I-CNC Turning Center

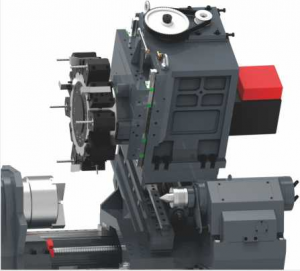

I-POSITIVEYAXIS Edidiyelwe

Isakhiwo eside, esiqinile kakhulu

Isakhiwo se-eksisi esingu-Y esihlanganisiwe singesokusika okuqinile okuqinile futhi ukusebenza kwaso kungcono kune-axis ye-interpolation engu-Y.

a. I-Single Y axis motion motion cutting ingcono kune-interpolation Y axis futhi i-eksisi ye-Y incike ku-eksisi engu-X.

b. Ukucubungula i-contour yendiza kulula futhi kuthambile.

c. Ilungele kakhulu indawo ehlanganisiwe ne-contour processing.

Imishini ehlanganisiwe ye-"Positive Y" yokugaya ijika inezinzuzo ezisobala ekugayweni kwendiza uma kuqhathaniswa ne-"interpolation Y" turn-milling kuhlangene. -ukunyakaza kwe-axis kanye nokunyakaza "kwe-interpolation Y" Y-axis ukuhlanganisa umugqa oqondile ngokunyakaza kanyekanye kwe-X-eksisi kanye ne-Y-eksisi, ukucaba kwendiza yokugaya kanye nokuqhathaniswa kwe-axis "positive Y" ukugaya kuhlangene, "Positive Y" i-axis turn-milling ukucubungula okuhlanganisiwe kusobala futhi kuyisicaba.

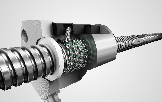

Isikulufu sebhola esilungisiwe kabili

Izikulufu zebhola ezisezingeni eliphezulu neziqondiso zamarola ezivela kubakhiqizi abaphezulu bomhlaba ziyasetshenziswa.

Nakuba kubiza, imikhiqizo yekhwalithi ephezulu kuphela engahlangabezana nokunemba okuphezulu nokude

impilo yesevisi edingwa amakhasimende.

Ama-Servomotor Ahlanganisiwe Aqondile

I-servo motor ixhunywe ngokuqondile ku-screw yebhola nge-coupling yensimbi, okuyinto

iqinisekisa ukuthi akukho ukuwohloka nokungahambi kahle ngisho nangaphansi kwemithwalo esindayo.

Lokhu kuzothuthukisa kakhulu ukunemba kokumisa, kanye nentambo kanye ne-contour machining

izonemba kakhudlwana.

106M 108M 208M

| Imodeli ye-ltm | Igama | Iyunithi | 106M | 108M | 208M |

| Ukuhamba | Ubukhulu. Evula Ububanzi phezu kombhede | mm | φ600 | φ600 | φ600 |

| Ubukhulu. Icubungula Ububanzi | mm | φ300 | φ300 | φ400 | |

| Ubukhulu . Icubungula Ububanzi Kusibambi Sethuluzi | mm | φ220 | φ200 | φ300 | |

| Ubukhulu. Icubungula Ubude | mm | 230 | 220 | 400 | |

| Ibanga Phakathi Kwezikhungo | mm | 300 | 300 | 600 | |

| I-Spindle Motor I-Hydrocylinder Isonto Ipharamitha | Ikhala Lokuphotha | uhlobo | A2-5 | A2-6 | A2-6 |

| Ubukhulu . Ijubane le-Spindle | rpm | 5500 | 4300 | 4200 | |

| I-Oil Cylinder / Chuck | lnch | 6” | 8” | 8” | |

| Spindle Bore | mm | φ56 | φ65 | φ65 | |

| Ibha Ububanzi | mm | φ45 | φ52 | φ52 | |

| Direct Drive Spindle Motor Power | kw | 17.5 | 22 | 22 | |

| Okuphakelayo kwe-eksisi ye-X/Z Ipharamitha | X Ukuhamba | mm | 180 | 180 | 280 |

| Ukucaciswa komhlahlandlela we-X/Z | ama-spes | I-Roller engu-35/35 | I-Roller engu-35/35 | I-Roller engu-35/35 | |

| Z Ukuhamba | mm | 300 | 300 | 600 | |

| X/Z/(Y) Amandla Ezimoto | kw | 1.8/1.8 | 1.8/1.8 | 1.8/1.8 | |

| X/Z/(Y) I-Rapid Traverse | m/min | 30/30 | 30/30 | 20/20 | |

| Ukunemba Kokumisa | mm | ±0.005 | ±0.005 | ±0.005 | |

| Phinda Ukunemba Kokumisa | mm | ±0.003 | ±0.003 | ±0.003 | |

| Ipharamitha ye-Turret | Isikhundla Sethuluzi | ama-pcs | I-BMT45-12T | I-BMT45-12T | I-BMT55-12T |

| Amandla Turret Motor | kw | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | |

