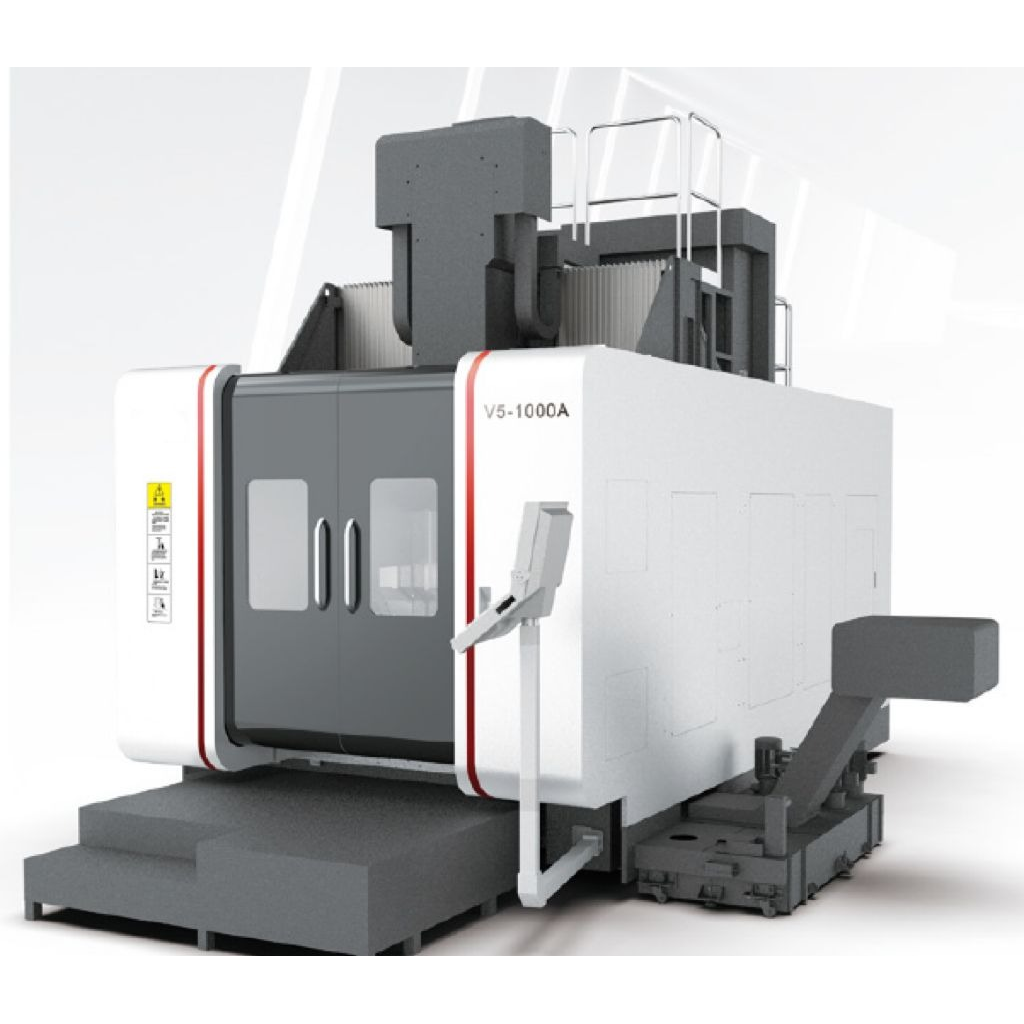

Isikhungo semishini ye-V5-1000A 5-axis

Isikhungo Somachining Esiqondile Se-Axis Ezinhlanu

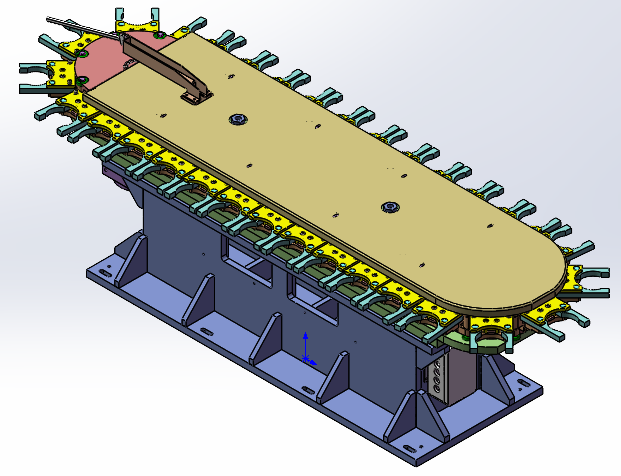

Isikhungo somshini we-V5-1000A se-axis emihlanu samukela isakhiwo esivaliwe se-gantry esizinzile futhi sifakwe i-spindle kagesi evamile, i-turntable ye-CNC ene-axis eqondile ye-CNC kanye ne-horizontal chain servo tool magazine. Ingabona ukwenziwa kwezingxenye eziyinkimbinkimbi, ukunemba okuphezulu, nokusebenza kahle kwezingxenye eziyinkimbinkimbi. Isetshenziswa kabanzi Ekukhiqizeni okusha kwezimoto zamandla, ama-blisk abalulekile endiza, izigxivizo ze-turbine yesitimu, isikhunta neminye imikhiqizo.

