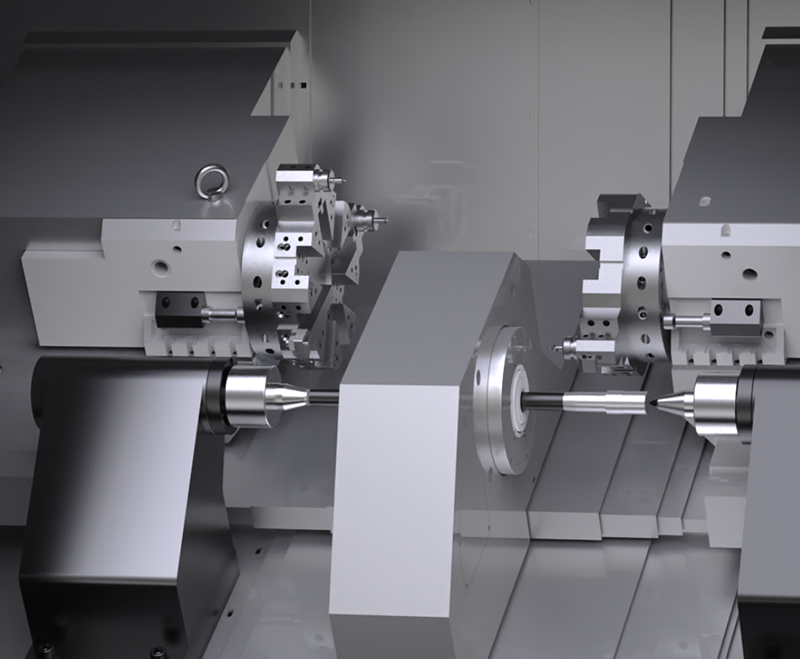

Izintambo ezimbili ze-CNC eziphotha kabilizingamathuluzi abalulekile ekwenziweni kwesimanjemanje, ngokuzinza kwawo nokusebenza kwawo kanye nokunemba kokucubungula okunomthelela ngqo ekusebenzeni kahle kokukhiqiza kanye nekhwalithi yomkhiqizo. Ngakho-ke, ukugcinwa kwansuku zonke kwale mishini kubaluleke kakhulu. Ngokulungiswa okufanele, akunakuphela nje kuphela isikhathi sokuphila semishini enwetshiwe, kodwa ukunemba kokucubungula kwayo nokuzinza kokusebenza kungabuye kuqinisekiswe, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kokukhiqiza nokunciphisa izindleko zokunakekela.

Ukubaluleka Kokugcinwa Kwansuku zonke

1.Ukwelula Ukuphila Kwezisetshenziswa

Amalathe e-CNC anezipindo ezimbili ahlangabezana namazinga ahlukene okuguga kanye nomthelela ezingxenyeni zawo ngesikhathi sokusetshenziswa. Ukuhlanza okuvamile, ukugcotshwa, nokuhlola kungasiza ekuhlonzeni nasekuxazululeni izinkinga ezingase zibe khona, njengamagayidi agugile nezixhumo ezixegayo, ukuvimbela izinkinga ezincane ekubeni amaphutha amakhulu futhi kunwetshwe ngempumelelo impilo yonke yezinto zokusebenza.

2.Ukuqinisekisa Ukunemba Kwezisetshenziswa

Ukunemba kokucubungula kweI-Double Spindle CNC latheiyinkomba eyinhloko yokusebenza kwazo. Ukunemba kwezingxenye ezibalulekile njengamagayidi nezikulufu zomthofu kuthinta ngokuqondile ukunemba kobukhulu kanye nekhwalithi yangaphezulu yezingxenye ezicutshunguliwe. Ngokulungiswa kwansuku zonke, okufana nokuhlanza njalo imfucumfucu evela kumagayidi nezikulufu zomthofu zokugcoba, lezi zingxenye zingagcina ukunemba kwazo, ziqinisekise ukuthi izingxenye ezicutshunguliwe zihlangabezana nezidingo zedizayini.

3.Ukuthuthukisa Ukuzinza Nokuthembeka Kokusebenza

Ngesikhathi sokusebenza, ama-lathes e-CNC ane-spindle dual-spindle adinga ukusebenza okuhlanganisiwe kwamasistimu angaphansi ahlukahlukene, okuhlanganisa amasistimu kagesi, okupholisa, namasistimu okugcoba. Noma yikuphi ukwehluleka kulawa masistimu angaphansi kungaholela ekuphelelweni kwesikhathi kwemishini, okunomthelela ezinhlelweni zokukhiqiza. Ukunakekelwa okuvamile, okufana nokuhlola ukuxhunywa kwamakhebula, ukuhlanza amasistimu okupholisa, nokufaka izinto zokugcoba esikhundleni, kuqinisekisa ukuthi zonke izinhlelo ezingaphansi zisebenza kahle, okuthuthukisa ukuzinza nokuthembeka kwezinto zokusebenza.

