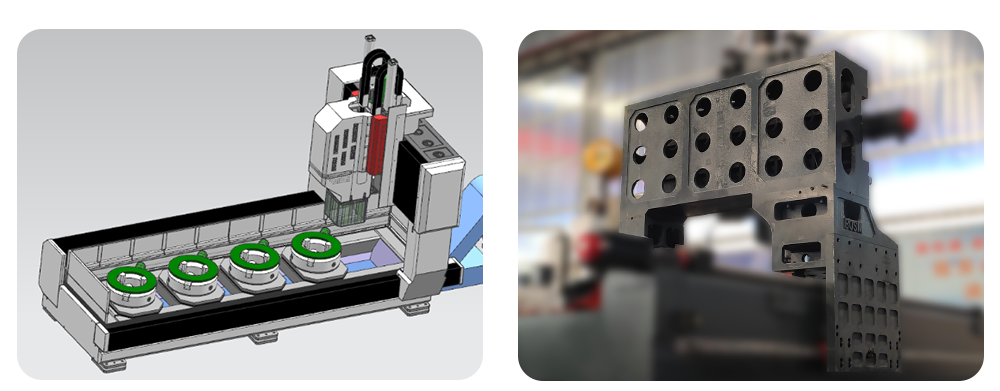

Four Station Shaft Flange Drilling Machine

Izici Zomshini

Uchungechunge lweziteshi ezine ze-CNC zokumba kanye nomshini wokugaya lusetshenziselwa ikakhulukazi ukucubungula i-flange eyindilinga, futhi lungasetshenziselwa ukubhola / ukugaya okusebenzayo kwezinto zokusebenza ezinobukhulu ngaphakathi kwebanga elisebenzayo njengama-shafts, amapuleti ayisicaba, ama-flange, amadiski nezindandatho. / Ukuthepha / ukulungisa kabusha / ukuqopha nezinye izinqubo. Ngezimbobo nezimbobo eziyimpumputhe zingabhobozwa ezingxenyeni ezilula zempahla nezinto eziyinhlanganisela. Ithuluzi lomshini lilawulwa ngedijithali ukuze lisebenze kalula. Ingakwazi ukufeza i-automation, ukunemba okuphezulu, izinhlobo eziningi, ukukhiqizwa okukhulu.

Isakhiwo somshini

Lo mshini unetafula lokusebenza, amasethi amane e-hydraulic emihlathini emine ezenzelayo, igantry ephathwayo, isihlalo sesihlalo esihambayo, inhloko yamandla okubhola neyokugaya, ithuluzi lokuthambisa elizenzakalelayo kanye nokuvikela, idivayisi yokupholisa ejikelezayo, uhlelo lokulawula idijithali, nohlelo lukagesi. Ukwakheka njll. Ukusekela nokuqondisa komhlahlandlela womugqa kanye nesikulufa sokuhola esinembayo, ithuluzi lomshini linokunemba kokuma okuphezulu kanye nokunemba kokuma okuphindaphindiwe.

1.Ithebula lomsebenzi wombhede:

Umbhede wenziwe izingxenye zensimbi. Iqedwa ngokwelashwa kwesibili kokushisa. Inokuqina okuhle okuguquguqukayo nokuma futhi ayigugi. Ithebula elisebenzayo lisebenzisa amasethi amane angu-500mm emihlathi emine egxile ku-hydraulic chuck ukuze kuhlanganiswe ngokushesha izinto zokusebenza. Amapheya amabili omugqa womugqa womthamo ophezulu womthamo ophezulu afakwe ezinhlangothini zombili zombhede. Ngemva kokumiswa, amasethi amabili okukhiya okunamandla aphezulu angenisiwe. I-clamp ilingana kahle ngaphandle kokulimaza isilayidi sesitimela. Isikhathi sokuvula nokuvala i-clamp singamasekhondi angu-0.06 kuphela, esinciphisa kakhulu isikhathi sokucubungula. Isistimu yokushayela isebenzisa ibhasi eliphelele le-servo motor kanye nokunemba Isikulufu sebhola sishayela i-gantry ukuze ihambe iqonde ku-Y-eksisi. Amabhawodi alungisekayo asatshalaliswa phansi kombhede, angalungisa kalula izinga letafula lombhede.

