Umshini we-lathe ojwayelekilekuwuhlobo lomshini we-lathe wendabuko ngaphandle kokulawula kodwa okwenziwa ngesandla. Inobubanzi obuhlukahlukene bokusika futhi ingacubungula izimbobo zangaphakathi, imibuthano yangaphandle, ubuso bokuphela, izindawo ezicijile, i-chamfering, i-grooving, izintambo kanye nezindawo ezihlukahlukene ze-arc. Izintambo ezijwayelekile ziwuhlobo lwemishini esetshenziswa kakhulu, olubalelwa ku-65% yenani eliphelele lomshini we-lathe. Abizwa ngokuthi ama-lathes avundlile ngenxa yokuthi ama-spindle awo abekwe ngokuvundlile.

Imisebenzi:

1. Ukuphenduka kwesilinda sangaphandle, ukuphenduka kwekhoni, ukuphenduka kwendawo egobile, ukuphenduka kwembobo engaphakathi, ukuphenduka kobuso ekugcineni, ukujikijela nokunye umshini;

2. Intambo yemethrikhi, intambo eyintshi, intambo ye-modular, ukusika intambo ye-pitch;

3. Ukudubula nokuphenduka kwe-taper ende;

4. Ukubhoboza, okuyisicefe, ukugqekeza nokugwaza;

5. Ukuphenduka kwesandla sokunxele kanye nokuphenduka kwesandla sokudla;

6. Ngisho nokugaya nokugaya ngokunamathisela nokugaya.

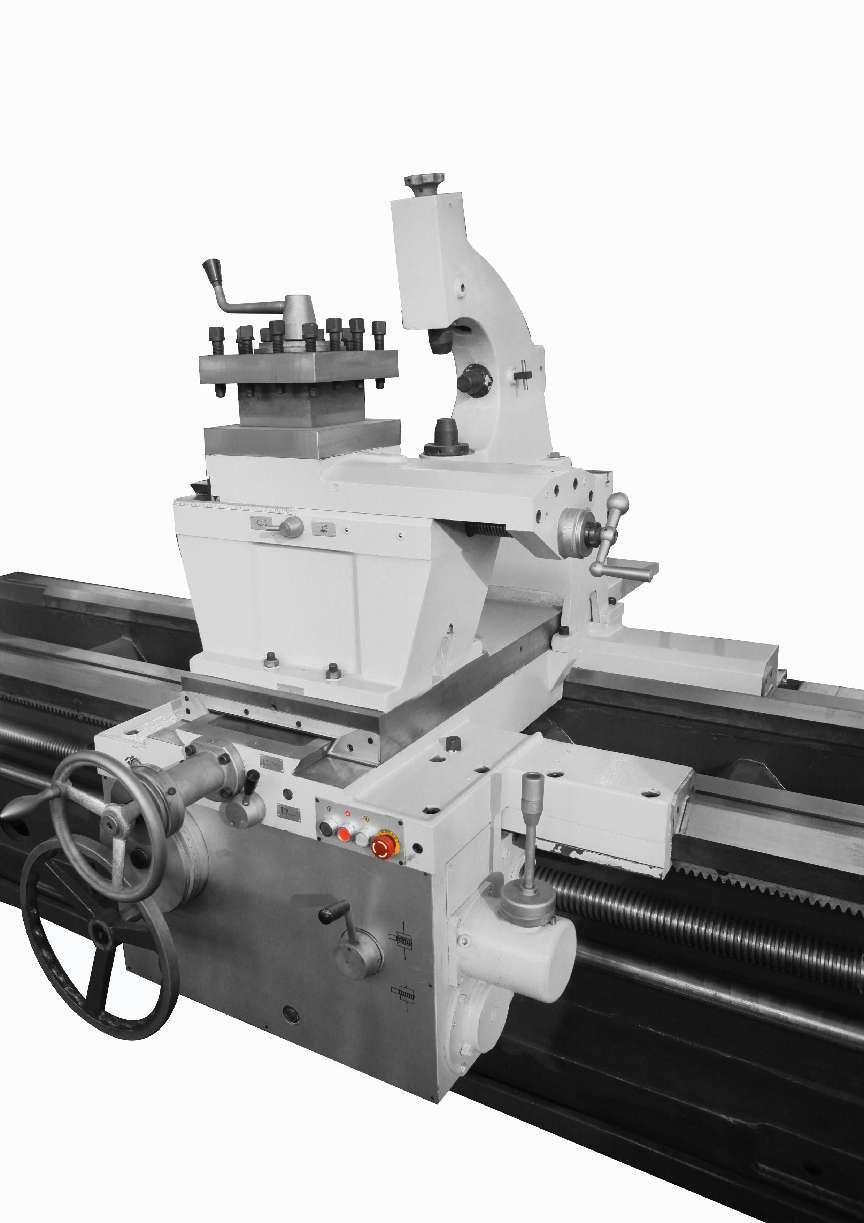

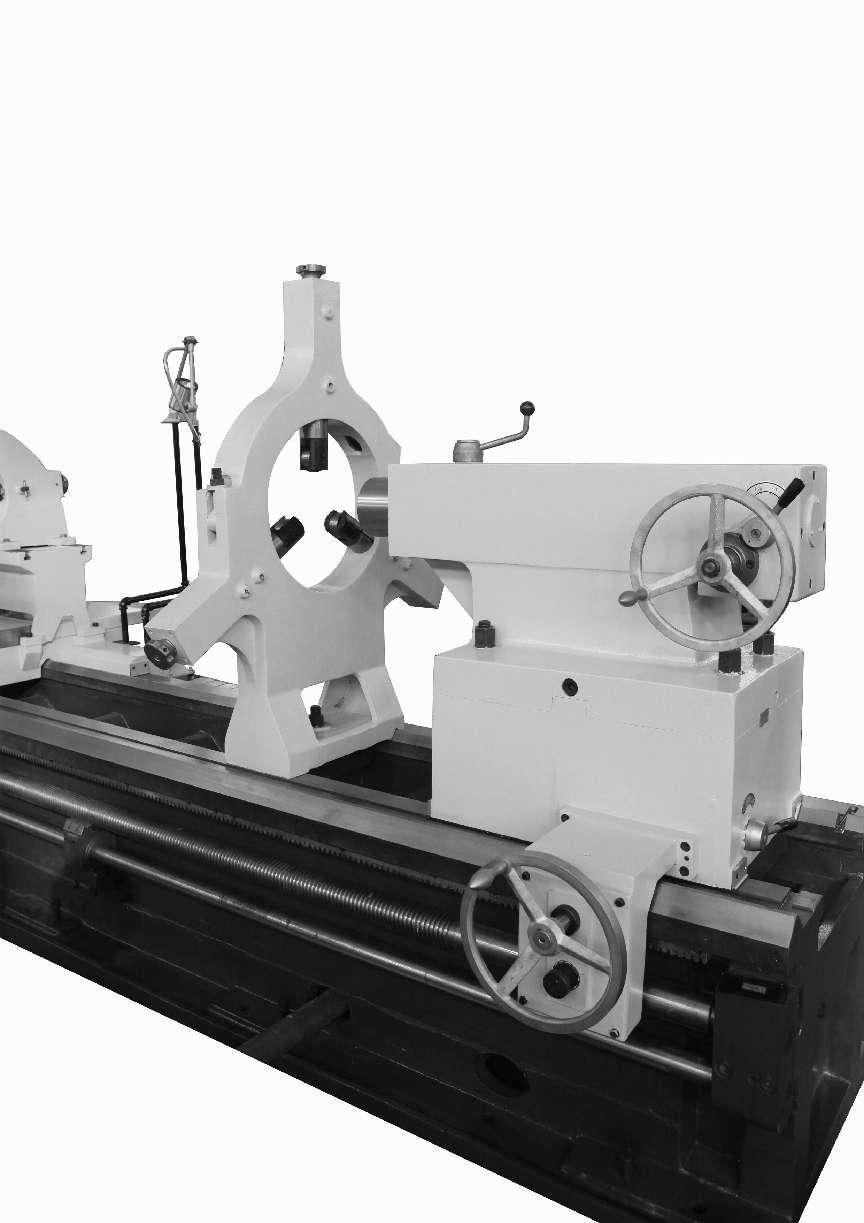

