Uchungechunge lwe-CBS lwama-axis amahlanu mpo

Izici

1.Izinzuzo zokusebenza eziyinhloko

1.1.I-X-axis isebenzisa ubuchwepheshe bokushayela okuqondile, i-Y-axis isebenzisa ubuchwepheshe be-parallel direct drive kanye nokulawula okuvumelanayo, ngokucindezela okuphezulu, umsindo ophansi, isivinini sokuphendula okusheshayo, nokusebenza okuhle kakhulu okuguquguqukayo. I-axis emithathu ye-X/Y/Z yonke isebenzisa impendulo yomugqa wokunemba okuphezulu, ngokunemba kokuma okuphezulu

1.2.Injini ye-torque ephezulu ishayela i-A-eksisi kanye ne-C-eksisi ukuthi ijikeleze, ngochungechunge lwe-zero transmission, i-zero backlash, kanye nokuqina okuhle; isifaki khodi se-engeli enembe kakhulu sifinyelela ukuma okunembile

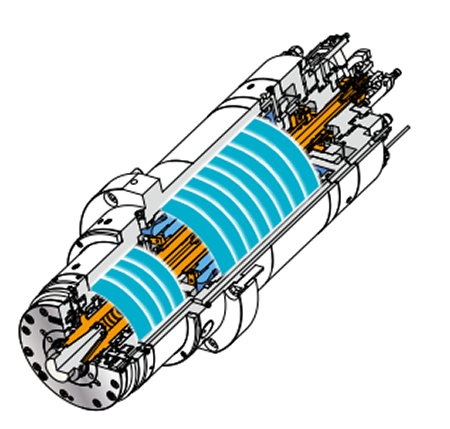

1.3.I-spindle ithatha isakhiwo sokuphotha sikagesi esinesivinini esikhulu esinesivinini esikhulu nomsindo ophansi.

2.Isakhiwo sebhuloho eliqinile

2.1.Uchungechunge lwe-CBS lwamukela ukwakheka kwesakhiwo sebhuloho, futhi i-X/Y/Z ifinyelela ukunyakaza okungaguquki, okungathintwa isisindo se-eksisi ye-A/C.

2.2.I-eksisi ye-A/C isebenza ngokuzimela, futhi isisindo se-workpiece ayithinti enye i-eksisi emithathu.

2.3.Isakhiwo se-gantry kanye netafula le-swing ne-rotary elisekelwe kuzo zombili iziphetho zingagcina ukucutshungulwa kokunemba okuphezulu isikhathi eside.

3.Umsebenzi wokujika osebenzayo

4.Ithebula elijikelezayo elinesivinini esikhulu neliqinile libona ukugaya okusebenzayo kanye nokucubungula okuyinhlanganisela

Ithebula eliqondile le-axis emihlanu elijikelezayo elishayelwa ngokuqondile i-torque motor lisetshenziswa kumathuluzi omshini we-CNC futhi lingenza ukucubungula kwe-axis emihlanu kanyekanye. Inezinzuzo zejubane eliphezulu, ukunemba okuphezulu, ukuzinza nokuthembeka, nokusebenza okulula.

5.Ukugcina ama-spindles womshini wokunemba okuphezulu

Ukuthola ubuchwepheshe obuyisisekelo kanye nokuzimela ngokuzimela ama-spindles

I-Oturn inobuchwepheshe obuyisisekelo futhi inekhono lokuklama, ukukhiqiza nokuhlanganisa ama-spindle. Ngeshabhu yokusebenzela yokushisa engu-1000m2 engaguquki kanye nemodeli yokukhiqiza eyinkimbinkimbi, ama-spindles e-Oturn anezici zokuqina okuphezulu, isivinini esikhulu, amandla aphezulu, i-torque ephezulu kanye nokuthembeka okuphezulu.

I-spindle eyakhelwe ngaphakathi i-HSKE40/HSKA63/HSKA100 eyakhiwe ngokuzimela iyamukelwa. Ngaphakathi kwebanga lokuzungezisa i-spindle, ukudlidliza nokudlidliza kuyasuswa ukuze kuzuzwe ukunemba okuzinzile ekucutshungulweni kwesivinini esikhulu kanye nesikhathi eside. I-spindle isebenzisa ukupholisa okuphoqelekile ukupholisa injini namabheringi angaphambili nangemuva.

6.Isakhiwo semoto esakhelwe ngaphakathi

Ngokususa igiya lokushayela, ukudlidliza ngesikhathi sokuzungezisa ngesivinini esikhulu kungancishiswa, ngaleyo ndlela kuthuthukiswe ukunemba kwendawo esebenza ngomshini futhi kwandise ukuphila kwethuluzi.