2.I-Mobile Gantry:

I-gantry ehambayo ifakwe ngensimbi empunga engu-250. Ukuphakama kwe-beam esindayo kungu-800mm ukuthuthukisa amandla ayo. Amapheya amabili alayini aginqayo aphezulu kakhulu afakwe ohlangothini olungaphambili lwe-gantry. Isilayidi esiluhlaza sisebenzisa isikulufu sebhola esinembayo kanye ne-servo motor ukuhambisa isilayidi sekhanda lamandla siye ku-Y axis. Ikhanda lamandla okubhola lifakwe kusilayidi sekhanda lamandla. Ukunyakaza kwe-gantry kubonakala injini ye-servo eshayela umama oyisikulufa sebhola ukuze ijikelezise esikulufini sebhola ngokusebenzisa ukuhlanganisa okunembayo.

3.Isihlalo esishelelayo sikamakhalekhukhwini:

Isihlalo sokushelela esihambayo siyingxenye yesakhiwo sensimbi enembile. Isihlalo sehhashi esishelelayo siyanwetshwa futhi sinyuswe ukuze kwandiswe ibanga elimaphakathi lesitimela esiqondisayo. Amasethi amabili amapheya esitimela ahamba phambili anamandla aphezulu kanye nezikulufu zebhola ezinembayo axhunywe engalweni enemba kakhulu I-servo motor yebhuleki ishayela ikhanda lamandla okubhola ukuze lihambe liye ohlangothini lwe-axis engu-Z, ekwazi ukusheshe ibheke phambili, ukuthuthukiswa kwezimboni, ukuhlehlisa ngokushesha, nokuma kwekhanda lamandla. Ngokuphulwa kwe-chip okuzenzakalelayo, ukususwa kwe-chip, imisebenzi yokumisa okwesikhashana.

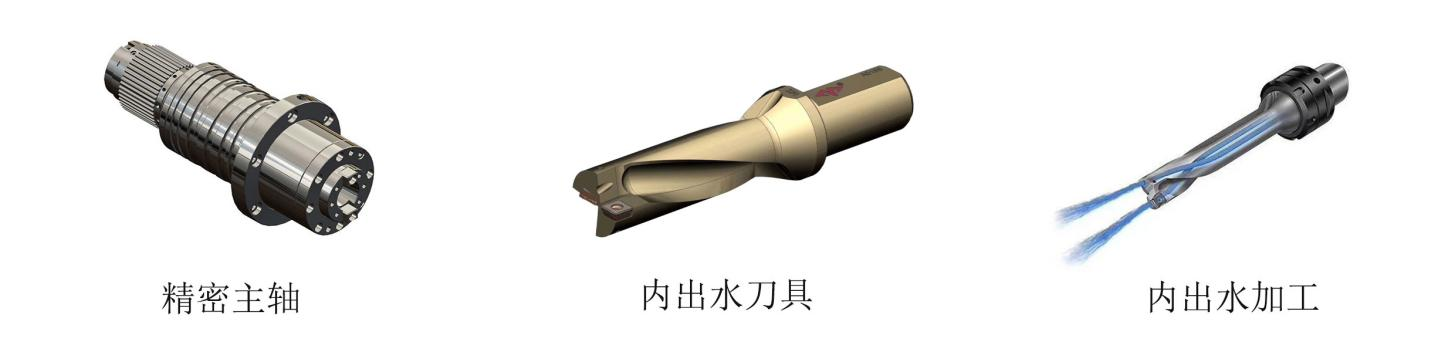

4.Ikhanda lamandla okugaya:

Ikhanda lamandla okumba lisebenzisa i-servo spindle motor ezinikele. I-precision mechanical spindle iqhutshwa ukwehliswa kwebhande le-synchronous elinamazinyo ukwandisa i-torque. I-spindle isebenzisa ama-angular angaphambili amathathu, amabili, kanye nama-angular angama-angular ase-Japan ukuze kuzuzwe ushintsho lwejubane olunganyatheli. Ukushintshwa okusheshayo nokulula, okuphakelayo kushayelwa yi-servo motor nesikulufu sebhola. Izimbazo zika-X kanye no-Y zingaxhunywa, futhi isilawuli seluphu esivalwe kancane singasetshenziswa ukuze kuzuzwe imisebenzi yokuhumusha ewumugqa kanye neyindilinga.

