I-Pipe thread lathe ibizwa nangokuthiuwoyela wezwe lathe,ukuguqulwa kwentambo ngokuvamile kubhekisela endleleni yokwenza izintambo kucezu lokusebenza ngethuluzi lokubumba, ikakhulukazi okuhlanganisa ukuphenduka, ukugaya, ukuthepha, ukugaya, ukugaya, nokusika isivunguvungu. Lapho ujika, ukugaya nokugaya izintambo, iketango lokudlulisela lethuluzi lomshini liqinisekisa ukuthi ithuluzi eliphendukayo, i-milling cutter noma isondo lokugaya lihamba ngokunembile nangokulinganayo eduze kwe-eksisi ye-workpiece ngokuhola okukodwa kokuphenduka ngakunye kwendawo yokusebenza. Uma uthepha noma ucucuza, ithuluzi (thepha noma shona) lizungeza ngokuhlobene nendawo yokusebenza, futhi i-groove yokuqala eyakhiwe iqondisa ithuluzi (noma ucezu lokusebenza) ukuhamba nge-axially.

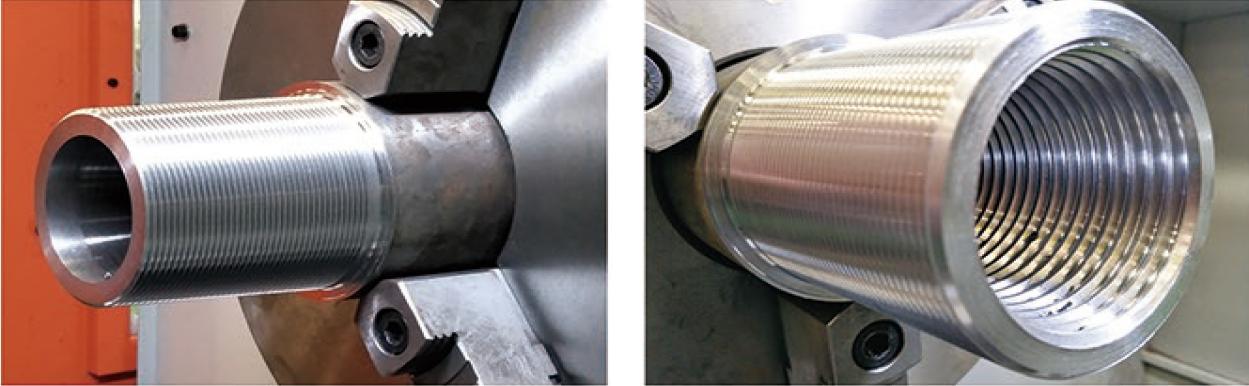

Futhi esikuhlosile kakhulu wukuguqula intambo sisebenzisaintambo yepayipi lathes. Ithuluzi lokwakha intambo noma ithuluzi lokukama intambo lingasetshenziswa ukuvula intambo ku-lathe wentambo yepayipi. Ukuguqula izintambo ngethuluzi lokujika elibunjwayo, isakhiwo samathuluzi esimanqikanqika silula, kuyindlela evamile yokukhiqiza inqwaba encane kanye nokucutshungulwa kwama-workpieces anentambo. Ukuphendula imicu ngethuluzi lokukama kwentambo kunokukhiqiza okuphezulu, kodwa ukwakheka kwethuluzi kuyinkimbinkimbi, futhi kulungele kuphela ukuguqulela ama-workpieces anemicu emifushane enamazinyo emfushane emkhiqizweni ophakathi nendawo nomkhulu.

Ukunemba kwephimbo lama-lathe ajwayelekile okuguqula imicu ye-trapezoidal ngokuvamile kungafinyelela ku-8-9 kuphela, kodwa ukusebenza kahle kokukhiqiza nokunemba kochwepheshe.Umshini wokuhlanganisa ipayipi le-CNCizothuthukiswa kakhulu.