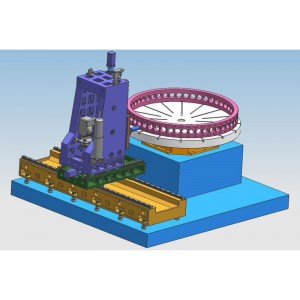

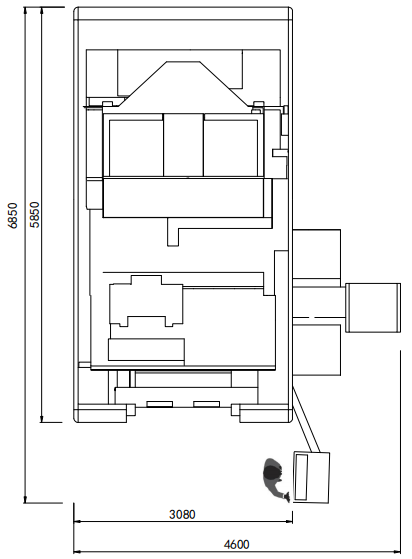

1. Isakhiwo sisonke somshini

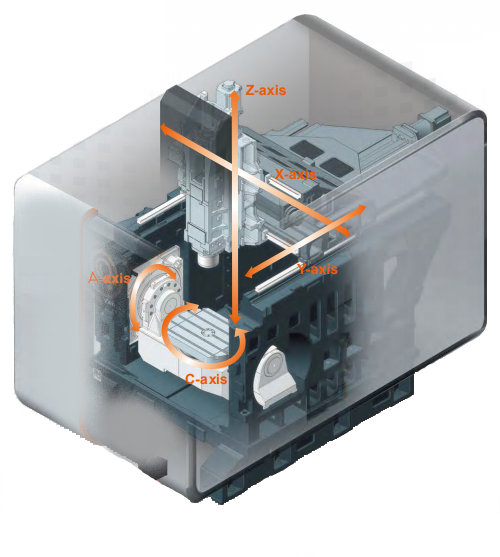

Isikhungo somshini se-V5-1000A se-axis emihlanu samukela isakhiwo esizinzile se-gantry, ikholomu igxilile esisekelweni, ugongolo luhamba ngobude eduze kwekholomu (isiqondiso sika-Y), ipuleti lesilayidi lihamba libheke eceleni eduze kohlaka (i-X direction), futhi I-headstock ihamba iqonde kupuleti lesilayidi (isiqondiso sika-Z) . Ibhentshi lomsebenzi lamukela ukwakheka kwembeleko ye-direct-drive ezithuthukisiwe, futhi izinkomba ezihlukene zokusebenza sezifinyelele ezingeni eliphezulu lamazwe ngamazwe.

2. Uhlelo lokudla

Ama-X, Y, Z ama-eksisi asebenzisa ukuqina okuphezulu kakhulu, imihlahlandlela eqondile yamarola anembayo nezikulufu zebhola ezisebenza kahle kakhulu, ezinokungqubuzana okuphansi okuguquguqukayo nokumile, ukuzwela okuphezulu, ukudlidliza okuphansi ngesivinini esikhulu, akukho kukhasa ngesivinini esiphansi, ukuma okuphezulu ukunemba, nokusebenza okuhle kakhulu kwe-servo drive.

I-X, Y, Z i-axis servo motors ixhunywe ngezikulufu zebhola ezinembayo ngokusebenzisa izinciphisi ezinembayo, ngokuphakela okuvumelana nezimo, ukuma okunembile kanye nokunemba okuphezulu kokudlulisela.

I-Z-axis servo motor inomsebenzi wamabhuleki. Uma kwenzeka ukuphelelwa amandla, ikwazi ukubamba ibhuleki ngokuzenzakalelayo ukuze ibambe i-motor shaft iqine ukuze ingakwazi ukujikeleza, okubamba iqhaza ekuvikeleni ukuphepha.