5. Isihambisi se-chip esizenzakalelayo se-flat chain kanye nedivayisi yokupholisa ejikelezayo

Lo mshini ufakwe i-flat chain automatic chip conveyor kanye nomqoqi wama-chip. Idivayisi yokupholisa ejikelezayo ifakwe isihlungi sephepha, esinepompo yokupholisa yangaphakathi yokucindezela okuphezulu kanye nepompo yokupholisa yangaphandle enokucindezela okuphansi kokupholisa kwangaphakathi nangaphandle kwethuluzi.

5.1 Idivayisi yokuthambisa ezenzakalelayo kanye nedivayisi yokuzivikela:

Lo mshini ufakwe i-Taiwan yasekuqaleni ye-volumetric partial lubricating device yokugcoba okuzenzakalelayo, engakwazi ukugcoba ngokuzenzakalelayo ama-rails angumhlahlandlela, izikulufu zokuhola namanye amapheya anyakazayo, futhi ayikho i-engeli efile yokuqinisekisa impilo yesevisi yomshini. I-X-axis kanye ne-Y-axis yethuluzi lomshini ifakwe izembozo zokuvikela ezivikela uthuli, futhi onogada be-splash abangenamanzi bafakwe eduze kwebhentshi lokusebenza.

6. CNCuhlelo lokulawula:

6.1. Ngomsebenzi wokuphulwa kwe-chip, isikhathi sokuphulwa kwe-chip kanye nomjikelezo wokuphulwa kwe-chip kungasethwa kusixhumi esibonakalayo somshini womuntu.

6.2. Ngomsebenzi wokuphakamisa ithuluzi, ubude bokuphakamisa ithuluzi bungasethwa kusixhumi esibonakalayo somshini womuntu. Uma ubhoboza lokhu kuphakama, i-drill bit iphakanyiswa ngokushesha ngaphezu kwendawo yokusebenza, bese i-chip iphihlizwa, bese idluliselwa ngokushesha endaweni yokubhoboza futhi iguqulelwe ngokuzenzakalelayo emsebenzini.

6.3. Ibhokisi eliphakathi nendawo elilawula ukusebenza kanye neyunithi ephathwa ngesandla isebenzisa isistimu yokulawula izinombolo, futhi ifakwe isixhumi esibonakalayo se-USB nesibonisi se-LCD. Ukuze kube lula ukuhlela, ukugcinwa, ukuboniswa nokuxhumana, okusetshenziswa kubonwa kunemisebenzi efana nengxoxo yomshini womuntu, isinxephezelo samaphutha, ne-alamu ezenzakalelayo.

6.4. Imishini inomsebenzi wokuhlola kuqala nokubheka kabusha indawo yembobo ngaphambi kokucubungula, futhi ukusebenza kulula kakhulu.

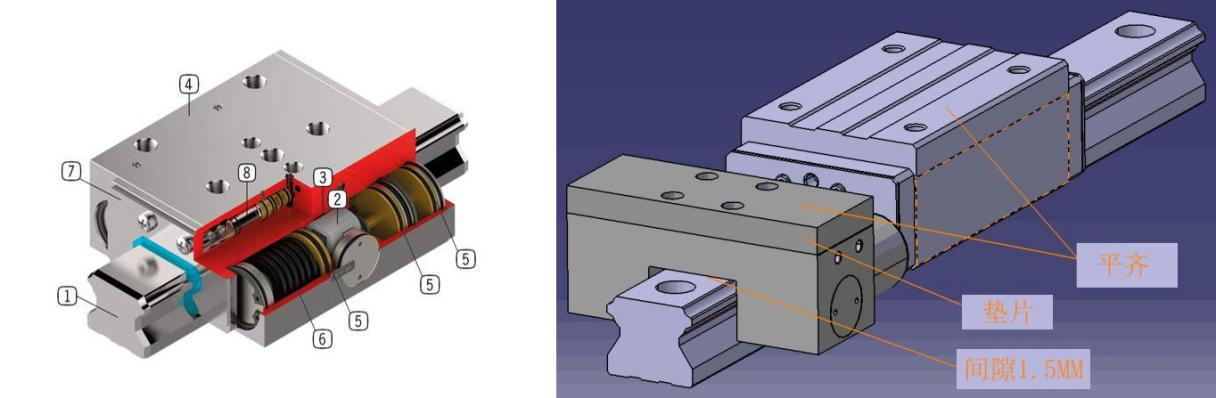

7.Isigcino sikaloliwe:

I-clamp yakhiwe indikimba eyinhloko ye-clamp, ama-actuator, njll. Iyingxenye esebenza kahle kakhulu esetshenziswa ngokuhambisana nokupheya komugqa womugqa ogoqayo. Ngokusebenzisa isimiso sokunwetshwa kwe-wedge block force, ikhiqiza amandla okubamba aqinile; ine-gantry engaguquki, ukuma okunembile, i-anti-vibration kanye nomsebenzi wokuthuthukisa ukuqina.

