluzi ezimbili zingaxhunywa ku-spindle ngesikhathi esisodwa noma ngokuhlukene ukuze kuqedelwe ukwenziwa kanyekanye noma ukulandelana kwamaphethelo amabili engxenye.

■ Umshini ifakwe headstocks kabili. I-headstock eyinhloko igxiliwe phakathi kombhede, futhi i-servo motor inikeza amandla ku-shaft eyinhloko ngebhande elinamazinyo. Ibhokisi le-sub-spindle lifakwe kumzila ophansi wokuqondisa wethuluzi lomshini, i-coaxial nebhokisi lokuphotha eliyinhloko, futhi lingahanjiswa nge-axially yi-servo motor ukuze kube lula ukulayishwa nokukhishwa kwezingxenye, futhi kulula ukulungisa ukugoqa okuhlukile. izikhundla. Lapho kwenziwa izingxenye zemishini, isisekelo se-sub-spindle sikhiyelwe kuloliwe womshini. Ukunemba kwe-coaxial kwama-headstocks amabili aqinisekisiwe yinqubo yokukhiqiza, okuholela ezingeni eliphakeme lokugxila kwezingxenye zomshini.

■I-Headstock ihlanganisa isistimu yokuphotha, i-fixture kanye nesistimu yokusabalalisa uwoyela, futhi inokwakheka okuhlangene nokusebenza okuthembekile. Ububanzi obuqondile bokubopha kanye nobubanzi besitokwe sekhanda kunqunywa izingxenye ze-asili zekhasimende.

I-headstock eyinhloko yehliswa ngezigaba ezimbili zebhande negiya, okwenza i-spindle ikwazi ukukhipha itorque enkulu. I-clamp ifakwa ekugcineni kwesobunxele kwe-headstock enkulu kanye nasekupheleni kwesokudla kwe-sub-headstock ngokulandelanayo ukuze kubonakale ukubopha kwezingxenye. Lapho i-headstock enkulu ishayela izingxenye ukuthi zijikeleze, izingxenye zokubopha ze-sub-headstock zizungeza ne-headstock enkulu.

I-fixture ifakwe amasilinda amathathu e-radial (amasilinda amane e-radial uma kokubili impahla eyindilinga kanye nesikwele kuboshwe), i-piston iphindiselwa yingcindezi ye-hydraulic, futhi izinzipho zifakwe ekugcineni kwepiston ukuze zibone ukuzi-self-. ukugxila kwezingxenye. I-clamping. Kuyashesha futhi kulula ukushintsha izinzipho lapho ushintsha izingxenye. I-clamping force ilungiswa yi-hydraulic system hydraulic pressure. Lapho ingxenye ilungiswa ngomshini, i-clamp izungeza ne-shaft eyinhloko, futhi uhlelo lokusabalalisa uwoyela lunikeza uwoyela ku-clamp, ukuze i-clamp ibe namandla anele okubamba ngesikhathi sokuzungezisa. I-clamp inezinzuzo ze-clamping force enkulu kanye ne-claw stroke enkulu.

■ Ukuze uxazulule inkinga yobukhulu bodonga obufanayo ngemuva komshini we-axle ongenalutho wekhasimende, umshini ungafakwa idivayisi yokuhlola i-workpiece ezenzakalelayo. Ngemuva kokuthi i-axle clamping isiqediwe, i-workpiece ithola ngokuzenzakalelayo ukuthi i-probe iyanweba futhi ilinganise indawo ye-workpiece; ngemva kokuqedwa kokulinganisa, idivayisi ihoxa endaweni evaliwe.

Ezinqubweni ezihlukene zomshini wama-axle angenalutho, uma indawo yokuthwala isetshenziswa njengereferensi yokubopha, isakhiwo somshini esinomshini wokugoqa okuzenzakalelayo kanye ne-clamping singakhethwa, futhi i-tailstock ehlelekayo inikezwa izinhlangothi zombili zekhanda lokuphotha eliyinhloko neliyisizayo ukuhlangabezana ne izidingo zomshini owodwa. Kulindeleke ukuthi kuqedelwe ukucutshungulwa kwezinyathelo ezimbili ngesikhathi. Ngesikhathi esifanayo, futhi yenza izingxenye zokulayisha nokukhipha okuzenzakalelayo zibe nokukhetha okuningi futhi okungcono.

■Izibambi zamathuluzi ezingakwesokunxele nezingakwesokudla zingahlonyiswa ngezibambi zamathuluzi ezijikelezayo ezivamile noma ama-turrets kagesi. Zinemisebenzi yokumba nokugaya, engaqedela ukubhoboza nokugaya izingxenye ezibalulekile.

■Ithuluzi lomshini livalwe ngokugcwele futhi lifakwe idivayisi yokuthambisa ezenzakalelayo kanye nedivayisi yokukhipha ama-chip (ngaphambili). Inokusebenza okuhle kokuvikela, ukubukeka okuhle, ukusebenza okulula nokugcinwa okulula.

■ Ukucaciswa komshini wemininingwane nokulungiselelwa kunqunywa ngokwezidingo ze-asi kanye nezidingo zekhasimende, futhi ngeke kuphindeke lapha.

Siyabonga ngokunaka kwakho!