3. I-spindle kagesi

I-spindle enenjini yamukela i-BT50 motorized spindle (HSKA100 motorized spindle is optional), futhi isiphetho sifakwe isifutho sendandatho yokupholisa ithuluzi. Inezinzuzo zejubane eliphezulu, ukunemba okuphezulu, ukusabela okuphezulu okuguquguqukayo, njll., futhi ingabona ukulawulwa kwesivinini esingenasinyathelo, isishumeki esakhelwe ngaphakathi sokunemba okuphezulu, singafinyelela isitobhi esiqondile esiqondisayo kanye nokuthepha okuqinile.

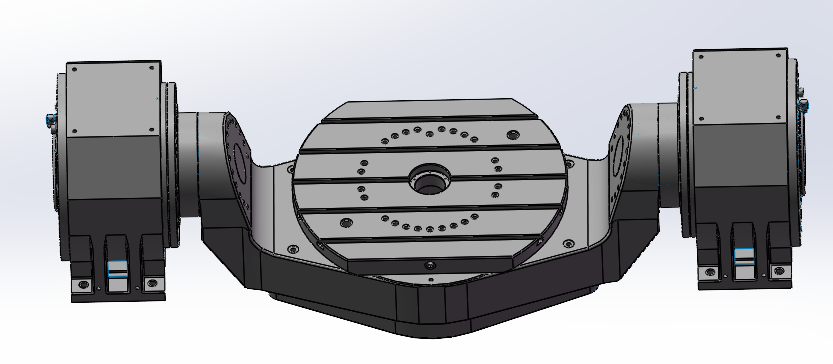

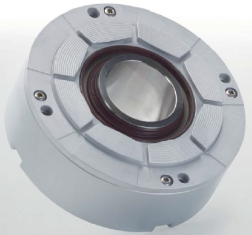

4. I-Turntable

I-double-axis direct-drive cradle turntable ezithuthukiselwe yona ifakwe isifaki khodi esinembe kakhulu futhi sipholiswa isipholile samanzi ngezinga lokushisa elingashintshi. Inezinzuzo zokuqina okuphezulu, ukunemba okuphezulu, kanye nokuphendula okuphezulu okuguquguqukayo. Ithebula lokusebenza lisebenzisa i-5-18mm radial T-slots, futhi umthwalo ovunyelwe ngu-2000kg (isatshalaliswa ngokulinganayo)

5. Umagazini wamathuluzi

Umagazini wamathuluzi wamukela umagazini we-BT50 ovundlile we-servo tool, ongahlalisa amathuluzi angama-30.

6. Uhlelo lwempendulo ye-loop evaliwe ngokugcwele

X, Y, Z izimbazo zomugqa zihlonyiswe nge-HEIDENHAIN LC195S irula legrating yenani eliphelele; Amathebula e-rotary A kanye no-C ahlonyiswe ngezishumeki ze-engeli zenani eliphelele le-HEIDENHAIN RCN2310 ukuze kutholakale impendulo egcwele yeluphu evaliwe yama-ax okuphakelayo angu-5, okuqinisekisa ukuthi umshini unokunemba okuphezulu kanye nokugcinwa ngokunemba okuphezulu.

7. Ukupholisa kanye nohlelo lwe-pneumatic

Ifakwe iphampu yokupholisa egelezayo nethangi lamanzi ukunikeza ukupholisa okwanele kwamathuluzi nezinto zokusebenza. Ubuso bokuphela kwe-headstock bufakwe izimbobo zokupholisa, ezingalawulwa ngekhodi engu-M noma iphaneli yokulawula.

Ifakwe isipholile samanzi sokupholisa izinga lokushisa njalo, ukuqinisekisa ukuthi i-spindle kagesi kanye ne-direct drive turntable kusesimweni esihle sokusebenza futhi kungasebenza kahle isikhathi eside.

Isistimu ye-pneumatic yamukela izingxenye zomoya zokuhlunga, futhi ibona imisebenzi yokuhlanza nokuphephetha imbobo ye-taper ye-spindle, ukuvikela uphawu lomoya we-spindle bear, kanye nokufutha nokuhlanza irula lokuphotha.

8. Uhlelo lokuthambisa oluphakathi nendawo

Ibhulokhi yesilayidi yesitimela somhlahlandlela kanye nenathi lesikulufu sebhola konke kugcotshwe ngamafutha amancane, futhi okokugcoba kunikezwa njalo nangobuningi ukuze kuqinisekiswe ukunemba nokuzinza kwesikulufu sebhola kanye nesitimela somhlahlandlela.