Inezici ezilandelayo:

Ø 1)Amandla okubamba aphephile futhi athembekile, aqinisa i-eksisi ye-XY enganyakazi phakathi nokubhoboza nokuthepha.

Ø 2)Amandla okubamba aphakeme kakhulu anyusa ukuqina kokuphakelayo kwe-axial futhi avimbele ukuphazamiseka okubangelwa ukudlidliza.

Ø 3)Impendulo esheshayo, isikhathi sokuphendula sokuvula nesokuvala amasekhondi angu-0.06 kuphela, angavikela ithuluzi lomshini futhi andise impilo yesikulufu sokuhola.

Ø 4) Indawo ehlala isikhathi eside, egcwele i-nickel, ukusebenza okuhle kokuqeda ukugqwala.

Ø 5) Idizayini yenoveli yokugwema umthelela oqinile lapho uqina.

Speification

| Imodeli | I-BOSM-DS500 | Iyunithi | |

| Ubukhulu bosayizi wocezu lokusebenza | Ububanzi bangaphandle | 50-500 | mm |

| Ubude be-workpiece enkulu | 300 | Kg | |

| I-half shaft workpiece ububanzi | ≤200 | mm | |

| Ubude bomgodi | 700mm inganyuswa ngokwesisekelo | mm | |

| Ubukhulu bomsebenzi | ≤5 izikhathi zokubhoboza ububanzi | mm | |

| Ikhanda lamandla okumba uhlobo lwenqama olume mpo | QTY | 1 | Ama-PC |

| I-spindle taper | I-BT40 | ||

| Drill ububanzi | Φ2-Φ36 | mm | |

| Ukuthepha ububanzi | i-M6-M24 | ||

| Isivinini se-spindle | 30 ~ 3000 | r/mm | |

| Amandla e-Servo spindle motor | 15 | Kw | |

| Ibanga ukusuka phansi kokuphotha kuya endaweni yokusebenza | 150-550mm±20 | mm | |

| Ukunyakaza kwe-lateral kwekhanda lamandla (X Axis) | MAX. ukuhamba | 2600 | mm |

| Isivinini se-X eksisi | 0~8 | m/min | |

| X Axis servo motor amandla | 2.4 | Kw | |

| Ukunyakaza kwe-longitudinal ye-beam ehambayo (Y Axis) | MAX. ukuhamba | 500 | mm |

| Ijubane le-eksisi Y | 0~8 | m/min | |

| I-Y Axis servo motor amandla | 2.4 | Kw | |

| Ukunyakaza kokuphakelayo kokulala okuqondile (i-axis Z) | MAX. ukuhamba | 400 | mm |

| Isivinini se-eksisi Z | 0~4 | m/min | |

| Z Axis servo motor amandla | 1 × 2.4 ibhuleki | Kw | |

| Ukumisa ukunemba | 500x500 | ±0.03 | mm |

| Ukunemba kwenkomba | 360° | ±0.001° | |

| Usayizi womshini | Ubude x ububanzi x ubude | 3600×1650×2300 | mm |

| Isisindo somshini | 8.5 | T | |

Ukuhlolwa Kwekhwalithi

Umshini ngamunye ulinganiswa nge-laser interferometer evela enkampanini yase-United Kingdom RENISHAW, ehlola ngokunembile futhi inxephezele amaphutha e-pitch, ukuhlehla, ukunemba kokuma, nokunemba kokuma okuphindaphindiwe ukuze kuqinisekiswe ukuguquguquka, ukuzinza komshini, nokunemba kokucubungula. . Ukuhlolwa kwebha yebhola Umshini ngamunye usebenzisa isihloli sebha yebhola esivela enkampanini yaseBrithani i-RENISHAW ukulungisa ukunemba kwendingilizi yeqiniso kanye nama

i-chine ukunemba kwejiyomethri, futhi wenze izivivinyo zokusika eziyindilinga ngesikhathi esifanayo ukuze uqinisekise ukunemba komshini we-3D womshini kanye nokunemba kwendingilizi.