Izingxenye eziyinhloko zeimishini evamile: umbhede, isitokwe sekhanda, ibhokisi lokuphakelayo, iposi lamathuluzi, inqola, isitokwe, kanye nemoto.

Umbhede: Izingxenye eziyinhloko zeumshini wokuthungathaafakwe phezu kombhede, ukuze agcine isimo esinembile esihlobene ngesikhathi somsebenzi.Inqola ne-tailstock ziyashibilika endaweni yombhede owenziwe kahle.

I-Headstock:I-headstock ifakwe ngokuqinile embhedeni futhi ibamba zonke izindlela, okuhlanganisa izinhlobo ezihlukahlukene kanye nenhlanganisela yama-pulleys noma amagiya.Umsebenzi wawo oyinhloko ukudlulisa ukunyakaza okujikelezayo kusuka ku-motor main ngokusebenzisa uchungechunge lwezindlela zokushintsha isivinini ukuze shaft enkulu ingathola isivinini esidingekayo sokujikeleza okuya phambili nokuhlehlayo, futhi ngesikhathi esifanayo, i-headstock ihlukanisa ingxenye yamandla okudlulisa ukunyakaza ebhokisini lokuphakelayo.I-Headstock Medium spindle iyingxenye ebalulekile ye-lathe.Ubushelelezi be-spindle ukusebenza ku-bearing kuthinta ngqo ikhwalithi yokucubungula ye-workpiece. Uma ukunemba kokujikeleza kwe-spindle kwehlisiwe, inani lokusetshenziswa kwe-ithuluzi lomshiniizoncishiswa.

