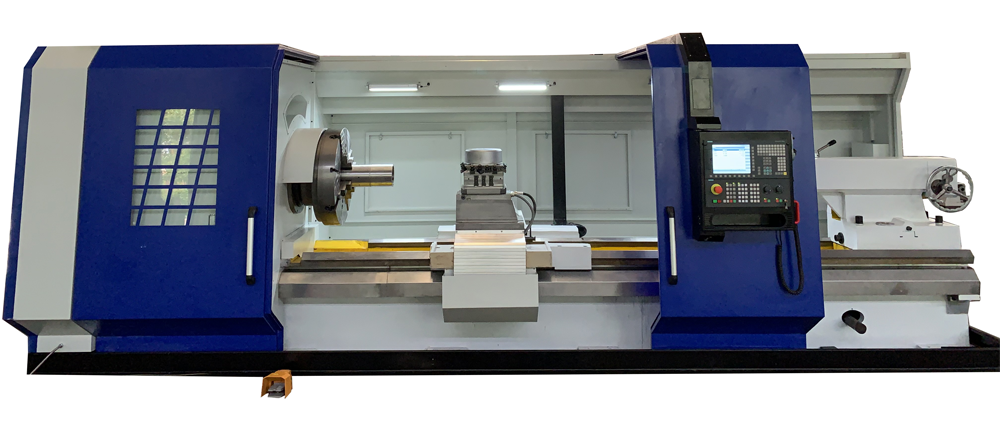

IIpayipi le-CNC lokuthunga i-latheingacubungula izindawo ezihlukene zomucu kanye nezindawo ezijikelezayo, futhi ifanele ukujika zonke izinhloboimicu yamapayipi. Ukuze umshini ongaphezulu odingekayo we-workpiece, ithuluzi kanye ne-workpiece kufanele igcine ukunyakaza okuhlobene okunembile, okutholwa yisistimu yesofthiwe. Ukunyakaza kokuphotha kwe-ai-lathe yokufaka ipayipiukunyakaza okuyinhloko, futhi ukunemba kokudluliselwa kwayo kuthinta ngokuqondile ikhwalithi yendawo esebenza ngomshini.

Nakuba ipayipiukuthunga i-lathei-lathe ekhethekile yemboni ye-oilfield, ingasetshenziswa futhi njenge-lathe yendabuko. Amandla okusika ahlobene nezinto ezikhethiwe zamathuluzi, impahla yokusebenza kanye nenani lokusika.

Sivame ukuhlangana nabanyeIthuluzi lomshini we-CNCabathengisi abazosicela ukuthi siguqule umklamo wokuphotha weintambo yepayipi lathesngokusekelwe kokuhlangenwe nakho kwama-lathes wendabuko ukuze akwenze kufane ngokuphelele nesakhiwo sokuphotha se-CNC lathes evamile, ukuze kuqinisekiswe ukuthi amathuluzi aphelele. Kodwa ukwenza ngokwezifiso okunjalo akunakwenzeka. Okulandelayo yisingeniso esiningiliziwe se-spindle yeuwoyela wezwe lathe.

Ingxenye yokuphotha yeintambo yepayipi latheingenye yezingxenye ezibalulekile zethuluzi lomshini, okuhlanganisa ukusekelwa kwe-spindle kanye nezingxenye zokudlulisela ezifakwe ku-spindle. Ngenxa yejubane eliphezulu, amandla aphezulu, nokulungiswa mathupha kweUmshini we-CNCamathuluzi ngesikhathi sokucubungula, ukunemba okuhle kokujikeleza, ukuqina kwesakhiwo, ukumelana nokushaqeka, ukuzinza kokushisa, ukumelana nokugqoka nokugcinwa kokunemba kwezingxenye kuyadingeka. Ukuze ubone ukulayishwa okuzenzakalelayo nokwehliswa kanye nokubopha ku-spindle, kufanele kube nedivaysi e-othomathikhi yokubopha ithuluzi, idivayisi yokumisa i-spindle kanye nedivaysi yokusika ecacile.

Ukusekelwa kwangaphambili kwe-intambo yepayipii-lathe spindle isebenzisa ama-roller angama-double cylindrical roller ane-tapered bore yangaphakathi ukuze ithwale amandla e-radial, okuthuthukisa ukuqina kwe-radial ye-spindle kanye nokunemba kokujikeleza kwe-spindle. Ama-thrust ball bearings amabili asetshenziselwa ukuthwala amandla e-axial nokunciphisa ukunyakaza kwe-axial ye-spindle. I-Momentum ithuthukisa ukuqina kwe-axial ye-spindle. Ukwesekwa kwangemuva kusebenzisa amarola ayimigqa ephindwe kabili ane-tapered bore yangaphakathi, edlala indima yokusekelwa kweradial.

II-CNC pipe thread latheithuthukiswe futhi yakhelwe ukuguqulwa kweipayipi lensimu kawoyelaimicu, futhi ilungele ukujika zonke izinhlobo zezintambo zamapayipi. Izici zokukhiphayo ze-spindle zithinta ngqo ukuzinza nokunemba okuphezulu kwethuluzi lomshini. Ngoba kudingekile kakhulu ukuhlaziya nokufunda izici eziguquguqukayo zeyunithi yokuphotha. Ngokuhlaziywa kwe-modal ye-spindle, umthelela wengqondo yesakhiwo sawo ekunembeni kwethuluzi lomshini uyacwaningwa, futhi izingxenye ezifanele ziyathuthukiswa ukuze zihlangabezane nezidingo zethuluzi lomshini lokucubungula ikhwalithi nokunemba.

Isikhathi sokuthumela: Nov-20-2021