IUmshini Okhethekile Wevalvuisetshenziswa kakhulu ekucubunguleni i-Valve(I-Butterfly valve/I-valve yesango/I-valve yebhola/i-globe valve, njll..),Umzimba wephampu, izingxenye ze-Auto, izingxenye zemishini yokwakha njll.

Isebenzela ukucubungula okuningi okuhlukile, okufana nalokhu: Ubuso bokugcina, indilinga yangaphandle, unqenqema lwangaphambili, Imbobo yangaphakathi, i-grooving, intambo yesikulufu, i-Bore-hole kanye ne-Sphere. Ingakwazi ukubona i-automation, ukunemba okuphezulu, izinhlobonhlobo eziningi kanye nokukhiqizwa okukhulu.Kusetshenziswa kakhulu embonini yamavalvu.

Mayelana ne-imboni ye-valve

Amavaluvu ayizesekeli zamapayipi asetshenziselwa ukuvula nokuvala amapayipi, ukulawula ukugeleza, ukulungisa nokulawula amapharamitha (izinga lokushisa, ingcindezi, nokugeleza) kwendawo edlulisayo. Ngokusho komsebenzi wayo, ingahlukaniswa nge-valve yokuvala,hlola i-valve, i-valve yokulawula, njalonjalo.

I-valve iyingxenye yokulawula ohlelweni lokudlulisa uketshezi. Inemisebenzi yokunqamula, ukulawula, ukuphambukisa, ukuvimbela ukugeleza okuhlehlayo, ukuzinzisa, ukuphambukisa noma ukuchichima, kanye nokukhulula ingcindezi. Amavalvu asetshenziswa ezinhlelweni zokulawula uketshezi, kusukela kumavalvu alula ukuvala kuya kumavalvu ahlukahlukene asetshenziswa ezinhlelweni zokulawula ezizenzakalelayo eziyinkimbinkimbi kakhulu, anezinhlobonhlobo zezinhlobonhlobo kanye nokucaciswa.

Ama-valve asetshenziswa kabanzi emikhakheni ehlukahlukene. Ikakhulukazi i-petroleum, i-metallurgy, amandla kagesi, ukongiwa kwamanzi, ukwakhiwa kwamadolobha, ukulwa nomlilo, imishini, amalahle, ukudla, njll.

Ukutholakala

Yiziphi izinzuzoUmshini Okhethekile Wevalvuembonini ye-valve

√Ukugaya kusebenzisa uhlobo lwe-multi-eksisi, futhi ukusebenza kahle kuthuthukiswa izikhathi ezimbalwa.

√Zuza ukucutshungulwa kwamakhanda amabili noma amathathu ngesikhathi esisodwa ngesikhathi sokucubungula ukuze ubone ukumisa nokusebenza kahle okuphezulu kweukucubungula i-valve yepayipi yephampu.

√Isistimu yokulawula izinombolo enelungelo lobunikazi, ukusebenza okuzenzakalelayo ngokugcwele.