9. Uhlelo lokugcoba uwoyela negesi

I-spindle kagesi ifakwe uwoyela negesi umshini wokugcoba ovela kwamanye amazwe, ongagcoba ngokugcwele futhi upholise i-spindle. Inzwa ingahlinzeka nge-alamu yokugcoba engavamile, engaqinisekisa ngempumelelo ukuthi i-spindle ingasebenza ngokuzinza ngesivinini esiphezulu isikhathi eside.

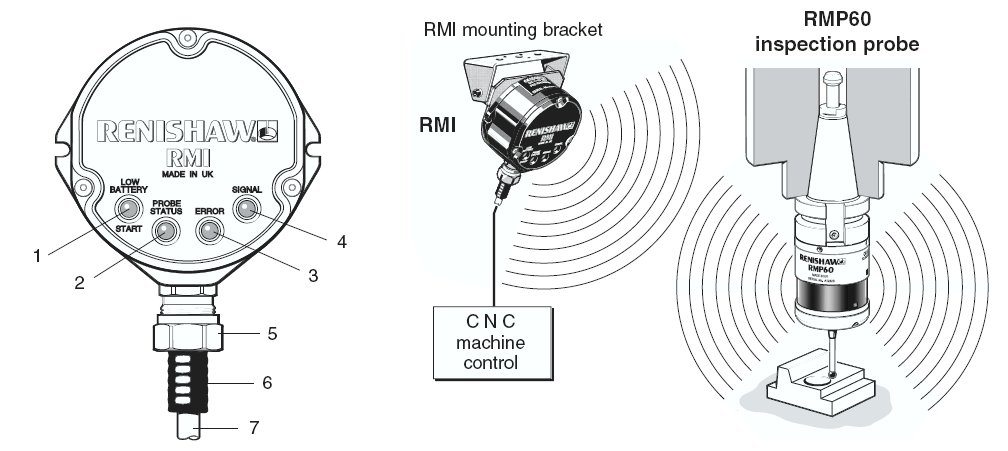

10. Uhlelo lokulinganisa i-workpiece

Umshini ufakwe i-Renishaw RMP60 probe radio, esetshenziswa ngokubambisana nesamukeli se-RMI, imvamisa yokusebenza ingu-2400 MHz kuya ku-2483.5 MHz, isilinganiso sokuphindaphinda kwendlela eyodwa singaphansi noma silingana no-1um (480mm/min isivinini sokulinganisa, sisebenzisa i- I-stylus engu-50mm), futhi izinga lokushisa elisebenzayo liyi-5°C kuya ku-55°C.

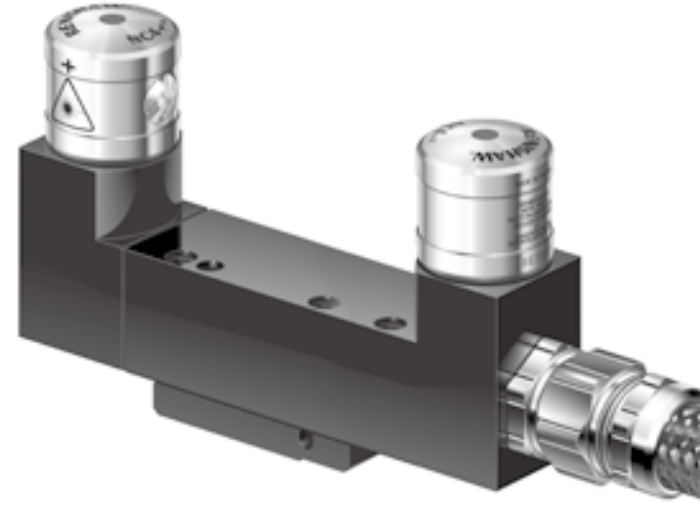

11. Uhlelo lokulinganisa lwamathuluzi

Umshini ufakwe i-Renishaw NC4 laser tool setter, ukuphindaphinda kwesilinganiso kungu-±0.1um, kanti izinga lokushisa elisebenzayo lingu-5°C kuya ku-50°C.

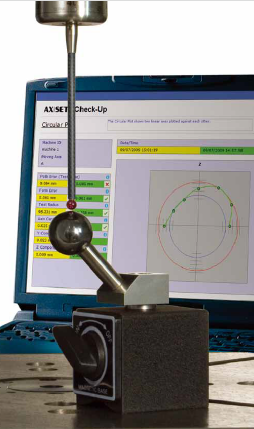

12. Umsebenzi wokulinganisa ukunemba kweeksisi ezinhlanu

Umshini ufakwe ikhithi yokuhlola ye-Renishaw's AxiSet Check-Up Rotary Axis Line, ebhangqwe nesistimu yokulinganisa ucezu lokusebenza RMP60, okuvumela abasebenzisi bomshini ukuthi bahlole ngokushesha futhi ngokunembile isimo sezimbazo ezijikelezayo futhi babone izinkinga ezibangelwa ukushintsha kwezinga lokushisa nokuswakama, ukushayisana kwemishini noma ukuguga. izinkinga, ingalungisa ngokushesha futhi ithole amasheke okusebenza, ilinganisele futhi iqaphe ukuthi imishini eyinkimbinkimbi ishintsha kanjani ngokuhamba kwesikhathi.