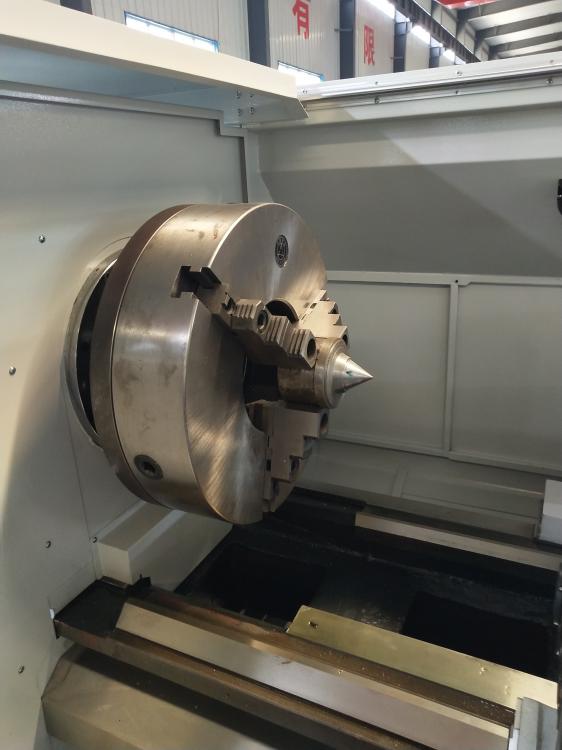

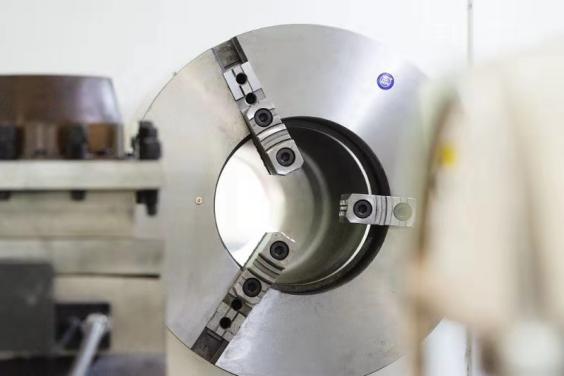

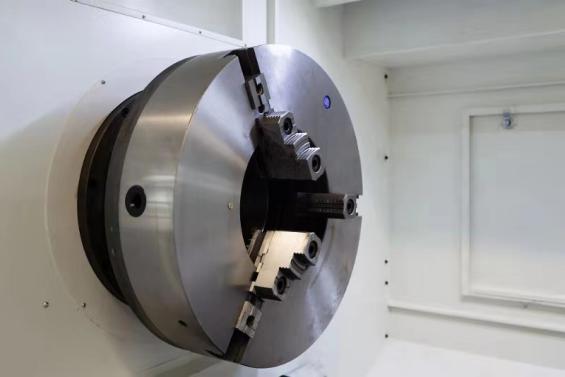

I-lathe yokufaka ipayipiumshiniiyilathe evundlile eklanyelwe ngokukhethekile ukushintsha ukufakwa kwamapayipi anobubanzi obukhulu. Ibonakala ngobubanzi obukhulu bembobo yokuphotha (imvamisa engaphezu kuka-135mm) kanye ne-chuck ngaphambili nangemuva kwebhokisi lokuphotha. , Ukwenza lula ukucindezelwa nokucutshungulwa kwamapayipi noma izinduku ezinobubanzi obukhulu.

Izwe lamafuthalathiumshiningokuvamile babe nembobo enkulu yokuphotha ibhokisi lokuphotha, futhi isiqeshana sokusebenza siboshelwa ama-chuck amabili emaphethelweni womabili we-spindle ukuze ajikelezise ngemva kokudlula embotsheni yokuphotha. Ngokuvamile kunezindlela ezimbili zokuphakela ithuluzi: eyodwa iyafana ne-lathe evamile ngesikulufu sokuhola ukushayela isilayidi kanye nesibambi samathuluzi ngaphambili kombhede; enye yikama eyisicaba ku-slide phakathi nendawo yombhede. Inhloko yokusika intambo yangaphandle yommese (bona inhloko yokusika intambo yokuvula nokuvala) isika kucezu lokusebenza bese iya phambili. Amanye amathuluzi omshini wokucubungula amapayipi amade nawo anamadivayisi asekela ucezu lokusebenza, njengohlaka oluphakathi nendawo, indawo yokuphumula yamathuluzi, nabakaki abangemuva.