Umshini wethu Wevalve Okhethekile onconyiwe

Izincomo zethudUmshini Okhethekile Wevalvu

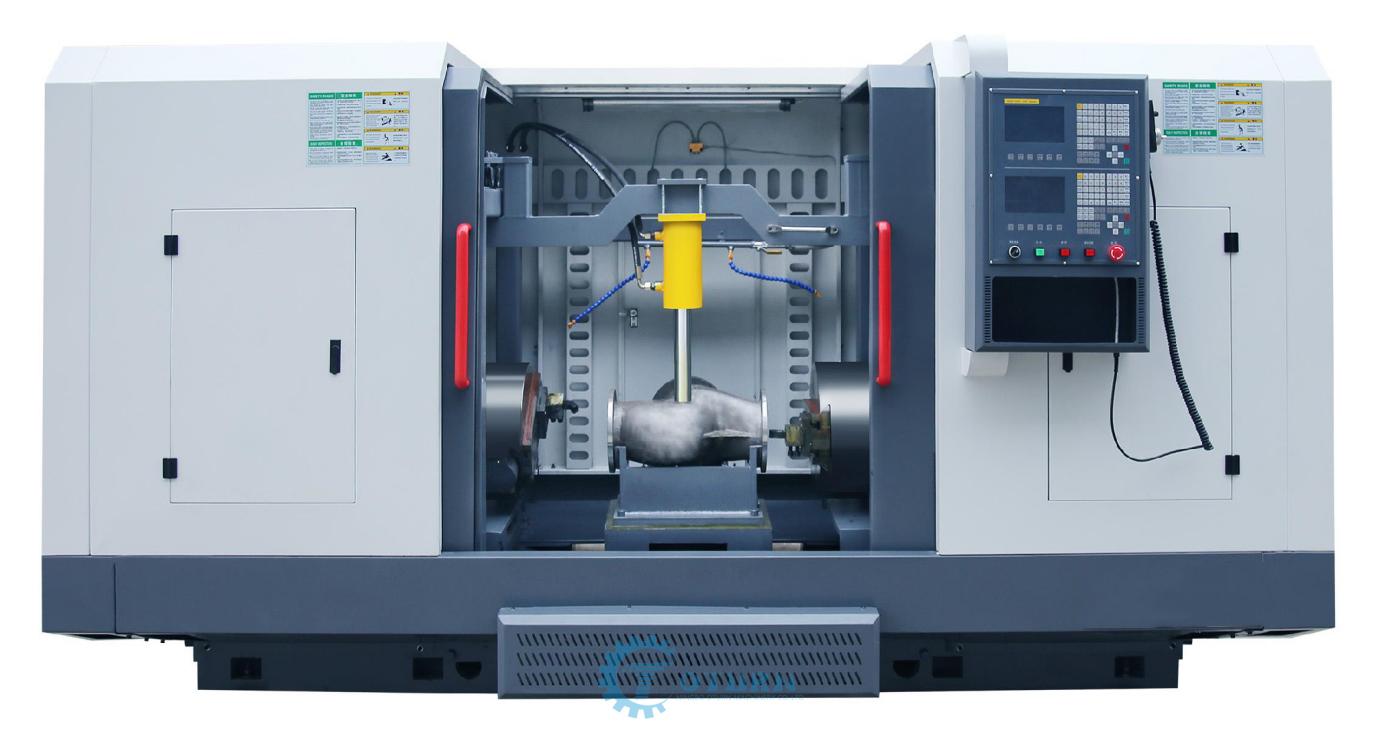

Umshini we-CNC onamakhanda amabili

1.Umzimba womshini

Umzimba womshini wenziwe ngekhwalithi ephezulu yokusakazwa kwensimbi empunga, umshini oqinile, ukuqeda, kanye nokwelashwa okuthukuthelisayo kokuguga ukuze kuqedwe ngokuphelele ingcindezi eyinsalela. Ingaphezulu lesitimela somhlahlandlela

Yamukela ukwelashwa kokucisha imvamisa yomsindo omkhulu futhi icutshungulwa ngokugaywa kwesitimela somhlahlandlela onemba kakhulu ukuze kuqinisekiswe ukunemba, ukuqina, nokuzinza kwethuluzi lomshini. √

2.Special Valve Machine

Ibhokisi Lekhanda

Ibhokisi le-Head lenziwe ngezinga eliphezulu, futhi i-shaft eyinhloko yenziwe nge-20GrMnTAi, eyakhiwe, yacinywa, futhi yagxiliswa, i-carburized futhi yacinywa, futhi yengezwa ngokunemba okuphezulu kwangaphakathi nangaphandle kwe-cylindrical grinder.

I-bearing yamukela ama-roller angama-cylindrical anemigqa emibili ephezulu enemba ephezulu ukuze kuqinisekiswe ukuqina nokunemba kwe-spindle. I-shaft eyinhloko ithatha ukuguqulwa kwesivinini sezinyathelo ezintathu nge-motor enamandla amakhulu ukuze kufinyelele isivinini esiphansi

I-torque enkulu, ingathwala umthwalo osindayo wokusika, ithuthukise ukusebenza kahle kokucubungula. √

7. Umshini wokugcoba ophakathi nendawo

Isistimu yokugcoba ifakwe idivayisi yokugcoba eqhubekayo ye-Nanjing Beqier, ehlala impompa uwoyela wokugcoba endaweni yokugcoba yengxenye ngayinye ehambayo, iqede ukusebenza kwezandla okukhathazayo.

