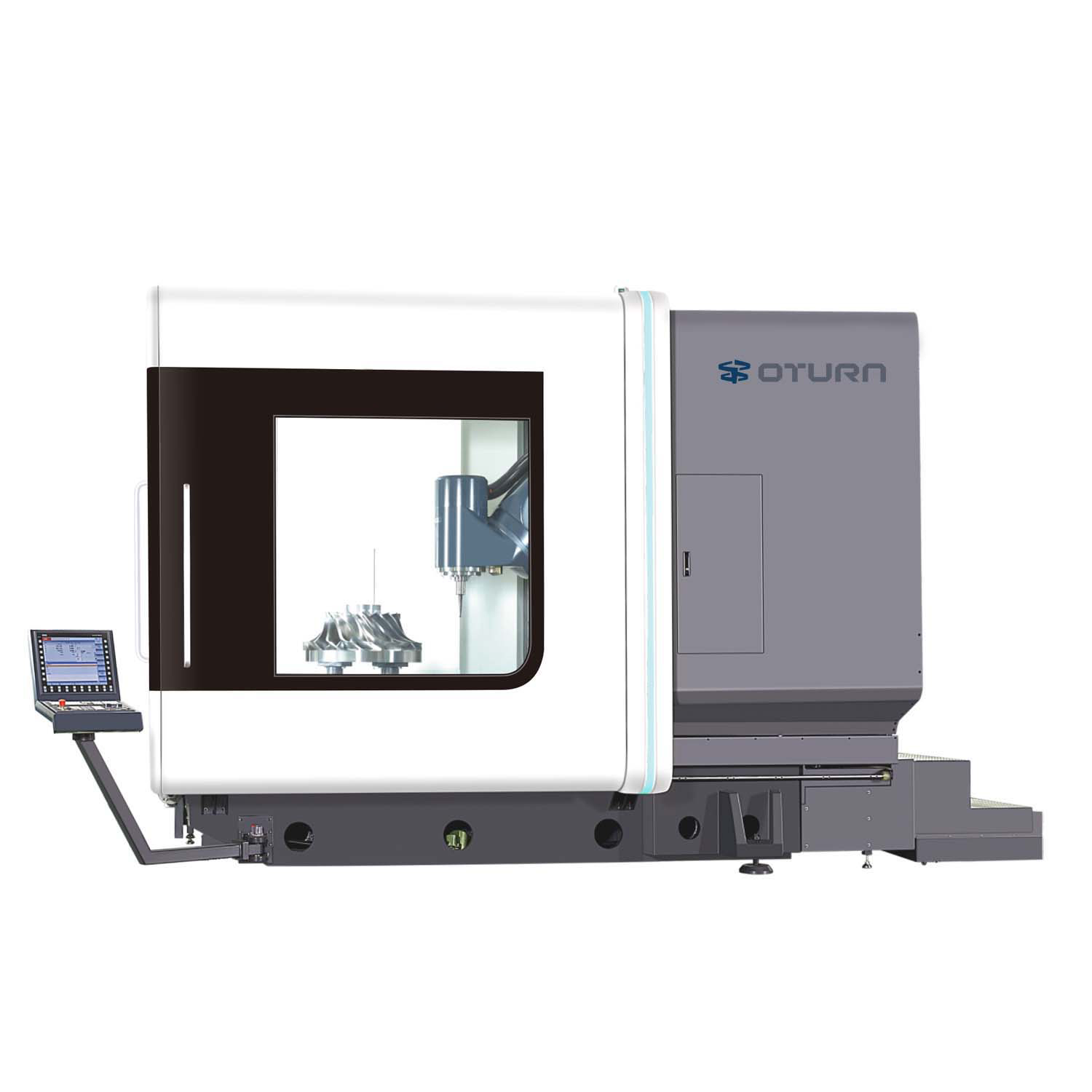

Emkhiqizweni wesimanje, lapho ukusebenza kahle nokunemba kubaluleke kakhulu,isikhungo semishini yokugaya nokujika i-CNCkuye kwavela njengesixazululo esiguquguqukayo sokusebenza okuphezulu kwensimbi. Lo mshini othuthukisiwe uhlanganisa kokubili imisebenzi yokuphenduka nokugaya ibe umshini owodwa, okuvumela ukwenziwa kwezingxenye eziyinkimbinkimbi ezinhlangothini eziningi ngokusetha okukodwa. Umphumela uba ukuncipha okuphawulekayo ezikhathini zomjikelezo wokukhiqiza kanye nokuba ngcono okuphawulekayo ekunembeni komshini.