13. ukuvikelwa komshini

Umshini wamukela ikhava yokuvikela evalekile ngokugcwele ehlangabezana nezindinganiso zokuphepha ukuze uvimbele ukuchaphazwa kwezinto ezipholile nama-chips, uqinisekise ukusebenza okuphephile, futhi ube nokubukeka okuhle. I-X-direction yomshini ifakwe isembozo sokuvikela esihlomile, esingavikela ngempumelelo isitimela somhlahlandlela nesikulufu sebhola.

14. izimo zokusebenza komshini

(1) Ukunikezwa kwamandla: 380V±10% 50HZ±1HZ umsinga oshintshashintshayo wezigaba ezintathu

(2) Izinga lokushisa le-ambient: 5℃-40℃

(3) Izinga lokushisa elingcono kakhulu: 20℃±2℃

(4) Umswakama ohlobene: 20-75%

(5) Umfutho womthombo womoya: 6±1 ibha

(6) Ukugeleza komthombo womoya: 500 L/min

15. Ukwethulwa komsebenzi wohlelo lwe-CNC

I-Siemens 840Dsl.730 CNC ukucushwa kwesistimu

| Into

| Igama

| Ukuphawula

|

| Imisebenzi yesistimu | Isilinganiso sokushaya kwenhliziyo esincane | I-eksisi yomugqa 0.001 mm, i-axis ejikelezayo engu-0.001° |

| Izinga lokuphakelayo ngomzuzu/inguquko | ||

| Okuphakelayo nokunqamula ngokushesha | ||

| Ukukhipha okuphakelayo 0~120% | ||

| Umkhawulo wesivinini se-spindle | ||

| Ukusika isivinini esingaguquguquki | ||

| Ukuqapha nge-spindle | ||

| Ukukhishwa kwe-Spindle 50 ~ 120% | ||

| Isibonisi sesivinini se-spindle | ||

| UHLAKA | Bona ukuxhumanisa ukuguqulwa kwesistimu kanye ne-bevel machining | |

| Ukushintshwa kwesistimu yokulinganisa okuqondile/okungaqondile | ||

| Umsebenzi wokubheka phambili noma umsebenzi wokubheka phambili | ||

| Isinxephezelo sephutha lesikulufu sokuhola | ||

| Isinxephezelo Sephutha Lesistimu Yokulinganisa | ||

| Isinxephezelo Sephutha Le-Quadrant | ||

| Isinxephezelo sokuhlehla | ||

| Ukuphathwa kwamathuluzi | ||

| Ukucushwa kwe-Hardware | Inombolo yezimbazo zokulawula | X, Y, Z, A, C ama-eksisi adidiyelwe amahlanu kanye ne-eksisi eyodwa eyinhloko |

| Ukulawulwa kanyekanye kwenani lezimbazo | X, Y, Z, A, C ukuxhumana kwama-eksisi amahlanu | |

| igama le-eksisi | X, Y, Z, A, C, SP | |

| qapha | 15" isibonisi se-LCD sombala, bonisa umbhalo ngesi-Chinese/English | |

| Iphaneli yokusebenza | OP015 umsebenzi ogcwele CNC keyboard | |

| isikhombikubona sokuxhumana somshini womuntu | I-TCU yokucushwa okujwayelekile | |

| Iphaneli yokulawula umshini | Iphaneli yokulawula ye-SINUMERIK MCP 483C PN, okhiye bemishini abangama-50 abane-LED, ene-PROFINET, isixhumi esibonakalayo se-Industrial Ethernet | |

| Iyunithi yokusebenza ephathwa ngesandla | ||

| Isixhumi esibonakalayo sekhibhodi esijwayelekile | ||

| Isixhumi esibonakalayo se-Ethernet | Kuhlanganiswe ku-NCU (umsebenzi wokuxhumana ovulekile we-workshop) | |