7.Spindle ukuphathwa lokushisa

Ngokujikeleza uwoyela wokupholisa olawulwa izinga lokushisa, ukufuduka okushisayo kwe-spindle okubangelwa ukushisa okukhiqizwa ingxenye ngayinye kungacindezelwa, ngaleyo ndlela kuvinjwe izinguquko ekunembeni komshini.

8.Ukuhola umhlaba ngamamotho aqondile

Amamotho alayini

8.1.Ifakwe i-linear motor drive, akukho ukuthintana kwemishini ngesikhathi sokunyakaza, akukho ukulahlekelwa komshini, akukho ukudluliselwa kwe-backlash, nesivinini sokuphendula ngokushesha.

8.2.Absolute optical isikali sokulawula okugcwele kweluphu evaliwe.

Irula eliphelele, ukunemba kokutholwa kweleveli ye-nanometer, ukulungiswa kufika ku-0.05μm, ukuze kuzuzwe ukulawula okugcwele kweluphu evaliwe.

9.Idizayini enhle kakhulu ye-ergonomic

Ngokusekelwe ekwakhiweni kwe-ergonomic, kulula ukuthi opharetha basebenzise futhi kuthuthukisa ukusebenza nokugcinwa.

9.1.Ukufinyeleleka okuhle kakhulu

Ukuze kuthuthukiswe ukusebenza kokungena ebhentshini lokusebenzela, ikhava engezansi komnyango wokusebenza ihlehliselwa eceleni kwebhentshi lokusebenzela ukuze kuqinisekiswe indawo yokusebenza eyanele.

9.2.Iwindi elikhulu ukuze kubhekwe kalula ukucutshungulwa

Iwindi elikhulu lenza kube lula ukubona isimo sokucubungula se-workpiece. Ikakhulukazi, ukuqinisekiswa okuvamile kwezimo zokusika kanye nezinguquko ekusebenzeni ngesikhathi sokusebenza kokulungiswa nakho kungaqedwa kalula, ukuthuthukisa ukusebenza kahle komsebenzi.

9.3.Ukumiswa endaweni eyodwa kwamayunithi okulungisa

Ukuze kuthuthukiswe ukusebenza kokungena ebhentshini lokusebenzela, ikhava engezansi komnyango wokusebenza ihlehliselwa eceleni kwebhentshi lokusebenzela ukuze kuqinisekiswe indawo yokusebenza eyanele.

9.4.Umnyango obanzi wokusebenza ukuze ungene kalula nge-crane

Lapho wenza imisebenzi efana nokushintshwa kwe-workpiece, umsebenzi wabasebenzi ungancishiswa, futhi ngesikhathi esifanayo, kunendawo yokusebenza eyanele uma usebenzisa i-crane.

9.5.Iphaneli yokusebenza ejabulisayo nenobungane

Iphaneli yokusebenza ephendukayo ehambisana nobude bomzimba womuntu ivumela opharetha ukuthi asebenzise futhi ahlele umshini ngendlela ethokomele.

Imininingwane Yezobuchwepheshe

| Into | I-CBS200 | I-CBS200C | I-CBS300 | I-CBS300C | I-CBS400 | I-CBS400C | |

| Ukuhamba | X/Y/Z uhambo lwe-eksisi | 300*350*250 | 300*350*250 | 460*390*400 | |||

| Ibanga ukusuka kubuso be-spindle ukuya esikhungweni sokusebenza | 130-380 | 130-380 | 155-555 | ||||

| I-spindle | I-spindle taper | E40 | E40 | E40 | |||

| Isivinini esiphezulu | 30000 | 30000 | 30000 | ||||

| Amandla e-spindle motor (aqhubekayo/S325%) | 11/13.2 | 11/13.2 | 11/13.2 | ||||

| I-Spindle motor torque (eqhubekayo/S325%) | 11.5/13.8 | 11.5/13.8 | 11.5/13.8 | ||||

| Okuphakelayo |

Isivinini esisheshayo se-eksisi ye-X/Y/Z (m/min)

| 48/48/48 | 48/48/48 | 30/30/30 | |||

| Isiphakeli sokusika(mm/min) | 1-24000 | 1-24000 | 1-12000 | ||||

| Itafula elijikelezayo | Ububanzi betafula elijikelezayo | 200 | 300 | 400 | |||