Ibhokisi lokuphakelayo: Ibhokisi lokuphakelayo lifakwe indlela yokushintsha isivinini yokunyakaza kokuphakelayo. Lungisa indlela yokushintsha isivinini ukuze uthole inani elidingekayo lokuphakelayo noma ukuphakama, futhi udlulisele ukunyakaza kusiphathi sethuluzi ngesikulufa esibushelelezi noma isikulufu somthofu sokusika.Isikulufu sokuhola sisetshenziswa ngokukhethekile ekuguquleni imicu ehlukahlukene. Lapho uphendula ezinye izindawo ze-workpiece, kusetshenziswa isikulufu esibushelelezi kuphela esikhundleni sesikulufu sokuhola.

Isiphathi samathuluzi: Isibambi samathuluzi sakhiwe izendlalelo ezimbalwa zokuthunyelwe kwamathuluzi. Umsebenzi wayo ukubophela ithuluzi nokwenza ithuluzi lihambe ngobude, libheke eceleni noma ngokugobile.

I-Tailstock: Njengesikhungo sangemuva sokusekelwa kokuma, singaphinda sifakwe ngamathuluzi okucubungula imbobo njengama-drill nama-reamers okucubungula imbobo.

izingxenye

I-chuck yemihlathi emithathu (yezingcezu zokusebenza eziyicylindrical)

i-four-jaw chuck (yezinto zokusebenza ezingajwayelekile)

isici

Amathuluzi omshini avamilezinesakhiwo esilula, ukusebenza okulula, ububanzi obukhulu bokuphotha, unyawo oluncane, ukuguquguquka okukhulu kokucubungula, ukugcinwa okulula, okulungele ukucubungula i-batch encane kanye nokusebenza kwezindleko eziphezulu.

