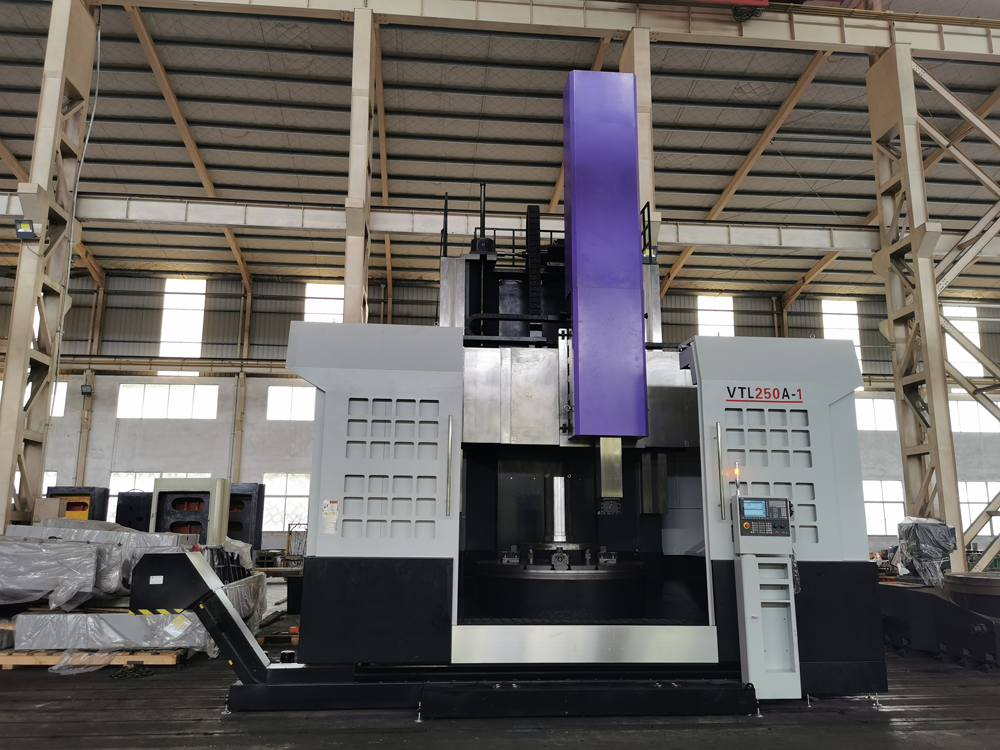

OkukhuluI-CNC lathes mpoziyimishini emikhulu, esetshenziselwa ukucubungula izingcezu zokusebenza ezinkulu nezisindayo ezinobukhulu obukhulu be-radial kanye nobukhulu obuncane be-axial, kanye nobujamo obuyinkimbinkimbi. Isibonelo, i-cylindrical surface, i-end surface, i-conical surface, i-cylindrical hole, imbobo ye-conical yama-discs ahlukahlukene, amasondo kanye namasethi wezinto zokusebenza nazo zingacutshungulwa ngosizo lwamadivayisi engeziwe wokuhlanganisa, indawo eyindilinga, iphrofayili, ukugaya nokugaya.

Isikhathi esiyisizayo sezinga elikhuluUmshini we-CNC VTLmfishane kakhulu. Ingakwazi ukuqedela konke ukucubungula okuqukethwe ngokucindezela okukodwa. Zama ukukhetha i-fixture evulekile enokuqina okuphezulu, engakwazi ukuphazamisa indlela yamathuluzi, futhi ingaqedela ukucutshungulwa kwendawo yokusebenza ngaphakathi kwebanga le-spindle stroke. Njengethuluzi lomshini elisebenza ngokuzenzakalelayo, ama-alamu ahlukahlukene azovela ngemva kwesikhathi esithile sokusetshenziswa. Ezinye ukwehluleka kwesistimu, ezinye izilungiselelo zepharamitha ezingafanele, kanti ezinye ukwehluleka kwemishini. Ama-alamu abalandeli angenye yawo.