Inzuzo eyinhloko yeumshini wokugaya i-CNCilele emandleni ayo okwenza imisebenzi eminingi ngaphakathi kweplathifomu eyodwa. Ngokwesiko, ukuphenduka nokugaya kwenziwa emishinini ehlukene, okwenza kudingeke ukuthi kudluliswe iziqephu zokusebenza phakathi kokusetha okuhlukene. Lokhu akugcinanga ngokudla isikhathi kodwa kuphinde kwandise amathuba okuba namaphutha phakathi nokudluliswa ngakunye nokuphinda kuhlanganiswe. Ngokuhlanganisa lezi zinqubo,umshini wokugaya uphendulela i-CNCithuthukisa ukusebenza kahle futhi inciphise amathuba okungalungile, njengoba isidingo sokusebenza kokubopha okuningi sincishiswa.

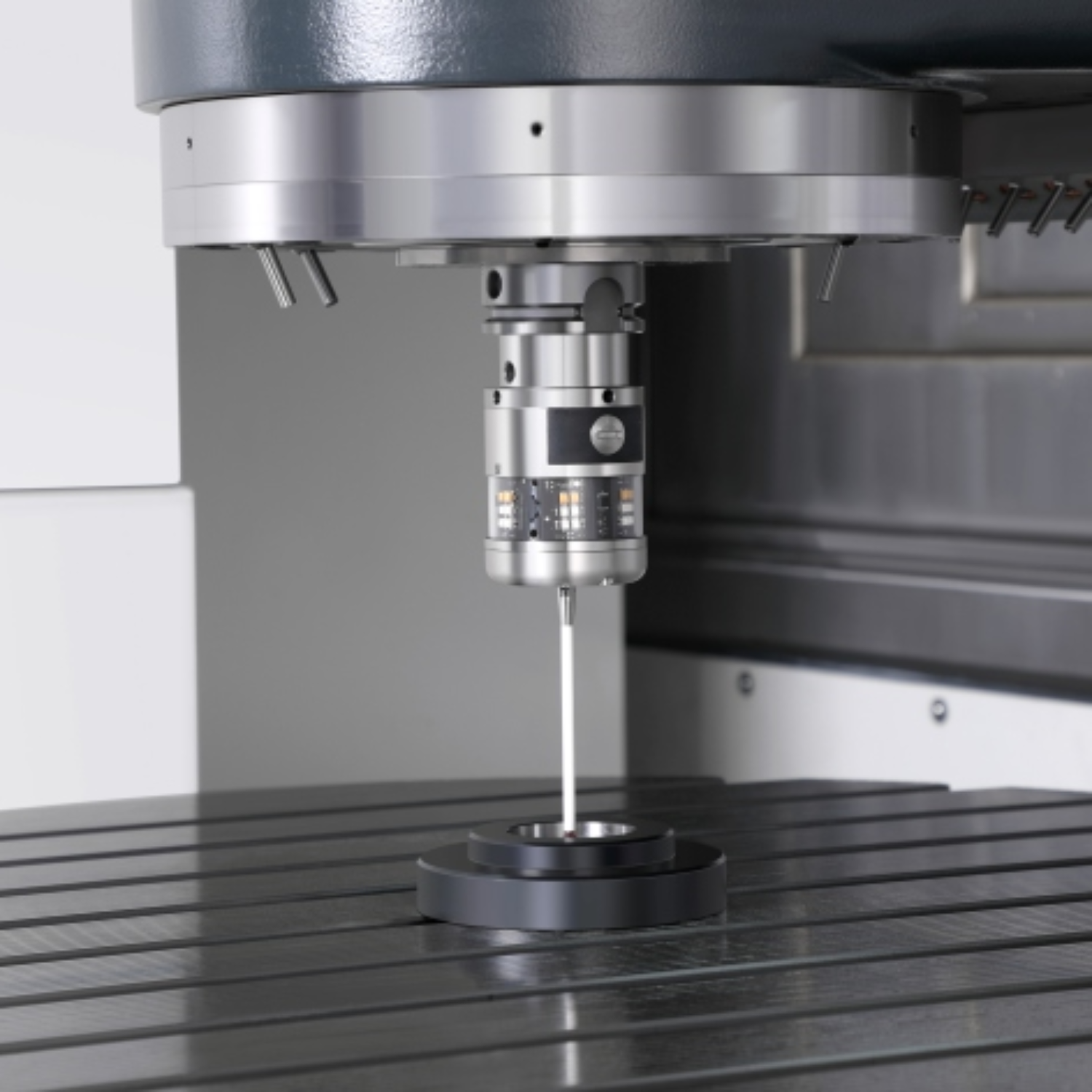

Ukusebenzisa umshini onjalo oyinkimbinkimbi kudinga ukusetshenziswa kwesistimu ye-CNC ethuthukisiwe. Ngohlelo olunembayo, umshini ungashintsha ngokuzenzakalelayo phakathi kokujika, ukugaya, ukubhola, nokuthinta. Leli zinga eliphakeme lokuzenzakalela alinciphisi umsebenzi wesisebenzisi kuphela kodwa futhi lehlisa izinga lekhono elidingekayo ukuze lisebenze, okwenza inqubo yokukhiqiza izinze futhi ithembeke.

I-CNC turning and milling compound amathuluzizisebenza kabanzi kuzo zonke izimboni eziningi, ikakhulukazi ku-aerospace, izimoto, ukwenza isikhunta, kanye nemishini enembayo. Isibonelo, ekukhiqizweni kwe-aerospace, le mishini isetshenziselwa ukukhiqiza izinsimbi zezinjini, kuyilapho emkhakheni wezimoto, iqashwe ekwenzeni izingxenye ezibalulekile ezifana nama-crankshafts enjini. Lezi zinhlelo zokusebenza zigcizelela ukubaluleka komshini kukho kokubili ukukhiqizwa okunembayo nokukhiqizwa ngobuningi.

