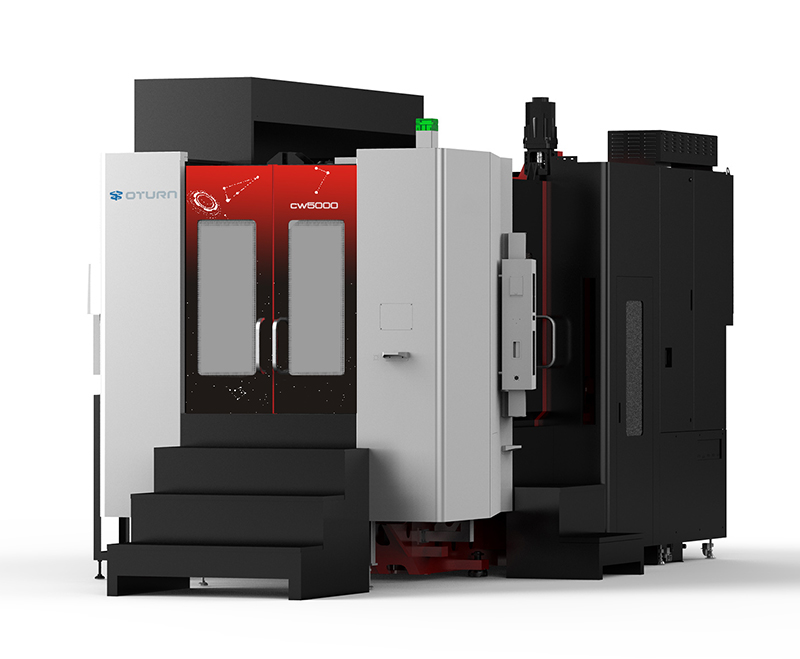

Iisikhungo semishini esivundlile se-CNC eneziteshi ezimbiliiwucezu olubalulekile lwemishini yokukhiqiza yesimanje enembayo, esetshenziswa kakhulu ezimbonini ezifana nezimoto, i-aerospace, kanye nokukhiqiza isikhunta ngenxa yokuqina kwayo okuphezulu, ukunemba okuphezulu, nokusebenza kahle okuphezulu.

Izici:

Idizayini Yeziteshi Ezikabili: Ivumela isiteshi esisodwa ukuthi senze imishini ngenkathi esinye siphatha ukulayisha noma ukuthulula, sithuthukisa ukusebenza kahle komshini kanye nokusetshenziswa kwemishini.

Isakhiwo Esivundlile: I-spindle ihlelwa ngokuvundlile, esiza ukukhishwa kwe-chip futhi ifanele ukukhiqizwa ngobuningi kanye nokumishini okuzenzakalelayo.

Ukuqina Okuphezulu Nokunemba: Ifanele izimboni ezifana ne-aerospace, ukukhiqizwa kwezimoto, nokucubungula isikhunta okudinga ukunemba okuphezulu nokusebenza kahle kwemishini.

I-Multi-Process Integration: Iyakwazi ukwenza ukuphenduka, ukugaya, ukubhola, nezinye izinqubo zokukhanda ngesikhathi esisodwa, ukunciphisa ukudluliswa kwe-workpiece kanye namaphutha esibili okubamba.

Lesi sihloko sizochaza izindlela ezimbalwa ezivamile zokushintsha amathuluzi ezisetshenziswa ezikhungweni zemishini ezivundlile ze-CNC ukuze kusize abafundi baqonde kangcono futhi basebenzise lobu buchwepheshe.

1. Ukuguqulwa Kwethuluzi Lemanuwali

Ukushintsha ithuluzi okwenziwa ngesandla kuyindlela eyisisekelo kakhulu, lapho u-opharetha ekhipha ngesandla ithuluzi kumagazini wamathuluzi futhi alifake ku-spindle ngokuya ngezidingo zomshini. Le ndlela ifanele izimo ezinamathuluzi ambalwa kanye nemvamisa yokushintsha kwamathuluzi aphansi. Nakuba kunzima, ukuguqulwa kwamathuluzi okwenziwa ngesandla kusenevelu yakho ezimeni ezithile, njengalapho izinhlobo zamathuluzi zilula noma imisebenzi yomshini ingeyinkimbinkimbi.