Indawo yokusebenzisa ithuluzi lomshini

1.1 Izidingo zemvelo yezinto zokusebenza

Ukugcina izinga elingaguquki lezinga lokushisa le-ambient kuyisici esibalulekile sokwenza imishini enembile.

(1) Izinga lokushisa le-ambient elitholakalayo ngu- -10 ℃ ~ 35 ℃. Lapho izinga lokushisa le-ambient lingama-20 ℃, umswakama kufanele ube ngu-40 ~ 75%.

(2) Ukuze kugcinwe ukunemba okumile kwethuluzi lomshini ngaphakathi kwebanga elishiwo, izinga lokushisa elifanele le-ambient liyadingeka ukuthi libe ngu-15 ° C kuya ku-25 ° C nomahluko wokushisa.

Akufanele idlule ± 2 ℃ / 24h.

1.2 I-voltage yokuphakelwa kwamandla: 3-isigaba, 380V, ukushintshashintsha kwamandla kagesi ngaphakathi ± 10%, imvamisa yokuphakelwa kwamandla: 50HZ.

1.3 Uma i-voltage endaweni esetshenziswayo ingazinzile, ithuluzi lomshini kufanele lifakwe ugesi olawulwayo ukuze kuqinisekiswe ukusebenza okuvamile kwethuluzi lomshini.

1.4. Ithuluzi lomshini kufanele libe nomhlabathi othembekile: intambo yaphansi iyintambo yethusi, ububanzi bocingo akufanele lube ngaphansi kuka-10mm², futhi ukumelana nomhlabathi kungaphansi kuka-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuvamile kwemishini, uma umoya ocindezelwe womthombo womoya wehluleka ukuhlangabezana nezidingo zomthombo womoya, isethi yamadivayisi okuhlanza umthombo womoya (ukukhipha umswakama, ukwehlisa, ukuhlunga) kufanele kwengezwe ngaphambi kokukhishwa kwemishini. ukungena komoya womshini.

1.6. Izinto ezisetshenziswayo kufanele zigcinwe kude nelanga eliqondile, ukudlidliza nemithombo yokushisa, futhi kude namajeneretha anemvamisa ephezulu, imishini yokushisela kagesi, njll., ukuze kugwenywe ukwehluleka kokukhiqiza umshini noma ukulahlekelwa ukunemba komshini.

Ngaphambi Nangemuva Kwesevisi

1) Ngaphambi Kwesevisi

Ngokutadisha isicelo nolwazi oludingekayo oluvela kumakhasimende bese impendulo konjiniyela bethu, ithimba le-Bossman Technical linesibopho sokuxhumana nobuchwepheshe namakhasimende kanye nokwakhiwa kwezixazululo, ukusiza ikhasimende ekukhetheni isixazululo esifanele somshini kanye nemishini efanelekile.

2) Ngemva Kwesevisi

A.Umshini onewaranti yonyaka owodwa futhi okhokhelwe ukunakekela impilo yonke.

B. Phakathi nenkathi yewaranti yonyaka owodwa ngemva kokuba umshini ufikile echwebeni lapho uya khona, i-BOSSMAN izohlinzeka ngezinsizakalo zokunakekela zamahhala nezifika ngesikhathi zamaphutha ahlukahlukene angenziwanga umuntu emshinini, futhi ibuyisele ngesikhathi zonke izinhlobo zezingxenye zomonakalo ongenziwanga ngumuntu mahhala. yenkokhiso . Ukwehluleka okwenzeka ngesikhathi sewaranti kuzolungiswa ngezindleko ezifanele.

Ukusekelwa kwe-C.Technical emahoreni angama-24 ku-inthanethi, i-TM, i-Skype, i-E-mail, ukuxazulula imibuzo ehlobene ngesikhathi. uma ingeke ixazululwe, i-BOSSMAN izohlela ngokushesha ukuthi unjiniyela wangemuva kokuthengisa afike esizeni ukuze alungiswe, umthengi udinga ukukhokhela i-VISA, amathikithi ezindiza kanye nendawo yokuhlala.

Isizinda Sekhasimende