Thuthukisa impilo yesevisi yethuluzi lomshini. √

Umshini we-CNC onamakhanda amabili

Butterflyumshini okhethekile we-valve

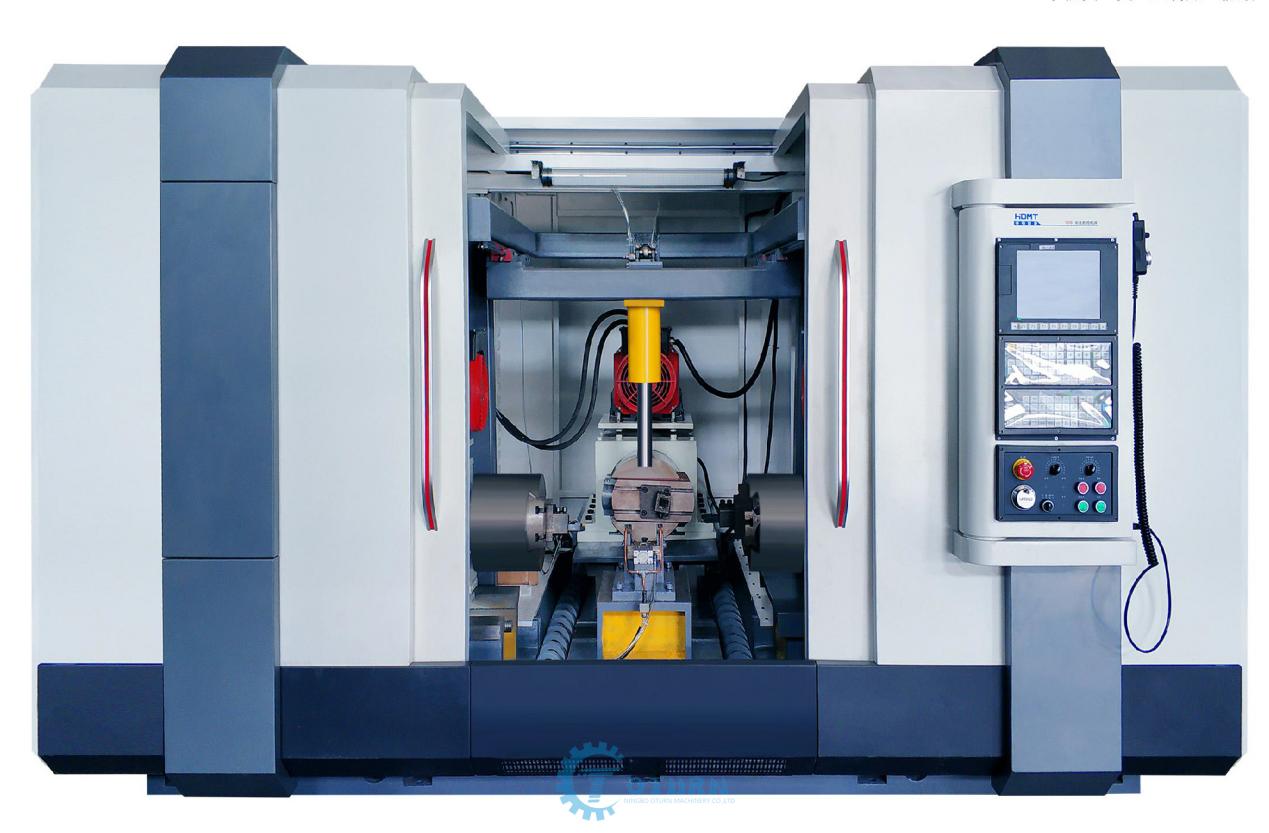

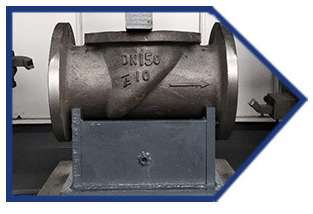

Isikhungo semishini esiyinhlanganisela ye-HDCX800,uvemvane valveIthuluzi elikhethekile lomshini wokucubungula lisetshenziswa ikakhulukazi kuma-butterfly valves kanye ne-zero

Ukuze kusetshenziswe izingxenye, imishini yobunjiniyela nezinye izingxenye, ubuso bokuphela, indilinga yangaphandle, i-spigot, imbobo yangaphakathi, i-groove, intambo, imbobo ye-taper kanye nesimo esiyindilinga se-workpiece singacutshungulwa.

Ukuphenduka. Inqubo yokucubungula ilawulwa uhlelo lwe-GSK CNC, olukwazi ukubona ukuzenzela, ukunemba okuphezulu, okuhlukahlukene, nokukhiqizwa ngobuningi.

isici esiyinhloko

1. I-HDCX800 Special Valve Machine yonke ilawulwa uhlelo lwe-GSK CNC, olungabonakala ngokuxhunywa kwe-dual-eksisi.

Ukucutshungulwa kwezimbobo ze-taper, izintambo, nezinqubo eziyindilinga. Isistimu yayo ye-CNC iyahambisana, inamandla, futhi kulula ukuyisebenzisa.