| Imbobo ye-USB | 3 x 0.5 I-USB ehlanganiswe ku-TCU | |

| Uhlelo lwe-PLC | I-PLC317-3PN/DP | |

| Umsebenzi wokuhumusha | Ikhefu lokuphakelayo | |

| ukusika intambo | ||

| Ukusika ngesikhathi esisodwa | ||

| Ukuhumusha komugqa okudidiyelwe okuthathu | ||

| Ukuhumusha okuyisiyingi okudidiyelwe okubili okudidiyelwe okubili | ||

| I-Helical interpolation | ||

| Ukuthepha / Ukuthepha Okuqinile | ||

| ukuhlela | I-chamfering/rounding ngokweqile | |

| umhleli wohlelo | Ukuthobelana nezinga le-DIN66025, elinezici zokuhlela zolimi ezisezingeni eliphezulu | |

| Uhlelo oluphelele noma olukhuphukayo | ||

| Ukuguquguquka komsebenzisi, kuyahleleka | ||

| Uhlelo lweqa kanye namagatsha | ||

| uhlelo olukhulu | ||

| Qondisa ukuhumusha kwesistimu nokuzungezisa | ||

| Ukuhlela kanye nokwenza imishini ngesikhathi esisodwa | ||

| Umyalelo wohlelo lokubuyela endaweni eyinkomba | ||

| Ukuhlelwa kwe-Contour kanye nezinhlelo zomjikelezo wamathini | ||

| Ukwenza isibuko nokukala | ||

| ukukhethwa kwendiza | ||

| Isistimu yokuhlanganisa i-Workpiece | ||

| Umjikelezo wokugaya nokugaya ethinini | ||

| I-Zero offset | ||

| vimba ukusesha | ||

| Ukusesha inombolo yohlelo | ||

| Ukuhlela okungemuva | ||

| ukuvikelwa kohlelo | ||

| Khetha uhlelo ngohla lwemibhalo | ||

| Imisebenzi ye-Arithmetic ne-trigonometric | ||

| Ukuqhathanisa nokusebenza okunengqondo | ||

| Iphakethe lesoftware yemishini ye-axis emihlanu | Ukuguqulwa kwe-axis emihlanu; isinxephezelo sethuluzi le-eksisi emihlanu; umsebenzi wokuzungezisa esikhungweni samathuluzi (RTCP) | |

| Umsebenzi wokuvikela ukuphepha | Imikhawulo yendawo yomshini ehlelekayo | |

| Umsebenzi wokuhlola uhlelo | ||

| isitobhi esiphuthumayo | ||

| Ukuqapha umkhawulo wesoftware | ||

| Ukuqapha ikhonsathi | ||

| Ukutholwa kokushayisana kwekhonta | ||

| Ukuqapha okuqinile | ||

| Ukuqapha indawo | ||

| ukuqapha isivinini | ||

| Imikhawulo yendawo yokucubungula | ||

| umkhawulo we-torque | ||

| Imisebenzi yokuphepha izilinganiso zokulinganisa iwashi, ukushisa ngokweqile, ibhethri, i-voltage, inkumbulo, amaswishi anomkhawulo, ukuqapha abalandeli | ||

| Indlela yokusebenza | NGOKUZENZAKALELAYO | |

| JOG (manual) ukulungiswa | ||

| Ukusebenza kwesondo lesandla | ||

| Ukufakwa kwedatha ye-MDA ngesandla | ||

| Ukuxilongwa kwe-NC ne-PLC ngesibonisi sombhalo, isilondolozi sesikrini | ||

| ukusebenza nesibonisi | Isibonisi somsebenzi wokuzihlola | Kubandakanya imodi ye-REF, imodi yokwengeza (x1, x10, x100) |

| Isibonisi sendawo yamanje | ||

| Isibonisi sesithombe | ||

| isibonisi sohlelo | ||

| isibonisi sephutha lohlelo | ||

| Isibonisi sephutha lokusebenza | ||

| Isibonisi sangempela sokusika | ||

| Isibonisi semenyu yesiShayina nesiNgisi | ||

| Isibonisi semininingwane ye-alamu | ||

| Amasethi amaningi emiyalo yekhodi ye-M | ||

| Sekela ukudluliswa kwedatha yebhasi ye-PROFINET | ||

| ukuxhumana kwedatha | Imbobo ye-USB | Idatha ye-NC, idatha ye-PLC nezinhlelo kwenzelwa ikhophi yasenqolobaneni kudiski ye-U ukuze uthole idatha yokufaka nokuphumayo |

| Ukudluliswa kwedatha ye-Ethernet | Ngesixhumi esibonakalayo se-Ethernet |

Ipharamitha eyinhloko

| Into | Imininingwane | Iyunithi | |||

| ibhentshi lokusebenza

| usayizi wedeski elisebenzayo | φ1000×800 | mm | ||

| umthamo omkhulu ovumelekile | 2000 | kg | |||

| T-slot usayizi | 5×18 | 个×mm | |||

| ukucubungula ububanzi

| I-X eksisi | 1150 | mm | ||

| Y eksisi | 1300 | mm | |||

| Z eksisi | 900 | mm | |||

| I-axis | -150+130 | ° | |||

| I-C eksisi | 360 | ° | |||

| Ibanga ukusuka ku-spindle end kuya etafuleni lomsebenzi | Ubukhulu | 1080 | mm | ||