| Isisindo somthwalo esivumelekile | 30 | 20 | 40 | 25 | 250 | 100 | |

| I-engeli enyakazayo ye-axis | ±110° | ±110° | ±110° | ||||

| Ukujikeleza kwe-C-eksisi | 360° | 360° | 360° | ||||

| I-A-eksisi ilinganiselwe/max.speed | 47/70 | 47/70 | 30/60 | ||||

| I-axis Ilinganiselwe/max.torque | 782/1540 | 782/1540 | 940/2000 | ||||

| I-C-axis ilinganiselwe/max.speed | 200/250 | 1500/2000 | 200/250 | 1500/2000 | 100/150 | 800/1500 | |

| I-C-axis ilinganiselwe/max.torque | 92/218 | 15/30 | 92/218 | 15/30 | 185/318 | 42/60 | |

| Ukunemba/ukuphindaphinda kokuma kwe-axis | 10/6 | 10/6 | 10/6 | ||||

| Ukunemba/ukuphindaphinda kokuma kwe-axis | 8/4 | 8/4 | 8/4 | ||||

| I-ATC | Amandla omagazini wethuluzi | 16 | 16 | 26 | |||

| Ubuningi bethuluzi. ububanzi/ ubude | 80/200 | 80/200 | 80/200 | ||||

| Max.ithuluzi isisindo | 3 | 3 | 3 | ||||

| Isikhathi sokushintsha ithuluzi (ithuluzi kuya ithuluzi) | 4 | 4 | 4 | ||||

| Okuthathu- i-eksisi | Umhlahlandlela we-X-eksisi (ububanzi bomugqa womhlahlandlela/ inombolo yezilayidi) | 30/2 | 30/2 | 35/2 | |||

| Umhlahlandlela we-X-eksisi (ububanzi bomugqa womhlahlandlela/ inombolo yezilayidi) | 35/2+30/2 | 35/2+30/2 | 45/2 | ||||

| Umhlahlandlela we-Z-eksisi (ububanzi bomugqa womhlahlandlela/ inombolo yezilayidi) | 25/2 | 25/2 | 35/2 | ||||

| I-X-axis linear motor amandla (aqhubekayo/ubukhulu.) | 1097/2750 | 1097/2750 | φ40×10 (isikulufu) | ||||

| I-Y-axis linear motor amandla (aqhubekayo/ubukhulu.) | 3250/8250 | 3250/8250 |

| ||||

| Amandla emoto yomugqa we-Z-axis (aqhubekayo/ubukhulu.) | 1033/1511 | 1033/1511 |

| ||||

| Ukunemba | Ukumisa ukunemba | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Ukuphindaphinda | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Umthombo wamandla | Umthamo wokuphakelwa kwamandla | 25 | 30 | 25 | 30 | 30 | 35 |

| Umfutho womoya | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Usayizi womshini | Usayizi womshini | 1920*3030*2360 | 1920*3030*2360 | 2000*2910*2850 | |||

| Usayizi womshini (okubandakanya isidluliseli se-chip nezinye izinto zokusebenza zasemngceleni) | 3580*3030*2360 | 3580*3030*2360 | 3360*2910*2850 | ||||

| Isisindo | 4.8T | 4.8T | 5T | ||||

| Into | I-CBS500 | I-CBS500C | I-CBS650 | I-CBS650C | I-CBS800 | I-CBS800C | |

| Ukuhamba | X/Y/Z uhambo lwe-eksisi | 500*600*450 | 650*800*560 | 800*910*560 | |||

| Ibanga ukusuka kubuso be-spindle ukuya esikhungweni sokusebenza | 130-580 | 110-670 | 100-660 | ||||

| I-spindle | I-spindle taper | A63 | A63 | A63 | |||

| Isivinini esiphezulu | 20000 | 20000 | 20000 | ||||

| Amandla e-spindle motor (aqhubekayo/S325%) | 30/34 | 30/34 | 30/34 | ||||

| I-Spindle motor torque (eqhubekayo/S325%) | 47.7/57.3 | 47.7/57.3 | 47.7157.3 | ||||

| Okuphakelayo | Isivinini esisheshayo se-eksisi ye-X/Y/Z (m/min)

| 48/48/48 | 48/48/48 | 48/48/48 | |||

| Isiphakeli sokusika(mm/min) | 1-24000 | 1-24000 | 1-24000 | ||||

| Itafula elijikelezayo | Ububanzi betafula elijikelezayo | 500 | 650 | 800 | |||

| Isisindo somthwalo esivumelekile | 600 | 240 | 800 | 400 | 1000 | 400 | |

| I-engeli enyakazayo ye-axis | ±110° | ±110° | ±110° | ||||

| Ukujikeleza kwe-C-eksisi | 360° | 360° | 360° | ||||

| I-A-eksisi ilinganiselwe/max.speed | 60/80 | 40/8C | 40/80 | ||||

| I-axis Ilinganiselwe/max.torque | 1500/4500 | 3500/7000 | 3500/7000 | ||||

| I-C-axis ilinganiselwe/max.speed | 80/120 | 600/1000 | 50/80 | 450/800 | 50/80 | 450/800 | |

