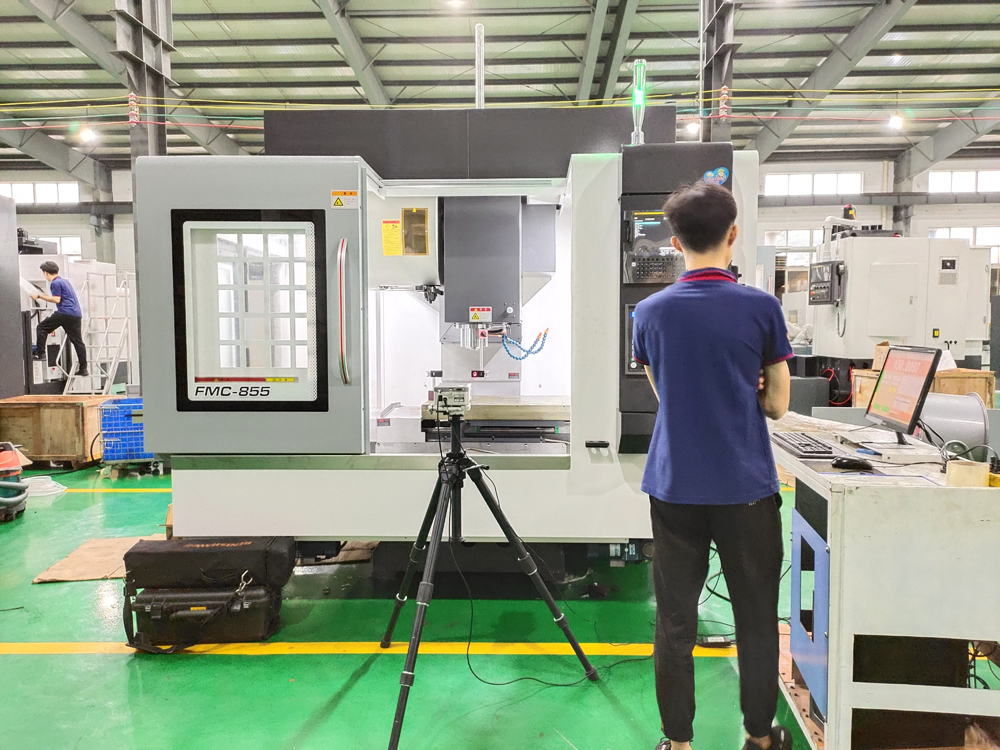

Izikhungo zomshiniziyimishini evame ukusetshenziswa ezimbonini zokusebenza zokucubungula izingxenye zensimbi.Ngokuvamile, itafula lokujikijela libekwe etafuleni lokucubungula, futhi izingxenye zensimbi zibekwe etafuleni lokujikijela ukuze zicutshungulwe.Ngesikhathi sokucutshungulwa, ithebula lokucubungula lihamba eduze nomzila wesitimela ukuze kucutshungulwe izingxenye zensimbi zibe yisimo esifunwayo.

Kuhlelo lokusebenzisa i-isikhungo somshini, zama ukuqedela konke ukucubungula okuqukethwe ekubambeni okukodwa.Uma kudingekile ukufaka esikhundleni sephuzu lokunamathisela, qaphela ngokukhethekile ukuthi ungalimazi ukunemba kokumisa ngenxa yokushintshwa kwendawo yokubopha, futhi uyicacise kufayela lenqubo uma kunesidingo.Ngokuthintana phakathi kwendawo engaphansi ye-fixture kanye netafula lokusebenza, ukucaba kwendawo engaphansi kwaleyo nto kufanele kube phakathi kuka-0.01-0.02mm, futhi ukuhwayela kwendawo akufanele kube kukhulu kuno-Ra3.2um.

Kuhlelo lokusebenzisa i-isikhungo somshini, zama ukuqedela konke ukucubungula okuqukethwe ekubambeni okukodwa.Uma kudingekile ukufaka esikhundleni sephuzu lokunamathisela, qaphela ngokukhethekile ukuthi ungalimazi ukunemba kokumisa ngenxa yokushintshwa kwendawo yokubopha, futhi uyicacise kufayela lenqubo uma kunesidingo.Ngokuthintana phakathi kwendawo engaphansi ye-fixture kanye netafula lokusebenza, ukucaba kwendawo engaphansi kwaleyo nto kufanele kube phakathi kuka-0.01-0.02mm, futhi ukuhwayela kwendawo akufanele kube kukhulu kuno-Ra3.2um.

Yiziphi izingxenye okufanele zigcinwe lapho kusetshenziswa isikhungo somshini?Ake sibheke ndawonye ngezansi.

Yiziphi izingxenye okufanele zigcinwe lapho kusetshenziswa isikhungo somshini?Ake sibheke ndawonye ngezansi.

1. Hlola izisetshenziswa zokuphepha ze-I-CNC lathe eqondile.

(1) Wonke amaswishi anomkhawulo, izibani zezinkomba, amasiginali, namadivayisi okuvikela ukuphepha kuphelele futhi kuthembekile.

(2) Ukufakwa kukagesi kufakwe kahle, ukufakwa kuthembekile futhi kusekelwe phansi, nokukhanyisa kuphephile.

2. Hlola futhi ulungise amafayili ensimbi, amapuleti okucindezela, izikhala, izikulufo zokulungisa, amantongomane, nezibambo zezingxenye ezihlukahlukene, eziguquguqukayo futhi kulula ukuzisebenzisa.

(1) Igebe phakathi kwensimbi ethambekele, ipuleti lokucindezela, nendawo eshelelayo yengxenye ngayinye ilungiswa ibe phakathi kuka-0.04mm, futhi izingxenye ezihambayo zingahamba ngokukhululeka.

(2) Akukho ukuxega noma ukushoda kwezikulufu zokulungisa namantongomane ezingxenyeni ezihlukahlukene.

3. Ukuhlanza, ukudonsa, isistimu yokugcoba nokupholisa, amapayipi, okuhlanganisa izimbobo zikawoyela, izinkomishi zikawoyela, izintambo zikawoyela, kanye nezisetshenziswa zokuhlunga ezizwakalayo.

(1) Ifasitela likawoyela licacile futhi liyakhanya, uphawu lukawoyela ludonsa amehlo, uwoyela usendaweni, futhi izinga likawoyela liyahlangabezana nezimfuneko.

(2) Ingaphakathi nangaphandle kwethangi likawoyela, ichibi likawoyela, kanye nezinto zokuhlunga kuhlanzekile, akunakungcola nokungcola.

(3) Kuyadingeka ukuqinisekisa ukuthi umugqa kawoyela weCNC Machining Centerisiphelile, i-linoleum ayigugi, indlela yamafutha okugcoba ayivaliwe, futhi akukho ukuvuza kwamafutha noma amanzi.

(4) Isibhamu sikawoyela namafutha kungaba kuhlanzekile futhi kulula ukuyisebenzisa, umlomo wombhobho kawoyela nenkomishi kawoyela kuphelile, futhi iphampu yesandla nepompo kawoyela kulula ukuyisebenzisa.

Isikhathi sokuthumela: Dec-13-2021