| Okuncane | 180 | mm | |||

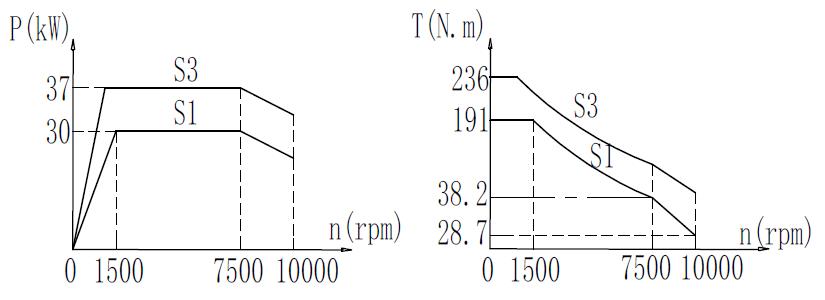

| I-spindle

| Imbobo yesigaxa | I-BT50 | |||

| Isivinini esilinganiselwe | 1500 | r/min | |||

| isivinini esiphezulu | 10000 | ||||

| I-torque ye-S1/S6 | 191/236 | Nm | |||

| Amandla e-spindle motor S1/S6 | 30/37 | kW | |||

| I-eksisi

| hamba ngokushesha | I-X eksisi | 25 | m/min | |

| Y eksisi | 25 | ||||

| Z eksisi | 25 | ||||

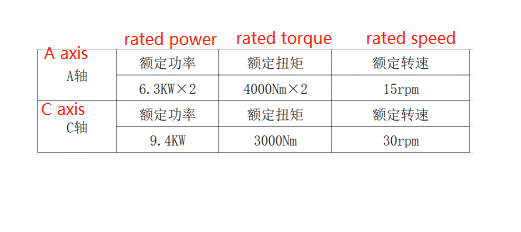

| Isivinini esiphezulu esiguqukayo | I-axis | 15 | rpm | ||

| I-C eksisi | 30 | rpm | |||

| Amandla e-axis motor ye-X/Y/Z | 3.1/4.4/2 | kW | |||

| A/C eksisi Amandla eMotor | 6.3 *2/ 9.4 | kW | |||

| I-axis | I-torque elinganiselwe | 4000×2 | Nm | ||

| I-C eksisi | I-torque elinganiselwe | 3000 | Nm | ||

| isilinganiso sokuphakelayo esiphezulu | X/Y/Z | 25 | m/min | ||

| I-A/C | 15/30 | rpm | |||

| Umagazini wamathuluzi

| Ifomu lomagazini wethuluzi | evundlile | |||

| indlela yokukhetha ithuluzi | Izindlela ezimbili zokukhetha ithuluzi eliseduze | ||||

| Amandla omagazini wethuluzi | 30 | T | |||

| Ubude bethuluzi obukhulu | 400 | mm | |||

| Isisindo sethuluzi esiphezulu | 20 | kg | |||

| Ubukhulu obukhulu bekhanda lomsiki | egcwele imimese | φ125 | mm | ||

| Ithuluzi eliseduze elingenalutho | φ180 | mm | |||

| isikhundla ukunemba | Izinga eliphezulu | I-GB/T20957.4 (ISO10791-4) | |||

| I-X-eksisi/Y-eksisi/Z-eksisi | 0.008/0.008/0.008 | mm | |||

| I-eksisi ye-B / i-C eksisi | 8″/8″ | ||||

| phinda isikhundla ukunemba | I-X-eksisi/Y-eksisi/Z-eksisi | 0.006/0.006/0.006 | mm | ||