Umbhede wamukela umbhede obalulekile onokuqina okuphezulu.Umshini ufakwe iphampu yamafutha ehlukile. Isilayidi, isibambi samathuluzi, nesihlalo sehhashi kungahamba ngokushesha. Leli thuluzi lomshini lingakwazi ukusebenzisa isistimu ye-GSK noma i-SIEMENS yokuzikhethela, isistimu yokulawula izinombolo ye-FANUC nezinye izinhlelo zokulawula izinombolo ngokuya ngezidingo zomsebenzisi, ezingakwazi ukusika ngesivinini esikhulu, okuqinile nezinzile, ukunemba komshini ophezulu kanye nohlelo olulula.

Impo futhi enezingqimbaOkuphakelayo kusebenzisa i-AC servo motor, futhi impendulo yesishumeki se-pulse isetshenziswa njengengxenye yempendulo. Ama-rails esiqondiso sokunyakaza aqondile futhi avundlile angaphansi kokuqina kwe-ultrasonic kanye nokwelashwa okuhle kokugaya. Isitimela sikamhlahlandlela wombhede sinanyathiselwe ngetheyiphu ethambile ye-PTFE, futhi i-coefficient yokushayisana incane.

Injini eyinhloko ithatha imodi yokulawula isivinini exubile yokulawulwa kazibuthe kanye nokulawulwa kwe-voltage, ukuze yenze ukulawulwa kwesivinini kwe-spindle ngaphandle kwesinyathelo.

Izinqubo zokusebenza

1. Ukuhlolwa ngaphambi kokuqala

1.1 Faka amafutha afanele ngokweshadi lomshini wokugcoba.

1.2 Hlola zonke izinsiza zikagesi, isibambo, izingxenye zokudlulisa, ukuvikela kanye nemishini yokukhawulela ukuthi kuphelele, kuthembekile futhi kuyavumelana nezimo.

1.3 Igiya ngalinye kufanele libe ku-zero, futhi ukuqina kwebhande kufanele kuhlangabezane nezidingo.

1.4 Akuvunyelwe ukugcina izinto zensimbi ngqo embhedeni, ukuze zingalimazi umbhede.

1.5 I-workpiece ezocutshungulwa ayinalo udaka nesihlabathi, ivimbela udaka nesihlabathi ukuthi zingaweli emshinini futhi ziguge nomzila wesitimela.

1.6 Ngaphambi kokuba i-workpiece iboshwe, ukuhlolwa kwemoto okungenalutho kufanele kwenziwe, futhi i-workpiece ingalayishwa kuphela ngemva kokuqinisekisa ukuthi konke kujwayelekile.

2. Inqubo yokusebenza

2.1 Ngemuva kokufakwa kwe-workpiece, qala iphampu kawoyela wokugcoba kuqala ukuze wenze umfutho kawoyela uhlangabezane nezidingo zethuluzi lomshini ngaphambi kokuqala.

2.2 Lapho ulungisa i-rack gear rack, lapho ulungisa isondo elilengayo, ukunikezwa kwamandla kufanele kunqanyulwe. Ngemuva kokulungiswa, wonke ama-bolts kufanele aqiniswe, i-wrench kufanele isuswe ngesikhathi, futhi i-workpiece kufanele inqanyulwe ukuze kusetshenziswe isilingo.

2.3 Ngemuva kokulayisha nokukhipha i-workpiece, isikrufu se-chuck nezingxenye ezintantayo ze-workpiece kufanele zisuswe ngokushesha.

2.4 I-tailstock, isibambo se-crank, njll. yethuluzi lomshini kufanele ilungiswe endaweni efanele ngokuya ngezidingo zokucubungula, futhi izoqiniswa noma iboshwe.

2.5 Izinto zokusebenza, amathuluzi nezinto ezilungiswayo kumele zifakwe ngokuvikelekile. Ithuluzi lamandla antantayo kufanele linwebe ingxenye yokuhola endaweni yokusebenza ngaphambi kokuqala ithuluzi lomshini.