| I-C-axis ilinganiselwe/max.torque | 355/685 | 160/240 | 964/1690 | 450/900 | 964/1690 | 450/900 | |

| Ukunemba/ukuphindaphinda kokuma kwe-axis | 10/6 | 10/6 | 10/6 | ||||

| Ukunemba/ukuphindaphinda kokuma kwe-axis | 8/4 | 8/4 | 8/4 | ||||

| I-ATC | Amandla omagazini wethuluzi | 25 | 30 | 30 | |||

| Ubuningi bethuluzi. ububanzi/ ubude | 80/300 | 80/300 | 80/300 | ||||

| Max.ithuluzi isisindo | 8 | 8 | 8 | ||||

| Isikhathi sokushintsha ithuluzi (ithuluzi kuya ithuluzi) | 4 | 4 | 4 | ||||

| Okuthathu- i-eksisi | Umhlahlandlela we-X-eksisi (ububanzi bomugqa womhlahlandlela/ inombolo yezilayidi) | 35/2 | 45/2 | 45/2 | |||

| Umhlahlandlela we-X-eksisi (ububanzi bomugqa womhlahlandlela/ inombolo yezilayidi) | 45/2 | 45/2 | 45/2 | ||||

| Umhlahlandlela we-Z-eksisi (ububanzi bomugqa womhlahlandlela/ inombolo yezilayidi) | 35/2 | 35/2 | 35/2 | ||||

| I-X-axis linear motor amandla (aqhubekayo/ubukhulu.) | 2167/5500 | 3250/8250 | 3250/8250 | ||||

| I-Y-axis linear motor amandla (aqhubekayo/ubukhulu.) |

|

|

| ||||

| Amandla emoto yomugqa we-Z-axis (aqhubekayo/ubukhulu.) | 2R40*20 (isikulufu) | 2R40*20 (isikulufu) | 2R40*20 (isikulufu) | ||||

| Ukunemba | Ukumisa ukunemba | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Ukuphindaphinda | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Umthombo wamandla | Umthamo wokuphakelwa kwamandla | 40 | 45 | 55 | 70 | 55 | 70 |

| Umfutho womoya | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Usayizi womshini | Usayizi womshini | 2230*3403*3070 | 2800*5081*3500 | 2800*5081*3500 | |||

| Usayizi womshini (okubandakanya isidluliseli se-chip nezinye izinto zokusebenza zasemngceleni) | 2230*5540*3070 | 2800*7205*3500 | 2800*7205*3500 | ||||

| Isisindo | 11T | 15T | 15.5T | ||||

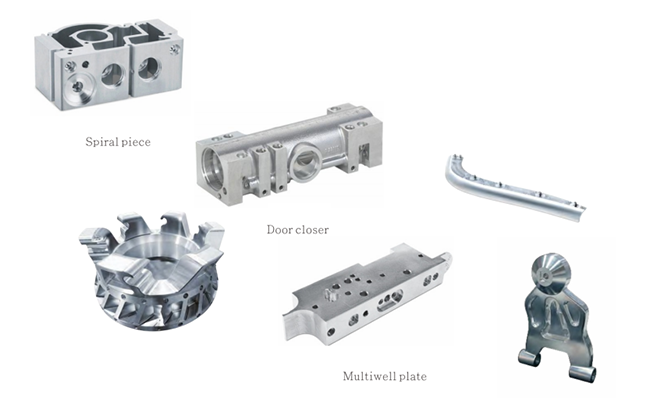

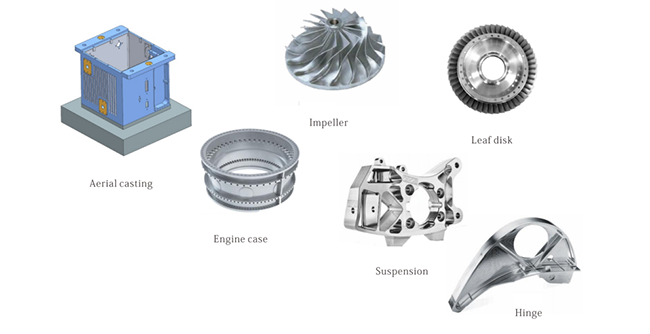

Ukucubungula Amacala

1.Imboni Yezimoto

2.I-Aerospace

3.Imishini Yokwakha