| Isibambi Sethuluzi lesikwele | mm | 20×20 | 20×20 | 20×20 | |

| Isibambi Sethuluzi Eliyisidina | mm | φ32 | φ32 | φ40 | |

| Isikhathi Sokushintsha Ithuluzi Eliseduze | isekhondi | 0.15 | 0.15 | 0.15 | |

| Ukunemba Kokumisa | / | ±2” | ±2” | ±2” | |

| Phinda Ukunemba Kokumisa | / | ±1” | ±1” | ±1” | |

| I-Tailstock Amapharamitha | I-Programmable Hydraulic Tailstock | / | √ | √ | √ |

| Ubukhulu . Ukuhamba kwe-Tailstock | mm | 360 | 360 | 440 | |

| I-Tailstock Sleeve Taper Hole | uhlobo | MT 5# | MT 5# | MT 5# | |

| I-Sleeve Diameter | mm | / | / | / | |

| I-Sleeve Travel | mm | / | / | / | |

| Usayizi Wemishini | Usayizi Womshini | mm | 2300×1800×1700 | 2300×1800×1700 | 2300×1800×1700 |

| Isisindo Somshini | kg | 3700kg | 3800kg | 5200kg |

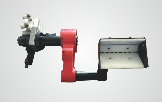

I-Servo Automatic Bar Feeder

Ama-feeders e-TENOLY afaka umsebenzi osindayo nomklamo ozenzakalelayo,

Ikhulisa kakhulu ukukhiqiza futhi yenza kube lula ukuguqula izinto.

Izingxenye Catcher

I-workpiece catcher yakhelwe ngomgomo wokuxhumanisa kwemishini, okungaba ngokushesha

exhunywe nomkhiqizo oqediwe ngemva kokucubungula.

I-THK roller linear guide

Igayidi yomugqa ine-zero clearance, i-arc cutting, i-bevel cutting, futhi ukuthungwa kwendawo kufana ngokufanayo. Ilungele ukusebenza ngesivinini esiphezulu futhi inciphisa kakhulu amandla okushayela amahhashi adingekayo emshinini Ama-linear guide rails asebenzisa ukugoqa esikhundleni sokuslayida, anokulahlekelwa ukushwibilika okuncane, ukusabela okubucayi kanye nokunemba kokuma okuphezulu. Ingakwazi ukuthwala umthwalo iqonde phezulu, phansi, kwesokunxele nakwesokudla ngesikhathi esisodwa. Ngaphansi komthwalo, indawo yokuxhumana yethrekhi isathintana namaphuzu amaningi, futhi ukuqina kokusika ngeke kuncishiswe; Umhlangano olula futhi oguquguqukayo kanye nesakhiwo esilula sokugcoba; iziqondiso zomugqa zinokuguga okuncane kakhulu futhi zihlala isikhathi eside.

I-THK Ball Screw

Kusetshenziswa isikulufu sebhola esinembe kakhulu, esinokulayisha kuqala amantongomane nesikulufu

ukwelashwa ukuzenzisa, i-backlash kanye nokukhuphuka kwezinga lokushisa kanye

ama-elongation aqedwa kusengaphambili, okubonisa ukuma okuhle kakhulu

nokuphindaphinda.

Ukushayela okuqondile nge-servo motor ukunciphisa iphutha lokubuyela emuva.

I-High Precision Motorized Arm ye-Lathe

Isetha samathuluzi wokudonsela phansi esinokuphinda okunemba okuphezulu Kutholakala ngamasayizi ahlukahlukene ukuze kuhlangatshezwane nezidingo zezimboni ezihlukahlukene Kutholakala ngosayizi abahlukahlukene abajwayelekile, kanye nezingalo zokulinganisa zensimbi ezenziwe ngokwezifiso ezine-coefficient ephansi yokunweba.

Sebenzisa i-zirconia probe eqinile

Ithatha indawo encane yomshini uma ingasetshenziswa

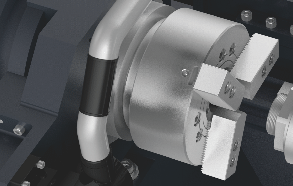

IHydraulic Chuck Workholding

I-lathe ifakwe i-hydraulic through-hole chuck njengokujwayelekile. I-chuck ingenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende, futhi izinketho ezahlukahlukene zizokunikeza i-clamping chuck efanelekile kakhulu.

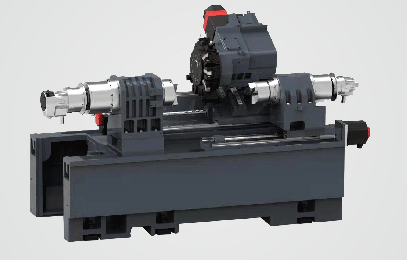

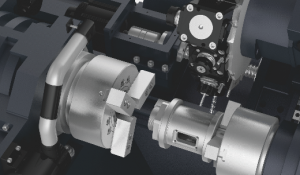

I-Spindle yesibili

Zombili iziphetho ze-workpiece zingenziwa ngomshini ngesikhathi esisodwa ku-clamping eyodwa, okwenza kube lula ukusebenza kwezandla.