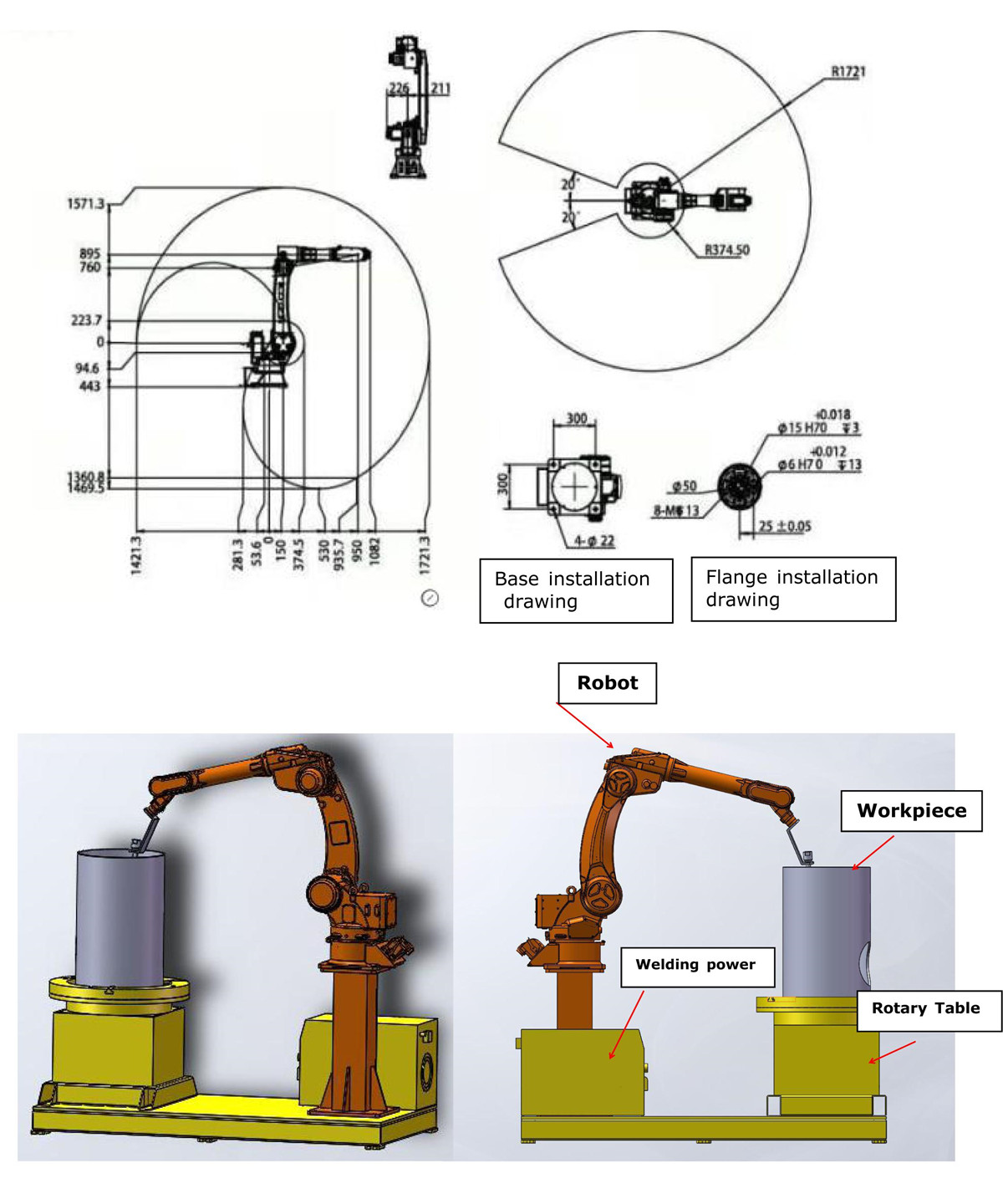

Uhlelo lwe-Robot Welding For Valve

Ukucaciswa

|

Imodeli |

TKB 2670/2690 |

|

|

Inkokhelo |

20kg |

|

|

UMax Working Radius |

1721 * 1921mm |

|

|

I-DOF |

6 eksisi |

|

|

Isisindo somzimba |

210kg |

|

|

Reducer Brand |

ukungenisa |

|

|

Kukalwe Amandla |

7.5kw |

|

|

Isivinini esikhulu |

J1 |

140 ° / s |

|

J2 |

111 ° / s |

|

|

J3 |

148 ° / s |

|

|

J4 |

234 ° / s |

|

|

J5 |

225 ° / s |

|

|

J6 |

360 ° / s |

|

|

Indawo Yokusebenza Enkulu |

J1 |

± 160 ° |

|

J2 |

I-150 ° ~ 90 ° |

|

|

J3 |

80 ° ~ 100 ° |

|

|

J4 |

± 150 ° |

|

|

J5 |

± 110 ° |

|

|

J6 |

± 300 ° |

|

|

Ukucaciswa kokuvikela |

54 |

|

|

Isikhundla Phinda Ukunemba |

± 0.1mm |

|

|

Ukushisa okusebenzayo |

0 ~ 45 ℃ |

|

|

Ngesitifiketi se-CE |

||

Ukusebenza Isakhiwo

Umshini wokushisela

Umshini owodwa usebenza ngezinhloso eziningi, futhi ungabona i-CO2 / MAG welding, i-welding yesandla, i-carbon arc gouging ngasikhathi sinye, futhi isebenzise amandla ayo ekucutshungweni kwamapuleti aminyene njengezakhiwo zensimbi, amabhuloho nokwakhiwa kwemikhumbi.

Ukulawulwa kweMicrocomputer, ukusethwa kwesimo sokushisela kungumsebenzi wokulungiswa onobunye ngokuphelele, okulula ukusebenza.

Ku-Welding ye-CO2 / MAG, noma ngabe isandla siyazamazama, i-microcomputer ingakwazi ukuyilawula ngokushesha futhi ngokushesha ngesikhathi sangempela ukugcina ngokuphelele ukuzinza kwe-arc welding.

Umsebenzi we-carbon arc gouging ungabona ukususwa kwempande emuva nokususwa kwamaphutha we-welding.

Umsebenzi wokuvikelwa okwenziwa ngokweqile kwe-SCR wenza ukusebenza komshini wokushisela kuthembeke kakhulu.

Ukuqala kokusebenza kwe-arc kuphakeme, futhi kungafaniswa kalula nendiza ekhethekile.

Ukucaciswa

|

Into |

XD600G |

||

|

Amandla wokushisela |

imodeli |

GPXDG-600 |

|

|

Amandla wokufaka |

V, Hz |

3,380V ± 10 %, 50 / 60Hz |

|

|

Kukalwe umthamo wokufaka |

kVA |

47.7 (36.6kW) |

|

|

Umphumela webanga lamanje |

I-CO2 / MAG / NMA |

A |

60 ~ 600 |

|

Ukugoqwa kwekhabhoni |

100 ~ 600 |

||

|

Kulinganiswe ngo isikhathi sokulayisha |

% |

100 |

|

|

Ubukhulu (WHD) |

mm |

508 * 724 * 894 |

|

|

isisindo |

Ama-Kg |

252 |

|

|

Isiphakeli sezintambo |

imodeli |

I-CMXL-2301 |

|

|

Isibhamu sokushisela |

imodeli |

I-WT5000-SCD |

|

|

Isilawuli sokugeleza kwegesi |

imodeli |

I-W-198-36V |

|

|

Intambo yokushisela |

Imodeli |

I-BKPT-7002 |

|