2. Umzila wesitimela wesilayidi sokuphakelayo wenziwe ngensimbi empunga yekhwalithi ephezulu, eye yabhekana nokwelashwa okushisayo okuthathu ngemva kokwenza ama-roughcast kanye nokuqedwa ukuze kuqedwe ngokugcwele ukucindezelwa kwangaphakathi okusalayo.

Ingaphezulu lisebenzisa ukwelashwa kokucisha imvamisa yomsindo omkhulu futhi ukuqina kufinyelela ku-HRC55. Ukunemba, ukuqina, nokuzinza kwethuluzi lomshini kuqinisekiswa ukugaya okunemba okuphezulu kwesitimela.

3. Izingxenye zokudlulisela ziqhutshwa yizikulufu zebhola ezinembile futhi izinyathelo zokuhlanganisa zisetshenziselwa ukuqeda izikhala, ukuqinisekisa ukudluliswa okushelelayo nokucubungula ithuluzi lomshini.

4. Isihloko samandla sithatha ukudluliselwa kwemanuwali kwezinyathelo ezintathu nge-motor enamandla amakhulu ukuze kuzuzwe isivinini esiphansi kanye ne-torque ephezulu, ingakwazi ukumelana nemithwalo esindayo yokusika, futhi ithuthukise ukusebenza kahle kokucubungula.

5. Amathuluzi asebenzisa i-hydraulic automatic clamping ukuze kuthuthukiswe ukusebenza kahle kanye nokunciphisa izinga lomsebenzi womuntu siqu.

6. I-HDCX800 Special Valve Machine,butterfly valve umshini wokucubungula okhethekileithuluzi lamukela ukuthambisa okuphakathi nendawo ukuze kuqinisekiswe ukuthi ingxenye ngayinye ehambayo igcotshwe ngokugcwele futhi ithuthukisa ithuluzi lomshini.

Umshini Okhethekile Wevalvu Isakhiwo

Ikhanda Lamandla

Umzimba we-headbox wamandla wenziwa ngokusakazwa kwekhwalithi ephezulu, kanti i-shaft eyinhloko yenziwe ngezinto ezingu-20GrMnTAi, ezicutshungulwa ngokufoja, ukucisha, nokufudumeza, ukungcwatshwa kwe-carburizing, nokucisha, kanye nokunemba okuphezulu kwama-cylindrical grinders angaphakathi nangaphandle.

I-bearing yamukela ama-NN30 uchungechunge olunemba okuphezulu kwamabhere angama-cylindrical roller anemigqa emibili ukuze kuqinisekiswe ukuqina nokunemba kwe-spindle.

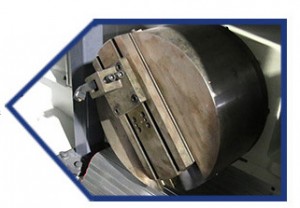

Ithebula lokusebenza

I-worktable iyibhentshi lokusebenzela elikhethekile elakhelwe ngokukhethekile ngokwezingxenye ezicutshunguliwe. Amabhulokhi okumisa kanye nezikhonkwane zokubeka zonke ziyacinywa ukuze kuqinisekiswe ukuma okuthembekile kwendawo yokusebenza.

I-Workpiece clamping isebenzisa i-clamping eyenziwa ngesandla ukuze kuthuthukiswe ukusebenza kahle kokucubungula kanye nokunciphisa izinga lomsebenzi womuntu siqu. Futhi i-worktable ingashintshwa ngamadigri angu-180, ukuphoqa isikhathi esisodwa, isikhathi esisodwa Qedela zonke izinqubo.

Umagazini wethuluzi lokushintsha ithuluzi elizenzakalelayo

Umagazini wethuluzi lokushintsha amathuluzi we-CNC ozenzakalelayo ngokugcwele, ongabamba amathuluzi ayi-16, amathuluzi angama-20, amathuluzi angama-24, njll., alawulwa ngokuzenzakalela uhlelo, ngesivinini sokushintsha ithuluzi elisheshayo nokunemba okunembile.