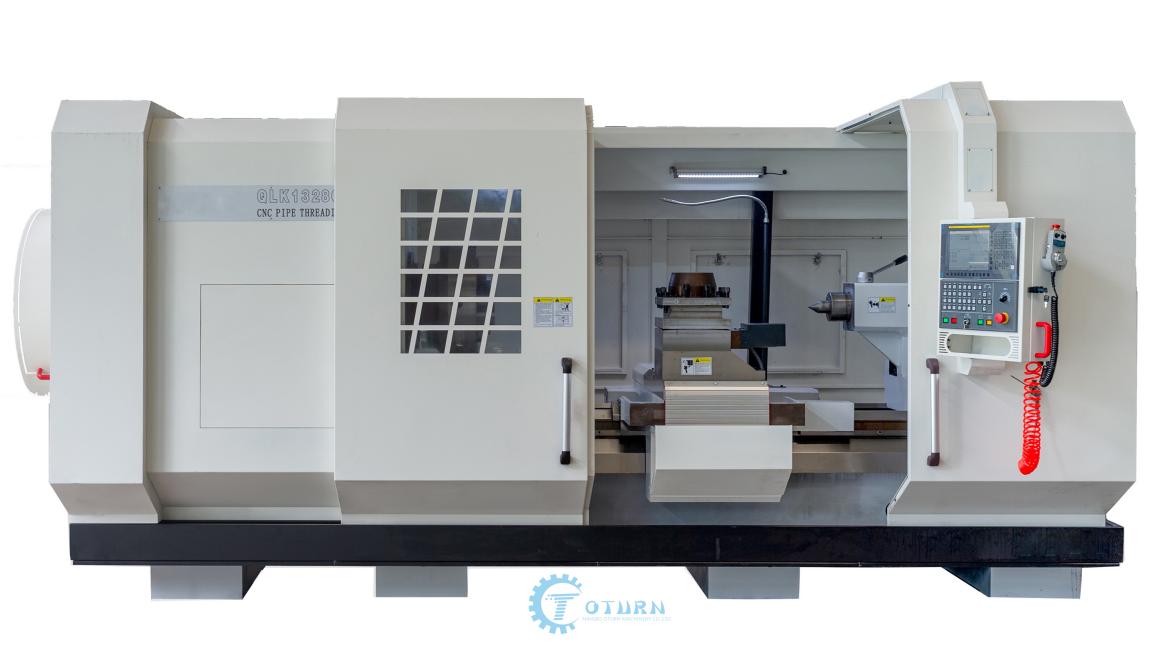

Ipayipi le-CNC lokuthunga i-lathencoma

QLK1315 / QLK1320 / QLK1323 / QLK1325 / QLK1328 / QLK1336 / QLK1345 / QKL1353 / QLK1363

I-QLK1320

Izici zeizinga eliphezului-lathe yokufaka ipayipi:

1. Umbhede unesakhiwo sokuqala sodonga lwezingqimba ezintathu, futhi udonga olungemuva luhlelwe ngendiza ethambekele ye-12-degree, ethuthukisa kakhulu ukuqina kwethuluzi lomshini.

2. Iketango eliyinhloko lokudlulisela ukudluliselwa kwezigaba, okunciphisa ukusetshenziswa kwamandla nomsindo wethuluzi lomshini.

3. Ukusebenzisa amabhokisi ahlukene kahydraulic, ukuthambisa okuphakathi nendawo, kanye nokupholisa okunamandla akunciphisi nje kuphela izinga lokushisa lokuphotha kodwa futhi kugcina ngempumelelo ukuhlanzeka nokuthambisa ibhokisi lokuphotha.