Uma sibheka phambili, intuthuko kwezobuchwepheshe izoqhubeka iqhubekisela phambili ukuvela kwemishini eyenza imisebenzi eminingi iye ekuhlakanipheni okukhulu nasekuzisebenzeleni. Ukuhlanganiswa kwezinzwa ezihlakaniphile kanye nezinhlelo zempendulo yesikhathi sangempela kuzovumela ukuqapha okuguquguqukayo nokulungiswa phakathi nenqubo yokuklama, kuthuthukise ngokwengeziwe ukunemba nokusebenza kahle. Ukwengeza, ukufakwa kobuchwepheshe be-inthanethi Yezinto (IoT) kuzovumela ukudluliswa kwedatha yokusebenza kude kubakhiqizi noma izikhungo zesevisi, kube lula ukugcinwa kokuvimbela kanye nokuxazulula izinkinga. Lokhu, kuzokwehlisa izindleko zokukhiqiza futhi kuthuthukise ukutholakala kwemishini.

Ekuphetheni,umshini oyinkimbinkimbi wokujika nowokugaya we-CNCakugcini nje ngokuhlanganisa ikusasa lemishini yesimanje kodwa futhi isebenza njengethuluzi elinamandla lokushayela kahle ekukhiqizeni. Ngokusebenza kwayo okuhlaba umxhwele kanye nezinhlobonhlobo zezinhlelo zokusebenza, isheshisa ukushintshela kwemboni ekunembeni nasekukhiqizeni okuphezulu. Kusukela ekuthuthukisweni kwenqubo ukuya ekukhiqizeni okuhlakaniphile, umshini we-mill-turn uhamba phambili ekusungulweni kwemboni futhi ubambe iqhaza elibalulekile ekuthuthukisweni kobunjiniyela obunembayo.

Isikhathi sokuthumela: Sep-13-2024

.png)