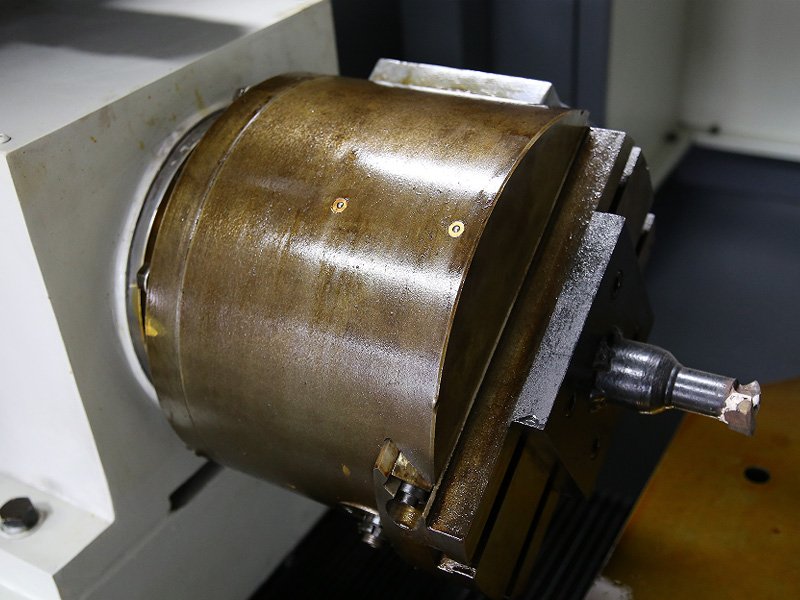

- Ikhanda lamandla

Ikhanda lamandla lamukela ukwakheka okukhethekile kwe-patent + screw screw, enezici zokunemba okuphezulu, ukuqina okuphezulu, nempilo ende.

- Amathuluzi

-

I-tooling iyithuluzi elikhethekile eliklanywe ngokwezingxenye ezizocutshungulwa. Amabhulokhi okumisa kanye nezikhonkwane zokubeka zonke ziyacishwa ukuze kuqinisekiswe ukuma okuthembekile kwendawo yokusebenza. I-workpiece iboshwe yi-hydraulic clamping, okuthuthukisa ukusebenza kahle kokucubungula futhi kunciphisa umfutho wokusebenza kwabasebenzi.

- Ikhabethe likagesi

Ikhabhinethi kagesi yamukela uhlobo oluzimele oluvaliwe, olunesistimu yokulawula eyakhelwe ngaphakathi, isiguquli semvamisa kanye nezingxenye zikagesi zokulawula isikhumulo sezindiza, futhi ifakwe izinto zokupholisa umoya ukuze kuqinisekiswe ukuthi izingxenye zikagesi zethuluzi lomshini zisebenza ngokujwayelekile futhi azingeni uthuli.

- I-CNC Cukulawula System

Inemisebenzi yobuchwepheshe bokulawula iziteshi eziningi, umshini wama-axis amahlanu, isivinini esikhulu nokunemba okuphezulu, ukujika nokugaya, ukulawula okuvumelanayo nokunye ukulawula kwe-CNC ephezulu.

Ukukhetha isisetshenziswa:

Ukulawulwa kwe-CNC

isilawuli sokupholisa

I-automatic chip conveyor

Ukuvikela okuyingxenye/ukuvikela okugcwele

Ngezinhlobo ezahlukene zama-valve, izinqubo ezahlukene zicutshungulwa. Isibonelo, imisebenzi yokukhiqiza kanye namalungiselelo ahlukahlukene obuchwepheshe adinga ukwenziwa ngaphambi kokucubungula. Onjiniyela badinga ukwenza amalungiselelo afanele ngokuya ngenqubo yokwakhiwa komkhiqizo ngokwawo kanye nokukhiqizwa kwemishini ekhethekile yendiza ye-valve yase-Huadian. Izingxenye ezingenalutho ze-valve zingaklanywa ngokusakazwa kwesihlabathi, ukubunjwa okunembayo noma ukuphonswa kwe-wax yomcibisholo lapho kwenziwa. Ngezinqubo zokubumba noma ze-welding, kuyadingeka ukuklama ngokuvumelana nezimo ezifanele ezingenalutho.