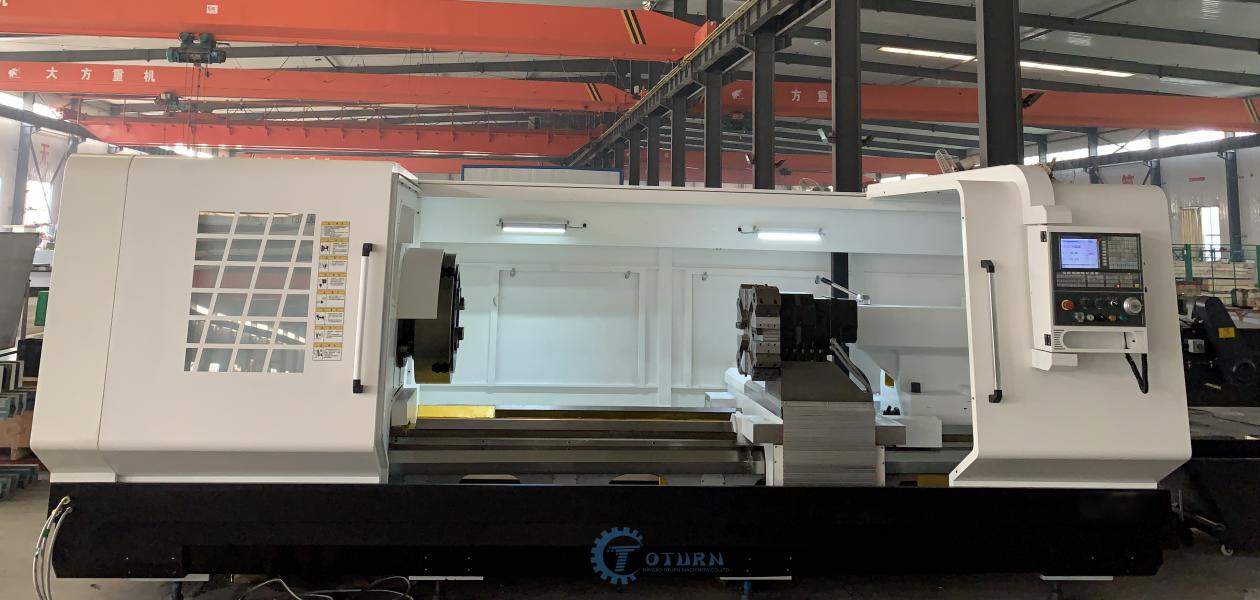

I-QLK1336

I-QLK1336CNC I-lathe yezwe lamafuthaiyilathe esanda kuklanywa yepayipi le-CNC. Idrayivu eyinhloko iklanyelwe ukufanisa uhla lokusebenza olukalwa lwemvamisa yenjini ekhethiwe ye-spindle servo. Ukulawulwa kwesivinini esigcwele esingenasinyathelo, uhla lokulawula isivinini esibanzi, olungagcini nje ngokuhlangabezana nezidingo zokuqedwa kwentambo enesivinini esikhulu, kodwa futhi lusebenza kahle kakhulu ukusika nomsindo ophansi.

Izinzuzo kanye nezinzuzo zamapayipi okuthunga ama-lathes

(1) Umzimba womshini

Ububanzi besitimela bomzimba bungu-650mm, okokusebenza kungu-HT300.I-Ultrasonic frequency quenching ifinyelelwa ku-HRC52.Ubunzima bungu-Ra0.63 ngemva kokugaywa umshini wokugaya onembayo ophezulu.Isebenza ngokunemba okuphezulu kanye nokuhuzuka. Umzimba womshini uyisakhiwo esibalulekile, esithuthukisa kakhulu ukuqina kwethuluzi lomshini.

(2)Izwe lamafutha e-CNC mubuhlunguIbhokisi Lekhanda

I-Integral gear box type spindle unit, amandla aphezulu we-spindle servo motor,

Ukuhanjiswa kwamagiya amabili, ukulawulwa kwesivinini esingenasinyathelo.

Uhlu olubanzi lokulawulwa kwejubane, hhayi nje ukuhlangabezana nezidingo zokuqedwa kwentambo yejubane eliphezulu, kodwa futhi nokufeza ukusika okuphumelelayo.Imishini yokugaya ecinyiwe futhi enembile, ama-bearings wekhwalithi ephezulu, ukuqinisekisa umsindo ophansi womshini, ikhwalithi enhle yomsindo.

Ibhokisi lokuphotha lisebenzisa ukuthambisa okupholisa okuqinile kokujikeleza kwangaphandle,

akugcini nje ukunciphisa izinga lokushisa lokuphotha, kodwa futhi kugcina ukuhlanzeka nokugcotshwa kwebhokisi lokuphotha.