2.6 Uma usebenzisa indawo yokuphumula emaphakathi noma indawo yokuphumula yamathuluzi, isikhungo kufanele silungiswe kahle, futhi kube nokugcotshwa okuhle nokusekela izindawo zokuthintana.

2.7 Lapho ucubungula izinto ezinde, ingxenye ephumayo ngemuva kwe-shaft eyinhloko akufanele ibe yinde kakhulu.

2.8 Lapho uphakela ummese, ummese kufanele usondele emsebenzini kancane ukuze ugweme ukungqubuzana; ijubane lenqola kufanele lifane. Lapho ushintsha ithuluzi, ithuluzi kanye ne-workpiece kufanele kugcinwe ebangeni elifanele.

2.9 Ithuluzi lokusika kufanele liqiniswe, futhi ubude besandiso bethuluzi lokujika ngokuvamile abudluli izikhathi ezingu-2.5 ubukhulu bethuluzi.

2.1.0 Uma kwenziwa izingxenye ezingagxilile, kufanele kube nesisindo esifanele sokulinganisa isikhungo samandla adonsela phansi e-chuck, futhi isivinini semoto kufanele sifaneleke.

2.1.1. Kumele kube nezinyathelo zokuzivikela ze-workpiece e-chuck yayo ingaphezu kwe-fuselage.

2.1.2 Ukulungiswa kwesethingi yethuluzi kumele kuhambe kancane. Uma ithiphu lethuluzi liku-40-60 mm kude nengxenye yokucubungula yesiqeshana sokusebenza, kufanele kusetshenziswe okuphakelayo okwenziwa ngesandla noma okusebenzayo, futhi okuphakelayo okusheshayo akuvunyelwe ukubandakanya ithuluzi ngokuqondile.

2.1.3 Lapho upholisha i-workpiece ngefayela, isibambi sethuluzi kufanele sibuyiselwe endaweni ephephile, futhi opharetha kufanele abhekane ne-chuck, isandla sokudla sibe ngaphambili nesandla sobunxele ngemuva. Kukhona ukhiye endaweni, futhi akuvunyelwe ukusebenzisa ifayela ukucubungula ucezu lokusebenza ngembobo yesikwele.

2.1.4 Lapho epholisha indilinga yangaphandle ye-workpiece ngendwangu ye-emery, osebenzisa i-emery kufanele abambe iziphetho ezimbili zendwangu ye-emery ngezandla zombili ukuze azipholishe ngokuvumelana nokuma okuchazwe esihlokweni esandulele. Akuvunyelwe ukusebenzisa iminwe yakho ukuze ubambe indwangu e-brasive ukupholisha imbobo yangaphakathi.

2.1.5 Ngesikhathi sokuphakelwa kommese okuzenzakalelayo, isibambi sommese esincane kufanele silungiswe ukuze sishaywe ngesisekelo ukuvimbela isisekelo ukuthi singathinti i-chuck.

2.1.6 Lapho usika izingcezu zokusebenza ezinkulu nezisindayo noma izinto zokwakha, imali eyanele yomshini kufanele igcinwe.

3. Umsebenzi wokupaka

3.1 Nquma amandla bese ukhipha ucezu lokusebenza.

3.2 Izibambo zengxenye ngayinye ziwiswa phansi ukuze zibe ziro, futhi amathuluzi ayabalwa futhi ahlanzwe.

3.3 Hlola isimo sedivayisi ngayinye yokuvikela.

4. Izinyathelo zokuqapha ngesikhathi sokusebenza

4.1 Akuvunyelwe ngokuphelele ukuthi abangasebenzi basebenzise umshini.

4.2 Akuvunyelwe ngokuphelele ukuthinta ithuluzi, ingxenye ejikelezayo yethuluzi lomshini noma i-workpiece ejikelezayo ngesikhathi sokusebenza.