| I-eksisi ye-B / i-C eksisi | 6″/6″ | ||||

| Isisindo somshini | 33000 | kg | |||

| umthamo kagesi ophelele | 80 | I-KVA | |||

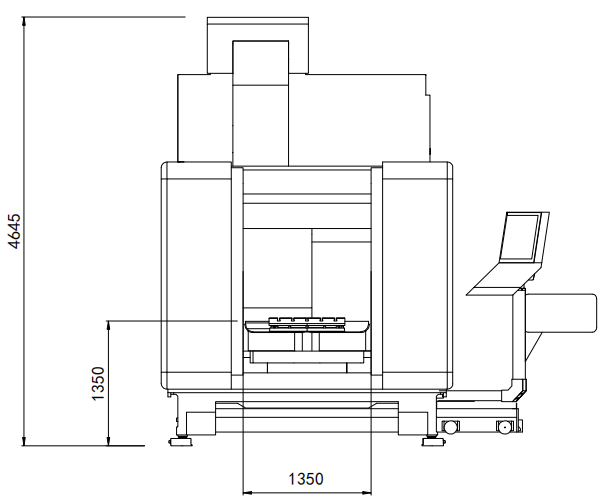

| usayizi wohlaka lomshini | 7420×4770×4800 | mm | |||

Uhlu Lokucushwa

Okujwayelekile

|

| 1. Izingxenye eziyinhloko (okuhlanganisa isisekelo, ikholomu, ugongolo, ipuleti lama-slide, ibhokisi lokuphotha) |

| 2. X, Y, Z isistimu yokuphakelayo yama-eksisi amathathu | |

| 3. Uhlobo lwe-Cradle turntable AC1000 | |

| 4. I-spindle kagesi | |

| 5. Uhlelo lokulawula ugesi (okuhlanganisa iKhabhinethi kagesi, imojula yamandla, imojula ye-servo, i-PLC, iphaneli yokusebenza, isibonisi, iyunithi ephathwa ngesandla, i-air conditioner yekhabhinethi kagesi, njll.) | |

| 6. Uhlelo lwe-hydraulic | |

| 7. Uhlelo lwe-pneumatic | |

| 8. Uhlelo lokuthambisa oluphakathi nendawo | |

| 9. Isibandisi samanzi | |

| 10. I-chip conveyor, ithangi lamanzi, umqoqi we-chip | |

| 11. Irula yokugaya | |

| 12. Ikhava yokuvikela ujantshi | |

| 13. umshini ikhava yokuvikela jikelele | |

| 14. Uhlelo lokulinganisa i-workpiece | |

| 15. Ithuluzi lokusetha ithuluzi | |

| 16. Umsebenzi wokulinganisa ukunemba kweeksisi ezinhlanu | |

|

| 1. Isitifiketi esi-1 sokuvumelana 2. Uhlu lokupakisha ikhophi engu-1 3. Isethi engu-1 yemanuwali yomshini (inguqulo ye-elekthronikhi) 4. idatha yokusekela ngomshini Isethi engu-1 (idiski ye-U) 5.840D imanuwali yokuxilongwa kwe-alamu isethi engu-1 (inguqulo ye-elekthronikhi)/828D umhlahlandlela wokuxilongwa ikhophi engu-1 (inguqulo ye-elekthronikhi) 6.840D imanuwali yokusebenza kokugaya Ikhophi engu-1 (inguqulo kagesi)/828D imanuwali yokusebenza Ikhophi engu-1 (inguqulo ye-elekthronikhi) Imanuwali yokuhlela ye-840D 1 ingxenye eyisisekelo (inguqulo ye-elekthronikhi) / 828D imanuwali yokuhlela 1 (inguqulo ye-elekthronikhi) |

| Into | Amabhrendi |

| I-X/Y/Z i-axis motor kanye nokushayela | Siemens, Germany |

| iketango lamandla | i-germany igus |

| i-screw bear | Japan NSK/NACHI |

| Linear Guides | Schneeberg, Germany |

| Umagazini wamathuluzi | Okada |

| isinciphisi | STOBER, Germany |

| Ukuthambisa okumaphakathi | Japan |

| Isikulufu sebhola | SHUTON, Spain |

| Izingxenye Zomoya | I-SMC yaseJapan |

| I-air conditioner yekhabhinethi kagesi | China |

| isipholile samanzi | China |

| irula egayayo | E-HEIDENHAIN, eJalimane |

| Isistimu yokulinganisa isiqeshana somsebenzi | Renishaw, UK |

| Isistimu yokulinganisa ithuluzi | Renishaw, UK |

| Ihlanganisa ngomshini | Imininingwane | Ubuningi |

| Insimbi kamatilasi yomshini |

| 8 amasethi |

| Amabhawodi ehange |

| 8 amasethi |

| izindandatho | M30 | 2 izingcezu |

| izindandatho | M36 | 2 izingcezu |

| ama-suspenders |

| 1 isethi |

| Ukhiye ka-Allen | 10 | 1 |

| Ukhiye ka-Allen | 12 | 1 |

| Ukhiye ka-Allen | 14 | 1 |

| Ukhiye ka-Allen | 19 | 1 |

| I-Z-axis ukukhweza |

| 1 |

| I-X-axis ukukhweza |

| 1 |

| Ukulungiswa kwe-Y-eksisi |

| 1 |

Siyabonga Ngokunaka kwakho!