Kungokokuqala ukuthi amakhasimende akwezinye izifunda ezikhethekile ahlangane nawoIzinhlobo ze-CNC, kanye nokusebenza kwama-lathe e-CNC akukakwazi ukuba yingcweti yamakhono okusebenza omshini kuphela kusukela ekuqondisweni kwebhukwana lokusebenza. Ukuhlanganisa isipiliyoni sokusebenza esiqoqwe abanolwaziI-China CNC latheopharetha emsebenzini wabo wansuku zonke, ngizochaza amakhono okusetha ithuluzi kanye nezinyathelo zokucubungula zezingxenye ezithile.

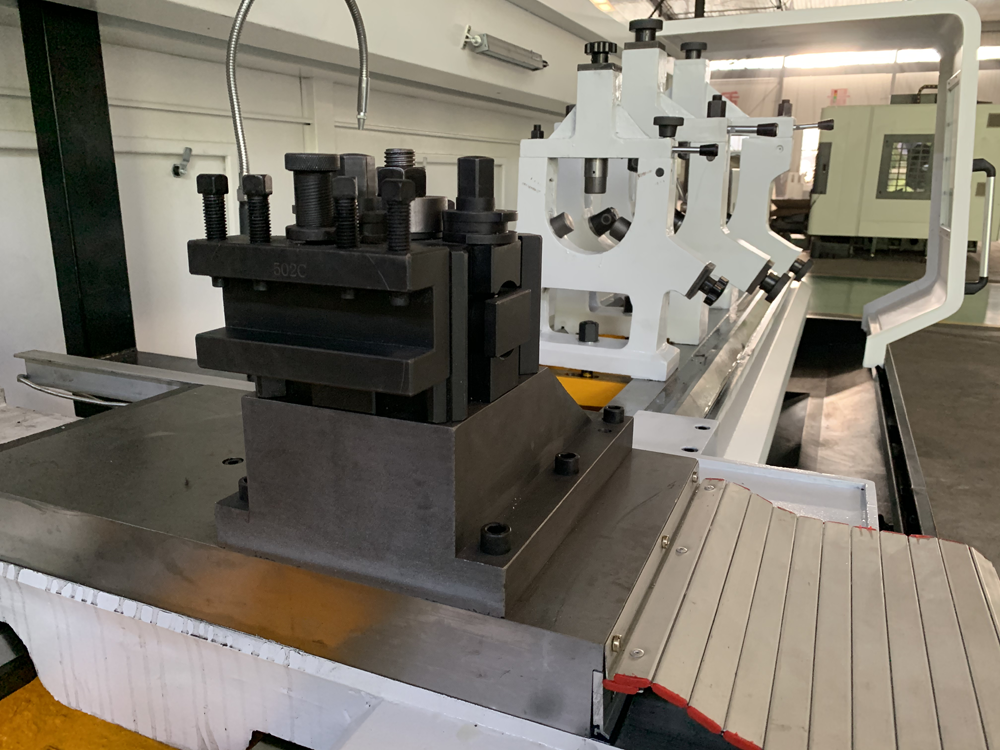

Izindlela namakhono okusetha amathuluzi embonini yemishini ingahlukaniswa ngezigaba ezimbili: ukulungiselelwa kwamathuluzi okuqondile kanye nokuhlelwa kwamathuluzi. Ngaphambi kokuthi i-CNC lathe ibuyele endaweni yokuqala, njaloukuphenduka futhil okudingeka kusetshenziswe isethwe nendawo emaphakathi yobuso bokugaya obungakwesokudla bengxenye njengephoyinti elingu-0, bese indawo emaphakathi yobuso obungakwesokudla bengxenye ikhethwa njengephoyinti elingu-0 futhiIthuluzi le-CNCiphuzu libekiwe. Uma ithuluzi elijikayo lithinta ikhibhodi yobuso bokugaya kwesokudla, faka u-Z0 bese uchofoza ukuze uthole, inani lesinxephezelo sethuluzi lethuluzi lokujika lizogcina idatha etholiwe ngokuzenzekelayo, okusho ukuthi ukulungiselelwa kwethuluzi le-Z-axis kuqediwe, kanye nokusetha kwethuluzi X. iyisilungiselelo sethuluzi lokusika lesilingo, futhi kusetshenziswa isisiki sokugaya Isiyingi esingaphandle sezingxenye zemoto sincane, futhi idatha yendingilizi yangaphandle yemoto etholiwe (efana no-x ingu-20 mm) okokufaka kwekhibhodi x20, chofoza ukuze uthole, inani lesinxephezelo sethuluzi lizogcina ngokuzenzakalelayo idatha etholiwe, ngalesi sikhathi i-x-eksisi nayo isiqediwe.

Lolu hlobo lwendlela yokusetha ithuluzi, noma ngabe i-I-CNC latheiphelelwe amandla, inani lokusetha ithuluzi ngeke lishintshwe ngemva kokuthi amandla eqalwe kabusha. Ingasetshenziswa ekukhiqizeni inqwaba yesikhathi eside kanye nokucutshungulwa kwezingxenye ezifanayo. Ngaleso sikhathi, umshini awudingi ukulinganiswa kabusha lapho umshini uvaliwe.

Izinyathelo Zokucubungula Izingxenye

Izinyathelo Zokucubungula Izingxenye

(1) Shaya ngesibhakela kuqala bese kuthi ekugcineni kube isicaba (lokhu ukugwema ukushwabana lapho ushaya).

(2) Ukuphenduka okungalungile kuqala, bese uphenduka kahle (lokhu ukuqinisekisa ukunemba kwezingxenye).

(3) Okokuqala cubungula lezo ezinezikhala ezinkulu bese wenza lezo ezinezikhala ezincane (lokhu ukuqinisekisa ukuthi indawo yangaphandle yesayizi encane yegebe ayiklwebheki futhi ugweme ukuhlanekezelwa kwezingxenye).

(4) Khetha isilinganiso esifanele sejubane, inani lokusika kanye nokujula kokusika ngokwezindinganiso zokuqina kwayo kwempahla. I-carbon steel plate material ikhethelwa ukujikeleza ngesivinini esikhulu, umthamo wokusika ophezulu, nokujula okukhulu kokusika. Okufana nokuthi: 1Gr11, sebenzisa i-S1 600, F0.2, futhi usike ukujula okungu-2 mm. Ingxubevange isebenzisa isilinganiso sejubane eliphansi, izinga lokuphakelayo eliphansi kanye nokujula okuncane kokusika. Okufana nokuthi: GH4033, khetha i-S800, F0.08, futhi usike ukujula ngo-0.5mm. Insimbi ye-Titanium alloy ikhetha isilinganiso sejubane eliphansi, umthamo wokusika ophezulu, nokujula okuncane kokusika. Okufana nokuthi: Ti6, sebenzisa i-S400, F0.2, futhi usike ukujula okungu-0.3mm. Thatha ukukhiqizwa kwengxenye ethile njengesibonelo: impahla iyi-K414, okuwumsebenzi onzima kakhulu. Ngemuva kokuhlolwa okuphindaphindiwe, ukukhethwa kokugcina yi-S360, F0.1, kanye nokujula kwe-cut 0.2, ngaphambi kokuba izingxenye ezijwayelekile zikhiqizwe. (Lokhu okokubhekisela kuphela, sicela wenze izinguquko zangempela ngokusekelwe kumapharamitha omshini wendawo, izinto zokwakha, njll. ngezimo ezithile!)

Isikhathi sokuthumela: Nov-29-2021