Uma isimo esinjalo senzeka, hlola ifeni yangaphakathi kuqala. Uma ingaphenduki, yihlukanise futhi ubone. Uma ingcole kakhulu, isule ngotshwala noma ngophethiloli ngaphambi kokuyifaka. Uma kukhona i-alamu, kufanele ufake esikhundleni se-servo amplifier. I-HC iyavela. I-alamu yamanje, ikakhulukazi ukuthola amandla angavamile ohlangothini lwe-DC, qala ngokubheka amapharamitha we-servo, bese ususa intambo yamandla enjini. Ngaleso sikhathi, kune-alamu yokushintsha i-servo amplifier. Ayikho i-alamu. Shintshanisa i-motor kanye nelayini yamandla namanye ama-eksisi ukuze unqume ukuthi injini noma intambo yamandla. Inkinga: Uma u-J evela esibukweni, kuya ngokuthi kuyinkinga ye-PC. Hlola ukuthi ingabe i-motherboard, ibhodi yokuguqula isixhumi esibonakalayo kanye nedivayisi yebhodi yokulawula ye-PCRAM zilungile, buyisela futhi ulungise kuze kutholakale imbangela, bese uxazulula inkinga.

Uma isimo esinjalo senzeka, hlola ifeni yangaphakathi kuqala. Uma ingaphenduki, yihlukanise futhi ubone. Uma ingcole kakhulu, isule ngotshwala noma ngophethiloli ngaphambi kokuyifaka. Uma kukhona i-alamu, kufanele ufake esikhundleni se-servo amplifier. I-HC iyavela. I-alamu yamanje, ikakhulukazi ukuthola amandla angavamile ohlangothini lwe-DC, qala ngokubheka amapharamitha we-servo, bese ususa intambo yamandla enjini. Ngaleso sikhathi, kune-alamu yokushintsha i-servo amplifier. Ayikho i-alamu. Shintshanisa i-motor kanye nelayini yamandla namanye ama-eksisi ukuze unqume ukuthi injini noma intambo yamandla. Inkinga: Uma u-J evela esibukweni, kuya ngokuthi kuyinkinga ye-PC. Hlola ukuthi ingabe i-motherboard, ibhodi yokuguqula isixhumi esibonakalayo kanye nedivayisi yebhodi yokulawula ye-PCRAM zilungile, buyisela futhi ulungise kuze kutholakale imbangela, bese uxazulula inkinga.

Yiziphi izinto ezidinga ukunakwa ekugcinweni kwe-CNC enkuluI-VTL Machining?

1. Ngemva kokuqala injini eyinhloko isikhathi ngasinye, i-spindle ayikwazi ukuqaliswa ngokushesha. Kuphela ngemva kokuba iphampu yokugcoba isebenze ngokujwayelekile futhi ifasitela likawoyela liza namafutha, i-spindle ingaqalwa ukuvumela ithuluzi lomshini lisebenze.

2. Isikulufu singasetshenziswa kuphela uma uphendula imicu ukuze kuqinisekiswe ukunemba kwaso nempilo.

3. Gcina ingaphakathi nangaphandle kweithuluzi lomshiniukuze uhlanzeke, izingxenye zomshini ziphelele, izikulufu nezinduku ezipholishiwe azinawo uwoyela, futhi indawo yesitimela esiqondisayo ihlanzekile futhi iqinile.

4. Yenza umsebenzi wokugcobisa wephoyinti ngalinye lokuthambisa ngokwezidingo ezishiwo (bheka imiyalelo yelebula yohlelo lokuthambisa lwamathuluzi omshini ukuze uthole imininingwane).

5. Hlola njalo futhi ulungise ukuqina kwebhande le-V le-I-CNC lathe eqondile.

6. Naka ukuhlola isimo sokusebenza sephampu yamafutha ukuze uqinisekise ukuthi ibhokisi lekhanda nebhokisi lokuphakelayo linamafutha okugcoba anele. Amafutha okugcoba ethangini ngalinye akufanele abe ngaphansi kwesikhungo sezinga likawoyela ngalinye, ngaphandle kwalokho ithuluzi lomshini lizolimala ngenxa yokungagcobi kahle.

7. Hlanza i-oil filter mesh yethusi yesihlungi samafutha endaweni yokufaka amafutha ebhokisini eliseceleni kombhede masonto onke ukuze uqinisekise ukuthi amafutha okugcoba ahlanzekile.

8. Uma i-spindle ijikeleza ngesivinini esikhulu, ngaphansi kwezimo akufanele udonse isibambo esishintshayo.

Isikhathi sokuthumela: Nov-24-2021