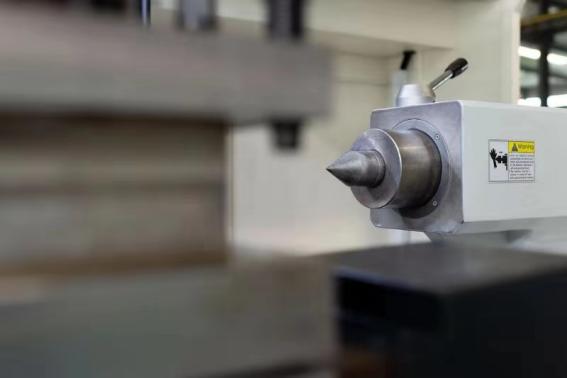

(3)Umsila

Leli thuluzi lomshini lijwayelekile ne-φ120 tailstock spindle. Mohs 6# phezulu.

(4)Isiphakeli se-double-eksisi

Kokubili i-axis engu-X kanye ne-Z isebenzisa isikulufu esiqondile esiphezulu sebhola kanye nesakhiwo sokucindezela isikulufu somthofu. Ukunemba kwe-screw bearings kusetshenziselwa ukubeka nokusekela; i-Z shaft screw nut rack iyisakhiwo sokuphonsa esibalulekile.

(5)I-CNC Turret

I-Adopts (HAK21280) CNC isibambi sethuluzi esime mpo . Inezici zokunemba okuphezulu, ukujikeleza okubushelelezi, ukusebenza okulula nokunye.

Izizathu ezine zokuthi ukhetheCNC ipayipi threadingmanina nomai-lathe ye-oil country machining

1.Iintambo yepayipi latheinezici zezinga eliphezulu lokuzenzakalela, ukusebenza kahle okuphezulu nokunemba okuphezulu, ububanzi bohlelo lokusebenza, nokusebenza okulula.

2.Ibhokisi eliseceleni kombhede lishayelwa i-frequency conversion motor, enokushintsha kwesivinini esingenasinyathelo. Ama-spindle bearings avela kubakhiqizi abaziwayo basekhaya, ama-chucks emihlathi emithathu avela kumikhiqizo yasekhaya eyaziwayo.

3.Idizayini ye-modular yesistimu yokulawula izinombolo kulula ukuyilungisa futhi kulula ukuyinakekela. Izimbazo ze-x ne-z zisebenzisa amandla aphezulu, ama-servo motors, ukusebenza okuthuthukile, nokuthembeka okuqinile.

4.Yamukela isihlalo sombhede okhonjiwe, ipuleti lesilayidi, ukwakheka kwezimbambo zangaphakathi ezinengqondo, isikulufu sebhola esinembayo esiphezulu, ukunemba okuphezulu, nokudluliswa okunembile.

Izingxenye Eziyinhloko Izithombe

Ukucushwa okujwayelekile

Iposi lamathuluzi kagesi eziteshi ezine, ukuthambisa okuzenzakalelayo okuphakathi nendawo, isistimu yokupholisa, ikhava yokuvikela evalwe kancane.

Lo mkhiqizo usetshenziswa kakhulu emisebenzini yokucubungula imishini ekwenziweni kwemishini, i-petroleum, amakhemikhali, amalahle, ukuhlola i-geological, ukuhlinzekwa kwamanzi emadolobheni kanye ne-drainage, nezinye izimboni.

Izingxenye ezisele eziyinhloko zihlanganisabhora amapayipi kanye nokuhlanganisa.

Imboni ye-petroleum iwumkhakha wezimboni okhipha i-petroleum (okuhlanganisa i-petroleum yemvelo, i-oyela shale, negesi yemvelo) futhi iyicwengisise futhi iyicubungule. Yakhiwe ukuhlola indawo ye-oilfield geological, ukuthuthukiswa kwendawo kawoyela kanye nokuhlola uwoyela, ezokuthutha, amayunithi okucwenga kanye nokucubungula.