4.3 Akuvunyelwe ukusebenzisa isitobhi esiphuthumayo. Esimeni esiphuthumayo, ngemva kokusebenzisa le nkinobho ukuyeka, kufanele ihlolwe futhi ngokuvumelana nemithethonqubo ngaphambi kokuqala ithuluzi lomshini.

4.4 Akuvunyelwe ukunyathela phezu komzila wesitimela, induku yesikulufu, induku epholishiwe, njll. ye-lathe. Ngaphandle kwemithethonqubo, akuvunyelwe ukusebenzisa isibambo ngezinyawo esikhundleni sezandla.

4.5 Ezingxenyeni ezinamabhamuza, izimbobo ezishwabene noma okhiye odongeni lwangaphakathi, ama-scrapers angama-triangular awavunyelwe ukusika izimbobo zangaphakathi.

4.6 Umoya ocindezelweyo noma umfutho we-liquid we-pneumatic hydraulic chuck yangemuva kufanele ufinyelele inani elishiwo ngaphambi kokuthi usetshenziswe.

4.7 Lapho uphendula ama-workpieces amancane, lapho ubude obuphuma phambili bezinhlangothi ezimbili zekhanda lombhede bungaphezu kuka-4 ububanzi, isikhungo kufanele sisetshenziswe ngokuvumelana nemithetho yenqubo. Ukuphumula kwesikhungo noma ukwesekwa kokuphumula kwesithende. Onogada nezimpawu eziyisixwayiso kufanele kwengezwe lapho kuphumela ngaphandle kwekhanda lombhede.

4.8 Lapho usika izinsimbi eziphukayo noma ukusika okuchaphazeka kalula (okuhlanganisa nokugaya), ama-baffles okuvikela kufanele kwengezwe, futhi opharetha kufanele bagqoke izibuko zokuzivikela.

okunye

Ngokuduma kweCNC imishini,ukwanda kwemishini ye-automation iyavela emakethe.Lathes Traditionalzinezinzuzo zazo ezingenakubuyiseleka futhi ziseyimishini edingekayo yezimboni eziningi zokucubungula.

1. Amathuluzi omshini avamilezithengeka kakhulu

Izindleko zokuthenga zeIzinhlobo ze-CNCibiza ngokuphindwe kaningana kunaleyo evamile i-lathe enamandla afanayo, kanye nokugcinwa kwakamuva, ukulungiswa, izinto ezisetshenziswayo ezisekelayo nezinye izindleko nazo ziphakeme kakhulu kunayo.

I-2.Ifaneleka kakhulu kumashini amancane

Lapho kuphela amaqoqo amancane ama-workpieces adinga ukwenziwa ngomshini,izisebenzi eziningi ezinamakhono zingakwazi umshini ingxenye ngamathuluzi omshini avamile anemidwebo yezingxenye.

3.Amaholo aphezulu abahleli bezinhlelo ze-CNC kanye namakhono ambalwa

Abahleli bezinhlelo ze-CNC bavame ukudinga amaholo aphezulu, futhi kunezinhlobo eziningi zezinhlelo ze-CNC. Ngokusobala kunzima kakhulu ukuthola umsebenzisi onolwaziAmathuluzi omshini we-CNCkunomsebenzi ojwayelekile wethuluzi lomshini.

4.Mayelana nezindleko zokufakwayo kwebhizinisi

Uma kucatshangelwa inzuzo enkulu yamabhizinisi kanye nokusetshenziswa okunengqondo kwemishini, amabhizinisi amaningi agcina ukukhiqizaumshini ovamileamathuluzi.