2. Ukushintsha Kwethuluzi Okuzenzakalelayo (Ukushintsha Ithuluzi Lengalo Yerobhothi)

Amasistimu okushintsha amathuluzi azenzakalelayo awukucushwa okujwayelekile kweziteshi ezimbili zesimanjeCNC izikhungo machining ovundlile. Lezi zinhlelo ngokuvamile zihlanganisa umagazini wamathuluzi, ingalo yerobhothi eshintsha amathuluzi, kanye nesistimu yokulawula. Ingalo yerobhothi ibamba ngokushesha, ikhethe, futhi iguqule amathuluzi. Le ndlela ifaka isivinini sokushintsha ithuluzi elisheshayo, ibanga elincane lokunyakaza, kanye ne-automation ephezulu, ithuthukisa kakhulu ukusebenza kahle kwemishini nokunemba.

3. Ukushintsha Ithuluzi Okuqondile

Ukushintsha ithuluzi okuqondile kwenziwa ngokubambisana phakathi kwephephabhuku lamathuluzi nebhokisi lokuphotha. Kuye ngokuthi umagazini wamathuluzi uyanyakaza yini, ukuguqulwa kwethuluzi eliqondile kungahlukaniswa kube izinhlobo ezishintshayo nomagazini. Ohlotsheni lokushintsha umagazini, iphephabhuku lamathuluzi liya endaweni yokushintsha ithuluzi; ohlotsheni olulungisiwe lomagazini, ibhokisi lokuphotha liyahamba ukuze ukhethe futhi ushintshe amathuluzi. Le ndlela inesakhiwo esilula kodwa idinga ukuhambisa umagazini noma ibhokisi lokuphotha ngesikhathi sokushintsha kwamathuluzi, okungase kuthinte isivinini sokushintsha ithuluzi.

4. Ukushintsha Ithuluzi le-Turret

Ukushintsha ithuluzi le-Turret kubandakanya ukuzungezisa i-turret ukuletha ithuluzi elidingekayo endaweni ukuze lishintshe. Lo mklamo ohlangene unika amandla izikhathi zokushintsha amathuluzi ezimfushane kakhulu futhi ulungele ukwenziwa kwemishini eyinkimbinkimbi yezingxenye ezizacile njengama-crankshaft adinga imisebenzi eminingi yokwenza imishini. Kodwa-ke, ukuguqulwa kwethuluzi le-turret kudinga ukuqina okuphezulu kwe-turret spindle futhi kukhawulela inani lama-spindle amathuluzi.

Isifinyezo

isikhungo semishini esivundlile se-CNC eneziteshi ezimbilinikeza izindlela eziningi zokushintsha amathuluzi, ngayinye enezici ezihlukile nezinhlelo zokusebenza ezifanele. Empeleni, ukukhetha indlela yokushintsha ithuluzi kufanele kucabangele izidingo zemishini, ukumiswa kwemishini, kanye nemikhuba yabasebenzisi ukukhetha isisombululo esifanele kakhulu.

Ngibheke Ngabomvu Ukuhlangana Nawe ku-CIMT 2025!

Kusukela ngomhlaka-21 kuMbasa kuya kumhla zingama-26, 2025, ithimba lethu lezobuchwepheshe lizobe likhona ku-CIMT 2025 ukuze liphendule yonke imibuzo yakho yobuchwepheshe. Uma ufuna ukufunda mayelana nempumelelo yakamuva kubuchwepheshe be-CNC nezisombululo, lesi umcimbi ongafuni ukuwuphuthelwa!

Isikhathi sokuthumela: Apr-18-2025