Iizinqubo zokucubungula i-valveziyinkimbinkimbi, futhi inani elengeziwe lomkhiqizo liphansi. Izinzuzo zokusebenzisa inhloso evamile nomaAmathuluzi omshini we-CNCayikwazi ukuboniswa. Ukucutshungulwa okuphelele kwe-valve kudinga ngisho nokuhlanganiswa kwemishini eminingi ukuze kuzuzwe umphumela wokucubungula. Ngaso sonke isikhathi lapho ushintsha usayizi noma ukuhlukahluka, udinga ukulungisa ithuluzi lomshini, bese udlulisela inqubo eqediwe kusukela kunqubo yangaphambilini ukuya ethuluzini lomshini elifanisiwe kwinqubo elandelayo. Lokhu akukhulisi nje kuphela izindleko zokukhiqiza, kodwa futhi kumosha izindleko zesikhathi esiningi. Ngokuvamile, izingcezu zokusebenza ezidinga ukunemba okuphezulu, ngenxa yezinguquko eziningi zokubopha, zandisa iphutha lokunemba le-workpiece. Ngakho izinzuzo ze-indiza ye-valveziyabonakala.

Ngokwesibonelo, forama-valve esango, ukuphenduka kwama-flanges anezinhlangothi ezintathu kungenziwa emshinini owodwa. Njengamanje, umshini okhethekile we-valve we-HDMT ungakwazi ngesikhathi esisodwa ukucubungula izinhlangothi ezimbili noma ezintathu ze-valve flange ngesikhathi esisodwa, okulula futhi okuphumelelayo, kuyilapho ukukhiqizwa kwendabuko Kungacutshungulwa i-valve eyodwa kuphela ngesikhathi, okudla isikhathi. kanye nokusebenza kanzima. Ngendlela efanayo, ukubhoboza i-flange ezinhlangothini ezintathu noma ezimbili ze-valve nakho kusekelwe esimisweni esifanayo, esingathuthukisi nje kuphela ukusebenza kahle, kodwa futhi kunciphisa ukubekezelelana kwesikhundla somgodi.

Ukusebenza kwe-umshini okhethekile we-valvefuthi ilula kakhulu, wonke amamodeli aqaphele ukwakheka okuzenzakalelayo, adinga kuphela ukufaka amapharamitha. Lokhu kunciphisa kakhulu ukusebenza kwezandla, kunciphisa izindleko zabasebenzi, futhi konga isikhathi nomzamo. Uma kukhona ukugcwala ngokweqile noma enye inkinga yenzeka phakathi nenqubo yokukhiqiza, umshini uzokhipha i-alamu ngokushesha noma uvale ngokuzenzakalelayo, ukuze ugweme ukulimala komshini ngezinga elikhulu kakhulu.

Ngemva kokuba indiza ye-valve isiqediwe, opharetha kufanele avale ukunikezwa kwamandla okuhlobene, enze umsebenzi omuhle wokuhlanza, futhi asebenzise izithambisi ezichwepheshile ukuze alungise futhi agcine indiza ye-valve. Kunezinto eziningi ezidinga ukunakwa ngesikhathi sokusebenza komshini okhethekile we-valve. Umshini we-valve okhethekile awukwazi ukwenza imisebenzi efana nokulungiswa kwamathuluzi, ukuhlolwa nokususwa ngesikhathi sokusebenza. Phakathi nayo yonke inqubo yokusebenza komshini we-valve okhethekile, abasebenzi abafanelekile kanye nabaqhubi akumele bashiye imisebenzi yabo, futhi kufanele benze umsebenzi omuhle wokuqondisa okufanele. Amathuluzi afana nezinto zokusebenza, izinto ezilungiswayo, kanye nemibese kufanele kuboshwe ngokuqinile, ngaphandle kwalokho ezinye izinkinga ngokunyakaza kwe-workpiece zizokwenzeka. Ukungasebenzi kahle kungabangela ukulimala okungadingekile. Uma ummese uphukile noma uphukile, udinga ukushintshwa ngesikhathi. Enkambweni yokusebenza evamile, asikwazi ukuthinta ngokuqondile indawo yokusebenza ngezandla zethu, futhi asikwazi ukususa ngokuqondile izinto eziyingozi njengokusika ngezandla zethu. Lokhu ngeke kulimaze izandla zethu kuphela, kodwa futhi kubangele ukugcwaliswa kwensimbi kundiza. Ingozi emehlweni. Ngesikhathi sokusebenza kwe-indiza ye-valve ekhethekile, kufanele ugqoke ama-ovaroli ahambisanayo, ugqoke isigqoko somsebenzi, futhi uqiniseke ukuthi ugxilisa izinwele zakho kusigqoko somsebenzi. Lapho ulayisha futhi uthulula ama-workpieces amakhulu, zama ukusebenzisa imishini yokuphakamisa, ukuze wonke umsebenzi uhambisane kahle kakhulu, futhi ukusebenza kokuphepha kuzoba phezulu.

Isikhathi sokuthumela: Sep-22-2021