Lesi sihloko sethula ngokuyinhloko indlela yokucubungula ephezulu kakhulu yamaqembu embobo yeshidi lensimbi yensimbi emikhulu esetshenziswa emikhunjini emikhulu yokusabela kanye nezishintshisi zokushisa ezimbonini ze-petroleum namakhemikhali. Ukukhetha imishini yendabuko eyisicefe neyokugaya kanye ne-radial drill ayikwazanga ukufeza izidingo zokusebenza kahle kakhulu, ingasaphathwa eyezidingo zokunemba. I-BOSM inenani elikhulu lomsebenzi onzimaCNC yokumbafuthi imishini yokugaya ithuthukiswa ngokukhethekile futhi ikhiqizwa kulo mkhakha. Njengamanje, ithole isethi yokuqala ye-BOSM-DS8585 ezweni, engakwazi ukubona ubukhulu be-workpiece ububanzi obuyi-8500mm, kanti amamodeli amancane angama-6000 × 6000, 5000 × 5000, 4000 × 4000, 3000 × 3000, 2000 × 2000 futhi 1000×1000.

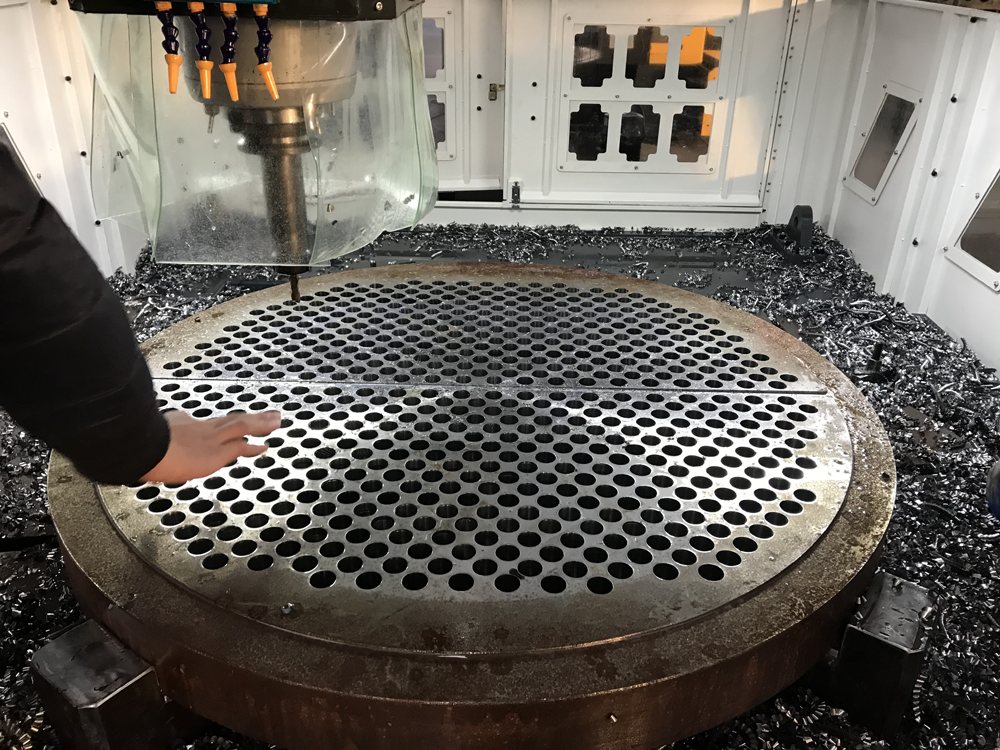

Gcoba ipuleti leshubhu kuUmshini wokugaya we-CNC nowokugaya, faka i-pilot hole drill emshinini wokugaya we-CNC nokugaya, qala ukubhola kwe-CNC futhiumshini wokugaya, futhi usebenzise umshini wokumba nokugaya we-CNC ukucubungula zonke izimbobo zamashubhu epuleti leshubhu elinembobo yokushayela ejulile engu-20 ~ 30 ㎜, Ukuze kuqinisekiswe ukunemba kwendawoizimbobo ze-tubeeshidini elikhulu lensimbi.

Indlela yokucubungula amaqembu amakhulu emigodi yeshidi lensimbi ngokwezidingo, ebonakala ngokuthi ububanzi beshidi le-tube 5000 mm ~ 8000 mm, ukujiya buyi-50 mm ~ 250 mm, kanti okokusebenza kungu-GB150.2 "Material ingxenye yesibili yomkhumbi wokucindezela” Izinto zensimbi ezishiwo; izinkulungwane kuya ezinkulungwaneni ze-reaction tube holes nomaizimbobo zamashubhu okushintshanisa ukushisazihlelwe epuleti leshubhu ukuze zenze izimbobo eziminyene ezihlelwe ngokomthetho othile.

Enqubweni yokucubungula, uma kusetshenziswa i-radial drill, ukucutshungulwa kobukhulu obujulile kuba nzima kakhulu, futhi amandla okusabela awakwazi ukwaneliseka ngokunyuka kwezinga lokuphakelayo. Ngenxa yokungaqini kahle kwebhithi yokubhoboza eyandisiwe, uma ibhithi enwetshiwe isetshenziselwa ngokuqondile imbobo yokuqala, amandla okusabela ocezu lokuhlola ipuleti leshubhu azokwenza kalula ukuthi ibhithi enwetshiwe igobe, futhi incitha enwetshiwe izogoba kalula ngaphansi amandla ajikelezayo, kanti ibhithi enwetshiwe iyazungeza. I-Circumferential jitter iqala ukubonakala esimweni, nakuba inani le-jitter lincishiswa ngemva kokubhobolwa ekujuleni okuthile, isiqondiso sokuhamba kwesiphelo sangaphambili siyachezuka kumzila womugqa olindelekile owehlayo, okuholela ekutheni imbobo yokugcina ibhojwe eshubhuni. umgodi weshidi leshubhu elikhulu neliminyene Ububanzi bebhuloho budlula izinga. Ngokuphambene nalokho, uma usebenzisa i-aCNC yokumbanomshini wokugaya, sebenzisa i-U drill, enokuqina okuhle namanzi aphuma phakathi nendawo. Ngesikhathi sokumba kokuqala, inqobo nje uma izinga lokudla lilawulwa, ukubhoboza ngeke kugobe noma kuphuke.

Idatha ye-BOSMUmshini wokugaya we-CNC nowokugayaithatha isikhundla sokuprakthiza kwe-radial okuvamile ukucubungula amashidi amashubhu amakhulu kakhulu. Isikhathi sokucubungula sokumba i-CNC kanyeumshini wokugayaama-23.5% kuphela alokho okwenziwa yi-radial drill. Ukubhola kwe-CNC akugcini nje ngokukhulula abasebenzi, kodwa futhi kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza. Ama-radial drill awakwazi ukucubungula amashidi amashubhu ashubile. Isibonelo, uma ubukhulu bungaphezu kuka-300mm, kufanele ifakwe umshini wokubhoboza we-CNC kanye nomshini wokugaya one-U-drill. Ngenxa yokuthi i-radial drill ayikwazi ukunqoba ukungalungi kokusika kwensimbi ebuyela phezulu, ikhwalithi yeshidi leshubhu nayo izothinteka kakhulu.

Isikhathi sokuthumela: Nov-20-2021