Sekukonke, nakuba ukukhiqizwa kwe-CNC sekuphenduke inkambiso enkulu ekuthuthukisweni kwemboni yokukhiqiza, amathuluzi emishini evamile asenezinzuzo zawo eziyingqayizivele esimweni sokuthandwa kwemishini ehlakaniphile. Ngokuthuthuka okuqhubekayo kobuhlakani beAmathuluzi omshini we-CNCngokuzayo, amathuluzi omshini wendabuko angase ashintshwe ngezinga elikhulu, kodwa akunakwenzeka ukuwaqeda ngokuphelele.

| INDLELA | CW61(2)63E | CW61(2)80E | CW61(2)100E | I-CW61(2)120E | CWA61100 |

| AMANDLA | |||||

| UMax.shwibeka phezu kombhede | 630 mm | 800mm | 1000mm | 1200mm | 1000mm |

| I-Max.shwibeka phezu kwesilayidi esiphambanayo | 350mm | 485 mm | 685 mm | 800mm | 620 mm |

| Ubude bokujika obukhulu | 750,1250,1750,2750,3750,4750,5750,7750,9750,11750mm | 1.5m 2m 3m 4m 5m 6m 8m 10m 12m | |||

| I-Max.swing phezu kwegebe | 830 mm | 1000mm | 1200mm | 1400mm | 780mm |

| Ubude obuvumelekile begebe | 230m | 8T | |||

| Ububanzi bombhede | 550 mm | ||||

| INHLOKO-ISITOKHI | Φ130 mm | ||||

| Imbobo yokuphotha | 105mm NOMA 130mm (NGIYAZITHANDELA CW6180E+) | Imethrikhi140# | |||

| Ikhala lokuphotha | I-D-11 noma i-C-11 | 3.15-315r/min noma 2.5-250r/min | |||

| I-spindle taper | Φ120mm taper1:20(Φ140, NGOKUZITHANDELA CW6180+) | Phambili 21izinhlobo,Ukubuyisela emuva12izinhlobo | |||

| Isivinini se-spindle(Inombolo) | 14-750RPM(18 IZINYATHELO) | ||||

| IGIYE IBHOKISI-IMICHUPHE KANYE NOKUPHAKISWA | 44izinhlobo 1-120mm | ||||

| Ibanga lochungechunge lwemethrikhi (izinhlobo) | 1-240mm(54 izinhlobo) | 31izinhlobo 1/4-24 T/I | |||

| Intshi yochungechunge lwama-rang(Izinhlobo) | 28-1 intshi (36 izinhlobo) | 45izinhlobo 0.5-60mm | |||

| Ibanga lemicu ye-Module (izinhlobo) | 0.5-60 DP(27 izinhlobo) | 38izinhlobo 1/2-56DP | |||

| Ibanga (izinhlobo) zemicu yediametral | 30-1 tpi(27 izinhlobo) | 56 izinhlobo 0.1-12mm | |||

| Ibanga lokuphakelayo okude (izinhlobo) | 0.048-24.3mm/r (izinhlobo ezingu-72) | 56izinhlobo 0.05-6mm | |||

| I-cross feed range(izinhlobo) | 0.024-12.15mm/r (72 izinhlobo) | 3400mm/min,1700mm/min | |||

| Okuphakelayo okusheshayo:Kude./Isiphambano | 4/2m/min | ||||

| Usayizi we-leadscrew: Ububanzi/Iphitshi | I-T48mm/12mm NOMA T55mm/12mm(ye-5M+) | 48mm | |||

| INKOLO | 45 * 45mm | ||||

| Uhambo lwama-slide oluphambanayo | 350mm | 420 mm | 520 mm | ||

| Uhambo lokuphumula oluhlanganisiwe | 200mm | 650mm | |||

| Usayizi we-shank yamathuluzi | 32*32mm | 280mm | |||

| I-TAILSTOCK | |||||

| Ububanzi be-spindle | 100mm | 120mm | Φ160mm | ||

| I-spindle taper | I-ORSE #6 | Metric 80# | |||

| Ukuhamba nge-spindle | 240mm | 300mm | |||

| MOTOR | |||||

| Main drive motor | 11kw | 22kw | |||

| Injini yepompo epholile | 0.09kw | 0.15kw | |||

| Injini yokuphakelayo esheshayo | 1.1kw | 1.5kw | |||

Isikhathi sokuthumela: Apr-14-2022