4.Ukunciphisa Izilinganiso Zephutha Nezindleko Zokulungisa

Ukunakekela okuvamile kungakhomba futhi kuxazulule amaphutha angaba khona ngokushesha, kuvimbele ukulahlekelwa kokukhiqiza ngenxa yokwehluleka kwemishini. Ukwengeza, ishejuli yokulungisa ehlelwe kahle inganweba umjikelezo omkhulu wokulungisa imishini, inciphise izindleko zokuyilungisa.

Izindlela Zokugcina Ezithize

1.Ukuhlanza Okujwayelekile Nokugcotshwa

Ukuhlanza Umhlahlandlela: Hlanza njalo imihlahlandlela ukuze ugcine ubushelelezi nokunemba.

I-Lead Screw Lubrication: Gcoba njalo izikulufu zomthofu ukuze unciphise ukungqubuzana futhi ugcine ukunemba kwazo nokuphila kwazo.

Ukuhlolwa Kwesistimu Yokugcoba: Njalo hlola izinga likawoyela wesistimu yokuthambisa kanye nekhwalithi ukuze uqinisekise ukuthi isebenza ngendlela evamile.

2.Ukuhlolwa Kwesistimu kagesi

Ukuhlola Ukuxhunywa Kwekhebula: Hlola njalo ukuxhunywa kwekhebula ukuze uqinisekise ukuthi avikelekile.

Ukuhlola Ingxenye Kagesi: Hlola njalo izingxenye zikagesi, njengama-relay kanye nezixhumi, ukuze uqinisekise ukuthi zisebenza kahle.

3.Ukugcinwa Kwesistimu Yokupholisa

Ukuhlola Ukupholisa: Hlola njalo izinga lokushisa lesipholisi kanye nezinga ukuze uqinisekise ukuthi isistimu yokupholisa isebenza ngendlela evamile.

Ukuhlanzwa Kwesistimu Yokupholisa: Hlanza njalo isistimu yokupholisa ukuze ususe udoti futhi ugcine ukuhlanzeka kwayo.

4.I-Tool Magazine kanye Nokugcinwa Kokushintsha Ithuluzi

Ithuluzi Lokuhlanza Umagazini: Hlanza njalo iphephabhuku lamathuluzi ukuze uqinisekise ukuthi amathuluzi agcinwe ngobunono futhi ugweme ukungqubuzana.

Ukuhlola Ukushintsha Ithuluzi: Njalo hlola isiguquli samathuluzi ukuze uqiniseke ukuthi sisebenza ngokujwayelekile.

5.Lathe Precision Maintenance

Ukuhlola Ukuma Kweleveli: Njalo hlola indawo yeleveli ukuze uqinisekise ukunemba kwayo.

Ukulinganisa Ukunemba Komshini: Linganisa ukunemba komshini njalo ukuze ugcine ukunemba kokucubungula kwe-lathe.

Ukwakha Uhlelo Lwesondlo

Ukuqinisekisa ukusebenza okuvamile kanye nempilo yeumshini we-CNC one-spindle kabili, izinkampani kufanele zenze uhlelo lokulungisa olusebenza ngokwesayensi. Lolu hlelo kufanele lufake:

Umjikelezo Wokulungisa: Sungula ishejuli yokulungisa evamile esekelwe ekusetshenzisweni kwemishini kanye nezincomo zomkhiqizi.

Okuqukethwe Kwesondlo: Chaza ngokucacile okuqukethwe kuseshini ngayinye yokulungisa, njengokuhlanza, ukuthambisa, nokuhlola.

Ukuqeqeshwa Kwabasebenzi Bezokunakekelwa: Nikeza ukuqeqeshwa okudingekayo kubasebenzi bezokulungisa ukuze kuqinisekiswe ukuthi bayakwazi ukwenza imisebenzi ngendlela efanele.

Amarekhodi Okunakekela: Gcina amarekhodi anemininingwane yokulungisa ukuze ulandelele isimo nomlando wemishini.

Ngokusebenzisa ngokuqinile uhlelo lokulungisa, izinkampani zingathuthukisa ngempumelelo ukusebenza nokuzinza kwezintambo ezimbili eziphothene ze-CNC, zinikeze ukwesekwa okuqinile kokukhiqiza nokuthuthukiswa.

Kafushane, ukugcinwa kwansuku zonke kwe-double-spindleI-CNC lathekubalulekile ekuqinisekiseni ukusebenza okuvamile, ukwandisa isikhathi sokuphila, ukuthuthukisa ukunemba kokucubungula, nokuthuthukisa ukuzinza. Izinkampani kufanele zibeke phambili umsebenzi wokulungisa, zenze uhlelo lokulungisa okunengqondo, futhi zilusebenzise ngokuqinile ukuze ziqhubeke zithuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

Isikhathi sokuthumela: Apr-02-2025