Itemu elisetshenziswa kakhulu ekusetshenzisweni kwamashubhu embonini kawoyela negesi i-Petroleum Tubing (OCTG). Inhloso yamapayipi e-petroleum ingase ihluke: ingase isetshenziselwe ukukhipha noma ukujova igesi, uwoyela, amanzi, umusi, njll., futhi ingahlukaniswa ngamabhokisi noma amashubhu ngokuya ngezicelo ezithile. I-Casing isetshenziswa njengesendlalelo sokuvikela ukusiza imithombo kawoyela imelane nokuguguleka kokungcola kwangaphakathi noma kwangaphandle ukuze kugcinwe ukuqina; ishubhu isetshenziselwa ukujova noma ukukhipha uwoyela.

Intambo yepayipiing amathuluzi omshini asetshenziselwa ukucubungula amapayipi kawoyela, asetshenziswa kakhulu embonini ye-petroleum. Kuyipayipi lensimbi elisetshenziselwa ukuthutha uwoyela negesi yemvelo emithonjeni kawoyela. Ifakwe ku-casing, futhi ukugeleza kwamafutha negesi kusuka epayipini likawoyela kuya emthonjeni.

Kukhona osayizi ababili bentambo ye-tubing, enye iyintambo yepayipi emise okwe-V ene-dome eyindilinga phansi enamazinyo angu-8 iyintshi ngayinye, kanti enye iyintambo yepayipi ye-taper emise okwe-V ene-dome eyindilinga phansi ngamazinyo ayi-10 iyintshi ngayinye.

Intambo iyiprotrusion eqhubekayo enephrofayili yamazinyo enqunyiwe eyakhiwe ngomugqa ovunguzayo ebusweni besilinda noma ikhoni. Kunezindlela eziningi zokwenza izintambo zomshini, futhi ukuthunga kuvame ukusetshenziswa ekwenzeni imishini ejwayelekile. Niniimicu yomshiniku-lathe evundlile, ubudlelwano bokunyakaza phakathi kwendawo yokusebenza nethuluzi kufanele kuqinisekiswe. Empeleniukuphenduka kwentambo, ngenxa yezizathu ezihlukahlukene, ukunyakaza phakathi kwe-spindle kanye nethuluzi kunezinkinga kusixhumanisi esithile, okubangela ukwehluleka ngesikhathi sokuguqula intambo futhi kuthinte ukukhiqizwa okuvamile. Ngalesi sikhathi, kufanele ixazululwe ngesikhathi.

Indlela yokuxazulula inkinga yobunzima obukhulu, okulandelayo yiziphakamiso zabanye abasebenzisa intambo yamapayipi abanolwazi:

1. Uma uphenduka ngethuluzi lokuguqula insimbi yesivinini esikhulu, isivinini sokuguqula kufanele sincishiswe futhi ukuguqula amafutha kufanele kwengezwe.

2. Khulisa indawo ye-cross-sectional ye-arbor futhi unciphise ubude besandiso (ngoba i-arbor ayiqinile ngokwanele, ijwayele ukudlidliza ngesikhathi sokusika)

3. Yehlisa i-engeli yangaphambili ye-longitudinal yethuluzi lokuphenduka futhi ulungise ukuphuma kwe-screw nut sepuleti lesilayidi elimaphakathi (i-engeli yobude yobude bethuluzi lokuphenduka inkulu kakhulu, futhi ukucaciswa kwentongomane yesikulufu sesilayidi kukhulu kakhulu, okuzokwenza kalula ithuluzi)

4. Uma intambo enesivinini esikhulu iphenduka, ukujiya kokusikwa kokugcina kuvamise ukuba kukhulu kuno-0.1mm, futhi ama-chips akhishwa ngokuhambisana nendawo ye-eksisi (umaukuphenduka kwentambo enesivinini esikhulu, ukujiya kokuguqula kuncane kakhulu noma ama-chips akhishwa ngendlela ye-oblique, kulula ukudonsa izintambo zentambo).

5. Uwoyela wokuthepha osezingeni eliphezulu noma uwoyela ojika i-lathe oqukethe i-ejenti yokucindezela okwedlulele kufanele usetshenziselwecubungula intambowe-workpiece ngokusebenzisa i-lathe. Ukusetshenziswa kwamafutha akhethekile okucubungula insimbi kungenza inkinga yokunemba okungalungile nokusebenza kahle okuphansi.

Isikhathi sokuthumela: Sep-21-2021